Professional Documents

Culture Documents

Eh Oil

Eh Oil

Uploaded by

Annazri ArnandaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eh Oil

Eh Oil

Uploaded by

Annazri ArnandaCopyright:

Available Formats

Once-Through Steam Boiler

EH OIL

500F ・ 750F ・ 1000F ・ 1000FS

[JAPAN] MIURA CO., Ltd.

7 Horie, Matsuyama, Ehime 799-2696, Japan

TEL 089-979-7123

䣈䣃䣚䢢䢲䢺䢻䢯䢻䢹䢻䢯䢹䢳䢲䢳

http://www.miura.co.id

EH - OIL INA Rev 2.1

printed in Indonesia April 2018

All right reserved.

Simple, High Performance Options That Take Full Basic Specification

EH-750F EH-1000F *1. Heat output for fuel is based on the following values.

MIURA TYPE EH-500F EH-750F EH-1000F EH-1000FS REMARK

Fuel type Lower heating value Density

Advantage of Boiler Power ITEM

Main Body

UNIT Oil (Kerosene / Heavy Oil A)

Kerosene 43.5 MJ/kg 0.80 g/cm3

---- Once-through steam boiler

Heavy Oil A 42.7 MJ/kg 0.86 g/cm3

Boiler Type

The EH series of oil-fired steam boilers is culmination of considerable research using the expertise and Working Pressure

Equivalent Output

MPa

kg/h 500 750

0.49–0.88

1000 1000

*9 , *11 *2. (1) Boiler efficiency is based on the following.

Operating Conditions : Connection Di

2

maintenance data that Miura has accumulated over many years. The series combines safety with Actual Output kg/h 419 629 838 838

627

*3 Operating pressure 0.49 MPa {5 kgf/cm },

feed water temperature 15°C, supply air temperature 35°C

Heat Output kW 313 470 627

economy, offering several models that designated to realize a number of environment issues. Boiler Efficiency % 85 95 *2

Land boilers - Heat balancing : JIS B 8222

(2) The error has the following tolerances.

Water Content L 140 175 150 150

Error for boiler efficiency ±1%, error for fuel consumption ±3.5%

L/h 38.1 57.2 76.2 68.3

*3. Actual output evaporation is based on a feed water temperature

Features Fuel Consumption OIL

Kerosene

kg/h 30.5 45.7 61.0 54.6

*1, *2 , *10 15ºC, and steam pressure 0.49 MPa.

L/h 36.1 54.2 72.3 64.7 *4. If the feed water temperature is 85ºC or higher, the high

Heavy Oil A

kg/h 31.1 46.6 62.2 55.7 temperature water specification must be used.

High efficiency and improved safety Superior new design for ease of use Power Supply ---- AC 380 V 50 Hz 3 phase

*5. The safety valve outlet shows the diameter of the elbow that

connects to the outlet of the safety valve.

Required Wire Diameter mm 2

2.0 2.0 2.0 2.0 *6

*6. Power supply wire diameter indicates the wire diameter of

Power Circuit Breaker Capacity A 15 20 30 30 *4 , *7

ω (omega) Flows Construction Easy Operation, inspection and maintenance due Rated Power Consumption kW 1.5 3.4 4.2 4.2 *4

crosslinked polyethylene insulated PVC sheathed cable (CV).

*7. The power circuit breaker must be an earth leakage circuit

The boilers using ω (omega) flows construction which to a simple structural design.

Max. Electrical Consumption 50Hz kVA 3.43 6.15 7.15 7.15 *4 breaker (with overcurrent protection).

Product Weight kg 990 1,250 1,420 1,680 *8. A copper joint 10 A and oil strainer 10 A are installed on the

consist of vertically - mounted water tubes sandwiched at Connection Diameter upstream side of the fuel inlet for each model.

32 40 50 *9. Install a pressure reducing valve or equivalent when the steam

Steam Outlet

the top and bottom between two annular headers. The Safety Valve Outlet 40 50 *5

lower than the working pressure range is required.

*10. When using Heavy Oil A, JIS Class 1 No. 1 is recommended.

