Professional Documents

Culture Documents

PF0009 SLB MR DAT 0007 - Rev.0

PF0009 SLB MR DAT 0007 - Rev.0

Uploaded by

bmanojkumar16Copyright:

Available Formats

You might also like

- Jane Greene and Anthony M. Grant. Solution Focused Coaching Managing People in A Complex World 2003. MomentumDocument209 pagesJane Greene and Anthony M. Grant. Solution Focused Coaching Managing People in A Complex World 2003. MomentumJadith Jesus Ezaine Gutierrez100% (2)

- FINAL SYNOPSIS On It ParkDocument11 pagesFINAL SYNOPSIS On It ParkAr Sonali Hadke100% (4)

- QMS-012 3rd Party Insp of Vendor Products, Issue 4 Apr 20Document9 pagesQMS-012 3rd Party Insp of Vendor Products, Issue 4 Apr 20bmanojkumar16No ratings yet

- IHA AssessmentDocument4 pagesIHA Assessmentbmanojkumar16No ratings yet

- First Quarter TestDocument6 pagesFirst Quarter TestBenj AlejoNo ratings yet

- Volte Ims Architecture 1 PDFDocument33 pagesVolte Ims Architecture 1 PDFRitesh100% (1)

- Wheeled Coach2Document2 pagesWheeled Coach2Rachelle Lim-Magtanggol67% (3)

- EDC15 Guia de REPROGRAMACIONDocument2 pagesEDC15 Guia de REPROGRAMACIONALZHEIMER 47100% (1)

- 290 Sundancer Smart Craft ManualDocument33 pages290 Sundancer Smart Craft ManualMitch Williams100% (1)

- PF0009 SLB MR DAT 0009 - Rev.00Document7 pagesPF0009 SLB MR DAT 0009 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0008 - Rev.00Document7 pagesPF0009 SLB MR DAT 0008 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0010 - Rev.00Document7 pagesPF0009 SLB MR DAT 0010 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0011 - Rev.00Document7 pagesPF0009 SLB MR DAT 0011 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB CV SPC 0002Document12 pagesPF0009 SLB CV SPC 0002bmanojkumar16No ratings yet

- Pf0009 SLB Pi SPC 0002 - Rev A Vms IdcDocument75 pagesPf0009 SLB Pi SPC 0002 - Rev A Vms Idckaifalam22031981No ratings yet

- PF0009 SLB CV SPC 0001Document19 pagesPF0009 SLB CV SPC 0001bmanojkumar16No ratings yet

- 6008t2diga27013 Exde00 07Document7 pages6008t2diga27013 Exde00 07juan.brito.imiNo ratings yet

- 6008t2diga27014 Exde00 06Document6 pages6008t2diga27014 Exde00 06juan.brito.imiNo ratings yet

- Subcontractor Document List (SDL) Construsoyo PO 1429859 MasterDocument5 pagesSubcontractor Document List (SDL) Construsoyo PO 1429859 MasterjoaoNo ratings yet

- PF0009 010 MS Dat 0015 - BDocument7 pagesPF0009 010 MS Dat 0015 - Byadav yadavNo ratings yet

- 140107DIEH00192 - Feuilles Des Données Des Instruments - EX-CO - 00Document23 pages140107DIEH00192 - Feuilles Des Données Des Instruments - EX-CO - 00ahmed chakrounNo ratings yet

- 600722dost09087 - Exde01 - 19 EspecifDocument19 pages600722dost09087 - Exde01 - 19 Especifmarcopr38No ratings yet

- Inspection & Test Plan TemplateDocument11 pagesInspection & Test Plan Templatefanghao5345No ratings yet

- 250611DECID1608 - EXDE02 - 27 (Update HH)Document29 pages250611DECID1608 - EXDE02 - 27 (Update HH)Mohammed HijaziNo ratings yet

- 250611DECID1608 - EXDE02 - 27 (Update HH)Document25 pages250611DECID1608 - EXDE02 - 27 (Update HH)Mohammed HijaziNo ratings yet

- 251213dtebd0666 Exde01 05Document5 pages251213dtebd0666 Exde01 05Mohammed HijaziNo ratings yet

- 251010cbmitb848 Exco00-193Document193 pages251010cbmitb848 Exco00-193Ali RaheemNo ratings yet

- 362200BPSG01009 - Exde01 - 12 Insulation & Tropicalisation PhilosophyDocument12 pages362200BPSG01009 - Exde01 - 12 Insulation & Tropicalisation Philosophyincipit32No ratings yet

- BP in Salah RB211-24G62 / DLE Onshore Power Generation (ONPG) M.A214Document5 pagesBP in Salah RB211-24G62 / DLE Onshore Power Generation (ONPG) M.A214khalid benessalahNo ratings yet

- 250600decid0134 Exde01 38'Document38 pages250600decid0134 Exde01 38'Mohammed HijaziNo ratings yet

- 251213dtebd0654 Exde02 04Document4 pages251213dtebd0654 Exde02 04Mohammed HijaziNo ratings yet

- 251213dtebd0662 Exde01 03Document3 pages251213dtebd0662 Exde01 03Mohammed HijaziNo ratings yet

- General Specification For Pipeline Field Welding & NDTDocument77 pagesGeneral Specification For Pipeline Field Welding & NDTRanjan KumarNo ratings yet

- Merakes Development Project: Floating Production Unit Upgrade EPCI-1Document34 pagesMerakes Development Project: Floating Production Unit Upgrade EPCI-1fajarNo ratings yet

- 250610dtebd2589 Exde01 05Document5 pages250610dtebd2589 Exde01 05Mohammed HijaziNo ratings yet

- 250611decid1608 Exde01 15 Zfod CommentsDocument17 pages250611decid1608 Exde01 15 Zfod CommentsMohammed HijaziNo ratings yet

- 250600decid0134 Exde00 20Document21 pages250600decid0134 Exde00 20Mohammed HijaziNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Flare Network Calculation Report Hammar Mishrif DGS: Eni - Iraq Zubair Oil Field Development ProjectDocument20 pagesFlare Network Calculation Report Hammar Mishrif DGS: Eni - Iraq Zubair Oil Field Development ProjectEslam ShiblNo ratings yet

- 251111dtebd1192 Exde01 04Document4 pages251111dtebd1192 Exde01 04Mohammed HijaziNo ratings yet

- 00251321defp70516 Exab00 37 BSDGDocument37 pages00251321defp70516 Exab00 37 BSDGfahadNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- 4i211a40z20 7Document5 pages4i211a40z20 7Ahmed MadaniNo ratings yet

- 251213dtebd0670 Exde01 05Document6 pages251213dtebd0670 Exde01 05Mohammed HijaziNo ratings yet

- C711 PDS2Document5 pagesC711 PDS2Jitendra ChaudhariNo ratings yet

- 250600DWQRD0087 Exde01 11Document11 pages250600DWQRD0087 Exde01 11Mohammed HijaziNo ratings yet

- 251001dtebd1189 Exde01 04Document4 pages251001dtebd1189 Exde01 04Mohammed HijaziNo ratings yet

- 351701digsf0053 Exco00 30Document30 pages351701digsf0053 Exco00 30Theophilus Oduro-NyarkoNo ratings yet

- 251213dtebd0658 Exab01 05Document5 pages251213dtebd0658 Exab01 05Mohammed HijaziNo ratings yet

- Concrete FoundationsDocument8 pagesConcrete FoundationssakrakirfanNo ratings yet

- VD 1233 330 Dig 001 1Document12 pagesVD 1233 330 Dig 001 1Reza AranNo ratings yet

- 251111dtebd1205 Exde01 05Document5 pages251111dtebd1205 Exde01 05Mohammed HijaziNo ratings yet

