Professional Documents

Culture Documents

Hazard Area Classification - Report Model

Hazard Area Classification - Report Model

Uploaded by

Balapravin PaselvamCopyright:

Available Formats

You might also like

- Warehouse Security Method Statement SimonDocument7 pagesWarehouse Security Method Statement SimonNita JamnuNo ratings yet

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- Firoz IGCDocument19 pagesFiroz IGCErshad Akhtar80% (5)

- Emergency Response and Preparedness Plan: 1.4 Roles, Responsibilities and Authorities of ERTDocument2 pagesEmergency Response and Preparedness Plan: 1.4 Roles, Responsibilities and Authorities of ERTAisamuddin Rohaizai100% (2)

- Master Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDocument6 pagesMaster Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDaniel JulianNo ratings yet

- Emergency Preparedness Plan NewDocument22 pagesEmergency Preparedness Plan NewtriveshNo ratings yet

- Safety AwarenessDocument27 pagesSafety AwarenessSuraj JhaNo ratings yet

- Risk Assessment 2 PDFDocument15 pagesRisk Assessment 2 PDFarunNo ratings yet

- 01-3-Nature of Accident Process-Inherent SafetyDocument20 pages01-3-Nature of Accident Process-Inherent SafetyAstra BeckettNo ratings yet

- Chapter-Vii Additional StudiesDocument26 pagesChapter-Vii Additional StudiesOMSAINATH MPONLINENo ratings yet

- Risk AssessmentDocument17 pagesRisk Assessmentanaik406No ratings yet

- 000a.how We Work - Rev. 0Document36 pages000a.how We Work - Rev. 0sawkariqbalNo ratings yet

- Health, Safety & Environment: Understanding Oil and Gas BusinessDocument34 pagesHealth, Safety & Environment: Understanding Oil and Gas BusinessMadhur ChopraNo ratings yet

- OHS Risk Register-OldDocument24 pagesOHS Risk Register-OldMohamed Rizwan100% (1)

- Safety Hazards IdentificationDocument14 pagesSafety Hazards IdentificationXian GoNo ratings yet

- 2022 13 Hazard Identification and Risk ControlDocument8 pages2022 13 Hazard Identification and Risk ControlTatak Bay AhmedNo ratings yet

- Hazard DatabaseDocument1,193 pagesHazard Database1009 AMILINENI SUDHEER CHANDRANo ratings yet

- This Article Is Not Available in Other LanguagesDocument3 pagesThis Article Is Not Available in Other LanguagesMarvz BautistaNo ratings yet

- R. Bhattacharya Atomic Energy Regulatory BoardDocument23 pagesR. Bhattacharya Atomic Energy Regulatory BoardAnonymous YYsE1BxrNo ratings yet

- Hazard DatabaseDocument1,140 pagesHazard DatabaseVero ColladoNo ratings yet

- Confined Space Drager Risk AssessmentDocument8 pagesConfined Space Drager Risk AssessmentChandresh SinghNo ratings yet

- Risk Assessment Tank FarmDocument57 pagesRisk Assessment Tank FarmAwolayeofori TamunosakiNo ratings yet

- Chemical Process Safety For ChE 405-September 2019Document49 pagesChemical Process Safety For ChE 405-September 2019Tanjina Tarannum PrithulaNo ratings yet

- 09102018D2LZB87XRADocument32 pages09102018D2LZB87XRAABAYNEGETAHUN getahunNo ratings yet

- Jsa Trial Run of DGDocument3 pagesJsa Trial Run of DGDwitikrushna RoutNo ratings yet

- Where Incident Lead ToDocument5 pagesWhere Incident Lead ToANo ratings yet

- JSA For Limit Switch Checking & AdjustmentDocument3 pagesJSA For Limit Switch Checking & AdjustmentSwagata BeraNo ratings yet

- 6 Hailwood RomeDocument20 pages6 Hailwood RomeTanmay BabreNo ratings yet

- Hazard DatabaseDocument955 pagesHazard DatabaseMohd ObaidullahNo ratings yet

- HSE Report FormDocument2 pagesHSE Report FormNabula ShabanNo ratings yet

- 000a.safe Execution of WorkDocument36 pages000a.safe Execution of Worknarasimhamurthy414No ratings yet

- Tugas 1 KPK - Amanda Novriza - 02211840000006Document6 pagesTugas 1 KPK - Amanda Novriza - 02211840000006amanda novrizaNo ratings yet

- CBB 40104 Bioplant Design Project 2: (Chapter 5: Process Safety)Document15 pagesCBB 40104 Bioplant Design Project 2: (Chapter 5: Process Safety)Mira Lucis CaelumNo ratings yet

- Idoy DakoDocument2 pagesIdoy DakogiangianrueloNo ratings yet

- XL 3 N 0 Xrgaa 010211761 HIRADocument38 pagesXL 3 N 0 Xrgaa 010211761 HIRASumit SardanaNo ratings yet

- Workshop About Hazard, Risks and Preventive MeasuresDocument7 pagesWorkshop About Hazard, Risks and Preventive MeasuresPili RodriguezNo ratings yet

- Risk Assessment 7.1 Risk Assessment: Rama Pulp & Paper LTDDocument32 pagesRisk Assessment 7.1 Risk Assessment: Rama Pulp & Paper LTDBorislav VulićNo ratings yet

- Risk Assessment & Damage ControlDocument29 pagesRisk Assessment & Damage ControlRa muNo ratings yet

- Hazard-Database Mining BAGUS SEKALIDocument1,156 pagesHazard-Database Mining BAGUS SEKALIherikNo ratings yet

- Rang Dong SustainabilityDocument21 pagesRang Dong SustainabilityNguyễn ViệtNo ratings yet

- Instruments Check - Compressor Maintenance Bonatti FormDocument8 pagesInstruments Check - Compressor Maintenance Bonatti Formmohamedtalaat691No ratings yet

- TGPL-AD-HSE01-TEM-001 HIRA Mech. Work-01-2Document3 pagesTGPL-AD-HSE01-TEM-001 HIRA Mech. Work-01-2Shubham ShuklaNo ratings yet

- Coolant Leakage Compressor Maintenance Bonatti FormDocument14 pagesCoolant Leakage Compressor Maintenance Bonatti Formmohamedtalaat691No ratings yet

- RA-GL-HAL-PPS-444 (Manual Handling)Document7 pagesRA-GL-HAL-PPS-444 (Manual Handling)BalasubramanianNo ratings yet

- JSA - RA 000-Water ProofingDocument5 pagesJSA - RA 000-Water ProofingNAGARJUNA100% (1)

- Risk Analysis Techniques NR10 Rev 01Document34 pagesRisk Analysis Techniques NR10 Rev 01leonardo guerraNo ratings yet

- Gas Cylinders Risk AssessmentDocument3 pagesGas Cylinders Risk AssessmentMAB AliNo ratings yet

- Hazard Identification and Risk AssessmentDocument32 pagesHazard Identification and Risk AssessmentPRINCE KUMARNo ratings yet

- GRA - Hot Work - Install New HandrailDocument21 pagesGRA - Hot Work - Install New HandrailMohamad Nazmi Mohamad RafianNo ratings yet

- General Risk Assessment - Mobilize Equipment To SiteDocument18 pagesGeneral Risk Assessment - Mobilize Equipment To SiteMohamad Nazmi Mohamad RafianNo ratings yet

- Coshh Assessment For Rbe 1000Document2 pagesCoshh Assessment For Rbe 1000muavizmahmoodNo ratings yet

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- Relief Valve - Compressor Maintenance Bonatti FormDocument8 pagesRelief Valve - Compressor Maintenance Bonatti Formmohamedtalaat691No ratings yet

