Professional Documents

Culture Documents

Vendor's System Audit (New)

Vendor's System Audit (New)

Uploaded by

sachinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vendor's System Audit (New)

Vendor's System Audit (New)

Uploaded by

sachinCopyright:

Available Formats

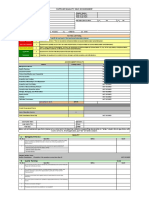

Vendor Audit Form Sheet

Section Department Topic Questions Nearest suitable answer Marks Observation Action Plan

A Management Process 1 Manual What Is The Scope Of Work? Category 0 ###

What Are Outsourced Process ? Enter Manually NA ###

2 Internal System Audit What is the Frequency for audit? Select 0 ###

Is the Last Audit conducted as per plan? Select 0 ###

What was the audit date? Date Month Year NA Plant technical head

Number of observation found? Numbers NA ###

How many Closer for observation found? Numbers NA ###

Root cause was correct? Select 0 ###

Improvement action was effective? Select 0 ###

Reoccurrence of the same non conformity observed? Select 0 ###

3 Internal Process Audit What is the Frequency? Select 0 ###

Last Audit conducted as per plan? Select 0 ###

What was the audit date? Date Month Year NA

Number of observation found? Numbers NA ###

How many Closer for observation found? Numbers NA ###

Root cause was correct? Select 0 ###

Improvement action was effective? Select 0 ###

Reoccurrence of the same non conformity observed? Select 0 ###

4 Internal Product Audit What is the Frequency? Select 0 ###

Last Audit conducted as per plan? Select 0 ###

What was the audit date? Date Month Year NA

Number of observation found? Numbers NA ###

How many Closer for observation found? Numbers NA ###

Root cause was correct? Select 0 ###

Improvement action was effective? Select 0 ###

Reoccurrence of the same non conformity observed? Date Month Year NA ###

5 5S Audit What is the Frequency? Select 0 ###

Last Audit conducted as per plan? Select 0 ###

What was the last audit date? Date Month Year NA

Number of observation found? Numbers NA ###

How many Closer for observation found? Numbers NA ###

Root cause was correct? Select 0 ###

Improvement action was effective? Select 0 ###

Reoccurrence of the same non conformity observed? Date Month Year NA ###

6 Management review meeting What is the frequency of MR? Select 0 ###

When was it last conducted? Date Month Year NA ###

Who chaired this meeting? Enter Manually NA ###

Does the Agenda captured EIL rating? Select 0 ###

Does the agenda covers quality issue at EIL end? Select 0 ###

Does agenda covers Delivery issues at EIL end? Select 0 ###

Does management review captures the action of last meeting conducted? Select 0 ###

Does all action taken against last management review meeting? Select 0 ###

7 Key result Area Monitoring Total Rejection PPM For The Month Select 0 ###

Total Rejection PPM Last 6 Month Select 0 ###

Process Audit Score Select 0 ###

TQM Implementation Select 0 ###

Schedule Adherence (Quantity ) on delivery Select 0 ###

Timeliness on delivery Select 0 ###

Cost Reduction in last 1 year Select 0 ###

Response & Communication Select 0 ###

Investment For Capacity Expansion / Technology Up gradation

Select 0

###

B Customer complaint 1 Quality complaint how many number of complaint in last 1 year? Select 0 ###

Which type of complaint are more? Select 0 ###

Is there any re-occurrence of the complaint? Select 0 ###

has the QPCR submitted to EIL? Select 0 More than 100

Is any QPCR are open? Select 0

How many are Open? Numbers NA

Does root cause analysed? Select

Does FMEA reviewed? Select

Does control plan reviewed? Select

Does Work Instruction reviewed? Select

Does the training imparted to the operators against QPCR? Select

2 Delivery Complaints Does any delivery related complaints? Select

How many are the complaint? Select 0

Does DPCR submitted to EIL? Select 0

Does the DPCR are effective? Select 0

Is there any reoccurrence of the same delivery issue? Select 0

Vendor Manual (Vendor Audit Form Sheet) Revision Date 31.03.15

Vendor Audit Form Sheet

Is there any training imparted against delivery failure? Select 0

C Purchase process 1 Selection of sub-vendor's Does selection criteria for the sub vendors defined? Select 0