- KS E11raa Exe I08 999 Inc Ga 0004 - 00Document4 pagesKS E11raa Exe I08 999 Inc Ga 0004 - 00nbmskbzcrsNo ratings yet

- 30a100dbqb23070 - Exde00 - 23 - 21032023 - Quality Control Plan For PipingDocument27 pages30a100dbqb23070 - Exde00 - 23 - 21032023 - Quality Control Plan For Pipingsamuel madisonNo ratings yet

- S001032-14 (Datalogger Specification)Document2 pagesS001032-14 (Datalogger Specification)akramhomriNo ratings yet

- Turret Piping Springs 14 Jan 2016 PrestressDocument22 pagesTurret Piping Springs 14 Jan 2016 PrestresscatullusNo ratings yet

- 251911dtebd1191 Exde01 04Document4 pages251911dtebd1191 Exde01 04Mohammed HijaziNo ratings yet

- 00250600bigc52238 Cdfe02 04Document4 pages00250600bigc52238 Cdfe02 04Mohammed HijaziNo ratings yet

- 3795-210-S20 - C04-0006 R0 Equipment Data Curves For Item No 20-P-223 AB - Flare K.O Drum Pump CommentedDocument2 pages3795-210-S20 - C04-0006 R0 Equipment Data Curves For Item No 20-P-223 AB - Flare K.O Drum Pump CommentedFomaa ElsayedNo ratings yet

- NDE-6407 Rev0Document116 pagesNDE-6407 Rev0konazoiNo ratings yet

- 00250600bigb52038 Cdfe02 07Document7 pages00250600bigb52038 Cdfe02 07Mohammed HijaziNo ratings yet

- Process Site Visit Report 25.03.2019Document15 pagesProcess Site Visit Report 25.03.2019hatem jlolNo ratings yet

- Supplier DocumentDocument20 pagesSupplier Documentkhalid benessalahNo ratings yet

- Contromatic - Self Regulating Valve (ORF) - Operating ManualDocument55 pagesContromatic - Self Regulating Valve (ORF) - Operating ManualEki NosaNo ratings yet

- 250600deqrd0198 Exde02 12Document12 pages250600deqrd0198 Exde02 12Mohammed HijaziNo ratings yet

- Combine PDFDocument4 pagesCombine PDFMorgan SidesoNo ratings yet

- A-Ele-Lst-000-47960-B - Cable Shedule For Pipeline Cathodic Protection SystemDocument44 pagesA-Ele-Lst-000-47960-B - Cable Shedule For Pipeline Cathodic Protection SystemBadiNo ratings yet

- The Contractor Payment Application Audit: Guidance for Auditing AIA Documents G702 & G703From EverandThe Contractor Payment Application Audit: Guidance for Auditing AIA Documents G702 & G703No ratings yet

- PF0009 SLB CV SPC 0001Document19 pagesPF0009 SLB CV SPC 0001bmanojkumar16No ratings yet

- 3.3 Reciprocating (LP-HP)Document3 pages3.3 Reciprocating (LP-HP)bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0011 - Rev.00Document7 pagesPF0009 SLB MR DAT 0011 - Rev.00bmanojkumar16No ratings yet

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0008 - Rev.00Document7 pagesPF0009 SLB MR DAT 0008 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0010 - Rev.00Document7 pagesPF0009 SLB MR DAT 0010 - Rev.00bmanojkumar16No ratings yet

- ITH-FP1-F03181-M-SPE-0001 - A01 - SignedDocument29 pagesITH-FP1-F03181-M-SPE-0001 - A01 - Signedbmanojkumar16No ratings yet

- Aug 2023Document1 pageAug 2023bmanojkumar16No ratings yet

- FPF1-ST-G00001-P-BOD-0002 - 0901ac658004d7efDocument49 pagesFPF1-ST-G00001-P-BOD-0002 - 0901ac658004d7efbmanojkumar16No ratings yet

- TP-WMS-05969-DAS-A4-D1-K - Demulsifier DatasheetDocument9 pagesTP-WMS-05969-DAS-A4-D1-K - Demulsifier Datasheetbmanojkumar16No ratings yet

- TP-WMS-05967-DAS-A4-D1-K - Biocide DatasheetDocument9 pagesTP-WMS-05967-DAS-A4-D1-K - Biocide Datasheetbmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0009 - Rev.00Document7 pagesPF0009 SLB MR DAT 0009 - Rev.00bmanojkumar16No ratings yet

- Dec 2022Document1 pageDec 2022bmanojkumar16No ratings yet

- Attchment-4 - Piping Class 013411-XDocument11 pagesAttchment-4 - Piping Class 013411-Xbmanojkumar16No ratings yet

- Scale Inhibitor MSDS (MC MX 2-3421)Document8 pagesScale Inhibitor MSDS (MC MX 2-3421)bmanojkumar16100% (1)

- TP-WMS-05940-SPC-A4-D1-L-Specification For ValvesDocument34 pagesTP-WMS-05940-SPC-A4-D1-L-Specification For Valvesbmanojkumar16100% (1)

- QMS-003 Procedure For Quality Control of Materials Issue 5 April 20Document107 pagesQMS-003 Procedure For Quality Control of Materials Issue 5 April 20bmanojkumar16100% (2)

- Cover Page - LG DSDocument2 pagesCover Page - LG DSbmanojkumar16No ratings yet

- MTR 09Document1 pageMTR 09bmanojkumar16No ratings yet

- SKid GAD CRS - Revised FormatDocument1 pageSKid GAD CRS - Revised Formatbmanojkumar16No ratings yet

- Cover Page - GADDocument2 pagesCover Page - GADbmanojkumar16No ratings yet

- Erg DRG Eng STR P.01 22 320 001 001 ADocument1 pageErg DRG Eng STR P.01 22 320 001 001 Abmanojkumar16No ratings yet

- 21DBBV12M-7 42inch (In) DimensionADoubleBlockandBleedNeedleValvewithFullBoreDocument3 pages21DBBV12M-7 42inch (In) DimensionADoubleBlockandBleedNeedleValvewithFullBorebmanojkumar16No ratings yet

- Line List - All PackagesDocument42 pagesLine List - All Packagesbmanojkumar16No ratings yet

- Marechal DX2 Decontactor Range enDocument2 pagesMarechal DX2 Decontactor Range enbmanojkumar16No ratings yet

- Marechal PNCX Range enDocument2 pagesMarechal PNCX Range enbmanojkumar16No ratings yet

- Line List - Methanol SkidDocument3 pagesLine List - Methanol Skidbmanojkumar16No ratings yet

- Sample IOM-SchlumbergerDocument10 pagesSample IOM-Schlumbergerbmanojkumar16No ratings yet

- Mision 8 9 12Document419 pagesMision 8 9 12auweia1No ratings yet

- ClementDocument22 pagesClementbettounyNo ratings yet

- Evolution 6000 BulletinDocument8 pagesEvolution 6000 BulletinHarold Fernando Guavita ReyesNo ratings yet

- Design Procedure For Loading Capacity Calculations For Classic Automobile DifferentialsDocument9 pagesDesign Procedure For Loading Capacity Calculations For Classic Automobile DifferentialsSergio ChavezNo ratings yet

- Faktor-Faktor Yang Mempengaruhi Yield To Maturity Obligasi - Dewi Ratih Permata AlmiDocument22 pagesFaktor-Faktor Yang Mempengaruhi Yield To Maturity Obligasi - Dewi Ratih Permata Almidewi ratihNo ratings yet

- 8050SDocument4 pages8050Sscr8510No ratings yet

- Duties and Responsibilities Related To Being A Retail Store ManagerDocument5 pagesDuties and Responsibilities Related To Being A Retail Store Managerroshan_krNo ratings yet

- HWP2013W-2012B Service Manual IIDocument109 pagesHWP2013W-2012B Service Manual IILuis Guillermo RoaNo ratings yet

