Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

14 viewsPatente TSP Us 2

Patente TSP Us 2

Uploaded by

Janaina1) The document describes a method for producing triple superphosphate fertilizer.

2) It involves mixing ground phosphate rock with concentrated phosphoric acid, which allows the mixture to harden into pellets quickly without drying, avoiding costly and unhealthy processes used previously.

3) The method uses coarsely ground phosphate rock and concentrated acid, making it less expensive than conventional methods while producing a dry, dust-free pelleted product.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- SSS 2 E-Note 3rd Term ChemistryDocument61 pagesSSS 2 E-Note 3rd Term ChemistryDave Blessed83% (6)

- O&M ManualDocument255 pagesO&M ManualSanjeev Kumar DasNo ratings yet

- United States Patent (191: Macdonald 145) Feb. 25, 1975Document4 pagesUnited States Patent (191: Macdonald 145) Feb. 25, 1975Javier Alejandro Rodriguez MelgozaNo ratings yet

- Afault and 4-Motov: March 13, 1962 B. C. Bigot 3,025,152Document4 pagesAfault and 4-Motov: March 13, 1962 B. C. Bigot 3,025,152Dikul BrahmbhattNo ratings yet

- Lecture 35 PDFDocument8 pagesLecture 35 PDFabderrahimn100% (1)

- Processing Phosphates For Use in The Fertilizer IndustryDocument4 pagesProcessing Phosphates For Use in The Fertilizer IndustrydzungNo ratings yet

- Paten Sulfur Mixer PDFDocument7 pagesPaten Sulfur Mixer PDFLily DianaNo ratings yet

- Us 4501724Document7 pagesUs 4501724DARWIN STALIN ALCACIEGA PILCONo ratings yet

- Phosphate Fertilizer Plants: Industry Description and PracticesDocument4 pagesPhosphate Fertilizer Plants: Industry Description and PracticesGbl BplNo ratings yet

- United States Patent Office: Patented Nov. 5, 1966Document6 pagesUnited States Patent Office: Patented Nov. 5, 1966Alexander Franco CastrillonNo ratings yet

- Us 2179174Document5 pagesUs 2179174Pat22 22patNo ratings yet

- SSPDocument11 pagesSSPMuhammad AmjadNo ratings yet

- Unite Sites Fret (19) : DahlinDocument3 pagesUnite Sites Fret (19) : Dahlintrinh xuan hiepNo ratings yet

- The Phosphates Processing Handbook PDFDocument29 pagesThe Phosphates Processing Handbook PDFJulian CadenaNo ratings yet

- History of Fluorine Recovery ProcessesDocument21 pagesHistory of Fluorine Recovery ProcessesFajar Zona100% (1)

- United States Patent Office.: This Invention Is Based Upon The DiscovDocument2 pagesUnited States Patent Office.: This Invention Is Based Upon The Discovchoi yoojungNo ratings yet

- United States Patent Office: Tion, It Will Be Understood To Have Been Calculated AsDocument2 pagesUnited States Patent Office: Tion, It Will Be Understood To Have Been Calculated Asthan zawNo ratings yet

- US4610862Document6 pagesUS4610862محمد عليNo ratings yet

- Other Phosphate Fertilizers - Part 1: Enriched SuperphosphateDocument10 pagesOther Phosphate Fertilizers - Part 1: Enriched SuperphosphatetegararazaqNo ratings yet

- History of Fluorine Recovery ProcessesDocument21 pagesHistory of Fluorine Recovery ProcessesmahaNo ratings yet

- US3416887Document6 pagesUS3416887khairulNo ratings yet

- J. N. CarothersDocument4 pagesJ. N. CarothershaviedNo ratings yet

- Articulo Patente 4Document4 pagesArticulo Patente 4AgentesteveNo ratings yet

- United States Patent ToDocument8 pagesUnited States Patent ToAwat MuhammadNo ratings yet

- United States: Patent OfficeDocument3 pagesUnited States: Patent OfficefredyNo ratings yet

- United States Patent Office: 2 Claims. (CI. 71-29)Document2 pagesUnited States Patent Office: 2 Claims. (CI. 71-29)Fernando Nieto OchoaNo ratings yet

- Int4D Ustrlal: and Engineering ChemistryDocument11 pagesInt4D Ustrlal: and Engineering Chemistryاحمد الدلالNo ratings yet

- Triple Superphosphate PDFDocument6 pagesTriple Superphosphate PDFsukhmaniNo ratings yet

- US3936501Document3 pagesUS3936501qaim abbasNo ratings yet

- Process For The Production of Sucrose Esters of Fatty AcidsDocument5 pagesProcess For The Production of Sucrose Esters of Fatty AcidsHarry CortezNo ratings yet

- PhosphaticDocument35 pagesPhosphaticSafyan ManzoorNo ratings yet

- 2000 Ifa Neworleans GobbitDocument14 pages2000 Ifa Neworleans GobbitFajar ZonaNo ratings yet

- Phosphate Beneficiation Process - Mineral Processing - MetallurgyDocument13 pagesPhosphate Beneficiation Process - Mineral Processing - MetallurgyTulika PaulNo ratings yet