- TIP-HSE-P02-01-F01 Risk Assessment R0Document10 pagesTIP-HSE-P02-01-F01 Risk Assessment R0Vijayakumar KarunanidhiNo ratings yet

- RA-IM-12A - Launching Girder - Marine-Rev-02Document52 pagesRA-IM-12A - Launching Girder - Marine-Rev-02Planning C7No ratings yet

- GRA - Civil Work - WWT HousekeepingDocument17 pagesGRA - Civil Work - WWT HousekeepingMohamad Nazmi Mohamad RafianNo ratings yet

- HAZIDDocument2 pagesHAZIDAnonymous zwSP5gvNo ratings yet

- An Outline of Various Facets of Safety and Health in A Chemical IndustryDocument19 pagesAn Outline of Various Facets of Safety and Health in A Chemical IndustryKo HeinNo ratings yet

- PROCESS RA Maidstone Animation Stop Motion BaysDocument4 pagesPROCESS RA Maidstone Animation Stop Motion BayslydsonewordNo ratings yet

- Unit 1 and 2Document57 pagesUnit 1 and 2AKNo ratings yet

- Db Shr 010 전사 안전보건방침Document2 pagesDb Shr 010 전사 안전보건방침Tigor GurningNo ratings yet

- Industrial Poisoning from Fumes, Gases and Poisons of Manufacturing ProcessesFrom EverandIndustrial Poisoning from Fumes, Gases and Poisons of Manufacturing ProcessesNo ratings yet

- Community Based Disaster Preparedness of Valenzuela City and Iriga CityDocument12 pagesCommunity Based Disaster Preparedness of Valenzuela City and Iriga CityIOER International Multidisciplinary Research Journal ( IIMRJ)No ratings yet

- EMS 131 Chapter 1Document38 pagesEMS 131 Chapter 1Gersonito SobreiraNo ratings yet

- MEDICAL EMERGENCY RESPONSE PLAN (Bilingual Template)Document42 pagesMEDICAL EMERGENCY RESPONSE PLAN (Bilingual Template)farid akbarNo ratings yet

- National Simultaneous Earthquake Drill Accomplishment ReportDocument8 pagesNational Simultaneous Earthquake Drill Accomplishment ReportKuyaJv Plaza EscareNo ratings yet

- STP BPOPS ACCOMPLISHMENT REPORT 2nd SemDocument2 pagesSTP BPOPS ACCOMPLISHMENT REPORT 2nd SemFrancis LayagNo ratings yet

- Basic Life SupportDocument42 pagesBasic Life SupportNiken Tri HapsariNo ratings yet

- Monthly Report For Month of Feb 2019Document4 pagesMonthly Report For Month of Feb 2019Engr: Sarmad HussainNo ratings yet

- Emergency Response PlanDocument14 pagesEmergency Response Planpabitra panda100% (1)

- Emergency Drill Execution Report - JAN 14, 2023Document4 pagesEmergency Drill Execution Report - JAN 14, 2023rehanhussain0333No ratings yet

- After Activity Report Ems TrainingDocument9 pagesAfter Activity Report Ems TrainingMdrrmoPontevedranegoccNo ratings yet

- Ra 10121Document39 pagesRa 10121nagtipunanNo ratings yet

- Prepared By: Noted By: Approved byDocument4 pagesPrepared By: Noted By: Approved byEmmanuel BatinganNo ratings yet

- Asd Darmex - Agro - Sustainability - Reporting - November - 2019 - PT. - DMPDocument139 pagesAsd Darmex - Agro - Sustainability - Reporting - November - 2019 - PT. - DMPbudak kecikNo ratings yet

- 1 - Barangay Skills Enhancement ProjectDocument4 pages1 - Barangay Skills Enhancement ProjectMaria GraciaNo ratings yet

- Fire Alarms Submittal Guide123Document4 pagesFire Alarms Submittal Guide123Junaid UllahNo ratings yet

- Nfirs Appendix CDocument13 pagesNfirs Appendix Caan_pkppkNo ratings yet

- NCTEU 2023 Brochure v5Document8 pagesNCTEU 2023 Brochure v5Peter VerčekNo ratings yet

- Peran Perawat Dalam BencanaDocument15 pagesPeran Perawat Dalam BencanaWahyu HidayatiNo ratings yet

- Revised 3.11 Individual Disaster PreparednessDocument1 pageRevised 3.11 Individual Disaster PreparednessErica A. Gallegos AriasNo ratings yet

- RikerDocument3 pagesRikerAnonymous lrNfcyiNo ratings yet

- Fire Management Training: Balanga City Hotline Numbers Limay BFP Hotline NumbersDocument16 pagesFire Management Training: Balanga City Hotline Numbers Limay BFP Hotline NumbersLee-Ann LimNo ratings yet

- Bfp-Car Abra Comprehensive PraDocument21 pagesBfp-Car Abra Comprehensive PraBfpCar AbraNo ratings yet

- Hull Employee Earnings 2022 TownDocument5 pagesHull Employee Earnings 2022 TownCaitlyn KelleherNo ratings yet

- Fire Kerala 2016 PDFDocument14 pagesFire Kerala 2016 PDFSunder RajagopalanNo ratings yet

- JTB-PP-S-CKL-000-0007 07. Form Hse Induction Jakarta OfficeDocument1 pageJTB-PP-S-CKL-000-0007 07. Form Hse Induction Jakarta OfficeMustofaNo ratings yet

- It Disaster Recovery and BCP Service LevelDocument1 pageIt Disaster Recovery and BCP Service LevelHector Eduardo ErmacoraNo ratings yet

- 2007 Bucor AnnexaDocument2 pages2007 Bucor AnnexaArmy Day DulmanNo ratings yet

- Confined Space RegisterDocument4 pagesConfined Space RegisterGustavo DucaNo ratings yet

Hazard Area Classification - Report Model

Hazard Area Classification - Report Model

Uploaded by

Balapravin PaselvamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Area Classification - Report Model

Hazard Area Classification - Report Model

Uploaded by

Balapravin PaselvamCopyright:

Available Formats

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant

& Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

RISK ASSESSMENT REPORT

1.0 RISK ASSESSMENT

Industrial accident results in great personal & financial loss. Managing these accidental risks in today's

environment is the concern of every industry, because either real or perceived incidents can quickly

jeopardize the financial viability of a business. Many facilities involve various manufacturing processes that

have the potential for accidents which may be catastrophic to the plant, work force and environment or

public. The main objective of the risk assessment study is to propose a comprehensive but simple approach

to carry out risk analysis and conducting feasibility studies for planning & management of industrial

prototype hazard analysis in Indian context.

1.1 Hazard Identification & Risk Assessment (HIRA)

Hazard identification involves the identification and quantification of the various hazards (unsafe condition)

that exist in the plant. On the other hand, risk analysis deals with the identification and quantification of the

risk, the plant equipment and Personnel are exposed to, due to accidents resulting from the hazards present

in the plant.

Risk assessment involves the identification and assessment of risks to the population exposed to hazards

present. This requires an assessment of failure probability, credible accident scenario, vulnerability of

population etc. Much of this information is difficult to get or generate consequently, the risk analysis in

present case is confined to maximum credible accident studies and safety and risk aspect related to

expansion and installation project.

Activities requiring assessment of risk due to occurrence of most probable instances of hazard and accident

are both onsite and off-site.

On-site- An incident which takes place in an industry and its effect are confined to the factory premises

involving only the people working in the factory.

Exposure to fugitive dust, noise, and other emissions

Housekeeping practices requiring contact with solid and liquid wastes

Alcohol leakage/ spillage through pipeline during pumping & subsequent fire

Off-site- If an incident takes place in an industry and its effects are felt outside the Factory premises, the

situation thus generated is called an offsite Emergency.