- Work Method - Ignite-Data Center CikarangDocument3 pagesWork Method - Ignite-Data Center CikarangaronmdavinchyNo ratings yet

- Time Varying SignalsDocument17 pagesTime Varying SignalsDiego Cancino SilvaNo ratings yet

- SGS PCA Kuwait Dat88asheet A4 EN 17 V1Document7 pagesSGS PCA Kuwait Dat88asheet A4 EN 17 V1Skander HamadiNo ratings yet

- MOM Extra ItemsDocument5 pagesMOM Extra ItemsshubhendrasahaNo ratings yet

- Milling PowerDocument1 pageMilling PowerRicardo VitorianoNo ratings yet

- The Scan-Path Technique For Testable Sequential Circuit DesignDocument11 pagesThe Scan-Path Technique For Testable Sequential Circuit DesignLavanya BjNo ratings yet

- Attendance ManagementDocument45 pagesAttendance ManagementSanjay GodboleNo ratings yet

- M/E Item Qty Unit: MBU BUDGET 2020-2021Document13 pagesM/E Item Qty Unit: MBU BUDGET 2020-2021Shiftmanager PICTNo ratings yet

- A Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar HussainDocument23 pagesA Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar Hussainoquintero99100% (2)

- Resume For WeeblyDocument2 pagesResume For Weeblyapi-259381516No ratings yet

- Solution To Chapter 7 Exercises: FluidizationDocument1 pageSolution To Chapter 7 Exercises: FluidizationqifniNo ratings yet

- Enrollment Form 3Document1 pageEnrollment Form 3حيدرالركابيNo ratings yet

- ReportDocument6 pagesReportLâmViênNo ratings yet

- SATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFDocument2 pagesSATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFRamziAhmedNo ratings yet

- 633-PDC2-LAPORAN KEJURUTERAAN (Signed)Document17 pages633-PDC2-LAPORAN KEJURUTERAAN (Signed)Mohd RafiqNo ratings yet

PF0009 SLB MR DAT 0007 - Rev.0

PF0009 SLB MR DAT 0007 - Rev.0

Uploaded by

bmanojkumar16Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PF0009 SLB MR DAT 0007 - Rev.0

PF0009 SLB MR DAT 0007 - Rev.0

Uploaded by

bmanojkumar16Copyright:

Available Formats

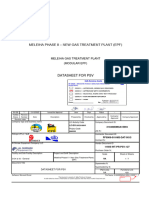

MELEIHA PHASE II – NEW GAS TREATMENT PLANT (EPF)

MELEIHA GAS TREATMENT PLANT

(MODULAR EPF)

MECHANICAL DATA SHEET - CORROSION INHIBITOR INJECTION

PACKAGE 001200XX100

Nitesh / Emmanuel /

EX-DE 00 9/18/2023 Issued for Comment Pramod S John K -

Rahul Shyam S

Validity Revision

Contractor Company

Status Number Date Description Prepared by Checked by Approved by

Approved Approved

Revision index

LCI Activity Code Company Document ID:

LCI-EG-2023-0004

313400DMGA12359

Project Code

000532 Job N.:

Petrojet (PTJ) / SLB Contractor Document ID:

PF0009-SLB-MR-DAT-0007

Contract N.:

VeeTech Vendor Document ID

SOIP23005-P-DS-251

Purchase Order N.:

Facility and Sub Facility Description Project and SoW Description Scale Sheet of Sheets

Meleiha Phase II – New Gas Treatment

3134 & 00 - General NA 1/7

Plant ( EPF)

Document Title Supersedes N.

Superseded by N.

MECHANICAL DATA SHEET - CORROSION INHIBITOR INJECTION

Plant area Functional unit

PACKAGE 001200XX100

NA 120

This document is property of Agiba Petroleum Company

It shall neither be shown to Third Parties nor used for purposes other than those for which it has been sent.

Validity Revision

Status Number

EX-DE 00

Company Document ID Contractor Document ID Vendor Document ID

Sheet of Sheets

313400DMGA12359 PF0009-SLB-MR-DAT-0007 SOIP23005-P-DS-251 2/7

REVISION LIST

18.09.23 00 A Issued for Comment

Client Contractor Vendor

Date Description

Rev Rev Rev

HOLD RECORD

B Hold 1 - Suction pressure

Client Contractor Vendor

Date Reason for HOLD

Rev Rev Rev

This document is property of Agiba Petroleum Company

It shall neither be shown to Third Parties nor used for purposes other than those for which it has been sent.

