Professional Documents

Culture Documents

CE20 Installation of Crosby Clamps

CE20 Installation of Crosby Clamps

Uploaded by

Tafireyi Tevera0 ratings0% found this document useful (0 votes)

26 views3 pagesThis document provides safety procedures for using Crosby clamps on cranes at Zimasco (Pvt) Ltd's Shurugwi & Mining Division. It outlines hazards like worn tools, lifting gear, and heavy materials. It specifies required personal protective equipment like safety shoes, work suits, goggles, and gloves. The document describes maintenance and care responsibilities and step-by-step job procedures for fitters and riggers. It prohibits applying maximum tension before taking up slack and provides special precautions for proper clamp installation to avoid reducing the working load limit.

Original Description:

Original Title

CE20 Installation of crosby clamps

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides safety procedures for using Crosby clamps on cranes at Zimasco (Pvt) Ltd's Shurugwi & Mining Division. It outlines hazards like worn tools, lifting gear, and heavy materials. It specifies required personal protective equipment like safety shoes, work suits, goggles, and gloves. The document describes maintenance and care responsibilities and step-by-step job procedures for fitters and riggers. It prohibits applying maximum tension before taking up slack and provides special precautions for proper clamp installation to avoid reducing the working load limit.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

26 views3 pagesCE20 Installation of Crosby Clamps

CE20 Installation of Crosby Clamps

Uploaded by

Tafireyi TeveraThis document provides safety procedures for using Crosby clamps on cranes at Zimasco (Pvt) Ltd's Shurugwi & Mining Division. It outlines hazards like worn tools, lifting gear, and heavy materials. It specifies required personal protective equipment like safety shoes, work suits, goggles, and gloves. The document describes maintenance and care responsibilities and step-by-step job procedures for fitters and riggers. It prohibits applying maximum tension before taking up slack and provides special precautions for proper clamp installation to avoid reducing the working load limit.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 3

Safety, Health & Environmental Standards

Z IMASCO (Pvt) Ltd

Shurugwi & Mining Division

– Section 8.- 8.1.29

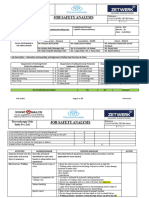

NOSA Element: Title: USE OF CROSBY CLAMPS ON CRANE, Procedure No.:

8.1.29 PROCEDURE CE 20

Intent: To ensure that this task is carried out safely in order to prevent injury to personnel

and damage to equipment.

Prepared By: R Jacobs, I Musiiwa, N Approved By: P.Maruta

Ngwenya, J Musungwa, and S Svoba Position: Maintenance Manager

(Occupational Health Officer) Issue Date: 03/08/23

Position: Mines Maintenance Foreman,

Fitter, Boiler maker, Boiler Maker Assist,

SHE Rep.

HOD Signature….

Application: This procedure applies to Mechanical and Electrical

Engineering

A. SPECIAL SKILLS REQURED

1 Knowledge on lifting equipment

B. MAN/JOB SPECIFICATION

1. Class 1 or Class 2 Fitter or Rigger

C. POSSIBLE HAZARDS AND RISKS

HAZARD RISK

1. Worn Tools Injury to personnel

2. Lifting gear Damage units or injure

personnel

3. Heavy Materials Damage units or injure

personnel

4. Covid-19 Human to human

contamination

D. PERSONAL PROTECTIVE EQUIPMENT (PPE) BODY PART PROTECTED

1. Safety shoes Toes and Feet

2. Work suit/ Overall (acid proof) Body

3. Goggles eye

4. Helmet Head

Revision No. Page 1 of 3

Effective Date 01/2021 09/2022

Safety, Health & Environmental Standards

Z IMASCO (Pvt) Ltd

Shurugwi & Mining Division

– Section 8.- 8.1.29

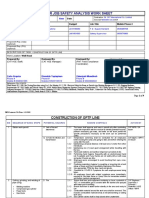

5. PVC Gloves Hands

6. Face mask Mouth and Nose

7. Sanitizer Hands

E MAINTENANCE AND CARE OF EQUIPMENT RESPONSIBILITY

1. Ensure wire rope is in good condition Fitter

2. Report any default immediately after they are Fitter

suspected.

F. JOB STEPS RESPONSIBILITY

LEVEL

1. Make sure clamps of the correct size have been Fitter/Rigger

selected

2. Cut off any unraveled or kinked portion of the wire

rope, make sure you tie the wire rope using serving

wire to keep the end tight.