Feed Water Inlet 25 *4

effective heat transfer surface area is large due to the bigger Boiler Blowdown Outlet A 25

Sulfur contents in fuels and dew drops make the inside of the

stack corrosive. In addition, when corrosives scatter, it may

combustion chamber and heat absorption from contact Fuel Inlet 20 *8 cause corrosion and contamination of roofs and other areas.

Inspection Port 50 Therefore, JIS Class 1 No. 1 such low-sulfur is recommended.

heat transfer is increased due to a faster combustion gas Surface Blowdown Outlet ----- 10 [10] *12 *11. If the pressure exceeds the working pressure range, steam leak

or blowout from the safety valve may occur. Contact your local

Stack Diameter φ mm 250 290 330 250

flow. Miura office when the steam pressure setting of the boiler

exceeds the working pressure range.

*12. The Connections with values in [ ] are connected to the Soot

New Structural Design blow drain outlet.

S Specification model is designed for use with feed water at a

The newly designed boiler construction and combustion temperature of 55°C or higher.

For the sake of safety, an earthquake detector should also be

gas flow help gain maximum heat transfer performance installed.

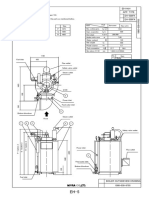

from a limited heat transfer area which less than 10m2. Overall Dimensions [EH-500F - 750F - 1000F - 1000FS]

W D H

Effective usage is made by the entire heat transfer area, the EH-500F 1140 1505 2055

EH-750F 1180 1705 2055

result is 85% boiler efficiency (for EH-1000FS is 95%). EH-1000F 1320 1915 2255

EH-1000FS 1320 2140 2255

Further, space saving is obtained by the compact design.

(compare to previous version)

Higher fuel economy and longer service life

Surface Blowdown

One drawback that small once-through boilers are

considered that the tendency for water to become *The diagram shows EH-1000FS

Flow Sheet [EH-500F - 750F - 1000F - 1000FS]

concentrated more quickly compared to fire tube and water

tube boilers because of their low water content. Accordingly, 1 Oil strainer 20 Check valve

2 Oil air vent valve 21 Feed water stop valve

blowdown of concentrated water helps keep water 3 Oil pump 22 Boiler blowdown valve

4 Y-type strainer 23 Water sampling port

concentration below a certain level and prevents alkaline 5 Oil pressure gauge 24 Ball valve

6 Solenoid valve (low fire) 25 Accumulator

corrosion of the water tube (EH-1000F & EH-1000FS). 7 Solenoid valve (high fire) 26 Air pressure switch

8 Shutoff solenoid valve 27 Check valve

9 Safety valve 28 Soot blow valve

Low-Noise Burner 10 Main steam valve 29 Leak detection valve

11 Air vent valve 30 Soot blow drain valve

Substantially improved burner combustion performance, 12 Steam pressure switch 31 Sight glass

13 Steam pressure gauge

Quiet operation and blower noise. The surrounding 14 Surface blowdown valve

15 Y-type strainer

environment is not affected, allowing operation at all hours 16 Surface blowdown solenoid valve

EH - 500F Front View 17 Orifice

of the day or night. 18 Y-type strainer

19 Feed water pump

*The diagram shows EH-1000FS

You might also like

- Manual Transmision A413 PDFDocument96 pagesManual Transmision A413 PDFJose Sanchez50% (2)

- Kubota Horizontal Water Cooled Diesel EnginesDocument2 pagesKubota Horizontal Water Cooled Diesel EnginesLuusoe LayNo ratings yet

- LT 9Document2 pagesLT 9ariwibowoNo ratings yet

- Hyundai D4da 98HP PDFDocument2 pagesHyundai D4da 98HP PDFNguyễn Thanh Tín75% (4)

- EI GAS - CompressedDocument2 pagesEI GAS - Compressedtony0% (1)

- Ipcrf Part II CompetenciesDocument1 pageIpcrf Part II CompetenciesStaCatalina DistrictTwo92% (12)

- B 1003 - 16 PDFDocument8 pagesB 1003 - 16 PDFTuanbk NguyenNo ratings yet

- Ygnis Ingl+ S Multiflam 170.1-200.1Document24 pagesYgnis Ingl+ S Multiflam 170.1-200.1DihorulNo ratings yet