# SLB-Private

Validity Revision

Status Number

EX-DE 00

Company Document ID Contractor Document ID Vendor Document ID

Sheet of Sheets

3 /7

313400DMGA12359 PF0009-SLB-MR-DAT-0007 SOIP23005-P-DS-251

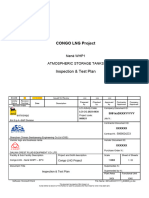

DATA SHEET FOR CONTROLLED VOLUME PUMP (API 675-3RD) SI UNITS (bar) Rev

1 APPLICABLE TO: PROPOSAL PURCHASE AS BUILT

2 FOR MELEIHA PHASE II – NEW GAS TREATMENT PLANT / EGYPT UNIT 120

3 SITE AGIBA eni / Egypt NO. OF PUMPS REQUIRED 2 (1 W + 1S)

4 SERVICE Corrosion Inhibitor MODEL MROY XA SIZE AND TYPE XA112(75) H2 H12.5 / 9.L.C5.HH3.Z

5 MANUFACTURER MILTON ROY EUROPE SERIAL NO. VTA

6 NOTE: INDICATES INFORMATION TO BE COMPLETED BY PURCHASER BY MANUFACTURER

7 GENERAL

8 NO. MOTORS DRIVEN 2 (ONE PER PUMP) OTHER DRIVER TYPE N/A

9 PUMP ITEM NO'S 001200PG422A/B PUMP ITEM NO'S N/A

10 MOTOR ITEM NO'S Later DRIVER ITEM NO'S N/A GEAR ITEM NO'S N/A

11 MOTOR PROVIDED BY ABB (FINLAND) DRIVER PROVIDED BY N/A GEAR PROVIDED BY N/A

12 MOTOR MOUNTED BY MILTON ROY (FRANCE) DRIVER MOUNTED BY N/A GEAR MOUNTED BY N/A

13 MOTOR DATA SHEET NO. VTA DRIVER DATA SHEET NO. N/A GEAR DATA SHEET NO. N/A

14 OPERATING CONDITIONS LIQUID

15 CAPACITY @ PT: (L/min) TYPE OR NAME OF LIQUID CORROSION INHIBITOR

16 MAXIMUM 0.120 MINIMUM 0.060 RATED 0.132 PUMPING TEMPERATURE: (°C)

17 DISCHARGE PRESSURE: (barG) NORMAL AMB MAX 85 MIN 1

18 MAXIMUM 12.5 MINIMUM 10 SPECIFIC GRAVITY 1.040 MAXIMUM 0.980 MINIMUM

19 SUCTION PRESSURE: (barG) SPECIFIC HEAT Cp (kJ/kg °C)

20 MAXIMUM 0.3 (Hold) MINIMUM 0.1 (Hold) VISCOSITY (cP) 21.06 MINIMUM MAXIMUM

21 DIFFERENTIAL PRESSURE: (bar) CORROSIVE/EROSIVE AGENTS

22 MAXIMUM MINIMUM CHLORIDE CONCENTRATION (PPM)

23 NPIP AVAILABLE: (barG) 0.967 (without acceleration loss) H2S CONCENTRATION (PPM)

24 (INCLUDING ACCELERATION LOSSES) LIQUID TOXIC FLAMMABLE OTHER

25 TURNDOWN RATIO 10:1

26 PERFORMANCE VTA SITE AND UTILITY DATA

27 NUMBER OF FEEDS 1 RATED CAPACITY (L/min) 0.238 LOCATION INDOOR OUTDOOR

28 NPIP REQUIRED (INCLUDING ACCEL LOSSES) 0.344 (barG) HEATED UNHEATED UNDER ROOF

29 BHP RATED 0.18 AT RELIEF SETTING 0.22 ELECTRICAL AREA CLASSIFICATION Zone 2, IIA/IIB, T3

30 PLUNGER SPEED (strokes/min) 75 DESIGN MAX 112 WINTERIZATION REQD TROPICALIZATION REQD

31 DIAMETER (mm) 15.9 LENGTH OF STROKE (mm) 18 SITE DATA

32 PUMP HEAD: SIMPLEX RANGE OF AMBIENT TEMPS:MIN/MAX 1 / 49 °C

33 MAXIMUM PRESSURE (barG) 19.5 UNUSUAL CONDITIONS

34 HYDRO TEST PRESSURE (barG) 29.25 DUST FUMES SALT ATMOSPHERE

35 MAX DISCH PRESS. W/ JOB DRIVER (barG) 19.5 OTHER sand

36 MAX BHP BASIS GEAR STRENGTH 110 daN UTILITY CONDITIONS

37 CONSTRUCTION ELECTRICITY DRIVERS HEATING CONTROL SHUTDOWN

38 SIZE ANSI FACING POSITION VOLTAGE 400 NA

39 CONNECTIONS RATING HERTZ 50 NA

40 SUCTION 1/2" 300# RF Horizontal PHASE 3phase + Neutral NA

41 DISCHARGE 1/2" 300# RF Horizontal COOLING WATER INLET RETURN DESIGN MAX D

42 FLUSH TEMP °F MAX

43 PRESS. (PSIG) MIN

44 LIQUID END JACKET REQ'D SOURCE

45 TYPE DIAPHRAGM PLUNGER INSTRUMENT AIR MAX MIN

46 DIAPHRAGM DIA (mm) 101 NO REQ. 2 PRESSURE (PSIG)

47 VALVES/FEED SUCTION DISCHARGE APPLICABLE SPECIFICATIONS:

48 TYPE Ball Ball API 675 POSITIVE DISPLACEMENT PUMPS - CONTROLLED VOLUME

49 NUMBER Double Double NACE MR-0103 (6.14.2.13) NACE MR-0175 (6.14.2.13)

50 OTHER

51 * NPIP provided 3.44 mlc is excluding acceleration loss

This document is property of Agiba Petroleum Company

It shall neither be shown to Third Parties nor used for purposes other than those for which it has been sent.

# SLB-Private

Validity Revision

Status Number

EX-DE 00

Company Document ID Contractor Document ID Vendor Document ID

Sheet of Sheets

4 /7

313400DMGA12359 PF0009-SLB-MR-DAT-0007 SOIP23005-P-DS-251

DATA SHEET FOR CONTROLLED VOLUME PUMP (API 675-3RD) SI UNITS (bar) Rev

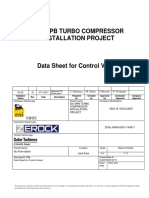

1 MATERIALS CONTROLS (Note-4)

2 LIQUID END SS316L TYPE: SIGNAL:

3 CONTOUR PLATE SS316L MANUAL REMOTE PNEUMATIC

4 HYDRAULIC DIAPHRAGM PTFE (VTA) AUTOMATIC LOCAL ELECTRONIC

5 PROCESS DIAPHRAGM PTFE (VTA) STROKE CONTROL:

6 PLUNGER Non-Wetted Part (Alloy Steel) PNEUMATIC: (barG)

7 LANTERN RING NA MINIMUM MAXIMUM

8 PACKING GLAND NA ELECTRONIC (mA):

9 PACKING NA MINIMUM MAXIMUM

10 VALVE SS316L OTHER PURCHASE REQUIREMENTS

11 VALVE SEAT SS316L NAMEPLATE UNITS U.S. CUSTOMARY SI

12 VALVE GUIDE SS316L VENDOR FURNISHED PROCESS PIPING

13 VALVE BODY SS316L

14 VALVE GASKET FPM VENDOR REVIEW PIPING DRAWINGS

15 FRAME Cast Iron VENDOR FURNISHED PULSATION SUPPRESSION DEVICES

16 SPECIAL MATERIAL TESTS (6.14.2.5) VENDOR FURNISHED RELIEF VALVE

17 INTERNAL 19.5 barg EXTERNAL

18 LOW AMBIENT TEMPERATURE MATERIALS TESTS (6.14.6) RELIEF VALVE SETTING (barG) 15

19 VENDOR FURNISHED BACK-PRESSURE VALVE

20 QA INSPECTION AND TEST DOUBLE CHECK VALVES REQUIRED

21 COMPLIANCE WITH INSPECTORS CHECK LIST OIL-FILLED PRESSURE GAUGES REQUIRED

22 CERTIFICATION OF MATERIALS (3.1 Certificate for Pressurized wetted parts) VENDOR FURNISHED CONTROL PANEL

23 FINAL ASSEMBLY CLEARANCES (user to define components in remarks) BASEPLATE PREPARED FOR EPOXY GROUT

24 SURFACE AND SUBSURFACE EXAMINATIONS PROVIDE TECHNICAL DATA MANUAL

25 RADIOGRAPHY

26 ULTRASONIC

27 MAGNETIC PARTICLE PREPARATION FOR SHIPMENT

28 LIQUID PENETRANT (WELDS) on welded joints only DOMESTIC EXPORT EXPORT BOXING

29 CLEANLINESS PRIOR TO FINAL ASSEMBLY OUTDOOR STORAGE MORE THAN 6 MONTHS

30 HARDNESS OF PARTS, WELDS & HEAT AFFECTED ZONES WEIGHTS (Kg) (VTA)

31 FURNISH PROCEDURES FOR OPTIONAL TESTS PUMP 20 BASE GEAR DRIVER 30

32 TESTS REQ'D WIT OBS DRIVERS

33 HYDROSTATIC (8.3.2) X MOTOR:

34 STEADY STATE ACCURACY X Note 52 MANUFACTURER ABB (FINLAND)

35 REPEATABILITY Note 52 TYPE Exdb eb IIB T4

36 LINEARITY Note 52 FRAME NO. 80

37 PERFORMANCE (8.3.4) CONSTANT SPEED YES

38 MECHANICAL RUN (8.3.5)

39 NPIP(8.3.7.1)

40 COMPLETE UNIT (8.3.7.2)

41 SOUND LEVEL (8.3.7.3)

42 HIGH DISCHARGE PRES (8.3.7.4)

43 FACTORY ACCEPTANCE (8.3.8) VARIABLE SPEED

44 LUBRICATION FLUID kW 0.55 RPM 937

45 CRANKCASE ISO VG 150 INTERMEDIATE VOLTS 400 PHASE 3

46 HYDRAULIC FLUID ISO VG 150 HERTZ 50 SERVICE FACTOR 1

47 ACCESSORIES ENCLOSURE IP55

48 SPEED REDUCER MANUFACTURER MILTON ROY OTHER (SEE SEPARATE DATA SHEETS)

49 INTEGRAL SEPARATE GAS DRIVEN

50 MODEL Worm Gear STEAM TURBINE

51 RATIO 1:12.5 OTHER

52 BASEPLATE UNDER

53 COUPLING MANUFACTURER MP FILTRI

54 TYPE INTEGRAL FELXIBLE DRY

This document is property of Agiba Petroleum Company

It shall neither be shown to Third Parties nor used for purposes other than those for which it has been sent.