2. Turn back specified length of wire rope from thimble Fitter/Rigger

(please refer tables given below). Put first clip one

saddle width from

seized “dead end”

3. Seat “live end” (load carrying) of the wire rope in Fitter/Rigger

saddle and position U-bolt over “dead end.”

Tighten nuts evenly to proper torque

4. Space the wire rope Crosby clamps equally and Fitter/Rigger

tighten the nuts

5. Alternate between the nuts to ensure even pressure. Fitter/Rigger

The use of a torque wrench will help to achieve the

recommended torque required for holding the load.

6. Be careful not to over-tighten the nuts as it can Fitter/Rigger

permanently kink the wire rope and lead to premature

failure.

7 Remove any slack in the cable between the clips by Fitter/Rigger

pushing the slack to the eye as you work your way

down tightening all the clips in the termination

G. PROHIBITIONS

1 Do not apply maximum tension to wire rope

assembly before you take up rope slack and

Revision No. Page 2 of 3

Effective Date 01/2021 09/2022

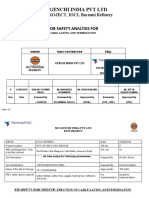

Safety, Health & Environmental Standards

Z IMASCO (Pvt) Ltd

Shurugwi & Mining Division

– Section 8.- 8.1.29

H. SPECIAL PRECAUTIONS

It is important to ensure wire rope Crosby clamps are

installed properly. Incorrect installation can reduce the

working load limit by 40%.

I. AUTHORITY, RESPONSIBILITY AND

ACCOUNTABILITY

1. Foreman/Charge hand

2. HOS of affected area

3. HOD

J REFERENCE

1. Mining (Management and Safety) Regulations, S1 109 of

1990

2. Mining (General) regulations, S1 247 of 1977

3. Factory and works (Machinery) S1 302 of 1976

4. Mining (Management and Safety) Regulations section 13

5. Equipment manual

6. NOSA Standards booklet

Revision No. Page 3 of 3

Effective Date 01/2021 09/2022

You might also like

- JHA For Plumbing and Piping TradesDocument84 pagesJHA For Plumbing and Piping TradesKhurram Iqbal100% (2)

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- Construction CompaniesDocument24 pagesConstruction Companiesmanup1980100% (1)

- SOP of Conveyor ReplacementDocument11 pagesSOP of Conveyor ReplacementDwitikrushna Rout100% (1)

- SOP of Idler ChangeDocument9 pagesSOP of Idler ChangeDwitikrushna RoutNo ratings yet

- Review of Measuring Methods and Results in Nonviscous Gas-Liquid Mass Transfer in Stirred VesselsDocument8 pagesReview of Measuring Methods and Results in Nonviscous Gas-Liquid Mass Transfer in Stirred VesselsAntonela PortaNo ratings yet

- Rohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkDocument3 pagesRohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkAbhaySngh100% (1)

- JHA Scaffolding ErectionDocument12 pagesJHA Scaffolding ErectionChayank TiwariNo ratings yet

- SOP of Bearing ChangeDocument9 pagesSOP of Bearing ChangeDwitikrushna Rout100% (4)

- JSA 06 - Towing-Rig MoveDocument6 pagesJSA 06 - Towing-Rig MoveHaldar Bishwajit100% (2)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocument5 pagesJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNo ratings yet

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisDocument3 pagesSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- Accounting and Finance For ManagersDocument322 pagesAccounting and Finance For ManagersPrasanna Aravindan100% (5)

- CE04 Replacing Light BulbsDocument3 pagesCE04 Replacing Light BulbsTafireyi TeveraNo ratings yet

- CE06 Use of Power SawDocument3 pagesCE06 Use of Power SawTafireyi TeveraNo ratings yet

- CE05 Working in A SubstationDocument4 pagesCE05 Working in A SubstationTafireyi TeveraNo ratings yet

- CE03 Hydraulic Testing of Pressure VesselsDocument5 pagesCE03 Hydraulic Testing of Pressure VesselsTafireyi TeveraNo ratings yet

- GVLNG Rum 49 Jha S 00001 - Rev 0 Jha Meter ProvingDocument3 pagesGVLNG Rum 49 Jha S 00001 - Rev 0 Jha Meter ProvingOparah BlessingNo ratings yet

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- Technical Notice ID S 3Document30 pagesTechnical Notice ID S 3sstalturascapitaldelejeNo ratings yet