- 12aym WetDocument2 pages12aym Wetghyd artiagaNo ratings yet

- Robin Subaru Ec12 PDFDocument66 pagesRobin Subaru Ec12 PDFStan Marius VictorNo ratings yet

- Specification EhDocument8 pagesSpecification Ehthanh thien nguyenNo ratings yet

- Yanmar Datasheet - 6LY2M WST WDTDocument2 pagesYanmar Datasheet - 6LY2M WST WDTĐông HừngNo ratings yet

- Steyr Monoblock Diesel: For Heavy Duty DemandsDocument6 pagesSteyr Monoblock Diesel: For Heavy Duty DemandsMarko CvijicNo ratings yet

- Tata Indica V2 Xeta: Car BrochureDocument3 pagesTata Indica V2 Xeta: Car BrochureRohit ChatterjeeNo ratings yet

- Kobelco SK260SRLC-3 - NaDocument8 pagesKobelco SK260SRLC-3 - NaGruppo ZECCANo ratings yet

- FBR Burners Model K x6-2 Evo - K x7-2Document5 pagesFBR Burners Model K x6-2 Evo - K x7-2kikokiko KarimNo ratings yet

- Product Brochure Integrated Pressure Management Solutions For Ethylene Plants Brochure Fisher en en 5976836Document4 pagesProduct Brochure Integrated Pressure Management Solutions For Ethylene Plants Brochure Fisher en en 5976836Omar Al SousliNo ratings yet

- Generator Engine IsuzuDocument1 pageGenerator Engine Isuzuibrahim salemNo ratings yet

- Lux M11 Led 2cilindrosDocument2 pagesLux M11 Led 2cilindrosalmasasrlinformesNo ratings yet

- 4D94 (L) E 4D98E: Service ManualDocument14 pages4D94 (L) E 4D98E: Service ManualLek MiniNo ratings yet

- SS FG230 enDocument2 pagesSS FG230 entolisNo ratings yet

- 12aym WGTDocument2 pages12aym WGTkhuong phamNo ratings yet

- Outside View Eh-500fk 1000-030-9705Document1 pageOutside View Eh-500fk 1000-030-9705thanh thien nguyenNo ratings yet

- Iriz BrochureDocument2 pagesIriz BrochureARVIN ARSENALNo ratings yet

- Atlas Copco Cobra Series Product Reference Sheet (Imperial)Document2 pagesAtlas Copco Cobra Series Product Reference Sheet (Imperial)Otoniel FernandezNo ratings yet

- Kobelco SK230SRLC-3 - NaDocument8 pagesKobelco SK230SRLC-3 - NaleonNo ratings yet

- 582 UL - Datasheet - 2020Document2 pages582 UL - Datasheet - 2020Jonata DantasNo ratings yet

- Vol 15033b-22x34 Mack Service at A Glance Poster v8 PDFDocument1 pageVol 15033b-22x34 Mack Service at A Glance Poster v8 PDFJenMicMarAguNo ratings yet

- Thermal Engine: Type Brand Fuel Number of Cylinders Bore Stroke Capacity PowerDocument1 pageThermal Engine: Type Brand Fuel Number of Cylinders Bore Stroke Capacity PowerGonçalo Filipe SousaNo ratings yet

- Catalog Gasoline EDocument3 pagesCatalog Gasoline ECorey StrongNo ratings yet

- Datasheet Aircraft Engine 912 Is ISc SportDocument2 pagesDatasheet Aircraft Engine 912 Is ISc SportAli HassanNo ratings yet

- Key Notes-Emb 145 & 175Document3 pagesKey Notes-Emb 145 & 175Dupinder SinghNo ratings yet

- Multiflam 170.1-200.1 Ab - Ab PDFDocument54 pagesMultiflam 170.1-200.1 Ab - Ab PDFMa VioNo ratings yet

