Professional Documents

Culture Documents

MTSC Mec-Dwg-Cpc-Dfd-D&e-M - 00-4

MTSC Mec-Dwg-Cpc-Dfd-D&e-M - 00-4

Uploaded by

Joenald SisonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTSC Mec-Dwg-Cpc-Dfd-D&e-M - 00-4

MTSC Mec-Dwg-Cpc-Dfd-D&e-M - 00-4

Uploaded by

Joenald SisonCopyright:

Available Formats

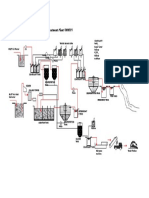

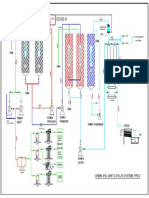

Air Blower

Flocculant: Disinfection

Coagulant

Base

REACTION TANK 1 Clear liquid For Discharge

From OG interceptor Overflow Overflow DISSOLVED AIR FLOTATION UNDERFLOW REACTION TANK 2 Overflow SEDIMENTATION EFFLUENT TANK

HOLDING TANK (AERATION TANK)

(MIXING TANK) TANK TANK

3. Chemical Tanks - 3 units 13. Dosing Pump - 1unit

1. Bar Screen 7. Oil Skimmer - 2 units 9. Fine Bubble Diffusers - 2 units

4. Flocculation Agitator 14. Chemical Tank - 1 unit

2. Baffles 8. Sludge Pump - 2 units 10. Service Pump - 2 units

5. Air tubes 11. SS Weir

12. Sludge Pump - 2 units

6. Dosing Pump - 3 units Sludge Sludge

RETURN ACTIVATED SLUDGE

PROCESS FLOW DIAGRAM SUDGE DISPOSAL

TANK

EQUIPMENT SCHEDULE (WASTE WATER TREATMENT PLANT)

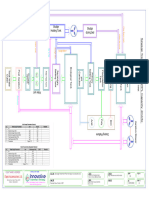

ITEM QTY EQUIPMENT SPECIFICATION

MATERIAL : STAINLESS STEEL (SS)

1 2X100% SLUDGE TRANSFER PUMP MAX. FLOW : 10 CMH

HEAD : 15 METERS

CAPACITY : 7 HP

POWER : 5 (HP)

2 2X100% AERATION BLOWER PHASE : 3PH, 220 V

ROOTS TYPE AIR BLOWER

MATERIAL : STAINLESS STEEL

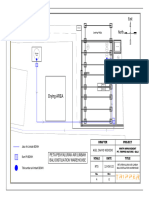

SEDIMENTATION 3 2X100% SERVICE PUMP AERATION MAX FLOW : 10 CMH

DISSOLVED FLOTATION TANK HEAD : 15 METERS

HOLDING EFFLUENT

AIR TANK 4

BRAND / TYPE : STAINLESS STEEL

TANK TANK

2x100% SLUDGE PUMP (DAP) MAX FLOW : 10 CMH

HEAD : 15 METERS

MATERIAL : ETHYLENE PROPYLENE DIENE

MONOMER (EPDM)

5 31 FINE BUBBLE DIFFUSER DIMENSION : 110 x 37 x 28 MM

6 MATERIAL : STAINLESS STEEL

OVERFLOW 2 WEIR

(CONNECT TO 7 2x100% DAF PUMP

BRAND / TYPE :

CAPACITY :

HELLBENDER / OTHERS

3 KW, 220V, 3 PH, 60 HS

DISCHARGE PIPE) BRAND / TYPE : HELLBENDER / OTHERS

8 2x100% FLOATING OIL SKIMMER

MIXING TANK AERATION TANK CAPACITY : 3 KW, 220V, 3 PH, 60 HZ

SHAFT LENGTH : 1 METER

9 1 FLOCCULATION AGITATOR CAPACITY : 0.25 KW, SINGLE PHASE, 220V

BRAND : SEKO

10 CHEMICAL DOSING PUMP MODEL : SEKO AKL 603

4

CAPACITY : 5 L/HOUR AT 10 BARS

RATING : 0.012 KILOWATTS (KW); 220 VOLTS (V);

