Professional Documents

Culture Documents

Zeos As Manual

Zeos As Manual

Uploaded by

Marco GaliassiCopyright:

Available Formats

You might also like

- Ma Zeosad 01 010004 en 220818Document2 pagesMa Zeosad 01 010004 en 220818Ricardo OliveiraNo ratings yet

- Zeos-As: Analogue Algorithmic Addressable Fire Detector W/ Smart Addressing Global Fire Equipment S.ADocument2 pagesZeos-As: Analogue Algorithmic Addressable Fire Detector W/ Smart Addressing Global Fire Equipment S.Aluther_02No ratings yet

- Zeos-C-Manual 240422 234516Document2 pagesZeos-C-Manual 240422 234516elmakedonNo ratings yet

- Detector de Fumaça ZEOS-C-S - ManualDocument2 pagesDetector de Fumaça ZEOS-C-S - ManualCarlos Cesar Silva Filho100% (2)

- ZEOS C SDocument2 pagesZEOS C SJunior SantosNo ratings yet

- ZEOS AS ManualDocument2 pagesZEOS AS Manualrss1311No ratings yet

- Zeos-Ad: Analogue Algorithmic Addressable Fire DetectorDocument2 pagesZeos-Ad: Analogue Algorithmic Addressable Fire DetectorMariusNo ratings yet

- Global - ZEOS-ADDocument3 pagesGlobal - ZEOS-ADEder Silva BorgesNo ratings yet

- ZEOS AD ManualDocument2 pagesZEOS AD ManualgeneramiguelaranaNo ratings yet

- Globalfire - AD Series Manual PDFDocument2 pagesGlobalfire - AD Series Manual PDFAdrian Oprisan100% (1)

- Detectores ZeosDocument1 pageDetectores ZeosPochito PonceNo ratings yet

- ZEOS-AS ManualDocument2 pagesZEOS-AS Manualrss1311No ratings yet

- ZEOS AD Data SheetDocument1 pageZEOS AD Data SheettojoNo ratings yet

- Detectores Temperatura HOCHIKIDocument2 pagesDetectores Temperatura HOCHIKIHugo RomoNo ratings yet

- Zeos Ad ManualDocument2 pagesZeos Ad ManualredecontraincendioNo ratings yet

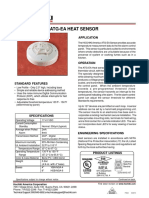

- Atj-Ea Fixed Temp/Rate of Rise Heat Sensor: ApplicationDocument2 pagesAtj-Ea Fixed Temp/Rate of Rise Heat Sensor: ApplicationElias GabrielNo ratings yet

- FST-951-SELFT Intelligent Programmable Temperature Self-Test SensorsDocument2 pagesFST-951-SELFT Intelligent Programmable Temperature Self-Test SensorsDinaNo ratings yet

- FSP-951T-SELFT Intelligent Photoelectric and Temperature Self-Test Smoke SensorDocument4 pagesFSP-951T-SELFT Intelligent Photoelectric and Temperature Self-Test Smoke SensorDinaNo ratings yet

- Data Sheet of Detector & Hooter - AppdDocument8 pagesData Sheet of Detector & Hooter - AppdArvnd VckyNo ratings yet

- B110LP Plug-In Detector Base: Installation and Maintenance InstructionsDocument2 pagesB110LP Plug-In Detector Base: Installation and Maintenance InstructionsTarfawi MNo ratings yet

- Pad300-HdDocument2 pagesPad300-HdÁngel Varón CalderónNo ratings yet

- ATJ-EA - 02-2014 - Detector de Temperatura FixaDocument2 pagesATJ-EA - 02-2014 - Detector de Temperatura FixaVictor MoraesNo ratings yet

- Man 125Document10 pagesMan 125pt.Sentra media cemerlangNo ratings yet

- FSP-951-SELFT Intelligent Photoelectric Self-Test Smoke SensorDocument4 pagesFSP-951-SELFT Intelligent Photoelectric Self-Test Smoke SensorDinaNo ratings yet

- 85001-0598 - 700 Series Self-Diagnostic Smoke DetectorsDocument2 pages85001-0598 - 700 Series Self-Diagnostic Smoke DetectorsDauXuan Huynh100% (1)

- Atg Ea - 04 2010.Document2 pagesAtg Ea - 04 2010.joseito741258No ratings yet

- 7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsDocument2 pages7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsAakash JunejaNo ratings yet