- Corolla 2020 HybridDocument1 pageCorolla 2020 HybridrajatnahataNo ratings yet

- BPF100P5 SiiDocument4 pagesBPF100P5 Siinal FxNo ratings yet

- D12 VolvoDocument2 pagesD12 Volvomaxim ivanovNo ratings yet

- JCB Rough Terrain Fork Lift 926, 930, 940Document4 pagesJCB Rough Terrain Fork Lift 926, 930, 940DarrenNo ratings yet

- Forklift Engine Powered Dan Electric PoweredDocument40 pagesForklift Engine Powered Dan Electric PoweredRaka RakaNo ratings yet

- GBG 7500te enDocument1 pageGBG 7500te enOliver StojchevskiNo ratings yet

- Volvo V90 Cross Country, La Scheda TecnicaDocument3 pagesVolvo V90 Cross Country, La Scheda TecnicaBlogo MotoriNo ratings yet

- Qa10 PS BW211D-40Document1 pageQa10 PS BW211D-40Andaru GunawanNo ratings yet

- 6LY3-ETP Series: Marine Diesel EnginesDocument4 pages6LY3-ETP Series: Marine Diesel EnginesJUNIOR OLIVONo ratings yet

- 4BY2-150, YanmarDocument2 pages4BY2-150, YanmarArul muuklisinNo ratings yet

- Elf QuoteDocument3 pagesElf QuoteHaikalNo ratings yet

- Sem 656DDocument1 pageSem 656DCarlos Arturo AcevedoNo ratings yet

- Oil List UtilityDocument3 pagesOil List UtilityM BNo ratings yet

- KW KW KW: Single TurboDocument2 pagesKW KW KW: Single TurboAlbertoNo ratings yet

- 1-1/2 Self-Priming Centrifugal Pumps: 888-Amt-Pump (268-7867)Document2 pages1-1/2 Self-Priming Centrifugal Pumps: 888-Amt-Pump (268-7867)joravicaNo ratings yet

- Deutz F3M 2011ext - enDocument4 pagesDeutz F3M 2011ext - enAhmed ZeharaNo ratings yet

- MHP MHP: For Harmonious Living With Global EnvironmentDocument2 pagesMHP MHP: For Harmonious Living With Global Environmentvictor siringoNo ratings yet

- Cyclone Engine Spec Sheet 2021Document4 pagesCyclone Engine Spec Sheet 2021Nadir JusićNo ratings yet

- Kubota k36-3Document2 pagesKubota k36-3Krzysiek TabasNo ratings yet

- 4LHA Series - : HTP / DTP / STPDocument2 pages4LHA Series - : HTP / DTP / STPFlavio MedranoNo ratings yet

- Intra V20 GoldDocument2 pagesIntra V20 GoldALLCV VijayawadaNo ratings yet

- 6hym WetDocument2 pages6hym WetAris RismansyahNo ratings yet

- Specifications Eh 500fDocument7 pagesSpecifications Eh 500fElfirman Syafei100% (1)

- Kubota Mobile Light TowerDocument1 pageKubota Mobile Light TowerabrhamtNo ratings yet

- EURL YAĞ TESİSİ YERLEŞİM R2 15.01.2018-ModelDocument1 pageEURL YAĞ TESİSİ YERLEŞİM R2 15.01.2018-ModelAbdessemed Mohamed Abd ElghaniNo ratings yet

- 368kW (500mhp) : First Class Power - The Yanmar 6HYDocument2 pages368kW (500mhp) : First Class Power - The Yanmar 6HYRudy PriatnaNo ratings yet

- Motor Gas DieselDocument13 pagesMotor Gas Dieselartemio CardosoNo ratings yet

- 6BY260, YanmarDocument2 pages6BY260, YanmarArul muuklisinNo ratings yet

- 2024 Alka Electric BoilersDocument1 page2024 Alka Electric BoilersAlkaBoiler WTS - Saudi ArabiaNo ratings yet

- Advanced Engineering Mathematics by Erwin Kreyszig - Advanced Engineering Mathematics For Everyone!!!! PDFDocument3 pagesAdvanced Engineering Mathematics by Erwin Kreyszig - Advanced Engineering Mathematics For Everyone!!!! PDFRose Hunter0% (3)

- Voice Logger For Control CommunicationDocument25 pagesVoice Logger For Control CommunicationPankaj kumarNo ratings yet