Check one sub vendor with the selection criteria? Select 0

2 Indent process Does indent process exist? Select 0

Does the indent raised by the store only? Select 0

Does the indent raised by individual department? Select 0

Does the purchase order given to the approved source only? Select 0

Does purchase order contains the right specification as defined by the indenters? Select 0

3 Schedule to sub vendor's Who is responsible for giving delivery schedule to Sub vendor's? Select 0

Schedule Adherence (Quantity ) and delivery? Select 0

Is their any delivery issues? Select NA

What action sub vendors had taken to over come these issues? Enter Manually NA

Are the outcome of the actions are satisfactory? Select 0

4 Sub vendor's audit Supplier audit carried out in a planned interval? Select 0

When was the last audit done? Date Month Year NA

Is their any non-conformity? Select 0

Closers are acceptable? Select 0

5 inventory management Does Finished good inventory fulfils the 4 days EIL inventory clause? Select 0

D Marketing 1 Order Review Any new order received by EIL? Select 0

when was the quotation reviewed? Date Month Year NA

Does the APQP time plan Exists? Select 0

Who approved the APQP plan from EIL? Select 0

Does the project completed as per APQP plan? Select 0

When was the Quotation approved? Date Month Year NA

What was the date of sample approval? Date Month Year NA

Does the sample passes in first time only? Select 0

How many days taken for sample submission after quotation approved? Numbers NA

Does the capacity planning done before the new order accepted? Select 0

Does the Capacity planning submitted to SQA or plant technical? Select 0

What was the company turn over this year? Enter Manually NA

Is their any major business loss this year? Select 0

E Stores 1 Storage condition Does storage condition are good? Select 0

Does identification and traceability are proper? Select 0

Is their any self life item? Select 0

Does FIFO is maintained for self life item? Select 0

What was the 5S condition in the store? Select 0

Are the rejected material are clearly identified with proper traceability? Select 0

2 Inward stock Does the vendor maintain the stock register for material inwards? Select 0

Does minimum stock level maintained for critical item? Select 0

F Production 1 Production planning Production plan vs. achievement? Select 0

Does any planning failure? Select 0

Does the Root cause for the failure analysed? Select 0

are the corrective action done properly? Select 0

Does the corrective action are effective? Select 0

2 process control Does the work instruction displayed on the machine? Select

Does the format for work instruction is same as per annexure attached in EIL vendor

manual? Select

Doe the operator has a training on work instruction? Select

Does the training record available for last 3 years? Select

Does the evaluation for training carried out after two months? Select

Does the records available as per annexure attached in EIL vendor manual? Select

Does the Skill Matrix available for the operators? Select

Does the process inspection sheet are duly filled? Select

Are the contents are correct in the process inspection sheet? Select

Does the process validation done by EIL team? Select

Are the machine parameters are running as per process data sheet? Select

Is the availability of control plan available for production running part number? Select

Is the PSW signed off by the EIL? Select

Does the PSW submitted to the EIL respective department? Select

When was the last Control plan reviewed? Date Month Year NA

Does all the formats are used as per annexure provided in the vendor manual? Select 0

If the process parameter are not as per control plan and process data sheet , Is the

deviation given by Eil? Select 0

Who has given the deviation from EIL ? Select 0

3 Daily production monitoring Does production log book maintained? Select

Does daily production losses captured? Select

Does daily production meeting conducted? Select

Does shift change over done effectively? Select

4 Control plan adherence? Does the control plan exist? Select

Does machine running process parameter are as per control plan? Select

Does product parameter (Physical inspection during audit) are as per control plan? Select

Does control method are as per control plan? Select

Vendor Manual (Vendor Audit Form Sheet) Revision Date 31.03.15

Vendor Audit Form Sheet

Does inspection sampling plan are as per control plan? Select

Does equipment define in the control plan are calibrated? Select

5 Process & Product Audits What is the frequency of process audit? Select 0

How many observation found in process audit? Select

Are the observation are effectively closed? Select 0

What is the frequency of product audit? Select 0

How many observation found in product audit? Numbers NA

Are the observation are effectively closed? Select 0

Does the packaging requirement approved by the EIL? Select 0

Does the labelling requirement approved by the EIL? Select 0

6 inventory management What was the work in progress inventory? Enter Manually

7 non conformity management Are the rejected material are clearly identified with proper traceability? Select

