Professional Documents

Culture Documents

Specification PAD-V 2020 - Eng

Specification PAD-V 2020 - Eng

Uploaded by

Faycel AMAYRAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification PAD-V 2020 - Eng

Specification PAD-V 2020 - Eng

Uploaded by

Faycel AMAYRACopyright:

Available Formats

ADIABATIC COOLER

Design Features

PAD-V Series

ENERGY SAVING RELIABILITY

AND QUALITY

1

G 2

R E

A C

V A

3

I X

G

T I4

R

Y AG

A

W LR

V

A FA

5 IT AV

G T

E NI

R Y

R T

A W 6

D Y

V A

I W

7

IT A

S

G

T E T

T

R

Y R E

R

A

W D R

I

V

A IB D

IT S I

U

T

E T S

T

Y

R R T

I

W

D IO R

A

IB I

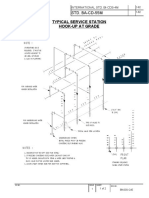

N Axial Fan Heavy Duty Adiabatic Cooler

T

S U B

E

T T Factory Assembled - Modular V-configuration Design

U

R I Motor(s) directly coupled with fan T

1 ECD

IO I

IB N O

2 Gravity water distribution

S

U N

3 HeatT exchange coils

R

I

4 PVC IO air inlet grids

B

N

U

5 Flocked PVC humidifier pack

T

6 Support

I structure

O

7 WaterN collection basin and recirculation circuit

8 Control Panel

MITA Cooling Technologies S.r.l.

Via del Benessere, 13 27010 Siziano (PV) – Italy

Ph. +39 0382 67599 - Fax +39 0382 617640

info@mitact.it

https://www.mitacoolingtechnologies.com/

ADIABATIC COOLER

Design Features

PAD-V Series

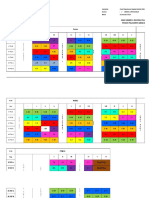

THEORY AND OPERATION OF ADIABATIC COOLING

The adiabatic process is a thermodynamic

transformation that occurs with no heat exchange

between bodies or fluids.

The cooling capacity of an adiabatic systems lies in

sensible heat exchange between a pre-cooled air

flow and the fluid inside coils. Adiabatic cooling

mechanism is based on mass transfer, between

water stored in the adiabatic pack and the air flow.

Relative humidity of air increases and its

temperature correspondently decreases, because

of latent heat absorbed by water during

evaporation.

The heat exchange itself occurs between

adiabatically cooled air and a process fluid, flowing

inside the heat exchange coils.

REGULATION STRATEGY AND ACCURATE SIZING

A sophisticated regulation strategy is the core

feature of PAD-V adiabatic cooler, with automatic

and tuneable switch between two operating modes:

Dry operation: provided during cold periods.

External air is drawn in and conveyed into the

finned coils. The humidification process is

deactivated, the system operates as a dry cooler,

with no water consumption.

Adiabatic operation: provided during hot periods.

External air is drawn in and forced through the

humidifier pack (protected inside the machine),

where decreases its temperature. Short wetting

cycles, with homogeneous distribution of water in

the pack, ensure the maximum air humidifying

efficiency.

The adiabatically cooled air is subsequently

conveyed to the finned coils. This wet mode

significantly increases the heat exchange efficiency

of the cooler in the hottest period of the year.

Wetting cycles consist of a large quantity of water

falling on the humidifier pack. The excess water is

recovered by means of a recirculation circuit, in

order to minimize water consumption.

The switch between the operating modes is

automatic and customizable, as operating

conditions are constantly controlled. Probes also

measure process water temperature and

regulate fan RPM in order to ensure optimized

operating costs.

MITA Cooling Technologies S.r.l.

Via del Benessere, 13 27010 Siziano (PV) – Italy

Ph. +39 0382 67599 - Fax +39 0382 617640

info@mitact.it

https://www.mitacoolingtechnologies.com/

ADIABATIC COOLER

Design Features

PAD-V Series

1. EC AXIAL FAN

Axial fan with electronic control is positioned

centrally with respect to the two V-shaped coils, for

homogeneous air distribution. Its rotation speed

decreases automatically during the wetting cycle, to

avoid dragging or aerosol.

ErP 2015 energy efficiency requirements compliant.

2. GRAVITY WATER DISTRIBUTION

Water distribution channel running on top of the

flocked pack is manufactured in stainless steel AISI

304. The wetting cycles are not operated with

spraying nozzles but by means of gravity

distribution, with easy access for cleaning.