- P117001 Photoelectric Heat Smoke DetectorDocument2 pagesP117001 Photoelectric Heat Smoke Detectormonchiss21No ratings yet

- 205-0003 Sita Multipoint ASD Detector, 205-0001 Sita Multipoint ASD With Sounder, 205-0012 Sita Multipoint ASD With Sounder / StrobeDocument4 pages205-0003 Sita Multipoint ASD Detector, 205-0001 Sita Multipoint ASD With Sounder, 205-0012 Sita Multipoint ASD With Sounder / Strobeamartins1974No ratings yet

- I56 3738 004 - Manual - B501 WHITE B501 IVDocument2 pagesI56 3738 004 - Manual - B501 WHITE B501 IVNafis TyagiNo ratings yet

- E85001-1003 -- Signature Optica Smoke and Heat DetectorDocument4 pagesE85001-1003 -- Signature Optica Smoke and Heat Detectoryogeshjadhav135No ratings yet

- Atj EaDocument2 pagesAtj Easonyz1den123No ratings yet

- VAR TEC FDR Series User ManualDocument2 pagesVAR TEC FDR Series User ManualmicrajacutNo ratings yet

- I Series: Photoelectric Smoke DetectorsDocument2 pagesI Series: Photoelectric Smoke DetectorsthienNo ratings yet

- I3 Sensor DN_6885Document2 pagesI3 Sensor DN_6885Benjamin Luis MoralesNo ratings yet

- Fdklu001 PshaDocument2 pagesFdklu001 PshaGUDANG BERITA KITANo ratings yet

- b710lp NotifierDocument4 pagesb710lp NotifierMarcelo Fabián OrtizNo ratings yet

- Red Lion Pirometro ChinoDocument16 pagesRed Lion Pirometro ChinoMaquinas IndexNo ratings yet

- Manual Do Sensor de Incendio - Globalfire - AD - Series - ManualDocument2 pagesManual Do Sensor de Incendio - Globalfire - AD - Series - ManualValódia VictorinoNo ratings yet

- H365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsDocument2 pagesH365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsAngel Jorge LLopiz IbarraNo ratings yet

- H365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsDocument2 pagesH365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsAlexamder CalleNo ratings yet

- Ziton ZP730-2PDocument2 pagesZiton ZP730-2PNithin MathaiNo ratings yet

- 3.11-Ht-Base Detector Fotoeléctrico ManualDocument2 pages3.11-Ht-Base Detector Fotoeléctrico Manualerick valenciaNo ratings yet

- Kidde KS-PS SmartOne Addressable Photoelectric Smoke Detector K-71-101Document4 pagesKidde KS-PS SmartOne Addressable Photoelectric Smoke Detector K-71-101Murali DaranNo ratings yet

- Siga-Phs Intelligent 3D Multisensor Smoke Detector: Product Description WarningsDocument2 pagesSiga-Phs Intelligent 3D Multisensor Smoke Detector: Product Description WarningsWill F AlvesNo ratings yet

- 326-0003 Sita Sounder With Deep BaseDocument3 pages326-0003 Sita Sounder With Deep Baseamartins1974No ratings yet

- ED810 Instruction Manual: Gas DetectorDocument20 pagesED810 Instruction Manual: Gas DetectordimasjosesmithNo ratings yet

- 322-ATE Series Wireless Temperature Sensor Installation Instruction V1.7-20200924Document11 pages322-ATE Series Wireless Temperature Sensor Installation Instruction V1.7-20200924Fathurrahman YudhiNo ratings yet

- Installation and Maintenance Instructions For Model Sdx-551/Sdx-551Th Plug-In Intelligent Photoelectronic Sensor With CommunicationsDocument4 pagesInstallation and Maintenance Instructions For Model Sdx-551/Sdx-551Th Plug-In Intelligent Photoelectronic Sensor With CommunicationsM. FakNo ratings yet

- ProReact EN Digital - LHD - Installation Instructions Rev 1-1Document11 pagesProReact EN Digital - LHD - Installation Instructions Rev 1-1Ionut BucurNo ratings yet

- 5151 - Manual - I56-5151 DHCDocument2 pages5151 - Manual - I56-5151 DHCmeribout adelNo ratings yet

- Notifier FSP 851 FSP 851t and FaptDocument2 pagesNotifier FSP 851 FSP 851t and FaptYhair Cortes SanchezNo ratings yet

- AUR450C Specification 1Document16 pagesAUR450C Specification 1ade irawanNo ratings yet