MATERIAL : HDPE

11 4 CHEMICAL TANKS CAPACITY : 120L

COLOR : WHITE

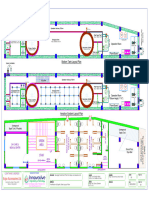

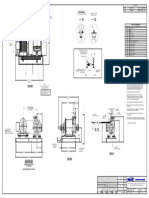

WASTE WATER TREATMENT PLANT LAYOUT 12

13

1

1

BAFFLES

BAR / MESH SCREEN

MATERIAL

MATERIAL

:

:

STAINLESS STEEL

STAINLESS STEEL

SCALE: 1:30M 14 1 BAR / MESH SCREEN MATERIAL : STAINLESS STEEL

MTSC MECHANICAL ENGINEERING CONSULTANCY ENGINEER: PROJECT TITLE: OWNER: SYSTEM / DISCIPLINE: SHEET CONTENT: Rev. Nos.: Rev. Date: Drawn By: SM

Checked By: AEC

COMPLETE HVAC/R & MECHANICAL DESIGN and ENGINEERING SERVICES MECHANICAL WWTP FLOW CHART Drw. Scale 1:50

Nos. 37 Fleur de Liz St. Villa San Mateo 2 Guitnang Bayan 2, San Mateo Rizal 1850

ARDEL E. CLARIDAD A PROPOSED SILO PIER Drw. Nos.

DTI Registration: 3339077 CENTURY PEAK CORPORATION SITE PLAN WWTP PLAN LAYOUT

Business Registration: 2023-02616

Professional Mechanical Engineer 00 06/02/2023

Contact Nos.: (63) 86372640 / 0921-6005436 Reg. Nos : 005562 PTR. Nos. 9404099 BRGY. MANGOTO, PINAMUNGAJAN, CEBU

14th Floor, Equitable Bank Tower, Paseo de Roxas , Makati City

Tel. No. (632) 856-0999, Fax No. (632) 8564844

WASTE WATER BILL OF MATERIALS-WWTP MTSC MEC-DWG-2023-SP-M-H_00

M 04

Email: mtscmec@gmail.com website: mtscmec.com Issued on : 01/10/2023 Issued at : Marikina City TREATMENT PLANT

You might also like

- Sanitation Code - Chapter 17 Revised IRRDocument32 pagesSanitation Code - Chapter 17 Revised IRRBoni MagtibayNo ratings yet

- Inspection Checklist Private WellsDocument1 pageInspection Checklist Private WellsNick Kick100% (1)

- Transformer - GA PDFDocument12 pagesTransformer - GA PDFepe civilNo ratings yet

- Introduction To Water Supply EngineeringDocument4 pagesIntroduction To Water Supply EngineeringShuvanjan Dahal90% (39)

- WWTP Process Flow Diagram Rev.01Document1 pageWWTP Process Flow Diagram Rev.01zayyanhtet.engrNo ratings yet

- Desain STP Intirub 24 MPDDocument13 pagesDesain STP Intirub 24 MPDlutfi informatikaNo ratings yet

- Well Control EquipmentDocument18 pagesWell Control Equipmentفؤاد ابوزيدNo ratings yet

- TACMINA EC066 AccessoriesDocument32 pagesTACMINA EC066 AccessorieswissanupNo ratings yet

- Etp FlowchatDocument1 pageEtp FlowchatNaveenVermaNo ratings yet

- Flow Chart WWTPDocument1 pageFlow Chart WWTPRahmi AsyariNo ratings yet

- Air Conditioning: Fan Coil UnitDocument1 pageAir Conditioning: Fan Coil UnitHasan NedariyaNo ratings yet