Connecting and equalizing piping in PVC.

3. HEAT EXCHANGE COILS

Heat exchange coils arranged in a V layout inside

the cooler are made of copper pipes and aluminium

fins. Angle between coils, diameter of pipes,

thickness and pitch of fins are designed to ensure

the best heat exchange performance with suitable

fluid and airflow pressure drops.

MITA Cooling Technologies S.r.l.

Via del Benessere, 13 27010 Siziano (PV) – Italy

Ph. +39 0382 67599 - Fax +39 0382 617640

info@mitact.it

https://www.mitacoolingtechnologies.com/

ADIABATIC COOLER

Design Features

PAD-V Series

4. PVC AIR INLET GRIDS

PVC air Inlet grilles, for flocked pack protection: this

element avoids direct exposure to sunlight and

penetration of impurities. It can be removed to allow

access to the adiabatic packs and water collection

gutters.

5. FLOCKED PVC HUMIDIFIER PACK

Flocked PVC humidifier pack is designed to allow

operation with untreated water.

The flocked pack is made of synthetic material. As

opposed to other types of adiabatic packs, it is

characterized by longer life and superior shape

resistance. This element requires short wetting

cycles, spaced with long time intervals (a few

seconds every 15 minutes): pump power and water

consumption are optimized. At the same time, any

dragging or aerosol phenomenon outside the cooler

is avoided. The adiabatic pack is easily accessible

and removable for cleaning and maintenance

operations.

6. SUPPORT STRUCTURE

Support structure made of press-folded

galvanized metal sheets and subsequently

protected by a RAL 7032 epoxy paint cycle. The

structure is designed to properly support the heat

exchange coils.

MITA Cooling Technologies S.r.l.

Via del Benessere, 13 27010 Siziano (PV) – Italy

Ph. +39 0382 67599 - Fax +39 0382 617640

info@mitact.it

https://www.mitacoolingtechnologies.com/

ADIABATIC COOLER

Design Features

PAD-V Series

7. WATER COLLECTION GUTTERS AND WATER MAKE UP

Water collection gutters made of stainless steel

AISI 304. Water flows from the collection gutters to

a central tank, where submersible pump and

hydraulic connections (makeup, blowdown,

overflow, drain plug) are positioned.

Submersible pump is used for wetting water

recirculation, providing significant water savings.

Capacitive level sensors are adopted to control

water level in the gutters. When water goes below

the minimum limit level, the solenoid valve opens to

prevent pump cavitation.

Solenoid valve for the automatic water makeup

and blowdown.

8. CONTROL PANEL

Control Panel is connected to a HMI that allows

simple monitoring and setting of cooler’s parameter.

The communication with other devices is possible

with Modbus protocol.

Supply of the cooler is limited to the parts listed above. Building and electrical works, pumps, collectors external to the cooler, valves, hoisting gear and

any scaffolding and labour are therefore excluded. Accessories and/or constructional variants are available on request.

MITA Cooling Technologies S.r.l.. may carry out constructional improvements without notice.

Images for illustration purposes only.

MITA Cooling Technologies S.r.l.

Via del Benessere, 13 27010 Siziano (PV) – Italy

Ph. +39 0382 67599 - Fax +39 0382 617640

info@mitact.it

https://www.mitacoolingtechnologies.com/

You might also like

- RE4F03BDocument118 pagesRE4F03Bossoski100% (2)

- Calculate Cable Tray SizeDocument50 pagesCalculate Cable Tray Sizerushi_007100% (2)

- Hole Size Inches Casing Size Inches Depth Wellbore Diagram Type of FormationDocument1 pageHole Size Inches Casing Size Inches Depth Wellbore Diagram Type of FormationJuan Miguel RobledoNo ratings yet

- Product Catalog 2022Document114 pagesProduct Catalog 2022shetupucNo ratings yet

- Section - 08 - Service - Kits - May '09Document6 pagesSection - 08 - Service - Kits - May '09XG WNo ratings yet

- D UC AT IO NA: Project DataDocument13 pagesD UC AT IO NA: Project DatashoebNo ratings yet

- Bunting LU 2Document1 pageBunting LU 2adiNo ratings yet

- As - Copia-UnlockedDocument3 pagesAs - Copia-UnlockedJames McGillNo ratings yet

- FundatieDocument14 pagesFundatieralucaNo ratings yet

- Esb Coaster 1200 GT (S 0017 & S 0018)Document34 pagesEsb Coaster 1200 GT (S 0017 & S 0018)Dita Ndudtz0% (1)