- 4 Multi Sensor Detector-58000-750AELDocument1 page4 Multi Sensor Detector-58000-750AELfahad.bengalfire23No ratings yet

- B524BI and B224BI Plug-In Isolator Detector BasesDocument4 pagesB524BI and B224BI Plug-In Isolator Detector Basesfaisal84inNo ratings yet

- System Sensor 2151 & 2151T - Installation ManualDocument2 pagesSystem Sensor 2151 & 2151T - Installation ManualAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Ewrc300 500 5000nt Quick Start GuideDocument16 pagesEwrc300 500 5000nt Quick Start GuideNikolaNo ratings yet

- Gsti 9103Document2 pagesGsti 9103aditgroupNo ratings yet

- Smoke and Heat Detector FCNDocument4 pagesSmoke and Heat Detector FCNuday245No ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Service Manual: PCG-GRS150/GRS170Document12 pagesService Manual: PCG-GRS150/GRS170Andrei RadulescuNo ratings yet

- Plasma Parts PricesDocument31 pagesPlasma Parts PricesMuhammad BustanNo ratings yet

- Certificado - Inversor SMA SunnyBoy-fusionadoDocument32 pagesCertificado - Inversor SMA SunnyBoy-fusionadoAlondra AlcazarNo ratings yet

- JVC Av - n48p55 Chasis RPDocument60 pagesJVC Av - n48p55 Chasis RPGustavoTovarNo ratings yet

- X-Ray Generators: Resident Physics LecturesDocument54 pagesX-Ray Generators: Resident Physics LecturesAhmed TorkyNo ratings yet

- BA 211 Exercise 4Document3 pagesBA 211 Exercise 4Eden Mae DeGuzmanNo ratings yet

- Digital Sound Projector: Owner'S ManualDocument106 pagesDigital Sound Projector: Owner'S ManualFrancisco Simón FuertesNo ratings yet

- Noja 7478 00 Rc10 15 Osm200 User Guide WebDocument42 pagesNoja 7478 00 Rc10 15 Osm200 User Guide WebMarlon Jairo Serván FernándezNo ratings yet

- Troubleshooting A Power Supply Cover Opened ErrorDocument7 pagesTroubleshooting A Power Supply Cover Opened ErrorMohammad A. BawtagNo ratings yet

- Samsung Cl21b501hlmxzs Chasis KSCB (N) - cb5hDocument42 pagesSamsung Cl21b501hlmxzs Chasis KSCB (N) - cb5hmister_w100% (1)

- Foph HIRA1Document6 pagesFoph HIRA1myforum1No ratings yet

- Decimator Getting Started: 1. Apply PowerDocument2 pagesDecimator Getting Started: 1. Apply PowerEduard LembaNo ratings yet

- Dst4400engmanual Gensets The Wide Range PDFDocument2 pagesDst4400engmanual Gensets The Wide Range PDFgereseNo ratings yet

- SS 460 60MDHDocument2 pagesSS 460 60MDHelisianeNo ratings yet

- GC-1502 2-ch High Speed Counter Module User ManualDocument13 pagesGC-1502 2-ch High Speed Counter Module User Manualgilson lopesNo ratings yet

- 3 D LCD Digital Panel Meter Model: LC035: 1. FeaturesDocument2 pages3 D LCD Digital Panel Meter Model: LC035: 1. FeaturesNouh NahnouhNo ratings yet

- Tavi 5 Specialuri Danisnulebis Interfeisebi: Ata/Atapi (Ide)Document14 pagesTavi 5 Specialuri Danisnulebis Interfeisebi: Ata/Atapi (Ide)avto sepashviliNo ratings yet

- Manual 3AP2 FI 420kV PDFDocument122 pagesManual 3AP2 FI 420kV PDFbesaret100% (1)

- UENR88640001 EVC600I Automatic Voltage Regulator (UENR8864-01)Document9 pagesUENR88640001 EVC600I Automatic Voltage Regulator (UENR8864-01)Carlos U. CallirgosNo ratings yet

- Wb3ayw Wire Collinear For 2 MetersDocument7 pagesWb3ayw Wire Collinear For 2 MetersEduard Gabi Ordean100% (1)

- Introducing Unisab II Version 2.05.1 and 2.05.2Document4 pagesIntroducing Unisab II Version 2.05.1 and 2.05.2Mahmoud Mohamed100% (1)

- OBD2 CodesDocument35 pagesOBD2 CodesJubril AkinwandeNo ratings yet

- Pepprl Fuchs Barrier Switch AmpDocument4 pagesPepprl Fuchs Barrier Switch AmpShabeer CVNo ratings yet