Exposure to pollutants released from offsite/ storage/related activities

Contamination due to accidental releases or normal release in combination with natural hazard

Deposition of toxic pollutants in vegetation / other sinks and possible sudden releases due to

accidental occurrences.

In view of the hazards involved in handling and storage of hazardous chemicals and processes “On Site

Emergency Plan” has been prepared. It gives a clear organization structure, including outside agencies and

elaborates the duties to be performed by each individual when situation demands. The plan enumerates the

actions required to be taken by various personal working at different work station in the plant. Particular

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

emphasis is given to eight most vital areas of disaster planning like Organization responsibilities, procedure,

training, mutual aid, communication, transportation and public relations.

1.1.1 Identification of Types of Hazards in Distillery & Co-generation Power Plant (HAZID)

The following types of hazards are identified at the company.

Table: 1

Hazard Identification

S. No. Name Description Severity Hazard

1. Transportation of raw Biomass Major Fire

material, fuel and Enzymes, yeast, nutrients, etc. Minor Exposure & inhalation

storage

Chemicals (Caustic, acids, etc.) Major Exposure to skin

2. Manufacturing Process Distillation Major Heat & Fire

3. Other Utilities Boiler, D.G Sets Major Noise, Heat, Fire & electrocution

4. Products Alcohol Major Fire

5. Other accidents Leakages from the vessels, rupture Major Exposure &Fire

of pressure vessels and storage

tanks

1.1.2 Types of Accidents Possible

Main hazard in the plant comes from handling of Class A Solvents – Ethanol

Causes of Incident Relevance for Jundla Works

Fire Very High

Loss of Containment High

Vandalism Low

Explosion Low

Loss of Process Control Very Low

Plant Modification Low

Management of Contractors Low

Causes of Incident Relevance for Jundla Works

Human Error Low

Runaway Reaction NIL

Electrocution Medium

Natural Causes

Floods High

Cyclonic Winds Low

Act of War Low

Earthquake Low

Sabotage Low

Major Injury/Illness Medium

1.1.3 Assessment of Risk along with mitigation measures

Qualitative risk assessment based on categorization of both probability and impactprovides greater insight

into the absolute risk severity. The riskimpact assessment investigates the potential effect on a project

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

objective such asschedule, cost, quality, or performance, including both negative effects for threats

andpositive effects for opportunities.

Table: 2

Risk Assessment table along with mitigation measures

S. Associated Associated risk/ Risk

Activity Mitigation Measures

No. hazards health impact rating

1. Storage & Bursting of Exposure, physical H • Use of PPEs.

handling of raw storage tanks injuries • Inspection & regular monitoring

material & • Training to workers for proper handling

Chemicals

• Proper system for loading operation to

prevent any spillage.

• Spill kit for Acid and other chemicals

2. Working near Heat & Fire Physical injuries H • Firefighting facility

Distillation and burning • Provision of pressure indicators in the

column vessels.

• Use of PPEs.

• Inspection & regular monitoring

• Training to workers for proper handling

3. Fuel yard Heat & Fire Physical injuries H • Storage should be away from ignition

and burning source

• Provision of Firefighting facility

• Provision of PPEs

• First aid box

4. APCD failure Release of PM in Air pollution M • Regular monitoring & inspection shall be

ambient air done.

• The plant shall immediately shut down on

APCD failure

5. Working at Slip, trips & falls Physical injuries H • Individual alertness of the workers.

height of operators • First aid boxes shall be provided

6. Storage of Exposure, Exposure to over H • Well ventilation

Alcohol inhalation, 100 ppm may • Keeping away from heat sparks & open

ingestion & Fire cause headache, flame.

drowsiness, etc. • PPEs.

Ingestion may lead • Firefighting measures shall be readily

to depression of available.

CNS, nausea, etc.

Burn injuries

8. Release of high Explosion Risk of severe H • Regular maintenance & inspection of

pressure steam injury, damage to parts.

from boiler equipment • Proper training to the individuals

• PPEs

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

S. Associated Associated risk/ Risk

Activity Mitigation Measures

No. hazards health impact rating

• First aid kit

9. Electrical Electric shock, Electrical shocks, H • Regular checking and maintenance of

maintenance short circuits in Injury or burn electrical units

work power room • PPEs

• Provision of First aid box

10. Working near High noise Noise induced M • Provision of PPEs to the workers.

Boiler, D.G. sets hearing losses

Note: H- High; M- Moderate

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

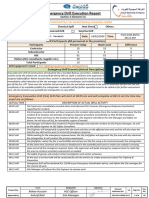

Table 3

Identification of Hazard and Risk, Risk Assessment and Risk Management Measure

Hazard/ Associated risk identification Risk assessment

Adequacy of Severity Overriding Risk

Condition Risk

Activity/ measures S2= LxC Total Risk factor(LC/D Management

Scal Detectabili

Services Hazard Gap Level of S1+S2+ classificati C/Any Measure

D/ R/N N/A Likeliho Consequen e S1 Likeliho ty (D)

Existing s, if Consequen D on others) required

I R N/E od ces od(L)

any ce (C )

Mandatory use

Falling or

Distillery Minute Injury on of helmets in

slippage D NR E Helmets N 8 5 6 10 48 low -

operations injury head the plant

from stairs

premises.

Fire

Fire Major

Boiler Fire & Burning extinguishers

D NR E extinguish N burning and 9 5 10 10 69 medium -

operations explosion of skin for emergency

ers loss of life

fire

Electric Facility of

Power

shock/shor D NR E N injury Loss of life 7 6 10 10 77 Medium - onsite fire

generation

t circuit extinguishers

Burning

On site

Handling Fire of

Fire & availability of

of alcohol D NR E extinguish N property Loss of life 8 4 9 10 54 Low -

explosion Fire

& storage ers and

extinguishers

persons

Water

Burning Fire

Storage of sprinkling

of life extinguishers

coal and Fire D NR E & fire N Loss of life 7 6 9 10 71 Medium -

and and water

biomass extinguish

property sprinkling

ers

Handling Proper

Burning, Material safety

& storage labeling Major burns

Spillage D R E N rashes 8 5 8 10 58 Low - data sheet and

of and on skin

on skin proper labeling

Chemicals storage

Legend:

LC: Legal Concern, if concerning activity/associated hazard is covered under Indian OHS Legislation, DC: Domino concern, if concerning activity/associated hazard can trigger series of

accident. Any other:Any other relevant factor if applicable related to /or affecting the significance of OHS risks.

D:Direct; I- Indirect; R= Routine; NR:Non-Routine; N: Normal; AN:Abnormal; E:Emergency

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

1.1.4 Safety Measures for Storage & Handling of Alcohol

The alcohol is being/will be directly fed to the storage tanks (bottling unit) mechanically and no manual

handling is being/will be involved which reduces/will reduce the risk of spillage. Following precautionary

measures would be taken for safety:

HANDLING AND STORAGE: Keeping away from heat, sparks and open flame, care is being/will be

taken for avoidance of spillage, skin and eye contact, well ventilation, use of approved respirator if air

contamination is above acceptable level is being/will be promoted. For Storage and handling

following precautions are being/will be taken:

Keeping away from oxidizers, heat and flames.

Avoidance of plastics, rubber and coatings in the storage area.

Cool, dry, & ventilated storage and closed containers.

Grounding of the container and transferring of equipment to eliminate static electric sparks.

Storage of acid and alkalies should be done properly as they can cause severe burns on skin.

In case of any emergency following measures are being/will be taken:

FIRST AID MEASURES: For skin contact, eye contact, & inhalation.

FIRE FIGHTING MEASURES:

In plant precautions have been taken by declaring plant operating area as No Smoking Zone.

All the Electrical installations are flame proof type in the alcohol storage area.