- Indian Stock MarketDocument37 pagesIndian Stock MarketheroNo ratings yet

- N Type: Hydraulic Power PacksDocument1 pageN Type: Hydraulic Power Packsvasanth kumarNo ratings yet

- L VE R IO N ID EA: Project DataDocument15 pagesL VE R IO N ID EA: Project DatashoebNo ratings yet

- STEINERT Business Unit BrochureDocument16 pagesSTEINERT Business Unit Brochurekaniappan sakthivelNo ratings yet

- Animated Electrical Wiring of The Enigma MachineDocument1 pageAnimated Electrical Wiring of The Enigma MachineRalph SimpsonNo ratings yet

- Curtain Plans SchematicsDocument3 pagesCurtain Plans SchematicsdaekwonparkNo ratings yet

- Connection Purlin-UnlockedDocument6 pagesConnection Purlin-UnlockedSuman Resolved NeupaneNo ratings yet

- RS IO N: Project DataDocument13 pagesRS IO N: Project DatashoebNo ratings yet

- Westinghouse Manuals PDFDocument38 pagesWestinghouse Manuals PDFCarl HensonNo ratings yet

- Copy Lista Incasari TURCANU 03.11.2023Document2 pagesCopy Lista Incasari TURCANU 03.11.2023Turcanu AdrianNo ratings yet

- S Ta Tic A Ed Uc at Io Na L Ve: Project DataDocument9 pagesS Ta Tic A Ed Uc at Io Na L Ve: Project DataVladimirNo ratings yet

- Samsung Chassis S66ADocument18 pagesSamsung Chassis S66AНиколай ПолNo ratings yet

- Typical Service Station Hook-Up at Grade: STD. BA-CD-55MDocument2 pagesTypical Service Station Hook-Up at Grade: STD. BA-CD-55MtechnicalNo ratings yet

- Enrolmentno.:0649/50242/00 222: A L P A R A A S S A M - 7 8 3 1 0 1 6 0 0 3 1 3 7 1 1 8Document2 pagesEnrolmentno.:0649/50242/00 222: A L P A R A A S S A M - 7 8 3 1 0 1 6 0 0 3 1 3 7 1 1 8Lynn DunnNo ratings yet

- June 30, 2009: Es DiDocument1 pageJune 30, 2009: Es DiEquality Case FilesNo ratings yet

- M Pac II™ 2-To 5-Ton Vertical Wall Mount Air Conditioners: General DescriptionDocument8 pagesM Pac II™ 2-To 5-Ton Vertical Wall Mount Air Conditioners: General DescriptionbbeisslerNo ratings yet

- Exam Sheet For Students (Fine Arts)Document1 pageExam Sheet For Students (Fine Arts)Merabo SimonishviliNo ratings yet

- Calling Line Identification Receiver: FeaturesDocument10 pagesCalling Line Identification Receiver: FeaturesEDERTREVISANNo ratings yet

- Answer Sheet - MODULE 4: Midterm Assessment ActivitiesDocument1 pageAnswer Sheet - MODULE 4: Midterm Assessment ActivitiesAnaximander MiletusNo ratings yet

- V Er Ea S Ta Tic A T N Id Ea S: Project DataDocument15 pagesV Er Ea S Ta Tic A T N Id Ea S: Project DataUjwal KhandokarNo ratings yet

- V H V T H T K K A Ii B T FDocument43 pagesV H V T H T K K A Ii B T FEduardo LozanoNo ratings yet

- IEEMA Transformer Protection FigsDocument8 pagesIEEMA Transformer Protection Figsardianto hamonanganNo ratings yet

- Tau Planters CatalogDocument25 pagesTau Planters CatalogSantosh BastolaNo ratings yet

- Es Di: Grant EDDocument1 pageEs Di: Grant EDEquality Case FilesNo ratings yet

- SMK Negeri 1 Rantau Pulung TAHUN PELAJARAN 2018/2019 Senin SelasaDocument14 pagesSMK Negeri 1 Rantau Pulung TAHUN PELAJARAN 2018/2019 Senin SelasaAnonymous jEvePfNo ratings yet

- Actividad de Aprendizaje 5: Dalmiro Alberto Terán MuñozDocument9 pagesActividad de Aprendizaje 5: Dalmiro Alberto Terán MuñozDalmiro Alberto Teran MuñozNo ratings yet