- Centralised-Lubrication-Systems Catalogue PDFDocument5 pagesCentralised-Lubrication-Systems Catalogue PDFPRECITECNo ratings yet

- Modul 2 - Principles of Function of The Major Component of The PlantDocument25 pagesModul 2 - Principles of Function of The Major Component of The PlantMuhammad Yusuf Halim PutraNo ratings yet

- Modified Flow Diagram 2 28022023Document1 pageModified Flow Diagram 2 28022023Envi QNo ratings yet

- Fire Emergency-A1Document1 pageFire Emergency-A1Agi AlghifariNo ratings yet

- Hay AL-Hussain Sports Forum Al-Basra Hay AL-Hussain: Approved byDocument1 pageHay AL-Hussain Sports Forum Al-Basra Hay AL-Hussain: Approved byTahirJabbarNo ratings yet

- Skema Desain IPAL BDocument1 pageSkema Desain IPAL BReza MuhammadNo ratings yet

- Raw Effluent InletDocument1 pageRaw Effluent Inletrahul.sopanengineersNo ratings yet

- 065 DWG MRT IV 2024 - Modif Pipa Cooling Tower Stasiun Istora - MRT Jakarta-2Document2 pages065 DWG MRT IV 2024 - Modif Pipa Cooling Tower Stasiun Istora - MRT Jakarta-2super_tlkNo ratings yet

- BAC VXC SpareParts Pv00ENDocument1 pageBAC VXC SpareParts Pv00ENMiguel-Angel RuizNo ratings yet

- Modul 1 - General Layout of The PlantDocument5 pagesModul 1 - General Layout of The PlantMuhammad Yusuf Halim PutraNo ratings yet

- Kolam Renang PDFDocument17 pagesKolam Renang PDFgilbert fristartoNo ratings yet

- Sprinkler System Schematic (MCV)Document1 pageSprinkler System Schematic (MCV)Bagus PrambudiNo ratings yet

- Bottom Tank Layout Plan: Green AreaDocument1 pageBottom Tank Layout Plan: Green AreaMd SuruzzamanNo ratings yet

- Peta Limbah BDWHDocument1 pagePeta Limbah BDWHAghilCahyooWiddhodooNo ratings yet

- Delivery Inspection Sheet: Checked Inspec-Tion NO Item Gambar KerjaDocument2 pagesDelivery Inspection Sheet: Checked Inspec-Tion NO Item Gambar KerjaMay FattahNo ratings yet

- Plano EsquematicoDocument1 pagePlano EsquematicoDaniel Alejandro García PérezNo ratings yet

- P&ID Lubrication SystemDocument1 pageP&ID Lubrication SystemtanalialayubiNo ratings yet

- lINE DIAGRAM SKIMMER TYPE POOLDocument1 pagelINE DIAGRAM SKIMMER TYPE POOLSAURABH PRADHANNo ratings yet

- SKEMA IPAL Type 3Document1 pageSKEMA IPAL Type 3Ririn SetiyaniNo ratings yet

- RIE93266 Instruction GuideDocument1 pageRIE93266 Instruction GuideMarco Antonio CastilloNo ratings yet

- Mrs NoraDocument66 pagesMrs NoraGaylan MuhsinNo ratings yet

- IPAL Cap. 90 M PDDocument3 pagesIPAL Cap. 90 M PDRomly Van PersieNo ratings yet

- D10T2传动系统液压图Document1 pageD10T2传动系统液压图Chunping SongNo ratings yet

- FGD AbsorberDocument1 pageFGD AbsorberASHUTOSHMECHNo ratings yet

- IPAL Cap. 22 M PDDocument2 pagesIPAL Cap. 22 M PDRomly Van PersieNo ratings yet

- Flow DiagramDocument1 pageFlow DiagramMuh ArnoldNo ratings yet

- PT - Ivo Mas Tunggal: Gambar 1: Pengolahan TBS Menjadi Minyak Sawit Kasar (CPO)Document2 pagesPT - Ivo Mas Tunggal: Gambar 1: Pengolahan TBS Menjadi Minyak Sawit Kasar (CPO)jenni sisika ria purbaNo ratings yet