# SLB-Private

Validity Status Revision Number

EX-DE 00

Company Document ID Contractor Document ID Vendor Document ID

Sheet of Sheets

5/7

313400DMGA12359 PF0009-SLB-MR-DAT-0007 SOIP23005-P-DS-251

Tank Datasheet

1 PLANT MELEIHA PHASE II – NEW GAS TREATMENT PLANT / EGYPT

2 LOCATION AGIBA eni / Egypt ITEM No.: 001200TC270

3 SERVICE CORROSION INHIBITOR

4 LENGTH 1395 (HOLD) BREADTH 1395 (HOLD) HEIGHT 1450 (HOLD)

5 CAPACITY 1.85 m3 Sp. Gr.-Contents No. Req. 1 No.

6 STANDARD REFERENCE DRAWINGS DESIGN DATA (Note 2)

7 PF0009-SLB-PR-PID-0021_001 CODE Vendor Standard STAMP REQ. No

8 DESIGN PRES. Ambient + Head DESIGN TEMP. 1 / 85

9 OPERATING PRES. Ambient OPER. TEMP. Ambient

10 CORROSION ALL'W. Nil

11 WIND LOAD. Note 39 SEISMIC FACTOR Note 39

12 COMMENTS STRESS RELIEVE No

13 Vendor shall provide nozzles, instrumentation TESTS

14 and valves as per P&ID (i.e.Man hole, RADIOGRAPHY Spot (min)

15 Flame Arrester, Bird screen, Level Gauge, Level HYDROTEST LEAK TEST @ ATM PRESSURE

16 Transmitter, Emergency vent Hatch, etc.)

17 ITEM THICKNESS MAT. L. COMMENTS

18 TOP PLATE VTA SS 316L

19 SIDE PLATE VTA SS 316L

20 BOTTOM PLATE VTA SS 316L

21 SUPPORT VTA VTA

22 GASKETS VTA VTA

23 NUTS & BOLTS VTA SS 316L

24 LADDER (CAGE) VTA VTA

25 PLATFORM #1 VTA VTA

26 NOZZLE NECKS VTA SS 316L

27 NOZZLE FLANGES VTA SS 316L

28

29 PAINT Not Applicable -- Note 24

30 INSULATION Not Applicable As per Insulation Spec

31

32 NOZZLE SCHEDULE

33 NOZZLE SERVICE SIZE RATING FACING PROJECTION

34 N-1 Filling 2" 150# WNRF VTA

35 N-2 Flame Arrester 2" 150# WNRF VTA

36 N-3 From PSV Outlet 1" 150# WNRF VTA

37 N-4 From Calibration Pot 1/2 " 150# WNRF VTA

38 N-5 Pump Inlet 1/2 " 600# WNRF VTA

39 N-6 Drain 2" 150# WNRF VTA

40 N-7 A/B LG / LT 2" 150# WNRF VTA

41 N-8 Over flow line 2" 150# WNRF VTA

42 N-9 / N10 LT 2" 150# WNRF VTA

43 - EH NA NA NA NA

44 - MH 16" PLATE FABRICATED FF VTA

45 NOTES

46 Refer Page 6 and 7 for notes

47

Schlumberger-Private

#

This document is property of Agiba Petroleum Company

It shall neither be shown to Third Parties nor used for purposes other than those for which it has been sent.

# SLB-Private

Validity Revision

Status Number

EX-DE 00

Company Document ID Contractor Document ID Vendor Document ID

Sheet of Sheets

6 /7

313400DMGA12359 PF0009-SLB-MR-DAT-0007 SOIP23005-P-DS-251

DATA SHEET FOR CONTROLLED VOLUME PUMP (API 675-3RD) SI UNITS (bar) Rev

1. Vendor shall submit this data sheet providing all the missing details along with Offer/Bid Submission. Here VTA stand for "Vendor To Advise".

1

2. Package shall be provided in compliance with "Clause. 7.5 of Mechanical Design Basis (PF0009-SLB-MS-DBP-0001) for Positive Displacement

2

Pumps - Controlled Volume" API 675 3rd Ed. and other specifications listed in the Technical Requisition. The Chemical storage tank shall be

3

rectangular

4

3. Refer to "Basis of Design - Process (Doc No. PF0009-SLB-PR-DBP-0001)" for site conditions and available utilities. Equipment and packages shall be designed

and be suitable for environmental conditions and data, wind, seismic and other appropriate design loading as specified in Civil and Structural Design Basis

5 PF0009-SLB-CV-DBP-0001.

4. Stroke adjustment (0-100%) is envisaged for controlling the dosing rate for chemical injection dosing pump. Local start /stop from local starter

6

panel and remote stop provided in DCS to local starter panel. Local starter panel shall have motor starters, start/stop, ESD push button,

7

run & trip fault indication and local/remote selector.

8

5. Pumps shall be designed for continuous operation and shall be sized in order to allow an extra 10% in excess flow of the maximum injection rate.

9

6. Vendor to ensure compliance with piping isolation requirements for pressure, level and temperature instruments as defined in Specifications PF0009-SLB-PR-

10 PHI-0004 (Isolation Philosophy)

7. All equipment, piping, hose connection (where applicable) , instrumentation ,process controls relief valves, skid frame, Tank support structure, any

11

maintenance platform, and access ladders as well as others auxiliaries required for smooth / proper operation of package shall be supplied by

12

VENDOR. VENDOR to confirm the actual scheme.

16

8. For each Chemical Injection Skid, the VENDOR shall guarantee, as a minimum, the following:

13

i) Injection Flow rate

14

ii) Flow control : Pump accuracy shall be ±1 % of full operating range

15

9. Factory acceptance test shall be carried out for complete package( including pumps)

17

10. Chemical Injection Package shall be suitable for Zone 2, IIA/IIB, T3

18

11. VENDOR shall confirm suitability of Material of Construction for all items supplied for this package. Material certification for all pressure parts and

19

its attachments shall be to EN 10204 3.1 and for non pressure part EN 10204 2.2.

20

12. Required lighting within the skid shall be provided by VENDOR. Lighting fixtures/JB etc. shall be suitable for Hazardous area classification

21

(minimum Zone 2).

22

13. VENDOR shall furnish two earthing bosses at diagonally opposite side of the skid. All equipment on the skid shall be earthed on the skid.

23

14. The manufacturer is responsible for ensuring that the equipment is designed and constructed in accordance with the specifications and codes parts

24

referred to in the data sheet/requisition. Furthermore, the manufacturer is responsible for ensuring that the design, including thickness of pressure

25

and structural parts are satisfactory for the design conditions indicated on the data sheet / requisition.

26

The manufacturer shall ensure that the equipment supplied conforms to all applicable codes/standards

27

as well as Egyptian laws and regulations.

28

15. Provision intended for detecting diaphragm failure such as pressure transmitter Shall be provided for Double diaphragm type pumps.

29

16. Instrument LCP or Junction Box material shall be SS 316L.

31

17. Drip pan shall be provided in the skid base plate. MOC of Drip Tray shall be carbon steel.

32

18. Each Pump discharge shall be provided with Pressure Safety Valve. Each PSV should be designed for blocked discharge. PSV to be located at

33

high point above Chemical Storage Tank and PSV vent routed into tank.

34

19. All piping component for wetted parts shall be SS 316L as minimum. All Flange dimensions shall be as per ASME B16.5.

35

20. Calibration pot to be provided with steel cage to avoid any accidental damage. The calibration pot shall be suitable for the suction conditions and

36

sized for minimum 60 seconds of the maximum pump capacity.

37

21. Tank inlet to be provided with male coupling & to be terminated at the skid edge. Suitable quick coupling with internal NRV to be provided for

38

loading pump connection.

39

22. VENDOR to ensure that the skid arrangement shall have adequate accessibility for maintenance and operation for all components of skid. All

40

termination point at skid edge shall be anchored. Each skid mounted unit shall be provided with lifting lugs, eyes, shackles, slings, chains etc.

41

required to lift the equipment during transport and installation.