- 441 Home Work7Document2 pages441 Home Work7python1750% (2)

- Til-0019 Satelline 3as and PCC CompatibilityDocument5 pagesTil-0019 Satelline 3as and PCC CompatibilityTheseus KokkinosNo ratings yet

- Installation & Maintenance ManualDocument2 pagesInstallation & Maintenance ManualMae BecherNo ratings yet

- Lec # 04 Substation Bus SchemesDocument12 pagesLec # 04 Substation Bus SchemesAwesh KumarNo ratings yet

- How To Design Your Own Inverter TransformerDocument4 pagesHow To Design Your Own Inverter Transformerkshyder67% (3)

- C264 Documentation: CPU275 (CPU Type 4)Document12 pagesC264 Documentation: CPU275 (CPU Type 4)lucasNo ratings yet

- GFK2220F Modbus RTU Master Comm User Manual 20150202 WebDocument50 pagesGFK2220F Modbus RTU Master Comm User Manual 20150202 WebSudipto MajumderNo ratings yet

Zeos As Manual

Zeos As Manual

Uploaded by

Marco GaliassiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zeos As Manual

Zeos As Manual

Uploaded by

Marco GaliassiCopyright:

Available Formats

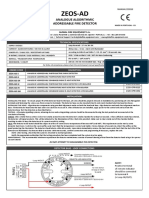

MANUAL 220818

ZEOS-AS

ANALOGUE ALGORITHMIC ADDRESSABLE

FIRE DETECTOR WITH SMART ADDRESSING MADE IN PORTUGAL - EU

GLOBAL FIRE EQUIPMENT S.A.

Sítio dos Barrabés, Armazém Nave Y, Caixa Postal 908-Z, 8150-016 São Brás de Alportel - PORTUGAL | Tel: +351 289 896 560

Email: info@globalfire-equipment.com | Technical Support: techs@globalfire-equipment.com | www.globalfire-equipment.com

TECHNICAL SPECIFICATIONS

SUPPLY VOLTAGE Loop Powered - 17V to 30V DC

CURRENT - QUIESCENT / SURGE 450 uA max.

CURRENT - DEVICE IN ALARM 4 mA - Alarm LED illuminated

SENSITIVITY According to EN54-5 or/and EN54-7, EN54-17

CABLE SIZE 0.5-2.5 mm²

RESET/START-UP TIMES 20 seconds max.

IP RATING / COLOUR / CASE MATERIAL / MAX. HUMIDITY IP20 / White or Black / ABS / 95% RH Non-Condensing

NORMAL / TRANSIENT OPER. TEMPERATURE 0°C to 50°C / -10°C to 85°C

DIMENSIONS / WEIGHT 100 mm (D) x 50 mm (H) included base / 144 g inc. base

For EN54-13 compliance, please check the control panel manual specifications.

ORDER CODE DESCRIPTION CERTIFICATE

ZEOS-AS-S ANALOGUE ADDRESSABLE PHOTOELECTRIC SMOKE DETECTOR WITH SMART ADDRESSING 1328-CPR-0526

ZEOS-AS-H ANALOGUE ADDR. TEMPERATURE/HEAT DETECTOR WITH SMART ADDRESSING 1328-CPR-0527

ZEOS-AS-SH ANALOGUE ADDR. COMBINED SMOKE & HEAT DETECTOR WITH SMART ADDRESSING 1328-CPR-0525

ZEOS-AS-SI ANALOGUE ADDR. PHOTOELECTRIC SMOKE DETECTOR WITH ISOLATOR & SMART ADDRESSING 1328-CPR-0609

ZEOS-AS-HI ANALOGUE ADDR. TEMPERATURE/HEAT DETECTOR WITH ISOLATOR & SMART ADDRESSING 1328-CPR-0608

ZEOS-AS-SHI ANALOGUE ADDR. COMBINED SMOKE & HEAT DETECTOR WITH ISOLATOR & SMART ADDRESSING 1328-CPR-0524

MECHANICAL SPECIFICATION

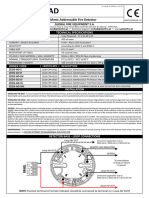

INSTALLATION

INSTALLING THE BASE

To ensure proper fit of the detector head to the base, all wires should be properly dressed at installation by positioning all wires flat against terminals and fastening the

wires away from connector terminals. The detector base can be mounted directly onto most standard electrical junction boxes.