- Flow SheetDocument1 pageFlow SheetJimmy EfraimNo ratings yet

- STP Plan LayoutDocument1 pageSTP Plan Layoutnerinel coronadoNo ratings yet

- Hemax530AL Fluidic Diagram VVDocument1 pageHemax530AL Fluidic Diagram VVÂn ĐìnhNo ratings yet

- Berita Acara (Check List)Document2 pagesBerita Acara (Check List)jana suryanaNo ratings yet

- Process Flow Diagram (Yakult Phiippines Sbr-Iceas WWTF)Document1 pageProcess Flow Diagram (Yakult Phiippines Sbr-Iceas WWTF)Darwin FabonNo ratings yet

- CPC ENG - ILY 1050 Rev.1Document1 pageCPC ENG - ILY 1050 Rev.1sarinkanokNo ratings yet

- Diagram Ipal JMSDocument1 pageDiagram Ipal JMSmarcelluis.a1No ratings yet

- Fixed Dry Chemical Powder Extinguishing SystemDocument1 pageFixed Dry Chemical Powder Extinguishing SystemSanchit KhannaNo ratings yet

- Smart 2013Document6 pagesSmart 2013ecupro checoNo ratings yet

- Steam Tunnel Before & AfterDocument1 pageSteam Tunnel Before & AfterlarasNo ratings yet

- Bottom Tank Layout Plan: U.G. STP Tank AreaDocument1 pageBottom Tank Layout Plan: U.G. STP Tank AreaMd SuruzzamanNo ratings yet

- Delivery Inspection Sheet: Left SideDocument2 pagesDelivery Inspection Sheet: Left SideMay FattahNo ratings yet

- QA1E102Document2 pagesQA1E102Faruq AhmadNo ratings yet

- HCP 8c PDFDocument2 pagesHCP 8c PDFsundharNo ratings yet

- Masoneilan Power Industry Control SolutionsDocument24 pagesMasoneilan Power Industry Control SolutionsEko PrasetyoNo ratings yet

- Khu - 11 - G - Bac20 - DS - 001 - 2Document2 pagesKhu - 11 - G - Bac20 - DS - 001 - 2Shafiqul IslamNo ratings yet

- Tank Construction Cost Solution.Document5 pagesTank Construction Cost Solution.Judges ConsultantsNo ratings yet

- Desalination: Process Flow DiagramsDocument8 pagesDesalination: Process Flow DiagramsJoseph Gil Salcedo100% (2)

- Well Control EquipmentDocument20 pagesWell Control Equipmenthitesh bhoiNo ratings yet

- Hydraulic AR1681Document2 pagesHydraulic AR1681Chokchai JitmonmanaNo ratings yet

- Water Supply CadDocument1 pageWater Supply CadKenzo RodeoNo ratings yet

- Overview Kerja PraktekDocument42 pagesOverview Kerja PraktekAmanda Talia LumentutNo ratings yet

- Pumping Line Schematic PPL-07 (Rotojet) Rev.1Document1 pagePumping Line Schematic PPL-07 (Rotojet) Rev.1Riski KurniawanNo ratings yet

- 420D, 430D, 432D, and 442D Hydraulic System Parallel Lift LoaderDocument4 pages420D, 430D, 432D, and 442D Hydraulic System Parallel Lift Loaderelizabeth100% (1)

- Expo Accessories Ltd. STP DrawingDocument4 pagesExpo Accessories Ltd. STP DrawingMd SuruzzamanNo ratings yet

- CES ProfileDocument12 pagesCES ProfileGanesh VijaykumarNo ratings yet

- Chapter 3 SBRDocument45 pagesChapter 3 SBRAtlantida Dërmaku100% (1)

- 2017 PNSDW - Anarna, SonabelDocument21 pages2017 PNSDW - Anarna, SonabelRonel Lora DaduralNo ratings yet