- NO Sket/Lokasi: Daftar Ukuran Pipa-Pipa Yang Harus Diganti Baru Mt. Minas / P.35 Main Pipe Branch Pipe FittingDocument5 pagesNO Sket/Lokasi: Daftar Ukuran Pipa-Pipa Yang Harus Diganti Baru Mt. Minas / P.35 Main Pipe Branch Pipe FittingDhabierzt JiehNo ratings yet

- DC Circuit Notes O LevelDocument6 pagesDC Circuit Notes O Levelaliayanraza5No ratings yet

- Flight Airworthiness Support Technology: December 2007Document23 pagesFlight Airworthiness Support Technology: December 2007Jason JiaNo ratings yet

- Nota Ops - 20240320 - 0001Document4 pagesNota Ops - 20240320 - 0001Fenty BerlianaNo ratings yet

- June 30, 2009: Es DiDocument1 pageJune 30, 2009: Es DiEquality Case FilesNo ratings yet

- PC Core EstorilDocument44 pagesPC Core Estorilsafa.ismail.safaNo ratings yet

- 04-Welcome Home SanitariumDocument1 page04-Welcome Home SanitariumPedro Miguel DiasNo ratings yet

- Workshop: Getting Started As A TranslatorDocument8 pagesWorkshop: Getting Started As A TranslatorTatiana Garrido SuarrezNo ratings yet

- Earthquake and Faults QuizDocument1 pageEarthquake and Faults QuizMARISTELA MACARANASNo ratings yet

- NO Sket/Lokasi: Daftar Ukuran Pipa-Pipa Yang Harus Diganti Baru Mt. Minas / P.35 Main Pipe Branch Pipe FittingDocument8 pagesNO Sket/Lokasi: Daftar Ukuran Pipa-Pipa Yang Harus Diganti Baru Mt. Minas / P.35 Main Pipe Branch Pipe FittingDhabierzt JiehNo ratings yet

- SCADA TrainingDocument53 pagesSCADA TrainingCojjo XenonNo ratings yet

- 2019.01.08 Indian Creek - Public Input - DraftDocument15 pages2019.01.08 Indian Creek - Public Input - DraftarlNo ratings yet

- TOPIC 9 ElectricalDocument13 pagesTOPIC 9 ElectricalVLADIMIR VERA VELARDE100% (1)

- AHW3e - Level 1 - U09 - PCMDocument1 pageAHW3e - Level 1 - U09 - PCMMarcelo Baldin NodariNo ratings yet

- V H V T H T K K A Ii B T FDocument35 pagesV H V T H T K K A Ii B T FEduardo LozanoNo ratings yet

- Part Number Paking Set D65E-6Document85 pagesPart Number Paking Set D65E-6Dede R KurniawanNo ratings yet

- Evidencia 5 BilinguismoDocument8 pagesEvidencia 5 BilinguismoValentina JimenezNo ratings yet

- E-Collateral - Row House Phase 2Document5 pagesE-Collateral - Row House Phase 2sushil aroraNo ratings yet

- E-02 Diagrama Unifilar Td-A, TD-B, TD-CDocument1 pageE-02 Diagrama Unifilar Td-A, TD-B, TD-COswaldo Fonseca RuedaNo ratings yet

- WS-Profit-loss and DiscountDocument6 pagesWS-Profit-loss and DiscountSoma Roy BoraiNo ratings yet

- Mep Coordination Procedure ManualDocument31 pagesMep Coordination Procedure Manualpadmasree2002No ratings yet

- Summary of Grades (First Quarter) : IE NC EDocument8 pagesSummary of Grades (First Quarter) : IE NC ECristelyne Cheyenne FiedacanNo ratings yet

- Answers Key Crosswords 3.4Document1 pageAnswers Key Crosswords 3.4XDMissShayXD -No ratings yet

- ES7 CHAP Ka5Document1 pageES7 CHAP Ka5phuongdiepNo ratings yet

- Shanghai Sollant CatalogDocument30 pagesShanghai Sollant CatalogFaycel AMAYRANo ratings yet

- Is 10990 2 1992Document16 pagesIs 10990 2 1992Faycel AMAYRANo ratings yet

- Oil Free Series Air Compressor Xa&g Series 3.7KW 375KWDocument12 pagesOil Free Series Air Compressor Xa&g Series 3.7KW 375KWFaycel AMAYRANo ratings yet

- Table 29 Maintenance and InspectionDocument3 pagesTable 29 Maintenance and InspectionFaycel AMAYRANo ratings yet