Does the procedure or work instruction provided for handling of rejected product? Select

Are the procedure followed? Select

G Quality 1 incoming inspection Incoming inspection done as per approved control plan? Select

Does the vendor follows the sampling plan? Select

retention period for 3 years records available? Select

Parameters are inspected as per defined in the control plan? Select

2 Final inspection Final Inspection carried out for each supply given to EIL? Select

inspection fulfils the sampling plan and acceptance criteria as defined in control plan? Select

inspection fulfils the sampling plan and acceptance criteria as defined in annexure of Eil

vendor manual? Select

3 calibration Calibration done in-house or outsourced? Select 0

Which equipment selected to check calibration? NA

When was the calibration done? Date Month Year NA

Does the calibration done in working zone? Select 0

What was the error available?

Is the error acceptable? Select 0

Is the error acceptable under deviation? Select 0

4 Statistical process control Type of SPC Select 0

What is the CpK Value? Select 0

Does the SPC submitted to EIL in monthly basis? Select 0

5 MSA (Variable) What is the R&R Value? Enter Manually NA

What is PV%? Enter Manually NA

What is AV%? Enter Manually NA

What is EV%? Enter Manually NA

6 MSA (Attribute) What is the KAPPA value? Enter Manually NA

Result for MSA is acceptable? Select 0

7 Layout inspection Layout inspection plan available? Select 0

Layout inspection carried out? Date Month Year NA

Does it capture all dimension captured in the drawings? Select 0

Does it capture all chamfers provided in the drawing? Select 0

Does is capture all radios provided in the drawing? Select 0

Does the layout inspection submitted to the EIL Plant technical? Select 0

EIL supplied tool/ Mould/

H Maintenance 1 machine. Is this clause applicable to the Vendor? Select 0

What is provided by the EIL? Select NA

Preventive maintenance schedule available? Select 0

check point available for EIL supplied tool/mould/ machine. Select 0

is the retention of the records are available for 3 years? Select 0

2 maintenance of machine Plan available for preventive maintenance? Select 0

check point available preventive maintenance? Select 0

Total Break down for the year? Select 0

I Training 1 Training & evaluation Does skill matrix exists for operator level (including contractual) ? Select

Does skillmatrix exist for management staffs? Select

Does the training is planned as per gap identified in skill matrix? Select

does the gap analysis done for the customer representative? Select

Does the training on EIL vendor manual given to customer representative? Select

does the evaluation done after two month? Select

what was the date of training? Date Month Year NA

What was the date for evaluation? Date Month Year NA

Does the criteria for the selection for trainer defined? Select

J Development 1 Drawing control Does the drawings are controlled? Select

Does the email from EIL exists at vendor end to check latest revision? Select

2 Process validation Does the process validation done by EIL? Select

Does validation sheet exists? Select

3 New product development In their any new development? Select

Does the APQP plan exists? Select

Does the project completed as per APQP plan? Select

Does APQP plan are approved by EIL? Select

4 PPAP Does the PPAP submitted to EIL? Select

Vendor Manual (Vendor Audit Form Sheet) Revision Date 31.03.15

Vendor Audit Form Sheet

Where is it submitted? Select 0

Does the PSW signed off by EIL? Select 0

Does the communication exist that vendor has given the reminder to specific

department? Select 0

Does the vendor submitted the PPAP as per category defined in the vendor manual? Select 0

Sum 0

Score 0.00%

Vendor Manual (Vendor Audit Form Sheet) Revision Date 31.03.15

You might also like

- Salvatore Schiavo-Campo - Government Budgeting and Expenditure Management - Principles and International Practice-Routledge (2017) (Z-Lib - Io)Document417 pagesSalvatore Schiavo-Campo - Government Budgeting and Expenditure Management - Principles and International Practice-Routledge (2017) (Z-Lib - Io)Angela BacharoNo ratings yet

- GM 1927-16b Tiered Supplier Process AuditDocument5 pagesGM 1927-16b Tiered Supplier Process AuditJOHNNo ratings yet

- EQMS Internal Audit Checklist: Part 6: Performance EvaluationDocument3 pagesEQMS Internal Audit Checklist: Part 6: Performance EvaluationAndro IgnacioNo ratings yet