INSTALLING THE HEAD

Align detector components using provided alignment marks on both the head and base. Align detector mark and short alignment mark on base.

Fit the detector head onto the base and twist clockwise to secure it. After all detectors are installed, apply power to the control unit and activate the detection loop.

Test the detectors as described below.

TESTING

All remote signalling systems, releasing devices and extinguishing systems should be disconnected during the test period and reconnected at the conclusion of testing.

SMOKE: Allow smoke from a cotton wick or test smoke aerosol to enter the detector’s smoke chamber for at least 10 seconds. When sufficient smoke has entered, the

detector will signal an alarm. This will be indicated by the illumination of the 2 Red LEDs provided. Make sure to clear smoke out of the chamber before resetting in order to

keep the detector at its current sensitivity setting.

HEAT: The detector to be tested should be subject to a flow of warm air at a temperature of between 65°C and 80°C. This requirement can be met by some domestic hair

dryers. Switch on the warm airflow and check that the temperature is correct and stable. From a distance of several cms, direct the airflow at the guard protecting the

thermistor. The detector should alarm within 60 seconds. Upon alarm immediately remove the heat source and check that the Red LEDs of the detector are illuminated.

If a detector fails to activate within 60 seconds, confirm connections and programming. If necessary, replace the unit.

NOTE: After testing, check that the system is returned to normal operation.

Notify the appropriate authorities that the testing procedure has been completed and the system is active again.

MAINTENANCE

The recommended minimum requirement for detector maintenance consists of annual cleaning of dust from the detector head using a low power vacuum cleaner.

DO NOT ATTEMPT TO DISASSEMBLE THE DETECTOR.

BASE LOCK

To unlock detector from its base

push provided unlock key

through hole available on the

base side wall as shown.

DETECTOR BASE - LOOP CONNECTIONS

NOTE: Positive terminal of remote indicator should be connected to terminal 4 (+ Loop IN/OUT).

ADDRESS PROGRAMMING

The ZEOS-AS range of Fire Detectors is SAM enabled and do not have their addresses set using switches. The address of a ZEOS-AS detector can be either

programmed using GFE’s device programmer or using Automatic Address Setting (ASET) which is a special install and commissioning mode that can be

activated on a per loop basis whilst in INSTALLATION mode. ASET mode is only required if Smart Addressing Mechanism (SAM) is used. When used in

conjunction with this mode they automatically assign their own addresses. ASET mode is only available in GFE’s range of analogue addressable fire

detection panels. ZEOS-AS can be mixed with other types of devices on the same loop. Each time a ZEOS-AS detector is programmed it takes the next free

address on its loop.

Before starting the programming procedure, care should be taken with the following:

a) Main Supply OK.

b) Auxiliary Supply (Batteries) OK.

c) Loop Supply OK.

d) Verify the non-existence of earth faults.

e) Verify the cable lengths for the loop.

f) Confirm the non-existence of short or open circuits within the loop.

g) Verify communications with standard analogue addressable devices is OK.

h) Verify communications between Main Panel, Sub-Panels and Repeaters with integrated Sub-Panel.

Verify that all ZEOS-AS detector connections to the loop are properly made in particular those regarding polarity when the detector incorporates a loop

isolator. Reversal of the supply polarity can cause failure or malfunction and prevent the detector from being programmed.

CAUTION

Verify that there are no faults or fire conditions in the loop or system. Clear all fault and fire conditions first.

Reset to normal operation all devices before applying power to the panel, in particular manual call points.

For further information on how to set the address of a ZEOS-AS fire detector please refer to ZEOS-AS Programming

and Troubleshooting Guide.

MORE INFO >> GLOBALFIRE-EQUIPMENT.COM

You might also like

- Ma Zeosad 01 010004 en 220818Document2 pagesMa Zeosad 01 010004 en 220818Ricardo OliveiraNo ratings yet

- Zeos-As: Analogue Algorithmic Addressable Fire Detector W/ Smart Addressing Global Fire Equipment S.ADocument2 pagesZeos-As: Analogue Algorithmic Addressable Fire Detector W/ Smart Addressing Global Fire Equipment S.Aluther_02No ratings yet

- Zeos-C-Manual 240422 234516Document2 pagesZeos-C-Manual 240422 234516elmakedonNo ratings yet

- Detector de Fumaça ZEOS-C-S - ManualDocument2 pagesDetector de Fumaça ZEOS-C-S - ManualCarlos Cesar Silva Filho100% (2)