Use of extinguishing media surrounding the fire as water, dry chemicals (BC or ABC powder), CO,

Sand, etc

Foam System for firefighting is being/will be provided to control fire from the alcohol storage

tank. The foam thus produced suppresses/will suppress fire by separating the fuel from the air

(oxygen), and hence avoiding the fire & explosion to occur in the tank. Foam would blanket the

fuel surface smothering the fire. The fuel is being/will also be cooled by the water content of the

foam.

The foam blanket suppresses/will suppress the release of flammable vapors that can mix with the

air.

Special Fire Fighting Procedures; Keeping the fire upwind. Shutting down of all possible sources

of ignition, keeping of run-off water out of sewers and water sources. Avoidance of water in

straight hose stream which will scatter and spread fire. Use of spray or fog nozzles will be

promoted, cool containers will be exposed to flames with water from the side until well after the

fire is out.

Hazardous Decomposition Products: gases of Carbon Monoxide (CO) & Carbon Dioxide (CO2).

A team of security Guards is kept to maintain security round the clock in whole of the factory

area. The Company has fully trained operating and security staff for fire fighting and fire drill is

conducted by the fire experts on regular intervals.

ACCIDENTAL RELEASE MEASURES: For Spill Cleanup well ventilation, shutting off or removal of all

possible sources of ignition, absorbance of small quantities with paper towels and evaporate in safe

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

place like fume hood and burning of these towels in a safe manner, Use of respiratory and/or liquid-

contact protection by the clean-up personnel is being/will be promoted.

Action to be taken by the First Person noticing the Fire/Leakage /Failure:

a) If it is a small fire, try to extinguish with fire extinguishers.

b) After noticing the fire, immediately call for assistance by shouting “Fire Fire” or by using

telephone facilities inform shift in-charge on intercom.

c) Inform security on intercom

Whenever disaster occurs, the incident should be communicated to the concerned authority in

minimum possible time, in case of failure of a means of communication due to electrical failure an

officer should rush to the nearest public telephone booth/ police station to transmit message through

line or police wireless.

During office hours on a working day

During office hours on working days senior most executive in the factory will take the charge of site main

controller in case of any emergency. In case of incident controller is not present in the factory production

chemist shall take over the function of incident controller as indicated in the organization chart.

1.2 Emergency Planning

1.2.1 Emergency Control Center

Emergency Control Centre (ECC) is a cell from which emergency operations are directed and coordinated.

This center activates as soon as on-site emergency is declared.

General Description of ECC

The ECC is located in an area that offers minimal risk being directly exposed to possible accidents. During an

emergency, the Emergency Management Staff, including the site controller shall gather in the ECC. Therefore,

the ECC shall be equipped with adequate communication systems in the form of telephones and other

equipment to allow unhampered organizations and other nearby facility personnel.

The ECC provides shelter to its occupants against the most common accidents; in addition, the ECC's

communication systems are protected from possible shutdown. The ECC has its own emergency lighting

arrangement and electric communication system operation.

Only a limited and prearranged number of people are admitted to the ECC, when in use. This eliminates

unnecessary interference and reduces confusion.

For the purpose of handling emergency, emergency control center has been identified and shown on the site

plan. All communications to and from will originate at this control center. The emergency control center will

have the following: -

Updated copies of the on–site Disaster Management Plan.

Emergency telephone numbers.

The names, phone number, and address of external agencies, response organizations and neighboring

facilities.

The adequate number of telephone (more than two).

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

Emergency lights, Clocks, Personal protective equipment.

List of fire extinguishers with their type no. and location, capacity, etc.

Safety helmets – List of quantity & location.

Status boards/message board.

Material safety data sheets for chemicals handled at the facility.

Several maps of the facility including drainage system for surrounding area showing:

Areas where hazardous materials are stored.

Plot plans of storage tanks, routes of pipelines, all water permanent lines etc.

The locations where personal protective equipment are stored.

The position of pumping stations and other water sources.

Roads and plant entrances.

Assembly areas & layout of Hydrant lines.

EMERGENCY ORGAINZATION CHART

1.3 DISASTER MANAGEMENT PLAN

Definition

A major emergency in an activity/project is one which has the potential to cause serious injury or loss of life.

It may cause extensive damage to property and serious disruption both inside and outside the

activity/project. It would normally require the assistance of emergency services to handle it effectively.

Scope An important element of mitigation risk is planning for emergency, i.e. identifying accident possibility,

assessing the consequences of such accidents and deciding on the emergency procedures, both on site and

off site that would need to be implemented in the event of an emergency.

Objective The overall objectives of the emergency plan will be:

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

• To localize the emergency and, eliminate it; and

• To minimize the effects of the accident on people and property.

Elimination will require prompt action by operations and work emergency staff using, for example, fire-

fighting equipment, water sprays etc. Minimizing the effects may include rescue, first aid, evacuation,

rehabilitation and giving information promptly to people living nearby.

1.3.1 Phases of Disaster

There are various phases of disaster including pre and post management of hazardous event that may or has

occurred.

Warning Phase Emergencies/disasters are generally preceded by warnings during which preventive

measures may be initiated. For example uncontrollable build-up of pressure in process equipment, weather

forecast give warning about formation of vapor cloud, equipment failure etc.

Period of impact phase This is the phase when emergency /disaster actually strike and preventive measures

may hardly be taken. However, control measures to minimize the effects may be taken through a well-

planned and ready-to-act disaster management plan already prepared by organization. The duration may be

from seconds to days.

Rescue Phase This is the phase when impact is almost over and efforts are concentrated on rescue and relief

measures.

Relief Phase In this phase, apart from organization and relief measures internally, depending on severity of

the disaster, external help are also to be summoned to provide relief measures (like evacuations to a safe

place and providing medical help, food clothing etc.). This phase will continue till normalcy is restored.

Rehabilitation Phase This is the final and longest phase. During which measures required to put the

situation back to normal as far as possible are taken. Checking the systems, estimating the damages, repair

of equipment and putting them again into service are taken up. Help from revenue/insurance authorities

need to be obtained to assess the damage, quantum of compensation to be paid etc.

1.3.2 Alarm System

A siren has been provided under the control of Security office in the plant premises to give warning. In case

of emergencies this is used on the instructions to shift in charge that is positioned round the clock. The

warning signal for emergency is as follows:

Emergency Siren: Waxing and waning sound for 3 minutes.

All clear signal: Continuous siren for one minute

1.3.3 Communication

Walkies & Talkies are located at strategic locations; internal telephone system EPBX with external P&T

telephones are provided.

1.3.4 Fire Fighting System

The fire protection system for the unit is to provide for early detection, alarm, containment and suppression

of fires. The fire detection and protection system has been planned to meet the above objective an all–

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

statutory and insurance requirement of Tariff Advisory Committee (TAC) of India. The complete fire

protection system comprises of the following.

(a) Fire brigade

Automatic / manual fire detection & alarm system

(b) Fire Hydrant

Fire hydrant will be provided at all around in the plant as per TAC Norms.

(c) Portable fire extinguishers

Various areas of the plant will have one or more of the above system depending upon the particular nature

of risk involved in that area.

(d) Portable chemical fire extinguishers

These are intended as a first line of defense, and hence are stationed at strategic locations in different

buildings and also for outdoor facilities. Portable fire extinguishers are of foam type; carbon dioxide type and

multipurpose dry chemical (MPDC) type.

(e) Fire detection and alarm system

Fire detection and alarm system an effective means of detection, visual indication of fire location and audible

alarm of any fire at its incipient stage. This system will comprise fire alarm panels, automatic fire detectors,

manual call points and fire siren (hooter).

The main fire alarm panel provides both visual and audible alarm of fire in any protected areas of the plant.

Manual break glass type fire alarms are provided at strategic locations where high hazards exits.