- Layered Audit Form: ProductionDocument4 pagesLayered Audit Form: ProductionEDUNo ratings yet

- Audit Checklist: Audit Technique Auditable Item, Observation, Procedure Etc. Individual Auditor Rating (Circle Rating)Document2 pagesAudit Checklist: Audit Technique Auditable Item, Observation, Procedure Etc. Individual Auditor Rating (Circle Rating)Abu BindongNo ratings yet

- Applied Diagnostics LayerDocument19 pagesApplied Diagnostics LayerJohn CubasNo ratings yet

- The Visual Workplace: Includes Excerpts From: The Visual Factory, by Michel Greif Productivity PressDocument21 pagesThe Visual Workplace: Includes Excerpts From: The Visual Factory, by Michel Greif Productivity Pressmilou88No ratings yet

- Turtle Diagram TemplateDocument2 pagesTurtle Diagram TemplateMirnes MehanovicNo ratings yet

- Annual Supplier AuditDocument13 pagesAnnual Supplier Auditori wahyuni100% (1)

- 5S Audit and Actions Required SheetDocument1 page5S Audit and Actions Required SheetSoulaimaNo ratings yet

- Fmea TemplateDocument1 pageFmea TemplatePaul MendozaNo ratings yet

- Martin FrameworkDocument2 pagesMartin FrameworkPajes RaymartNo ratings yet

- Special Audit of Key Characteristics in Control Plan: Evaluation Item Questionnaire Point Expectation (4point Level)Document6 pagesSpecial Audit of Key Characteristics in Control Plan: Evaluation Item Questionnaire Point Expectation (4point Level)KarlNo ratings yet

- Internal Audit Check Sheet MaintDocument3 pagesInternal Audit Check Sheet MaintRamdas Paithankar100% (1)

- Dokumen - Tips - Bsi Action Manager Welcome WorkbookDocument15 pagesDokumen - Tips - Bsi Action Manager Welcome Workbookfilipivanovski79No ratings yet

- Internal Auditor Training: Top CertifierDocument46 pagesInternal Auditor Training: Top CertifierJeelani BashaNo ratings yet

- Special Audit of Key Characteritics in Control Plan FAU-F-PSG-0800-En-4Document1 pageSpecial Audit of Key Characteritics in Control Plan FAU-F-PSG-0800-En-4KarlNo ratings yet

- 18.1 - App - 1 - IMS - Internal - System - Checklist - (ISO9001.14001 45001)Document15 pages18.1 - App - 1 - IMS - Internal - System - Checklist - (ISO9001.14001 45001)HenryNo ratings yet

- 5s - Office ChecklistDocument1 page5s - Office ChecklistChokri AouinaNo ratings yet

- QA-F20-Process Audit ChecksheetDocument2 pagesQA-F20-Process Audit ChecksheetYogesh bhatNo ratings yet

- Scop IatfDocument1 pageScop IatfJeevanandhamNo ratings yet

- THESIS3 GroupJRMDocument163 pagesTHESIS3 GroupJRMSomething.No ratings yet

- MCE 476 - Nondestructive Testing Methods: InstructorDocument120 pagesMCE 476 - Nondestructive Testing Methods: InstructorasotjaNo ratings yet

- A Paperless Inspection and Maintenance Approach To EX ComplianceDocument9 pagesA Paperless Inspection and Maintenance Approach To EX CompliancemhafizanNo ratings yet

- A Paperless Inspection and Maintenance Approach To EX ComplianceDocument10 pagesA Paperless Inspection and Maintenance Approach To EX CompliancemhafizanNo ratings yet

- Chapter 3 - Static TestingDocument17 pagesChapter 3 - Static TestingLuis Manuel Bravo AgüeroNo ratings yet

- PT-KCL20240325001_320374435_0882-20_20240325_M18-H Vacuum(N)Document17 pagesPT-KCL20240325001_320374435_0882-20_20240325_M18-H Vacuum(N)cuongvina1133No ratings yet

- EQMS Integrated Internal Audit Checklist SampleDocument3 pagesEQMS Integrated Internal Audit Checklist SampleKishore RathodNo ratings yet