- Sewage Manual CPEEHO1Document614 pagesSewage Manual CPEEHO1asex4u100% (2)

- Experiment No. 5 Date: Title:: Determination of Sludge Volume Index in A Given Wastewater SampleDocument7 pagesExperiment No. 5 Date: Title:: Determination of Sludge Volume Index in A Given Wastewater SampleMac357GNo ratings yet

- Integrated Urban Development ProjectDocument24 pagesIntegrated Urban Development ProjectGautamNo ratings yet

- Additional Charges of Daos in Agt 2019Document17 pagesAdditional Charges of Daos in Agt 2019heraldNo ratings yet

- Waste Water TreatmentDocument39 pagesWaste Water TreatmentIr. feizzsal kent100% (4)

- Training Laundry WWTUDocument15 pagesTraining Laundry WWTUSyaiful AkhmadNo ratings yet

- Water Grid in Telangana: ManagementDocument3 pagesWater Grid in Telangana: ManagementMangesh KulkarniNo ratings yet

- 1.1 An Investigation On The Urban Water Supply Systems in Small Towns of Karoi and MaronnderaDocument3 pages1.1 An Investigation On The Urban Water Supply Systems in Small Towns of Karoi and MaronnderaBest JohnNo ratings yet

- Water Scarcity SolutionsDocument2 pagesWater Scarcity SolutionshhNo ratings yet

- Operation of A Submerged Hollow Fiber Membrane Bioreactor For Wastewater Treatment On Meeting Reclamation Criteria PDFDocument19 pagesOperation of A Submerged Hollow Fiber Membrane Bioreactor For Wastewater Treatment On Meeting Reclamation Criteria PDFShiva Kumar S MNo ratings yet

- Sewage Treatment Plant PDF in Hindi 1Document64 pagesSewage Treatment Plant PDF in Hindi 1Pankaj Gogoi100% (1)

- By: Michael Sam Aradillos Vincent VasquezDocument11 pagesBy: Michael Sam Aradillos Vincent VasquezClive Delos ReyesNo ratings yet

- Wabag Biopur: Biofi Ltration For Wastewater TreatmentDocument6 pagesWabag Biopur: Biofi Ltration For Wastewater TreatmentNguyen AnNo ratings yet

- Soak Pits: What Is A Soak Pit?Document1 pageSoak Pits: What Is A Soak Pit?ascensionNo ratings yet

- Trincity Mall Water Harvesting and ReuseDocument3 pagesTrincity Mall Water Harvesting and ReuseSheenan R. MedfordNo ratings yet

- Small Drinking Water Systems Risk Assessment Guideline 2018 enDocument14 pagesSmall Drinking Water Systems Risk Assessment Guideline 2018 enchristianNo ratings yet

- Emergency Leak at Mapleton Booster Pumping Station Affecting PumpingDocument3 pagesEmergency Leak at Mapleton Booster Pumping Station Affecting PumpingMmangaliso KhumaloNo ratings yet

- Eng - Mohamed Abdelhady Mohamed ElsayedDocument3 pagesEng - Mohamed Abdelhady Mohamed ElsayedMohamed AbdelhadyNo ratings yet

- Schools Division Office I Pangasinan Updated Wins Facilities Number of Enrolment Number of Handwashin G Facilities Source of Water SupplyDocument4 pagesSchools Division Office I Pangasinan Updated Wins Facilities Number of Enrolment Number of Handwashin G Facilities Source of Water Supplyrufino delacruzNo ratings yet

- Extra Examples For Ch.4-Part 2Document4 pagesExtra Examples For Ch.4-Part 2hassan alzaidyNo ratings yet

- Percolation - Tank DesignDocument25 pagesPercolation - Tank DesignSanthosh Kumar Baswa100% (1)

- Water Treatment For HemodialysisDocument3 pagesWater Treatment For Hemodialysismisya23No ratings yet