- YorkDocument1 pageYorkFaycel AMAYRANo ratings yet

- AVI39441-01-160101 - Ind 0Document37 pagesAVI39441-01-160101 - Ind 0Faycel AMAYRA100% (1)

- 450 32.5 KUBOTA GAS: VENDOR: Woods SECTION: Figure Listing Diagram: Kubota Engine Cooling SystemDocument3 pages450 32.5 KUBOTA GAS: VENDOR: Woods SECTION: Figure Listing Diagram: Kubota Engine Cooling SystemFaycel AMAYRANo ratings yet

- NS and NSX - Zs ValuesDocument5 pagesNS and NSX - Zs ValuesmostafabasionyNo ratings yet

- Name - Prem Kumar Sharma U. ROLL - 10800717065 (A2) Dept.-Mechanical Engg. Year - 3 Section - A S.CODE - ME 694 Subject-Dynamics of Machine LABDocument5 pagesName - Prem Kumar Sharma U. ROLL - 10800717065 (A2) Dept.-Mechanical Engg. Year - 3 Section - A S.CODE - ME 694 Subject-Dynamics of Machine LABPrem sharmaNo ratings yet

- Practical No. 2Document3 pagesPractical No. 2ZAIN UL ABIDENNo ratings yet

- Module 2Document20 pagesModule 2Jamie FederizoNo ratings yet

- Power System Chapter-1Document70 pagesPower System Chapter-1abdul hadi psNo ratings yet

- Time Overcurrent Relays: General Electr1CDocument16 pagesTime Overcurrent Relays: General Electr1Calex pardoNo ratings yet

- Study Material Chemistry-1 PDFDocument340 pagesStudy Material Chemistry-1 PDFYash ShrivastavaNo ratings yet

- Nits AND Easurement: Hapter WODocument23 pagesNits AND Easurement: Hapter WOFelipeNo ratings yet

- Current Electricity - Answer KeyDocument8 pagesCurrent Electricity - Answer KeyADITYA SINGHNo ratings yet

- Lab ReportDocument8 pagesLab ReportMuhammad Faizan TariqNo ratings yet

- Processes: An Investigation of Heat Transfer Performance in An Agitated VesselDocument18 pagesProcesses: An Investigation of Heat Transfer Performance in An Agitated VesselFederico CaloNo ratings yet

- Helmholtz ResonanceDocument9 pagesHelmholtz ResonanceDewi Ummu ZubairNo ratings yet

- BS4 End TermDocument2 pagesBS4 End TermShubham SinghNo ratings yet

- Exam 2012 PDFDocument12 pagesExam 2012 PDFYuChenQianNo ratings yet

- Basics of Heat Transfer: 1.1 Difference Between Heat and TemperatureDocument5 pagesBasics of Heat Transfer: 1.1 Difference Between Heat and TemperatureVivek MishraNo ratings yet

- US4661747Document7 pagesUS4661747Lee FarrandNo ratings yet

- How Do You Calculate BMIDocument1 pageHow Do You Calculate BMIzelenobijelaNo ratings yet

- 07-Electromagnetic WaveDocument48 pages07-Electromagnetic WaveRithish BarathNo ratings yet

- Lab - 4 - Running Kinematics Part I - Spring 2019Document5 pagesLab - 4 - Running Kinematics Part I - Spring 2019markNo ratings yet

- Questions On Unit I (Basics of Electromagnetics)Document2 pagesQuestions On Unit I (Basics of Electromagnetics)Thota Venkata Lakshmi Manasa 22120487101No ratings yet

- Tut 3 - BalancingDocument3 pagesTut 3 - Balancinglittleprince889No ratings yet

- Phys 242 Note SRDocument69 pagesPhys 242 Note SROwen ZhaoNo ratings yet

- 11 - 135 TOP Transformers - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsDocument15 pages11 - 135 TOP Transformers - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsHussam Gujjar100% (2)

- P3, LED Lights Installation, CO2 Reduction ReportDocument1 pageP3, LED Lights Installation, CO2 Reduction ReportSikandar KhanNo ratings yet

- Ics U1 QBDocument31 pagesIcs U1 QB19951A0337 KOTHAPALLI PRANAY TEJANo ratings yet

- Pump Sizing With ExercisesDocument25 pagesPump Sizing With ExercisesAkilaJosephNo ratings yet

- Automotive Battery ServicingDocument24 pagesAutomotive Battery ServicingEmmanuel Lucena100% (1)

- CablesDocument29 pagesCablesbimaNo ratings yet