- Communication Aids and Strategies Using Tool of TechnologyDocument3 pagesCommunication Aids and Strategies Using Tool of TechnologyJequel Bayor JabagatNo ratings yet

- 9A05703 Grid and Cluster Computing PDFDocument4 pages9A05703 Grid and Cluster Computing PDFReddy Kiran KDNo ratings yet

- JGB Product List 2023Document2 pagesJGB Product List 2023ahmed hamdyNo ratings yet

- Project ManagementDocument28 pagesProject ManagementSAVINo ratings yet

- Arg WritingDocument60 pagesArg Writingsamantha sisonNo ratings yet

- Job Analysis Questionnaire: Page 1 of 24Document24 pagesJob Analysis Questionnaire: Page 1 of 24abusyed alhasanNo ratings yet

- Lab #8 Ce336Document10 pagesLab #8 Ce336husseinfarhatmNo ratings yet

- 19 LED Animated Christmas StarDocument38 pages19 LED Animated Christmas StarJane-Josanin ElizanNo ratings yet

- Availability and Fade Margin Calculations For 5G MDocument22 pagesAvailability and Fade Margin Calculations For 5G Mili ilievNo ratings yet

- Hotkeys TWSDocument9 pagesHotkeys TWSvasseNo ratings yet

- DOOM 3 - CheatsDocument21 pagesDOOM 3 - CheatsRizzoRo1No ratings yet

- TallyDocument26 pagesTallyAnshul AggarwalNo ratings yet

- Rupali Santosh Kadam: Career ObjectiveDocument3 pagesRupali Santosh Kadam: Career ObjectiveFantasy DreamNo ratings yet

- Datasheet Phoenix Battery Charger ENDocument2 pagesDatasheet Phoenix Battery Charger ENcueNo ratings yet

- Schools Division of Zamboanga Del Sur: Region IX - Zamboanga Peninsula Dao, Pagadian CityDocument6 pagesSchools Division of Zamboanga Del Sur: Region IX - Zamboanga Peninsula Dao, Pagadian CityDaryl Mutia AlvizNo ratings yet

- Hall Ticket: Current Session: Exam Type: Registration No.: Exam Roll No.: Name: Father's Name: Course Name: AddressDocument2 pagesHall Ticket: Current Session: Exam Type: Registration No.: Exam Roll No.: Name: Father's Name: Course Name: AddressKartikeya GuptaNo ratings yet

- Power Source: 78 HIACE (EWD622E)Document4 pagesPower Source: 78 HIACE (EWD622E)Egoro KapitoNo ratings yet

- Connectivity in GraphsDocument33 pagesConnectivity in GraphsZaruhi AndreasyanNo ratings yet

- Proposed Mixed-Use Development in SRP: No. Clarification ReplyDocument2 pagesProposed Mixed-Use Development in SRP: No. Clarification ReplyJustine CejalvoNo ratings yet

- Karner - Use Case Points - 1993Document9 pagesKarner - Use Case Points - 1993Saeful BahriNo ratings yet

- TEDxBeirut Sponsorship KitDocument7 pagesTEDxBeirut Sponsorship KitHafidhMohammadNo ratings yet

- Oldsmobile Straight-6 Engine: 505 380 177 169.3 185 197.5 213.3 221.4 229.7 216 238 257 See Also ReferencesDocument3 pagesOldsmobile Straight-6 Engine: 505 380 177 169.3 185 197.5 213.3 221.4 229.7 216 238 257 See Also ReferencesRoberto Ortega MicalizziNo ratings yet

- TA7280P, TA7281P: 5.8W Dual Audio Power Amplifier. 22W BTL Audio Power AmplifierDocument15 pagesTA7280P, TA7281P: 5.8W Dual Audio Power Amplifier. 22W BTL Audio Power AmplifierMates IoanNo ratings yet

- Exp No 6Document11 pagesExp No 6حسين عبد الرحيم شاكرNo ratings yet

- Dokumen - Tips Sa A SeriesmanualDocument19 pagesDokumen - Tips Sa A SeriesmanualJay Peria2100% (1)