Automatic fire detectors are provided in plant areas such as control rooms, switchgear rooms, cable galleries

etc.

1.3.5 Fire -fighting groups

The Fire Fighting groups are classified into three teams, Fire-in-chief who co-ordinates all the groups shall

be safety officer:

a) Fire Fighting Team:-

I. This team will be doing the first line fire- fighting.

II. This team will be headed by shift in-charge/production chemist.

III. This team will be assisted by all employees in the plant and those near the place of fire.

b) Assisting Team:-

I. This team will assist the fire-fighting team.

II. This team will be headed by Maintenance Head.

III. This team shall be assisted Quality Control, production and Maintenance employees.

c) Rescue Team:-

I. This team will communicate with outside agencies and arrange first aid.

II. This team shall be headed by accounts in-charge.

III. This team shall be assisted by all employees in administrative office and medical services.

Action to be taken by different types of teams (name and action is as below):

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

Action by Fire Fighting team: -

Employees in the production department shall stop all their operations except emergency cooling.

Fire pump operator will ensure that the hydrant and sprinkler lines have sufficient pressure.

Employees working in production shall put off all the electrical supplies. If the accident occurs during

the night hours, the lighting switches shall be kept on.

Action by Rescue Teams

All office staff on hearing the alarm shall remove the important documents to a safe place.

Cashier shall lock the cash and related documents in the locker.

The group in-charge shall depute the employees for various jobs as mentioned below.

One employee shall take charge of telephone and contact fire brigade, police, neighboring industries

and hospitals for assistance.

One employee shall regulate the traffic at main gate.

One employee shall guide all outside of the plant.

One employee shall go around the plant and ensure all plants and machineries are closed.

Rest of the employees shall carry first aid box, various fire-fighting equipment from stores to the place

of fire.

Action plan for fire/Explosion during night:

Persons observing the fire/leakage should raise alarm by shouting and operate the nearest available

hand siren.

On hearing the hand siren, the watchman at the main gate shall operate electric siren intermittently to

communicate emergency.

Efforts should be made to put off the fire using fire extinguishers, sand buckets, hydrants and

sprinklers in the area.

All the electric supply (except lighting if it is night time) should be put off.

Shift in-charge should contact chief technical manager, factory manager, and occupier and apprise

them of the situation. If needed police, fire control, civil hospital and neighboring industries to be

contacted for help.

First Aid

A first aid center with adequate facilities has been provided. It is being/shall be maintained round the clock

by a compounder cum dresser and a doctor. An Ambulance shall also be provided at site to carry affected

people to hospital.

Security The security requirements of the company premises are being/shall be taken care of by CSO

assisted by a Fire In charge. The team, apart from the normal security functions manages/will manage the

role required during a disaster management operation as a part of the crisis control team.

Safety

The safety wing led by a Safety Manager will meet the requirement of emergencies round the clock. The

required safety appliances shall be distributed at different locations of the plant to meet any eventualities.

Poster/placards reflecting safety awareness will be placed at different locations in the plant area.

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

Evacuation Procedure

If it becomes necessary to have an emergency evacuation the Emergency Controller will make the decision.

On sounding of the emergency siren the employees are expected to move to the Emergency Assembly point

(main gate). This excludes the emergency staff. Emergency Controller will give instructions for evacuation by

the emergency staff, which will then proceed to the assembly point.

If there are employees left behind in different sections, the Incident controller will organize a rescue.Decision

to allow reentry shall be taken by the Emergency Controller.

Personal Protective Equipment (PPE) This equipment is used mainly for three reasons; to protect personnel

from a hazard while performing rescue/accident control operations, to do maintenance and repair work

under hazardous conditions, and for escape purposes.

Mock Drill

Mock Drill is being/should be carried out at a minimum frequency of once every six-month.

External mock drill with external authorities at an annual frequency is desirable.

Training

Adequate training is being/to be given to all JundlaTeam Members including regular Contractors and

Security. Special Training is being/to be given to the Emergency Task Force on Area Specific Emergency

Response. Specific training is being/to be given to Security for normal as well as Nightshift Emergency

Response.

Rehearsal and Updating of Plan

Emergency plans need to be tested when first devised and thereafter to be rehearsed at suitable intervals.

Individual personnel with duties under the plan should be qualified by exercise which will help to refine the

procedures by identifying deficiencies, difficulties and monitoring response time. To create awareness about

safety and emergency response procedure among the personnel, mock drill should preferably be carried out

monthly.

Rehearsals or exercise are important for all personnel likely to be involved in an accident on or off the site

because:

I. They familiarize on-site personnel with their roles, their equipment and the details of the plans.

II. They allow the professional emergency services to test their parts at the plan and the co-ordination

of all the different organizations.

III. They provide the current accuracy of the details of the plan (telephone numbers etc.) and the

availability of special equipment (fire and rescue breathing sets etc.)

IV. They give experience and build confidence in the team members. In the initial shock and confusion

of real incident, the ability to fall back on established initial actions are invaluable.

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

The on-site emergency procedures for each process plant, storage facility etc. should be tested regularly and

that all employees receive initial and refresher training, exercise should be arranged to test each part of the

emergency plan on each plant, stage by stage. Emergency isolation and shut down should be rehearsed.

After each rehearsal or practice, the plan should be reviewed to take account of any shortcomings

highlighted by the exercise.

1.4 Emergency Response & Responsibilities

1.4.1 Person Discovering Fire / Possible Emergency Situation

• In case of fire shout “FIRE" and inform concern authority & security for blowing the emergency siren.

• In case of Spillage / Other Emergencies try to control locally. If it cannot be controlled locally

informsecurity for blowing the emergency siren.

• Inform Plant Manager / Shift In charge about the incident when he reaches the incident site with

details of place, magnitude of mishap and follow instructions.

1.4.2 Security Services

GENERAL SHIFT HOURS

• Blow the emergency sire.

• Ensure Emergency Vehicle is ready for Action.

• Ensure both gates are clear.

• Arrange to relocate tankers to safe location

• Be available at the Main gate to assist the Emergency Admin Controller.

OUTSIDE GENERAL SHIFT HOURS

• Blow the emergency sire.

• Ensure Emergency Vehicle is ready for Action.

• Ensure both gates are clear.

• Arrange to relocate tankers to safe location.

• Inform people as per emergency roll call chart displayed.

• Be available at the Main gate to assist the Emergency Admin Controller.

• Do not talk to external world till emergency controller arrives.

1.4.3 ROLE OF EMERGENCY TASK FORCE

• Emergency task force becomes aware of the Site of Emergency either through direct sight as in their

work area or through the phone.

• ETF Members should proceed straight to the Incident Site and follow the instructions of the Works

Incident Controller.

• Emergency Task force should control the event without endangering themselves.

• Fire Fighting & Manhunt should be done with due precaution

Person Raw water system

• Ensure water supply in the fire hydrant points.

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

• Ensure all Borewell are running

Person in Electrical PCC Room

• Ensure electrical supply to raw water system

• Maintain vigil on Power availability

• Start DG Set and keep it on Standby.

Person for First Aid

Provide First aid and required help

1.4.4 Asst. Vice President (Works) as Emergency Controller

Immediately he is aware of the emergency, The Emergency controller will proceed to the Emergency Control

Centre (AVP Office) through the Site of Emergency. He will remain at the Emergency Control center till

cessation of Emergency. In absence of AVP (works), Asst Manager (CPU) & General Manager Bottling shall

jointly become emergency controller.

• Assess and evaluate the scale of emergency and activate the emergency plan accordingly.

• Ensure that the emergency services have been called in and where required that nearby firms have

been informed. Relevant authorities for public facilities must also be contacted as appropriate.

• Ensure that all key personnel have been called in.