- D020aa00 Id S. Descensor AutofrenanteDocument31 pagesD020aa00 Id S. Descensor AutofrenanteFerreteros ingenierosNo ratings yet

- 621-CC#09 Idler and Frame ChangingDocument4 pages621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- JSA Fire Fighting WorkDocument8 pagesJSA Fire Fighting WorkMehul KolambkarNo ratings yet

- 3. job-safety Sheet piling 钢板桩工作安全分析Document3 pages3. job-safety Sheet piling 钢板桩工作安全分析ADEN LIUNo ratings yet

- Welding and Cutting S O P 3FDocument14 pagesWelding and Cutting S O P 3Fyadavnitin000756No ratings yet

- 18 - Maintenance of Skip HoistDocument5 pages18 - Maintenance of Skip Hoistgiet11aei010No ratings yet

- 1-JHA - ExcavationDocument2 pages1-JHA - ExcavationAnna Marie Filipinas RajilNo ratings yet

- SOP of Conveyor Belt Re-JointingDocument9 pagesSOP of Conveyor Belt Re-JointingDwitikrushna RoutNo ratings yet

- 81 - Slab Tilting - ModDocument6 pages81 - Slab Tilting - Modjaikishangiri010No ratings yet

- Bha SMP T-11 - SdiDocument75 pagesBha SMP T-11 - SdiPutra NugrahaNo ratings yet

- Training Guidance - PPEDocument5 pagesTraining Guidance - PPEanon_691482227No ratings yet

- JSA GrinderAngleDocument2 pagesJSA GrinderAngleslamet_rNo ratings yet

- Section A Operation & Maintenance ManualDocument20 pagesSection A Operation & Maintenance ManualManh DoanNo ratings yet

- Duct InstallationDocument2 pagesDuct InstallationKrishna PatilNo ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- CDSP - JSA - Piling ActivityDocument9 pagesCDSP - JSA - Piling ActivitynrphsebarauniNo ratings yet

- 1 Hot Metal Tapping SOPDocument25 pages1 Hot Metal Tapping SOPSANJAY KUMAR PATINo ratings yet

- Technical Notice VERTEX 1Document16 pagesTechnical Notice VERTEX 1j.mejia07pNo ratings yet

- 001 - Personal Protective Equipment Rev-03Document5 pages001 - Personal Protective Equipment Rev-03Rooney SharonNo ratings yet

- SOP of Pump Changing JobDocument11 pagesSOP of Pump Changing JobDwitikrushna Rout100% (1)

- Q4 TLE AFA Horticulture 7 8 Week5Document4 pagesQ4 TLE AFA Horticulture 7 8 Week5myehuligangaNo ratings yet

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- HIRA Format (2) Structural WorkDocument9 pagesHIRA Format (2) Structural WorkR. Ayyanuperumal AyyanuperumalNo ratings yet

- JSA-Fabrication, AssemblyDocument19 pagesJSA-Fabrication, AssemblyAshfaq Husain AnsariNo ratings yet

- Power Tools JsaDocument1 pagePower Tools JsanabeelNo ratings yet

- JSA Shutdown 30Document10 pagesJSA Shutdown 30eeverpauldNo ratings yet

- Accident InvestigationDocument20 pagesAccident InvestigationdhazliNo ratings yet

- 11 Construction of Kill LineDocument9 pages11 Construction of Kill LinePangky AbasoloNo ratings yet

- 14 Construction of Optf LineDocument9 pages14 Construction of Optf LinePangky AbasoloNo ratings yet

- Instructions Hydraulic Table PressDocument26 pagesInstructions Hydraulic Table PressHanna HorváthNo ratings yet

- Jsa For Cable Laying & TermnationDocument7 pagesJsa For Cable Laying & Termnationsakthi venkat0% (1)

- M/S Arun Kumar Mitra: Job Hazard AnalysisDocument5 pagesM/S Arun Kumar Mitra: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Taws Recieving SotreDocument5 pagesTaws Recieving SotresahilNo ratings yet

- TM 9 2520 272 34 and PDocument729 pagesTM 9 2520 272 34 and P이동훈No ratings yet

- REBAR ActivitiesDocument3 pagesREBAR ActivitiesFrank NicodemusNo ratings yet

- AHA - Aluminum Windows Installation - 14-3-2019 Revie-2Document6 pagesAHA - Aluminum Windows Installation - 14-3-2019 Revie-2Eyal BabuNo ratings yet