- Ipcr Accomplishment - Ahig RDocument135 pagesIpcr Accomplishment - Ahig RMA. DIVINA LAPURANo ratings yet

- Internal Audit Flow ChartDocument1 pageInternal Audit Flow ChartstevierayoNo ratings yet

- Ipcr LguDocument2 pagesIpcr LguLen FCNo ratings yet

- Annual Review (Autosaved)Document17 pagesAnnual Review (Autosaved)Roel Jr Pinaroc DolaypanNo ratings yet

- Audit - Visio-Template Process MapDocument1 pageAudit - Visio-Template Process MapPurushothama Nanje GowdaNo ratings yet

- Problems: With Your Rca ProcessDocument38 pagesProblems: With Your Rca ProcessCarlos Oliver MontejanoNo ratings yet

- M&e Sample Data-IndicatorsDocument18 pagesM&e Sample Data-Indicatorsroyd dakaNo ratings yet

- Diligent-IT Risk Board Reporting Dashboard OverviewDocument6 pagesDiligent-IT Risk Board Reporting Dashboard OverviewBikash JhaNo ratings yet

- FAB - Suppplier Assesment CheksheetDocument4 pagesFAB - Suppplier Assesment CheksheetMahesh KhairnarNo ratings yet

- Week 5 & 6 Risk Assessment and ResponseDocument53 pagesWeek 5 & 6 Risk Assessment and ResponsefauziahezzyNo ratings yet

- 5s ChecklistDocument3 pages5s Checklistvickram_chandu9526No ratings yet

- Internal Audit Summary ReportDocument1 pageInternal Audit Summary Reportsupady5751No ratings yet

- (Audit Result) Environment Management SystemDocument7 pages(Audit Result) Environment Management SystemAyush NarangNo ratings yet

- CPNPs 5 Focus AgendaDocument2 pagesCPNPs 5 Focus AgendaMae ANo ratings yet

- Material 2019X1 ECO526 01 132577Document1 pageMaterial 2019X1 ECO526 01 132577SCQA SHEIKHPURANo ratings yet

- Keyword DetectionDocument6 pagesKeyword Detection202002025.jayeshsvmNo ratings yet

- Process/Product Potential Failure Modes and Effects Analysis (FMEA)Document8 pagesProcess/Product Potential Failure Modes and Effects Analysis (FMEA)Carlos De Gracia NúñezNo ratings yet

- The Quality Improvement Model: Select MeasuresDocument19 pagesThe Quality Improvement Model: Select MeasuresAkbarLaylaLita 17No ratings yet

- Dognition Data Set Analysis PlanDocument1 pageDognition Data Set Analysis PlanfrankNo ratings yet

- Perfomance Appraisal Concept and Techniques of Reliance (Adag)Document16 pagesPerfomance Appraisal Concept and Techniques of Reliance (Adag)JerrleyNo ratings yet

- Checklist IMS 29.06.2021Document6 pagesChecklist IMS 29.06.2021NISOL HRNo ratings yet

- GM 1927 16b Resistance Spot Welding Process AuditDocument6 pagesGM 1927 16b Resistance Spot Welding Process AuditGabriel SánchezNo ratings yet

- A. Individual Performance Commitment Review (Ipcr)Document4 pagesA. Individual Performance Commitment Review (Ipcr)GretchenNo ratings yet

- 5'S Check ListDocument6 pages5'S Check ListRAJESH SNo ratings yet

- MOR-JRM-Healthcare IT BPO Call Center Non-Voice Agent Performance and Rewards Management SystemDocument136 pagesMOR-JRM-Healthcare IT BPO Call Center Non-Voice Agent Performance and Rewards Management SystemSomething.No ratings yet

- ES - SQM - 029-03 - Acceptance MMRDocument3 pagesES - SQM - 029-03 - Acceptance MMRCassildaTavaresNo ratings yet

- Buyers Guide To Data Integration Software CloverETL June 2018Document36 pagesBuyers Guide To Data Integration Software CloverETL June 2018Tom KakanowskiNo ratings yet

- SIPOC DiagramDocument2 pagesSIPOC DiagramKaline FróesNo ratings yet

- A Guide to Assessing Needs: Essential Tools for Collecting Information, Making Decisions, and Achieving Development ResultsFrom EverandA Guide to Assessing Needs: Essential Tools for Collecting Information, Making Decisions, and Achieving Development ResultsRating: 3 out of 5 stars3/5 (2)