• Inform the necessary External agencies including HLPL Senior Management of the emergency.

• Exercise direct operational control of those parts of site outside the affected area.

• Maintain continuous review of possible developments and direct shutting down and evacuation of

plant in consultation with the Works Incident Controller.

• Ensure that casualties are receiving adequate attention. Arrange for additional help if required. Ensure

that relatives are advised. Communications are passed on to OHC through security.

• Liaise with chief officers of Emergency and Police services, Health and Safety authorities.

• Provide advice of possible effects on areas outside the works.

• Ensure that all Personnel are accounted for.

• Arrange traffic control at site.

• Liaise with media spokesperson.

• Arrange for chronological record of the emergency to be maintained and ensure that evidence is

preserved for enquiries conducted by statutory authorities.

• Where the emergency is prolonged, arrange for relief of personnel and the provision of catering

facility.

• Control rehabilitation of affected area on cessation of emergency.

• Revoke emergency after the situation has become normal.

1.4.5 Role of Incident Controller

It is the duty of the Works Incident Controller to reach the scene of the incident as quickly as possible and

assess the situation. He will remain at the incident site till cessation of emergency. On arrival at incident

site he will:

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

1. He will assess the scale of emergency and send information to the Emergency Controller through

phone or through any of the emergency task force member

2. Direct the safe shutting down of operations and try to minimize the damage to plant property and

environment.

3. Ensure that all key personnel and help from fire brigade/first aiders/hospitals are called for through

Emergency Controller

4. Co-ordinate operations on Incident Site.

5. Assume duties of Emergency Controller until he is in position. In particular ensuring that emergency

services and key personnel on site are informed of the situation.

6. Communicate continually with Emergency Controller and inform all developments as appropriate.

7. Conduct search for casualties.

8. Liaise with Emergency Task Force during the incident.

9. Ensure that any evidence which may be required for further investigation is Preserved.

11. Ensure that after cessation of emergency, emergency task force members are safe

1.4.6 Role of Communication Controller

It is the duty of the Communication Controller to reach the control room of the incident as quickly as

possible and assist the emergency controller. He will remain at the control room till cessation of

emergency. On arrival he will:

1. He will advise the Site Emergency Controller of the situation, recommending (if necessary) evacuation

of the staff from assembly points.

2. Assist Emergency Controller in communicating nature of assistance required from Civic

Authorities (District Magistrate's Office, Police etc.)

3. Assist Emergency Controller in declaring Major Emergency to the Civic Authorities like District

Emergency Authority

4. Keep necessary transport at the Gate Office.

5. Co-ordinate Traffic at Site under advice from Emergency Controller.

6. Receive instruction from the Emergency Controller for any assistance from thefollowing authorities

and manage relationship / communication with them:

Hospitals

Fire Brigade

Police

Ambulance

7. Communicate Termination of Emergency under advice of the Emergency Controller.

1.4.7 Role of Engineering Co-Ordinators

It is the duty of the Engineering coordinators to reach the incident site and coordinate with the incident

controller.

1. Co-ordinate closes down of services.

2. Ensure Electrical Team has assumed position at the Substation with his emergency team.

3. Ensure for the water supply and safety equipment.

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

1.4.8 Emergency Administration Co-coordinator: Asst. Manger HR

On becoming aware of the Emergency, The Asst Manager HR, shall proceed to the Main gate Security Office.

He will remain there till cessation of Emergency. On reaching there he will:

1. Obtain the number of people at site from Security.

2. Keep necessary transport at the Gate Office

3. All incoming people should be retained at the Gate Office

4. Assist Emergency Controller in declaring Major Emergency to the Civic Authorities like District

Emergency Authority.

5. Keep necessary transport at the Gate Office

6. Direct relief team (selected by him at spot ) to proceed to the Emergency site along with First Aid Kits

under advise of the Emergency Controller.

7. Co-ordinate Traffic at Site under advice from Emergency Controller

1.4.9 Asst Works Incident Controller: Shift In charge

On becoming aware of the emergency, the Shift Officer, shall proceed to the place of Incident. He shall assist

the Works Incident Controller in execution of his responsibilities. After Office hours he shall assume the role

of full Works Incident Controller

1.4.10 Off-site emergency control plan:

The off-site emergency plan is an integral part of any hazard control system. It is based on those accidents

identified by the works management, which could affect people and the environment outside the works.

Thus, the off-site plan follows logically from the analysis that took place to provide the basis for the on-site

plan and the two plans therefore complement each other. The roles of the various parties that may be

involved in the implementation of an off-site plan are described below. The responsibility for the off-site plan

will be likely to rest either with the works management or with the local authority. Schematic representation

of various organization involved during emergency is shown below in Figure & Table below shows

communication nos. during offsite emergency.

Action Plan:-

The site Main Controller will assess the situation and if the emergency is likely to spread outside the

installation or affect the neighbor industry and people outside the factory premises, will declare off-site

emergency. He will coordinate with the incident controller and get intouch with all essential local authorities

and mutual aid members for controlling the disaster. The local authorities will work under the direct

supervision of the site Main Controller.

The help of the following agencies is summoned: -

Local police

Fire Brigade

Hospitals

Ambulance

Blood Banks

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

Home guards

Voluntary Agencies.

Table: 4

Emergency contact no. of various organizations involved during emergency

S.No. Name Telephone No.

1. Fire Brigade 0184-2253799, 0184-2270799

2. Police Station 01745274159

3. Hospital 0174-5274284, 0184-2266252

4. Ambulance 9468090885

Either way, the plan must identify an emergency coordinating officer who would take overall command of the

off-site activities. Consideration of evacuation may include the following factors:

In the case of a major fire but without explosion risk (e.g. an oil storage tank), only houses close to the

fire are likely to need evacuation

If fire is escalating very fast it is necessary to evacuate people nearby as soon as possible

In acute emergency people are advised to stay indoors and shield themselves from the fire.

Figure 7.1: Various organizations involved during emergency

Organization Organizational details of command structure, warning systems, implementation procedures,

emergency control centres include name and appointments of incident controller, site main controller, their

deputies and other key personnel involved during emergency.

Communications Identification of personnel involved, communication centre, call signs, network, list of

telephone numbers.

Special Emergency Equipment Details of availability and location of heavy lifting gear, specified fire-

fighting equipment, fireboats etc.

Voluntary Organizations Details of Voluntary organizations, telephone numbers nearby of hospitals,

Emergency helpline, resources etc. are to be available with chief authorities.

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

Non-governmental Organizations (NGO) NGO's could provide a valuable source of expertise and

information to support emergency response efforts. Members of NGOs could assist response personnel by

performing specified tasks, as planned during the emergency planning process.

• Evacuation of personnel from the affected area

• Arrangements at rallying posts and parking yards

• Rehabilitation of evacuated persons

Chemical information Details of the hazardous substances (MSDS information) and a summary of the risks

associated with them are to be made available at respective site.

Meteorological information There are arrangements for obtaining details of weather conditions prevailing

at or before the time of accident and weather forecast updates.

Humanitarian Arrangements Transport, evacuation centers, emergency feeding, treatment of injured, first

aid, ambulances, temporary mortuaries.

Public Information

• Dealing with the media-press office

• Informing relatives, etc.

Assessment

• Collecting information on the causes of the emergency

• Reviewing the efficiency and effectiveness of all aspects of the emergency plan.

Role of local authority

Local Authorities like Panchayat, Sabha, Samiti, municipalities can help in combating emergency situation

after assessing the impact scenario in rescue phase.

Role of Police

Police are to assist in controlling of the accident site, organizing evacuation and removing of any seriously

injured people to hospitals.