- Jsa For PCCDocument6 pagesJsa For PCCCICON EngineersNo ratings yet

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- Cold Bonded Lagging Application ProcedureDocument17 pagesCold Bonded Lagging Application ProcedureMuhammad YanuarNo ratings yet

- SMP For Pullcord and BeltswayDocument2 pagesSMP For Pullcord and BeltswayROHIT SINGHNo ratings yet

- Garudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Document3 pagesGarudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Dwitikrushna Rout0% (1)

- DM-PH&SD-P4-TG08 - (Guidelines For Personal Protective Equipment-Head Protection)Document3 pagesDM-PH&SD-P4-TG08 - (Guidelines For Personal Protective Equipment-Head Protection)narma143No ratings yet

- solrad_ver12 solar energy calculations for anylatitude andlohhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjDocument120 pagessolrad_ver12 solar energy calculations for anylatitude andlohhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjBob HunkaNo ratings yet

- Contoh CV Resume Satu Muka SuratDocument2 pagesContoh CV Resume Satu Muka SuratAnnur SyuhadahNo ratings yet

- C-18 Dme-I-SemDocument94 pagesC-18 Dme-I-SemBollu SatyanarayanaNo ratings yet

- AnycubicSlicer - Usage Instructions - V1.0 - ENDocument16 pagesAnycubicSlicer - Usage Instructions - V1.0 - ENkokiNo ratings yet

- Chapter 6 Linear Regression Using Excel 2010-GOODDocument5 pagesChapter 6 Linear Regression Using Excel 2010-GOODS0% (1)

- Associated Labor Union v. BorromeoDocument2 pagesAssociated Labor Union v. BorromeoJaneen ZamudioNo ratings yet

- Family Profile: HusbandDocument6 pagesFamily Profile: HusbandFau Fau DheoboNo ratings yet

- ReticulateDocument35 pagesReticulateazure penguinNo ratings yet

- Harga Daikin ACDocument9 pagesHarga Daikin ACIlham CaisarNo ratings yet

- TAB Installation Instruction v1.1Document15 pagesTAB Installation Instruction v1.1vignesh. viswanathanNo ratings yet

- Diploma in Business: Assignment BriefDocument10 pagesDiploma in Business: Assignment Brief陈肇远No ratings yet

- PHD Pharma 23 IdDocument1 pagePHD Pharma 23 Idos krishnaNo ratings yet

- MFI 2 - Unit 3 - SB - L+SDocument10 pagesMFI 2 - Unit 3 - SB - L+SHoan HoàngNo ratings yet

- UK Terms Shell Collection Granny Square Pattern by Shelley Husband 2014Document5 pagesUK Terms Shell Collection Granny Square Pattern by Shelley Husband 2014Liz MatzNo ratings yet

- Portarlington Parish NewsletterDocument2 pagesPortarlington Parish NewsletterJohn HayesNo ratings yet

- Police RRDocument17 pagesPolice RRindrajitdhadhal400No ratings yet

- Explosion Proof HMI Solutions: For Use in Hazardous AreasDocument4 pagesExplosion Proof HMI Solutions: For Use in Hazardous Areaskutts76No ratings yet

- Openepi Sampel FixDocument7 pagesOpenepi Sampel FixainindyaNo ratings yet

- Bridget Wisnewski ResumeDocument2 pagesBridget Wisnewski Resumeapi-425692010No ratings yet

- The Secret SharerDocument3 pagesThe Secret ShareranbarasiNo ratings yet

- Property Still Be Your Pot of GoldDocument56 pagesProperty Still Be Your Pot of GoldNon FadNo ratings yet

- Reproductive and Child HealthDocument18 pagesReproductive and Child HealthSoumya BiswasNo ratings yet

- Frac Pack Offshore Sand ControlDocument15 pagesFrac Pack Offshore Sand ControlRamanamurthy PalliNo ratings yet

- 3.3.2.3 Lab - Configuring Rapid PVST, PortFast, and BPDU GuardDocument9 pages3.3.2.3 Lab - Configuring Rapid PVST, PortFast, and BPDU Guardsebastian ruiz100% (1)

- Cyber CrimeDocument366 pagesCyber CrimeRufino Gerard MorenoNo ratings yet

- Angew,. Chem. Int. Ed. Engl. 1993, 32, No. 9, 1306Document3 pagesAngew,. Chem. Int. Ed. Engl. 1993, 32, No. 9, 1306elderwanNo ratings yet

- 08 - Chapter 3 PDFDocument36 pages08 - Chapter 3 PDF1921 Vishwanath PakhareNo ratings yet