30

23. Name plate for all equipment's shall have essential data engraved on SS 316L and affixed to the equipment.

42

24. Painting and coating of equipment, RAL color code shall comply with Company Standard 29001.E.ENG.CPI.STD & 27591.E.ENG.CPI.STD and as

43

per Project specific requirement PF0009-SLB-PI-SPC-0005

44

This document is property of Agiba Petroleum Company

It shall neither be shown to Third Parties nor used for purposes other than those for which it has been sent.

# SLB-Private

Validity Revision

Status Number

EX-DE 00

Company Document ID Contractor Document ID Vendor Document ID

Sheet of Sheets

7/7

313400DMGA12359 PF0009-SLB-MR-DAT-0007 SOIP23005-P-DS-251

DATA SHEET FOR CONTROLLED VOLUME PUMP (API 675-3RD) SI UNITS (bar) Rev

25. VENDOR to confirm the rating of motor with due consideration to power required at PSV Set Pressure and accumulation, Gear/Coupling losses

1

(as applicable) or 10% higher than the power at rated condition whichever is higher.

2

26. The pump shall be electric motor driven. Motors shall be of the squirrel cage induction type. Electrical motor shall comply IOGP S-703 Supplementary

3

Specification to IEC 60034-1 Low Voltage, Three Phase Cage Induction Motors.

4

27. The Chemical Injection Package Skid shall be provided with dedicated Local Control Panel by the Vendor for interface with plant PCS and Electrical

5

System. The single source power from the remote MCC will be supplied to the Local Control Panel by CONTRACTOR and further power distribution

6

on the skid will be by the Vendor. The required starter for each motor shall be provided within the local control panel. If any other power supply is

7

required, VENDOR shall derive it from 400V as provided at one point supply.

8

28. Each skid shall be provided with local control panel, which shall include pump stroke control station and controllers, motor starters, Motor Start / Stop

9

push button and HOA switch, signal lamps, switches, relays, etc. Pump Status Indication to Purchaser's DCS, Trip from Purchaser's ESD system

10

29. High pressure alarm and pump trip at high pressure or due to diaphragm rupture shall be provided. Diaphragm detection system shall be by means

11

of pressure transmitter with local indication. Skid installed instrumentation shall be terminated at skid edge mounted Junction box and local control

12

panel with sunshade. Interconnecting wiring between skid instruments & JB/local control panel shall be by VENDOR (further connection

13

to PCS (DCS) & ESD system from JB/LCP by BUYER).

14

30. All electronic instruments shall be intrinsically safe (Ex d) to the area classification and weatherproof to IP65. Instruments shall be provided

15

with sunshade.

16

31. In case of duty pumps failure, the standby pump shall be started automatically. Spare pump cannot run simultaneously to the operating pump.

17

32. The pulsation in the liquid leaving the pumps shall not exceed 3% (total amplitude)of the operating pressure.

18

33. VENDOR shall provide the sizing calculation and its criteria in compliance with API-675 requirements for pulsation dampener sizing. Pulsation

19

dampeners shall be designed, fabricated and tested as per ASME Sec VIII Div 1 and shall have only flange connections. Nitrogen charge kit for the

20

dampeners shall be supplied by pump vendor.

21

34. The dosing pumps shall trip at low-low liquid level in the tank to prevent the pump from running dry.

22

35. VENDOR shall provide shelter requirement (sunshade) for chemical injection packages.

23

36. When flanged suction and discharge connections are provided, the rating shall be at least 300#.

24

25 37. The difference between NPSH Available (including allowances for acceleration head) and NPSH Required shall be 1 meter

26 38. The Pump MAWP shall be higher than the external pressure relief valve set pressure

39. • Wind - 45 m/sec

• Seismic parameters

Zone factor - 2A

Importance factor - 1.5

Soil type - SB

27 Concrete cylindrical strength - 35 N/mm2

28 40. Vendor to design and supply the Anchor bolts as per company standard drawing 313400DADM12654 and specification 313400DAST13282.

29 41. Instrument Index, IO loops, Loop drawings Cause and effect to be added with FAT and to be tested on SAT

30 42. Flow meter details to be provided and calibration to be witnessed

31 43. Ex-Register to be maintained in Template for E&I Equipment’s and to be added in VDRL

44. Pressure boundary parts of alloy materials, including overlays shall be subject to positive material identification (PMI) using recognized testing methods,

32 instrumentation and standard 28077.ENG.COR.STD PMI as applicable

45. Data sheet of Each skid to be mentioned with appropriate alarms and automated controls like immediate switchover from running to standby pump, in case of

33 Main pump failure.

34 46. Skid Outer Area lighting to be controlled Automatically with Photocell.

35 47. Vibration of the skid requirements shall be complied from Company Standard (opi sg hse 012 e&p r01)

36 48. Storage Tank Vent will be provided with End of line Flame arrestor with Pipe routed to 1 meter above Tank Top A

49. Below requirements from Company Standard (opi sg hse 012 e&p r01) shall be complied:

• A maximum limit for noise emission to the SPL at one meter from equipment in open field conditions :

85 dB(A) or less for continuous or intermittent noise sources

110 dB(A) or less for noise sources active only on emergency

• For pumps located in groups, the following reduction shall be applied for the value of the noise limit:

Items in pair: - 3 dB for each item:

37 More than two items in a row: - 5 dB for each item;

38 50. Final inspection must include:

1. P&ID check and Air leak test

2.Earth continuity

3.Accessibility and operation of valves

4. Instrument contunity check

5. Tag identification

6.Packing preservation

39 51. Rating for flanged connections and piping items (e.g., valves) with DN ≤ 1” ½ in Piping Classes up to rating 600# shall be 600#.

Rating 1500# shall be used for DN ≤ 2” flanged connections and piping items (e.g., valves) in Piping Classes rating 900#

40 52. Steady state accuracy test, Repeatability test and linearity test shall be combined with performance and MRT and can be witnessed

41

This document is property of Agiba Petroleum Company

It shall neither be shown to Third Parties nor used for purposes other than those for which it has been sent.

# SLB-Private

You might also like

- Jane Greene and Anthony M. Grant. Solution Focused Coaching Managing People in A Complex World 2003. MomentumDocument209 pagesJane Greene and Anthony M. Grant. Solution Focused Coaching Managing People in A Complex World 2003. MomentumJadith Jesus Ezaine Gutierrez100% (2)

- FINAL SYNOPSIS On It ParkDocument11 pagesFINAL SYNOPSIS On It ParkAr Sonali Hadke100% (4)

- QMS-012 3rd Party Insp of Vendor Products, Issue 4 Apr 20Document9 pagesQMS-012 3rd Party Insp of Vendor Products, Issue 4 Apr 20bmanojkumar16No ratings yet

- IHA AssessmentDocument4 pagesIHA Assessmentbmanojkumar16No ratings yet

- First Quarter TestDocument6 pagesFirst Quarter TestBenj AlejoNo ratings yet

- Volte Ims Architecture 1 PDFDocument33 pagesVolte Ims Architecture 1 PDFRitesh100% (1)

- Wheeled Coach2Document2 pagesWheeled Coach2Rachelle Lim-Magtanggol67% (3)

- EDC15 Guia de REPROGRAMACIONDocument2 pagesEDC15 Guia de REPROGRAMACIONALZHEIMER 47100% (1)

- 290 Sundancer Smart Craft ManualDocument33 pages290 Sundancer Smart Craft ManualMitch Williams100% (1)

- PF0009 SLB MR DAT 0009 - Rev.00Document7 pagesPF0009 SLB MR DAT 0009 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0008 - Rev.00Document7 pagesPF0009 SLB MR DAT 0008 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0010 - Rev.00Document7 pagesPF0009 SLB MR DAT 0010 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0011 - Rev.00Document7 pagesPF0009 SLB MR DAT 0011 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB CV SPC 0002Document12 pagesPF0009 SLB CV SPC 0002bmanojkumar16No ratings yet