• Co-ordination with the transport authorities, civil defence and home guards

• Co-ordination with army, navy, air force and state fire services

• Arrange for post mortem of dead bodies

• Establish communication centre with easy contact with ECC

Role of Fire BrigadeThe fire brigade is to be organized to put out fires and provide assistance as required

during emergency.

Media

• The media needs to have ready and continuous access to designated officials with relevant

information, as well as to other sources in order to provide essential and accurate information to

public throughout the emergency and to avoid commotion and confusion.

• Efforts will be made to check the clarity and reliability of information as it becomes available, and

before it is communicated to public.

• Public health authorities will be consulted when issuing statements to the media concerning health

aspects of chemical accidents

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

• Members of the media are to facilitate response efforts by providing means for informing the public

with credible information about accidents involving hazardous substances

Role of health care authorities

• Hospitals and doctors must be ready to treat all type of injuries to causalities during emergency.

• Co-ordinate the activities of Primary Health Centres and Municipal Dispensaries to ensure required

quantities of drugs and equipment

• Securing assistance of medical and paramedical personnel from nearby hospitals/institutions

• Temporary mortuary and identification of dead bodies.

1.5 OCCUPATIONAL HEALTH AND SAFETY MEASURES

To control and minimize the risks at workplace, Haryana Liquors Pvt. Ltd. has implemented Health, Safety

and Environment Policy with the following objectives:

To prevent hazards

To provide safe and healthy environment to all the employees.

The company, therefore, has adopted the policy set below for the purpose of creating and maintaining safe

and healthy environment.

1.5.1 Occupational Health and Safety Hazards

(1) Dust

A) Risks involved

Following risks are involved:

• Presence of dust may cause respiratory disorders

• Systemic intoxications

B) Management Measures

• Implementation of adequate dust control systems and good housekeeping.

• Water sprinkling in the places where dust dispersion can occur.

• Regular sweeping of roads within plant premises

• Providing dust masks to employees working in handling and storage yards.

(2) Noise

A) Risks involved

Following risks are involved:

• Hearing Impairment, Hypertension, Increase Pulse rate

• Annoyance, Tinnitus, Sleep Disturbances

B) Management Measures

• Proper maintenance of machineries

• Installation of compressors and turbine in closed buildings

• Regular monitoring of noise level

• Display of noise level with permission level

• Display instruction to use of PPEs at high noise level area

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

• Periodic health checkup will be kept as audiometric records for the persons working in high noise

area.

(3) Heat stress

A) Risks involved

• Increase in core body temperature which leads to dehydration

• Increase in heart rate and muscle cramps

• Heat exhaustion

B) Management measures

• Monitor workers who are at risk of heat stress

• Provide rest periods with water breaks

• Use of personal protective equipment

(4) Electrical Hazards

A) Risks involved

• Electric Shock, Electric Burns, Fires and Explosions

B) Causes of Hazards

• Insulation Failure, Equipment Failure, Poor Maintenance.

• Wrong Work Methods, Substandard Material and workmanship

• Unauthorized personal & Lack of Training and Knowledge, etc.

C) Management Measures

• Proper earthing is being/will be done as per IS 3043

• Low Voltage Supply is being/will be ensured

• Isolating Transformers

• Double Insulated Tools

• Over Load Protection

• Protection Against Leakages (G.F.C.I.)

• Flame- Proof Equipment

• Lightning Protection

(5) Fire and Explosion

A) Risks involved

• Fire catching in store, bag godown, conveyors, oil storage area, fuel storage yard, transformers

etc.

B) Management Measures

• Suitable fire extinguisher, fire hydrant system and fire buckets. Dry power type in oil and fire

buckets are kept near transformer, cable, general store and office area. Fire tender is kept ready at

plant main gate.

• Oil and Flammable Gases storage area fenced and declared as Fire Hazardous Area-“No Smoking

Area”

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

• Permit and safety instruction to use welding / gas cutting in the area of oil storage, coal storage

and godown.

• Predictive interlock in transformers to give alarm and trip the system

• Adequate height of brick walls for separation of all transformers, soak pits for storage of oil

leakages from transformers

(6) Other Hazards

A) Risks involved

• Silo/tank and Buildings Collapse

• Slipped and fall from working at height

• Failure of lifting tools, tackles and pressure vessel

• Occupational injuries

• Hit by moving, flying or falling object

B) Management Measures

• Structural soundness of buildings

• Installation of light arrestors at all tall buildings

• Permit to work at height with work instruction to use safety belts etc.

• Testing of all lifting tools, tackles and pressure vessel.

• Safe working pressure is maintained in air receiver.

• Safe working load for cranes and ropes etc.

• Good housekeeping & Speed limit of 20 km/hr in plant area.

• Display of emergency number at all suitable location.

• Fire tender, ambulance and emergency staff ready at the plant main gate at all the time.

• First aid kits are kept at the sites and training provided.

• Use of mobile while driving, alcohol, smoking etc are ban in plant area.

• Proper illumination in office

1.5.2 Occupational Health Surveillance

In the plant, the occupational health surveillance of the employee is being/will be done on a regular basis

and records of the same are being/will be maintained as per the Factories Act. The occupational health

surveillance program will include/includes lung function; sputum analysis and audiometric analysis on regular

basis to observe any contraction due to exposure to dust and noise and corrective measures will be taken

accordingly.

Vocational training programs are being/will also be conducted. Under vocational training the workers are

being/will be given training related to all safety and health aspects pertaining to their vocation and thereafter

every quarter special training courses/ Awareness program for Malaria eradication, HIV and health effects on

exposure to dust, heat, noise, chemicals are being/will be organized for employed person.

Periodical medical camps with specialized doctors of various disciplines will also provide/provides the

specialized medical assistance to employees as well as neighboring communities.

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

A. Pre placement and periodical health status

Pre / Post-employment checkup will be carried out and following tests are being/will be conducted:

Chest X- rays

Audiometry

Spirometry

Vision testing (Far & near vision, color vision & other ocular effect)

ECG

Post-employment occupational health check-up such as lung function, audiometry, CBC, Blood

Sugar, Lipid Profile etc.

Medical records of each employee will be maintained separately and will be updated as per

finding during monitoring.

Medical records of the employee at the end of his / her term will be updated.

B. Frequency of medical examination

Once in a year

C. Personal protective devices and measures

Industrial Safety helmets, Crash helmets

Face shield

Goggles

Safety Shoes & Rubber Gumboots: Safety shoes are mandatory to be worn by all the employees

and rubber gumboots are being/will be provided to person who handles sulphuric acid. Full suit

having hand-gloves, goggles, helmet and aprons will be provided.

Face Shield Helmet: The people deputed for welding work are being/will be provided with face

shield helmet.

Ear muffs and Ear Plugs

Full body Safety harness

Leather hand gloves, Asbestos hand gloves, Electrical hand gloves, Heat Resistive hand gloves,

Chemical hand gloves and Cut resistance hand gloves

Safety net, Barricading net

Protective clothing, Dangari etc.

Safety belt / line man's safety belt

D. Details of Test conducted

Details of various test conducted of the working employees is done.

F. Anticipated occupational & safety hazards

Heat Stress and Stroke

Physical activity

Dehydration

Cardiovascular disease

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

Skin disorders

Dust Exposure

Metallic dust exposure

Noise

Burns and shocks due to electricity

1.5.3 Implementation of OHS standards as per OHSAS/USEPA

The overall objective of the company is to provide a system that is capable of delivering healthy and safe

workplace. Following measures have been adopted for implementation of OHS standards.