- ZEOS C SDocument2 pagesZEOS C SJunior SantosNo ratings yet

- ZEOS AS ManualDocument2 pagesZEOS AS Manualrss1311No ratings yet

- Zeos-Ad: Analogue Algorithmic Addressable Fire DetectorDocument2 pagesZeos-Ad: Analogue Algorithmic Addressable Fire DetectorMariusNo ratings yet

- Global - ZEOS-ADDocument3 pagesGlobal - ZEOS-ADEder Silva BorgesNo ratings yet

- ZEOS AD ManualDocument2 pagesZEOS AD ManualgeneramiguelaranaNo ratings yet

- Globalfire - AD Series Manual PDFDocument2 pagesGlobalfire - AD Series Manual PDFAdrian Oprisan100% (1)

- Detectores ZeosDocument1 pageDetectores ZeosPochito PonceNo ratings yet

- ZEOS-AS ManualDocument2 pagesZEOS-AS Manualrss1311No ratings yet

- ZEOS AD Data SheetDocument1 pageZEOS AD Data SheettojoNo ratings yet

- Detectores Temperatura HOCHIKIDocument2 pagesDetectores Temperatura HOCHIKIHugo RomoNo ratings yet

- Zeos Ad ManualDocument2 pagesZeos Ad ManualredecontraincendioNo ratings yet

- Atj-Ea Fixed Temp/Rate of Rise Heat Sensor: ApplicationDocument2 pagesAtj-Ea Fixed Temp/Rate of Rise Heat Sensor: ApplicationElias GabrielNo ratings yet

- FST-951-SELFT Intelligent Programmable Temperature Self-Test SensorsDocument2 pagesFST-951-SELFT Intelligent Programmable Temperature Self-Test SensorsDinaNo ratings yet

- FSP-951T-SELFT Intelligent Photoelectric and Temperature Self-Test Smoke SensorDocument4 pagesFSP-951T-SELFT Intelligent Photoelectric and Temperature Self-Test Smoke SensorDinaNo ratings yet

- Data Sheet of Detector & Hooter - AppdDocument8 pagesData Sheet of Detector & Hooter - AppdArvnd VckyNo ratings yet

- B110LP Plug-In Detector Base: Installation and Maintenance InstructionsDocument2 pagesB110LP Plug-In Detector Base: Installation and Maintenance InstructionsTarfawi MNo ratings yet

- Pad300-HdDocument2 pagesPad300-HdÁngel Varón CalderónNo ratings yet

- ATJ-EA - 02-2014 - Detector de Temperatura FixaDocument2 pagesATJ-EA - 02-2014 - Detector de Temperatura FixaVictor MoraesNo ratings yet

- Man 125Document10 pagesMan 125pt.Sentra media cemerlangNo ratings yet

- FSP-951-SELFT Intelligent Photoelectric Self-Test Smoke SensorDocument4 pagesFSP-951-SELFT Intelligent Photoelectric Self-Test Smoke SensorDinaNo ratings yet

- 85001-0598 - 700 Series Self-Diagnostic Smoke DetectorsDocument2 pages85001-0598 - 700 Series Self-Diagnostic Smoke DetectorsDauXuan Huynh100% (1)

- Atg Ea - 04 2010.Document2 pagesAtg Ea - 04 2010.joseito741258No ratings yet

- 7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsDocument2 pages7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsAakash JunejaNo ratings yet

- P117001 Photoelectric Heat Smoke DetectorDocument2 pagesP117001 Photoelectric Heat Smoke Detectormonchiss21No ratings yet

- 205-0003 Sita Multipoint ASD Detector, 205-0001 Sita Multipoint ASD With Sounder, 205-0012 Sita Multipoint ASD With Sounder / StrobeDocument4 pages205-0003 Sita Multipoint ASD Detector, 205-0001 Sita Multipoint ASD With Sounder, 205-0012 Sita Multipoint ASD With Sounder / Strobeamartins1974No ratings yet

- I56 3738 004 - Manual - B501 WHITE B501 IVDocument2 pagesI56 3738 004 - Manual - B501 WHITE B501 IVNafis TyagiNo ratings yet

- E85001-1003 -- Signature Optica Smoke and Heat DetectorDocument4 pagesE85001-1003 -- Signature Optica Smoke and Heat Detectoryogeshjadhav135No ratings yet

- Atj EaDocument2 pagesAtj Easonyz1den123No ratings yet

- VAR TEC FDR Series User ManualDocument2 pagesVAR TEC FDR Series User ManualmicrajacutNo ratings yet