- Pf0009 SLB Pi SPC 0002 - Rev A Vms IdcDocument75 pagesPf0009 SLB Pi SPC 0002 - Rev A Vms Idckaifalam22031981No ratings yet

- PF0009 SLB CV SPC 0001Document19 pagesPF0009 SLB CV SPC 0001bmanojkumar16No ratings yet

- 6008t2diga27013 Exde00 07Document7 pages6008t2diga27013 Exde00 07juan.brito.imiNo ratings yet

- 6008t2diga27014 Exde00 06Document6 pages6008t2diga27014 Exde00 06juan.brito.imiNo ratings yet

- Subcontractor Document List (SDL) Construsoyo PO 1429859 MasterDocument5 pagesSubcontractor Document List (SDL) Construsoyo PO 1429859 MasterjoaoNo ratings yet

- PF0009 010 MS Dat 0015 - BDocument7 pagesPF0009 010 MS Dat 0015 - Byadav yadavNo ratings yet

- 140107DIEH00192 - Feuilles Des Données Des Instruments - EX-CO - 00Document23 pages140107DIEH00192 - Feuilles Des Données Des Instruments - EX-CO - 00ahmed chakrounNo ratings yet

- 600722dost09087 - Exde01 - 19 EspecifDocument19 pages600722dost09087 - Exde01 - 19 Especifmarcopr38No ratings yet

- Inspection & Test Plan TemplateDocument11 pagesInspection & Test Plan Templatefanghao5345No ratings yet

- 250611DECID1608 - EXDE02 - 27 (Update HH)Document29 pages250611DECID1608 - EXDE02 - 27 (Update HH)Mohammed HijaziNo ratings yet

- 250611DECID1608 - EXDE02 - 27 (Update HH)Document25 pages250611DECID1608 - EXDE02 - 27 (Update HH)Mohammed HijaziNo ratings yet

- 251213dtebd0666 Exde01 05Document5 pages251213dtebd0666 Exde01 05Mohammed HijaziNo ratings yet

- 251010cbmitb848 Exco00-193Document193 pages251010cbmitb848 Exco00-193Ali RaheemNo ratings yet

- 362200BPSG01009 - Exde01 - 12 Insulation & Tropicalisation PhilosophyDocument12 pages362200BPSG01009 - Exde01 - 12 Insulation & Tropicalisation Philosophyincipit32No ratings yet

- BP in Salah RB211-24G62 / DLE Onshore Power Generation (ONPG) M.A214Document5 pagesBP in Salah RB211-24G62 / DLE Onshore Power Generation (ONPG) M.A214khalid benessalahNo ratings yet

- 250600decid0134 Exde01 38'Document38 pages250600decid0134 Exde01 38'Mohammed HijaziNo ratings yet

- 251213dtebd0654 Exde02 04Document4 pages251213dtebd0654 Exde02 04Mohammed HijaziNo ratings yet

- 251213dtebd0662 Exde01 03Document3 pages251213dtebd0662 Exde01 03Mohammed HijaziNo ratings yet

- General Specification For Pipeline Field Welding & NDTDocument77 pagesGeneral Specification For Pipeline Field Welding & NDTRanjan KumarNo ratings yet

- Merakes Development Project: Floating Production Unit Upgrade EPCI-1Document34 pagesMerakes Development Project: Floating Production Unit Upgrade EPCI-1fajarNo ratings yet

- 250610dtebd2589 Exde01 05Document5 pages250610dtebd2589 Exde01 05Mohammed HijaziNo ratings yet

- 250611decid1608 Exde01 15 Zfod CommentsDocument17 pages250611decid1608 Exde01 15 Zfod CommentsMohammed HijaziNo ratings yet

- 250600decid0134 Exde00 20Document21 pages250600decid0134 Exde00 20Mohammed HijaziNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Flare Network Calculation Report Hammar Mishrif DGS: Eni - Iraq Zubair Oil Field Development ProjectDocument20 pagesFlare Network Calculation Report Hammar Mishrif DGS: Eni - Iraq Zubair Oil Field Development ProjectEslam ShiblNo ratings yet

- 251111dtebd1192 Exde01 04Document4 pages251111dtebd1192 Exde01 04Mohammed HijaziNo ratings yet

- 00251321defp70516 Exab00 37 BSDGDocument37 pages00251321defp70516 Exab00 37 BSDGfahadNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- 4i211a40z20 7Document5 pages4i211a40z20 7Ahmed MadaniNo ratings yet

- 251213dtebd0670 Exde01 05Document6 pages251213dtebd0670 Exde01 05Mohammed HijaziNo ratings yet

- C711 PDS2Document5 pagesC711 PDS2Jitendra ChaudhariNo ratings yet

- 250600DWQRD0087 Exde01 11Document11 pages250600DWQRD0087 Exde01 11Mohammed HijaziNo ratings yet

- 251001dtebd1189 Exde01 04Document4 pages251001dtebd1189 Exde01 04Mohammed HijaziNo ratings yet

- 351701digsf0053 Exco00 30Document30 pages351701digsf0053 Exco00 30Theophilus Oduro-NyarkoNo ratings yet

- 251213dtebd0658 Exab01 05Document5 pages251213dtebd0658 Exab01 05Mohammed HijaziNo ratings yet

- Concrete FoundationsDocument8 pagesConcrete FoundationssakrakirfanNo ratings yet

- VD 1233 330 Dig 001 1Document12 pagesVD 1233 330 Dig 001 1Reza AranNo ratings yet

- 251111dtebd1205 Exde01 05Document5 pages251111dtebd1205 Exde01 05Mohammed HijaziNo ratings yet

- KS E11raa Exe I08 999 Inc Ga 0004 - 00Document4 pagesKS E11raa Exe I08 999 Inc Ga 0004 - 00nbmskbzcrsNo ratings yet

- 30a100dbqb23070 - Exde00 - 23 - 21032023 - Quality Control Plan For PipingDocument27 pages30a100dbqb23070 - Exde00 - 23 - 21032023 - Quality Control Plan For Pipingsamuel madisonNo ratings yet

- S001032-14 (Datalogger Specification)Document2 pagesS001032-14 (Datalogger Specification)akramhomriNo ratings yet

- Turret Piping Springs 14 Jan 2016 PrestressDocument22 pagesTurret Piping Springs 14 Jan 2016 PrestresscatullusNo ratings yet

- 251911dtebd1191 Exde01 04Document4 pages251911dtebd1191 Exde01 04Mohammed HijaziNo ratings yet

- 00250600bigc52238 Cdfe02 04Document4 pages00250600bigc52238 Cdfe02 04Mohammed HijaziNo ratings yet

- 3795-210-S20 - C04-0006 R0 Equipment Data Curves For Item No 20-P-223 AB - Flare K.O Drum Pump CommentedDocument2 pages3795-210-S20 - C04-0006 R0 Equipment Data Curves For Item No 20-P-223 AB - Flare K.O Drum Pump CommentedFomaa ElsayedNo ratings yet

- NDE-6407 Rev0Document116 pagesNDE-6407 Rev0konazoiNo ratings yet

- 00250600bigb52038 Cdfe02 07Document7 pages00250600bigb52038 Cdfe02 07Mohammed HijaziNo ratings yet

- Process Site Visit Report 25.03.2019Document15 pagesProcess Site Visit Report 25.03.2019hatem jlolNo ratings yet

- Supplier DocumentDocument20 pagesSupplier Documentkhalid benessalahNo ratings yet

- Contromatic - Self Regulating Valve (ORF) - Operating ManualDocument55 pagesContromatic - Self Regulating Valve (ORF) - Operating ManualEki NosaNo ratings yet