Well-equipped Occupational Health Centre with adequate paramedical staff

Routine and special investigation related to occupational health

Health surveillance and maintenance of health record

Rules and procedure for effective implementation of Safety Health and Environment policy and made

to know all employees

Round the clock Ambulance facility

Sufficient number of First aid boxes

Implementation of OHSAS 18001 for Occupational Health and Safety Management System

Formulation of OHS implementation team/ cell

Risk assessment of each and every activity

Implementation of OHS management program

Displaying the safety and health policy and instructions at various locations

Display of safe operating procedure (SOP) at various locations

Job safety analysis

Carry out daily plant safety inspection by internal safety department

Investigation of fatal, serious accidents and near miss accident

Investigation of reports of occupational diseases

Monthly safety meeting of all employees & workers to discuss last month accident if any, reason and

corrective measures taken.

Organize campaigns, competitions, contests etc. to promote safety

Organize safety training, seminars for safe working and safe vehicle and traffic movement within the

plant premises and regular training for safe driving outside the plant premises

Prepare annual reports of accidents and occupational diseases. Preparation and updating of Onsite

Emergency Plan and Liaison with external agencies and authorities

Ensure use of PPEs according to the job like helmet, safety shoes, goggle, dust mask, ear plug and

hand gloves etc.

Establishment of Occupational Health Centre for pre and periodic medical examination of workers and

staff to detect any onset of occupational disease and corrective manures

Display Material Safety Data Sheets (MSDS) for use of every hazardous substance

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

Implement the recommendations of HAZOP (A hazard and operability study) for examination of

problems in existing process / operation that may represent risks to personnel or equipment

Periodic Safety Audits both internal and external, review and implementation of recommendations

1.5.4 Safety Committee

A safety committee is formed and manned by equal participation from management and workers with the

following functions:

a) Accident prevention and control including ensuring the use of safety appliances.

b) Publicity, propaganda, education and training.

c) Assisting and cooperating with the management in achieving the aims and objectives outlined in the

“Health and Safety Policy” of the occupier.

d) Carrying out health and safety surveys for identifying unsafe working condition/practices, which

causes accident.

1.5.5 Medical Facilities

The company has/will be provided with occupational health centre functioning round the clock along with

the trained staff. The company has facility for ambulance for the workers. Tie up arrangements are/will be

there with nearest hospital and nursing home for the plant. First aid boxes are/will be kept in all identified

locations for emergency.

Apart from these, specialists will visit/visits the Plant to render consultation. Camps for immunization, family

planning, blood donation and free medical checkup programs are being/will be organized on regular basis

for employees as well as neighboring communities.

First Aid Boxes

First aid boxes have been/will be provided at prominent places with following items:

Small size sterilized dressing.

Medium size sterilized dressing.

Large size sterilized dressing.

Burnol Ointment.

Packets of sterilized cotton wool.

Bottle (120 ml) of cetramide solution (1%) of suitable antiseptic solution.

Mercurochrome solution (in 2% water).

Scissors.

Adhesive plaster (2cm x 1 m).

Sterilized eye pads in separate sealed packets.

Aspirin tablets.

Potassium Permanganate crystals.

First aid boxes are being/will be kept in every department for emergency. First aid training will be organized

for the employees.

Haryana Liquors Pvt. Ltd.

Expansion of Grain based Distillery from 165 KLPD to 465 KLPD by installation of new 300 KLPD Ethanol Plant & Co-Generation Power Plant from

3.3 to 13.5 MW

At Village Jundla, Tehsil Karnal, District Karnal, Haryana

Risk Assessment Report

1.6 PLAN & FUND ALLOCATION FOR OCCUPATIONAL HEALTH & SAFETY

Proposed budget details for expenditure on Occupational Health & Safety will be Rs 20 lakhs/annum.

Table: 5

Fund allocation for Occupational Health & Safety

Particular Amount (Lakhs)

Estimated Expenses on worker health checkup 6

Doctor fees & other facilities 14

Total Budget 20

1.7 CONCLUSION

It is concluded that there will be no major risk involved due to installation project. Proper precautionary

measures are being/ will be taken to minimize risks. Personal Protective Equipment (PPEs) will help to

minimize the health hazards and accidental casualties. So, it is safe to say that there will be no major risk

involved due to the installation project.

Haryana Liquors Pvt. Ltd.

You might also like

- Warehouse Security Method Statement SimonDocument7 pagesWarehouse Security Method Statement SimonNita JamnuNo ratings yet

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- Firoz IGCDocument19 pagesFiroz IGCErshad Akhtar80% (5)

- Emergency Response and Preparedness Plan: 1.4 Roles, Responsibilities and Authorities of ERTDocument2 pagesEmergency Response and Preparedness Plan: 1.4 Roles, Responsibilities and Authorities of ERTAisamuddin Rohaizai100% (2)

- Master Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDocument6 pagesMaster Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDaniel JulianNo ratings yet

- Emergency Preparedness Plan NewDocument22 pagesEmergency Preparedness Plan NewtriveshNo ratings yet

- Safety AwarenessDocument27 pagesSafety AwarenessSuraj JhaNo ratings yet

- Risk Assessment 2 PDFDocument15 pagesRisk Assessment 2 PDFarunNo ratings yet

- 01-3-Nature of Accident Process-Inherent SafetyDocument20 pages01-3-Nature of Accident Process-Inherent SafetyAstra BeckettNo ratings yet

- Chapter-Vii Additional StudiesDocument26 pagesChapter-Vii Additional StudiesOMSAINATH MPONLINENo ratings yet

- Risk AssessmentDocument17 pagesRisk Assessmentanaik406No ratings yet

- 000a.how We Work - Rev. 0Document36 pages000a.how We Work - Rev. 0sawkariqbalNo ratings yet

- Health, Safety & Environment: Understanding Oil and Gas BusinessDocument34 pagesHealth, Safety & Environment: Understanding Oil and Gas BusinessMadhur ChopraNo ratings yet

- OHS Risk Register-OldDocument24 pagesOHS Risk Register-OldMohamed Rizwan100% (1)

- Safety Hazards IdentificationDocument14 pagesSafety Hazards IdentificationXian GoNo ratings yet

- 2022 13 Hazard Identification and Risk ControlDocument8 pages2022 13 Hazard Identification and Risk ControlTatak Bay AhmedNo ratings yet

- Hazard DatabaseDocument1,193 pagesHazard Database1009 AMILINENI SUDHEER CHANDRANo ratings yet

- This Article Is Not Available in Other LanguagesDocument3 pagesThis Article Is Not Available in Other LanguagesMarvz BautistaNo ratings yet

- R. Bhattacharya Atomic Energy Regulatory BoardDocument23 pagesR. Bhattacharya Atomic Energy Regulatory BoardAnonymous YYsE1BxrNo ratings yet

- Hazard DatabaseDocument1,140 pagesHazard DatabaseVero ColladoNo ratings yet

- Confined Space Drager Risk AssessmentDocument8 pagesConfined Space Drager Risk AssessmentChandresh SinghNo ratings yet

- Risk Assessment Tank FarmDocument57 pagesRisk Assessment Tank FarmAwolayeofori TamunosakiNo ratings yet

- Chemical Process Safety For ChE 405-September 2019Document49 pagesChemical Process Safety For ChE 405-September 2019Tanjina Tarannum PrithulaNo ratings yet

- 09102018D2LZB87XRADocument32 pages09102018D2LZB87XRAABAYNEGETAHUN getahunNo ratings yet

- Jsa Trial Run of DGDocument3 pagesJsa Trial Run of DGDwitikrushna RoutNo ratings yet

- Where Incident Lead ToDocument5 pagesWhere Incident Lead ToANo ratings yet

- JSA For Limit Switch Checking & AdjustmentDocument3 pagesJSA For Limit Switch Checking & AdjustmentSwagata BeraNo ratings yet

- 6 Hailwood RomeDocument20 pages6 Hailwood RomeTanmay BabreNo ratings yet

- Hazard DatabaseDocument955 pagesHazard DatabaseMohd ObaidullahNo ratings yet