- I Series: Photoelectric Smoke DetectorsDocument2 pagesI Series: Photoelectric Smoke DetectorsthienNo ratings yet

- I3 Sensor DN_6885Document2 pagesI3 Sensor DN_6885Benjamin Luis MoralesNo ratings yet

- Fdklu001 PshaDocument2 pagesFdklu001 PshaGUDANG BERITA KITANo ratings yet

- b710lp NotifierDocument4 pagesb710lp NotifierMarcelo Fabián OrtizNo ratings yet

- Red Lion Pirometro ChinoDocument16 pagesRed Lion Pirometro ChinoMaquinas IndexNo ratings yet

- Manual Do Sensor de Incendio - Globalfire - AD - Series - ManualDocument2 pagesManual Do Sensor de Incendio - Globalfire - AD - Series - ManualValódia VictorinoNo ratings yet

- H365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsDocument2 pagesH365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsAngel Jorge LLopiz IbarraNo ratings yet

- H365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsDocument2 pagesH365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsAlexamder CalleNo ratings yet

- Ziton ZP730-2PDocument2 pagesZiton ZP730-2PNithin MathaiNo ratings yet

- 3.11-Ht-Base Detector Fotoeléctrico ManualDocument2 pages3.11-Ht-Base Detector Fotoeléctrico Manualerick valenciaNo ratings yet

- Kidde KS-PS SmartOne Addressable Photoelectric Smoke Detector K-71-101Document4 pagesKidde KS-PS SmartOne Addressable Photoelectric Smoke Detector K-71-101Murali DaranNo ratings yet

- Siga-Phs Intelligent 3D Multisensor Smoke Detector: Product Description WarningsDocument2 pagesSiga-Phs Intelligent 3D Multisensor Smoke Detector: Product Description WarningsWill F AlvesNo ratings yet

- 326-0003 Sita Sounder With Deep BaseDocument3 pages326-0003 Sita Sounder With Deep Baseamartins1974No ratings yet

- ED810 Instruction Manual: Gas DetectorDocument20 pagesED810 Instruction Manual: Gas DetectordimasjosesmithNo ratings yet

- 322-ATE Series Wireless Temperature Sensor Installation Instruction V1.7-20200924Document11 pages322-ATE Series Wireless Temperature Sensor Installation Instruction V1.7-20200924Fathurrahman YudhiNo ratings yet

- Installation and Maintenance Instructions For Model Sdx-551/Sdx-551Th Plug-In Intelligent Photoelectronic Sensor With CommunicationsDocument4 pagesInstallation and Maintenance Instructions For Model Sdx-551/Sdx-551Th Plug-In Intelligent Photoelectronic Sensor With CommunicationsM. FakNo ratings yet

- ProReact EN Digital - LHD - Installation Instructions Rev 1-1Document11 pagesProReact EN Digital - LHD - Installation Instructions Rev 1-1Ionut BucurNo ratings yet

- 5151 - Manual - I56-5151 DHCDocument2 pages5151 - Manual - I56-5151 DHCmeribout adelNo ratings yet

- Notifier FSP 851 FSP 851t and FaptDocument2 pagesNotifier FSP 851 FSP 851t and FaptYhair Cortes SanchezNo ratings yet

- AUR450C Specification 1Document16 pagesAUR450C Specification 1ade irawanNo ratings yet

- 4 Multi Sensor Detector-58000-750AELDocument1 page4 Multi Sensor Detector-58000-750AELfahad.bengalfire23No ratings yet

- B524BI and B224BI Plug-In Isolator Detector BasesDocument4 pagesB524BI and B224BI Plug-In Isolator Detector Basesfaisal84inNo ratings yet

- System Sensor 2151 & 2151T - Installation ManualDocument2 pagesSystem Sensor 2151 & 2151T - Installation ManualAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Ewrc300 500 5000nt Quick Start GuideDocument16 pagesEwrc300 500 5000nt Quick Start GuideNikolaNo ratings yet

- Gsti 9103Document2 pagesGsti 9103aditgroupNo ratings yet

- Smoke and Heat Detector FCNDocument4 pagesSmoke and Heat Detector FCNuday245No ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Service Manual: PCG-GRS150/GRS170Document12 pagesService Manual: PCG-GRS150/GRS170Andrei RadulescuNo ratings yet

- Plasma Parts PricesDocument31 pagesPlasma Parts PricesMuhammad BustanNo ratings yet