- 250600deqrd0198 Exde02 12Document12 pages250600deqrd0198 Exde02 12Mohammed HijaziNo ratings yet

- Combine PDFDocument4 pagesCombine PDFMorgan SidesoNo ratings yet

- A-Ele-Lst-000-47960-B - Cable Shedule For Pipeline Cathodic Protection SystemDocument44 pagesA-Ele-Lst-000-47960-B - Cable Shedule For Pipeline Cathodic Protection SystemBadiNo ratings yet

- The Contractor Payment Application Audit: Guidance for Auditing AIA Documents G702 & G703From EverandThe Contractor Payment Application Audit: Guidance for Auditing AIA Documents G702 & G703No ratings yet

- PF0009 SLB CV SPC 0001Document19 pagesPF0009 SLB CV SPC 0001bmanojkumar16No ratings yet

- 3.3 Reciprocating (LP-HP)Document3 pages3.3 Reciprocating (LP-HP)bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0011 - Rev.00Document7 pagesPF0009 SLB MR DAT 0011 - Rev.00bmanojkumar16No ratings yet

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0008 - Rev.00Document7 pagesPF0009 SLB MR DAT 0008 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0010 - Rev.00Document7 pagesPF0009 SLB MR DAT 0010 - Rev.00bmanojkumar16No ratings yet

- ITH-FP1-F03181-M-SPE-0001 - A01 - SignedDocument29 pagesITH-FP1-F03181-M-SPE-0001 - A01 - Signedbmanojkumar16No ratings yet

- Aug 2023Document1 pageAug 2023bmanojkumar16No ratings yet

- FPF1-ST-G00001-P-BOD-0002 - 0901ac658004d7efDocument49 pagesFPF1-ST-G00001-P-BOD-0002 - 0901ac658004d7efbmanojkumar16No ratings yet

- TP-WMS-05969-DAS-A4-D1-K - Demulsifier DatasheetDocument9 pagesTP-WMS-05969-DAS-A4-D1-K - Demulsifier Datasheetbmanojkumar16No ratings yet

- TP-WMS-05967-DAS-A4-D1-K - Biocide DatasheetDocument9 pagesTP-WMS-05967-DAS-A4-D1-K - Biocide Datasheetbmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0009 - Rev.00Document7 pagesPF0009 SLB MR DAT 0009 - Rev.00bmanojkumar16No ratings yet

- Dec 2022Document1 pageDec 2022bmanojkumar16No ratings yet

- Attchment-4 - Piping Class 013411-XDocument11 pagesAttchment-4 - Piping Class 013411-Xbmanojkumar16No ratings yet

- Scale Inhibitor MSDS (MC MX 2-3421)Document8 pagesScale Inhibitor MSDS (MC MX 2-3421)bmanojkumar16100% (1)

- TP-WMS-05940-SPC-A4-D1-L-Specification For ValvesDocument34 pagesTP-WMS-05940-SPC-A4-D1-L-Specification For Valvesbmanojkumar16100% (1)

- QMS-003 Procedure For Quality Control of Materials Issue 5 April 20Document107 pagesQMS-003 Procedure For Quality Control of Materials Issue 5 April 20bmanojkumar16100% (2)

- Cover Page - LG DSDocument2 pagesCover Page - LG DSbmanojkumar16No ratings yet

- MTR 09Document1 pageMTR 09bmanojkumar16No ratings yet

- SKid GAD CRS - Revised FormatDocument1 pageSKid GAD CRS - Revised Formatbmanojkumar16No ratings yet

- Cover Page - GADDocument2 pagesCover Page - GADbmanojkumar16No ratings yet

- Erg DRG Eng STR P.01 22 320 001 001 ADocument1 pageErg DRG Eng STR P.01 22 320 001 001 Abmanojkumar16No ratings yet

- 21DBBV12M-7 42inch (In) DimensionADoubleBlockandBleedNeedleValvewithFullBoreDocument3 pages21DBBV12M-7 42inch (In) DimensionADoubleBlockandBleedNeedleValvewithFullBorebmanojkumar16No ratings yet

- Line List - All PackagesDocument42 pagesLine List - All Packagesbmanojkumar16No ratings yet

- Marechal DX2 Decontactor Range enDocument2 pagesMarechal DX2 Decontactor Range enbmanojkumar16No ratings yet

- Marechal PNCX Range enDocument2 pagesMarechal PNCX Range enbmanojkumar16No ratings yet

- Line List - Methanol SkidDocument3 pagesLine List - Methanol Skidbmanojkumar16No ratings yet

- Sample IOM-SchlumbergerDocument10 pagesSample IOM-Schlumbergerbmanojkumar16No ratings yet

- Mision 8 9 12Document419 pagesMision 8 9 12auweia1No ratings yet

- ClementDocument22 pagesClementbettounyNo ratings yet

- Evolution 6000 BulletinDocument8 pagesEvolution 6000 BulletinHarold Fernando Guavita ReyesNo ratings yet

- Design Procedure For Loading Capacity Calculations For Classic Automobile DifferentialsDocument9 pagesDesign Procedure For Loading Capacity Calculations For Classic Automobile DifferentialsSergio ChavezNo ratings yet

- Faktor-Faktor Yang Mempengaruhi Yield To Maturity Obligasi - Dewi Ratih Permata AlmiDocument22 pagesFaktor-Faktor Yang Mempengaruhi Yield To Maturity Obligasi - Dewi Ratih Permata Almidewi ratihNo ratings yet

- 8050SDocument4 pages8050Sscr8510No ratings yet

- Duties and Responsibilities Related To Being A Retail Store ManagerDocument5 pagesDuties and Responsibilities Related To Being A Retail Store Managerroshan_krNo ratings yet

- HWP2013W-2012B Service Manual IIDocument109 pagesHWP2013W-2012B Service Manual IILuis Guillermo RoaNo ratings yet

- Work Method - Ignite-Data Center CikarangDocument3 pagesWork Method - Ignite-Data Center CikarangaronmdavinchyNo ratings yet

- Time Varying SignalsDocument17 pagesTime Varying SignalsDiego Cancino SilvaNo ratings yet

- SGS PCA Kuwait Dat88asheet A4 EN 17 V1Document7 pagesSGS PCA Kuwait Dat88asheet A4 EN 17 V1Skander HamadiNo ratings yet

- MOM Extra ItemsDocument5 pagesMOM Extra ItemsshubhendrasahaNo ratings yet

- Milling PowerDocument1 pageMilling PowerRicardo VitorianoNo ratings yet

- The Scan-Path Technique For Testable Sequential Circuit DesignDocument11 pagesThe Scan-Path Technique For Testable Sequential Circuit DesignLavanya BjNo ratings yet

- Attendance ManagementDocument45 pagesAttendance ManagementSanjay GodboleNo ratings yet

- M/E Item Qty Unit: MBU BUDGET 2020-2021Document13 pagesM/E Item Qty Unit: MBU BUDGET 2020-2021Shiftmanager PICTNo ratings yet

- A Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar HussainDocument23 pagesA Study of Casting Characteristics For Die Cast Aluminum Alloy-Anwar Hussainoquintero99100% (2)

- Resume For WeeblyDocument2 pagesResume For Weeblyapi-259381516No ratings yet

- Solution To Chapter 7 Exercises: FluidizationDocument1 pageSolution To Chapter 7 Exercises: FluidizationqifniNo ratings yet

- Enrollment Form 3Document1 pageEnrollment Form 3حيدرالركابيNo ratings yet

- ReportDocument6 pagesReportLâmViênNo ratings yet

- SATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFDocument2 pagesSATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFRamziAhmedNo ratings yet

- 633-PDC2-LAPORAN KEJURUTERAAN (Signed)Document17 pages633-PDC2-LAPORAN KEJURUTERAAN (Signed)Mohd RafiqNo ratings yet