- URCDocument27 pagesURCqcNo ratings yet

- HSE Plan - PT Anugrah Pacific KencanaDocument15 pagesHSE Plan - PT Anugrah Pacific Kencananew auctionNo ratings yet

- Ethics AssignmentDocument5 pagesEthics AssignmentAbdul latif Abdul latifNo ratings yet

- Mock AuditDocument20 pagesMock AuditKalyan ChinimilliNo ratings yet

- Information Security Declaration - v1 - 13012023 - ExelliusB2BSystemsDocument2 pagesInformation Security Declaration - v1 - 13012023 - ExelliusB2BSystemsSaurab GhoshNo ratings yet

- Ed213 - Financial Planning and ControlDocument22 pagesEd213 - Financial Planning and Controlsharon agustinNo ratings yet

- Advanced Auditing: The Institute of Chartered Accountants of PakistanDocument1 pageAdvanced Auditing: The Institute of Chartered Accountants of PakistanAhmad MalikNo ratings yet

- Chapt. 2 - The Professional StandardsDocument31 pagesChapt. 2 - The Professional StandardsJanna Hazel Villarino VillanuevaNo ratings yet

- Implementation OF Five S' ProgramDocument15 pagesImplementation OF Five S' ProgramSamNo ratings yet

- FIASA FPT Customer Specific Requirements ISO TS 16949Document7 pagesFIASA FPT Customer Specific Requirements ISO TS 16949VERONICA ROSALES GONZALEZNo ratings yet

- ISO 9001:2008 - Clause 4: 4.1 General RequirementsDocument14 pagesISO 9001:2008 - Clause 4: 4.1 General RequirementsRaajha MunibathiranNo ratings yet

- Global Recycled Standard v3 PDFDocument29 pagesGlobal Recycled Standard v3 PDFJuice Guava100% (1)

- JH TrainingDocument218 pagesJH TrainingMAngesh GadeNo ratings yet

- NIB Annual Report 2008 PDFDocument32 pagesNIB Annual Report 2008 PDFMinte TubeNo ratings yet

- Ajems 04 2018 0102Document16 pagesAjems 04 2018 0102gitaNo ratings yet

- Compliance Program in HealthcareDocument31 pagesCompliance Program in HealthcareJorge Ignacio Muñoz MartinezNo ratings yet

- Quality Assurance Plan (Template)Document16 pagesQuality Assurance Plan (Template)Sajeel ZamanNo ratings yet

- Ch. 1 - Accounting - Information For Decision MakingDocument22 pagesCh. 1 - Accounting - Information For Decision MakingAndrew Hanna100% (1)

- RM Assignment WriteupDocument31 pagesRM Assignment WriteupEileen WongNo ratings yet

- 2004 Reasonable ExpectationDocument7 pages2004 Reasonable ExpectationdeeptimanneyNo ratings yet

- Chapter 1Document198 pagesChapter 1jamila fatimaNo ratings yet

- Techniques of AuditingDocument35 pagesTechniques of AuditingyuvashankarNo ratings yet

- What Is ISO 27001 - 2003 - TestDocument8 pagesWhat Is ISO 27001 - 2003 - Testvladislav2902No ratings yet

- Accountant in Business (For Exams From February 2014 To August 2015) - SQBDocument62 pagesAccountant in Business (For Exams From February 2014 To August 2015) - SQBAsadMughal0% (1)

- Auditing 2nd Sem AY 2020-2021 Institutional Mock Board ExamDocument10 pagesAuditing 2nd Sem AY 2020-2021 Institutional Mock Board ExamGet BurnNo ratings yet

- Audit SeminarDocument5 pagesAudit SeminarHARI HARA RAO GUJJAR100% (1)

- Child Safeguarding Audit - Methodology - FinalDocument10 pagesChild Safeguarding Audit - Methodology - FinalLopes CassamáNo ratings yet

- Curriculum PDFDocument1 pageCurriculum PDFRina RaymundoNo ratings yet

- Opm538 Topic 1 - 3Document67 pagesOpm538 Topic 1 - 3Hijrah HayatiNo ratings yet