- Certificado - Inversor SMA SunnyBoy-fusionadoDocument32 pagesCertificado - Inversor SMA SunnyBoy-fusionadoAlondra AlcazarNo ratings yet

- JVC Av - n48p55 Chasis RPDocument60 pagesJVC Av - n48p55 Chasis RPGustavoTovarNo ratings yet

- X-Ray Generators: Resident Physics LecturesDocument54 pagesX-Ray Generators: Resident Physics LecturesAhmed TorkyNo ratings yet

- BA 211 Exercise 4Document3 pagesBA 211 Exercise 4Eden Mae DeGuzmanNo ratings yet

- Digital Sound Projector: Owner'S ManualDocument106 pagesDigital Sound Projector: Owner'S ManualFrancisco Simón FuertesNo ratings yet

- Noja 7478 00 Rc10 15 Osm200 User Guide WebDocument42 pagesNoja 7478 00 Rc10 15 Osm200 User Guide WebMarlon Jairo Serván FernándezNo ratings yet

- Troubleshooting A Power Supply Cover Opened ErrorDocument7 pagesTroubleshooting A Power Supply Cover Opened ErrorMohammad A. BawtagNo ratings yet

- Samsung Cl21b501hlmxzs Chasis KSCB (N) - cb5hDocument42 pagesSamsung Cl21b501hlmxzs Chasis KSCB (N) - cb5hmister_w100% (1)

- Foph HIRA1Document6 pagesFoph HIRA1myforum1No ratings yet

- Decimator Getting Started: 1. Apply PowerDocument2 pagesDecimator Getting Started: 1. Apply PowerEduard LembaNo ratings yet

- Dst4400engmanual Gensets The Wide Range PDFDocument2 pagesDst4400engmanual Gensets The Wide Range PDFgereseNo ratings yet

- SS 460 60MDHDocument2 pagesSS 460 60MDHelisianeNo ratings yet

- GC-1502 2-ch High Speed Counter Module User ManualDocument13 pagesGC-1502 2-ch High Speed Counter Module User Manualgilson lopesNo ratings yet

- 3 D LCD Digital Panel Meter Model: LC035: 1. FeaturesDocument2 pages3 D LCD Digital Panel Meter Model: LC035: 1. FeaturesNouh NahnouhNo ratings yet

- Tavi 5 Specialuri Danisnulebis Interfeisebi: Ata/Atapi (Ide)Document14 pagesTavi 5 Specialuri Danisnulebis Interfeisebi: Ata/Atapi (Ide)avto sepashviliNo ratings yet

- Manual 3AP2 FI 420kV PDFDocument122 pagesManual 3AP2 FI 420kV PDFbesaret100% (1)

- UENR88640001 EVC600I Automatic Voltage Regulator (UENR8864-01)Document9 pagesUENR88640001 EVC600I Automatic Voltage Regulator (UENR8864-01)Carlos U. CallirgosNo ratings yet

- Wb3ayw Wire Collinear For 2 MetersDocument7 pagesWb3ayw Wire Collinear For 2 MetersEduard Gabi Ordean100% (1)

- Introducing Unisab II Version 2.05.1 and 2.05.2Document4 pagesIntroducing Unisab II Version 2.05.1 and 2.05.2Mahmoud Mohamed100% (1)

- OBD2 CodesDocument35 pagesOBD2 CodesJubril AkinwandeNo ratings yet

- Pepprl Fuchs Barrier Switch AmpDocument4 pagesPepprl Fuchs Barrier Switch AmpShabeer CVNo ratings yet

- 441 Home Work7Document2 pages441 Home Work7python1750% (2)

- Til-0019 Satelline 3as and PCC CompatibilityDocument5 pagesTil-0019 Satelline 3as and PCC CompatibilityTheseus KokkinosNo ratings yet

- Installation & Maintenance ManualDocument2 pagesInstallation & Maintenance ManualMae BecherNo ratings yet

- Lec # 04 Substation Bus SchemesDocument12 pagesLec # 04 Substation Bus SchemesAwesh KumarNo ratings yet

- How To Design Your Own Inverter TransformerDocument4 pagesHow To Design Your Own Inverter Transformerkshyder67% (3)

- C264 Documentation: CPU275 (CPU Type 4)Document12 pagesC264 Documentation: CPU275 (CPU Type 4)lucasNo ratings yet

- GFK2220F Modbus RTU Master Comm User Manual 20150202 WebDocument50 pagesGFK2220F Modbus RTU Master Comm User Manual 20150202 WebSudipto MajumderNo ratings yet