- III Sem ICTDocument56 pagesIII Sem ICToctoviancletusNo ratings yet

- Pilot-Plant Development Ofthe Foam Distribution Process For Production OF Wet-Process PhosphoricDocument5 pagesPilot-Plant Development Ofthe Foam Distribution Process For Production OF Wet-Process PhosphoricIngrid ContrerasNo ratings yet

- Us 2427642Document2 pagesUs 2427642SatyamSahuNo ratings yet

- III Sem ICTDocument20 pagesIII Sem ICToctoviancletusNo ratings yet

- Guy H BuchananDocument4 pagesGuy H BuchananVizzy VishalNo ratings yet

- United States Patent (19) : Story Et AlDocument14 pagesUnited States Patent (19) : Story Et Alahmed khaledNo ratings yet

- Under The Guidance Of: Project Report On P Neutralisation of Gypsum in Phosphoric Acid PlantDocument18 pagesUnder The Guidance Of: Project Report On P Neutralisation of Gypsum in Phosphoric Acid PlantsurendraNo ratings yet

- Fosfato Simple 2Document4 pagesFosfato Simple 2Jose CortezNo ratings yet

- Us4643848 Fumaric RosinDocument5 pagesUs4643848 Fumaric RosinPudien MuhamadNo ratings yet

- Es Patent Office IDocument7 pagesEs Patent Office IShandy ArmandoNo ratings yet

- Inorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyDocument37 pagesInorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyMohamed AbdelaalNo ratings yet

- By 22-Le: April 8, 1969 J. S. Sproul Etal 3,437,434Document6 pagesBy 22-Le: April 8, 1969 J. S. Sproul Etal 3,437,434Cris AcevedoNo ratings yet

- Us 4315763Document11 pagesUs 4315763Thusith WijayawardenaNo ratings yet

- US3689216Document5 pagesUS3689216PABLO URIZ CEREZONo ratings yet

- Removal of Fluorine From Wet Process Phosphoric AcidDocument2 pagesRemoval of Fluorine From Wet Process Phosphoric AcidAdios ANo ratings yet

- Becker Pierre. - Phosphates and Phosphoric Acid - Raw Materials, Technology and Economics of The Wet Process. 1983Document301 pagesBecker Pierre. - Phosphates and Phosphoric Acid - Raw Materials, Technology and Economics of The Wet Process. 1983احمد العنزيNo ratings yet

- The FEECO Phosphates Processing HandbookDocument33 pagesThe FEECO Phosphates Processing HandbookThe EAKNo ratings yet

- Us 2600253Document5 pagesUs 2600253Michael Kang'eriNo ratings yet

- SuperphosphateDocument12 pagesSuperphosphateSusbsisvNo ratings yet

- High Performance Oilfield Scale InhibitorsDocument27 pagesHigh Performance Oilfield Scale InhibitorsRégis OngolloNo ratings yet

- Process For Producing Granular Triple Superphosphate: F. DunbarDocument5 pagesProcess For Producing Granular Triple Superphosphate: F. DunbarOscar SobradosNo ratings yet

- 21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8Document14 pages21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8kaldjdsjkaNo ratings yet

- Us4117092 Phosphoric Acid Recovery by Solvent ExtractionDocument5 pagesUs4117092 Phosphoric Acid Recovery by Solvent ExtractionM.zuhair asifNo ratings yet

- H3PO4Document23 pagesH3PO4Leo Edrik Cortez VidalNo ratings yet

- US3347627Document3 pagesUS3347627Nuttapong JongjitsatitmunNo ratings yet

- United States Patent (19) : PistoriusDocument5 pagesUnited States Patent (19) : Pistoriusmasood kblNo ratings yet

- Sulphuric AcidDocument9 pagesSulphuric AcidHasnat AhmadNo ratings yet

- Farm Gardening with Hints on Cheap Manuring: Quick Cash Crops and How to Grow ThemFrom EverandFarm Gardening with Hints on Cheap Manuring: Quick Cash Crops and How to Grow ThemNo ratings yet

- The Handbook of Soap ManufactureFrom EverandThe Handbook of Soap ManufactureRating: 3 out of 5 stars3/5 (1)

- Processes 11 01753Document25 pagesProcesses 11 01753JanainaNo ratings yet

- Phosphoric Acid AspenDocument14 pagesPhosphoric Acid AspenJanaina0% (1)

- The Treatment of Waste Gas From Fertilizer Production - An Industrial CaseDocument10 pagesThe Treatment of Waste Gas From Fertilizer Production - An Industrial CaseJanainaNo ratings yet

- MAP ReferenciaDocument4 pagesMAP ReferenciaJanainaNo ratings yet

- MT1 BiomesDocument20 pagesMT1 BiomesBaby Hazel RamirezNo ratings yet

- MENA Reference MBR Durrat Al BahreinDocument2 pagesMENA Reference MBR Durrat Al BahreinNermeen ElmelegaeNo ratings yet

- Solar StillDocument18 pagesSolar StillJORDAN MALLARINo ratings yet

- Ostenberg RossDocument24 pagesOstenberg RossidigitiNo ratings yet

- P1 88thminutesDocument42 pagesP1 88thminutesVaishnavi JayakumarNo ratings yet

- Research ArticleDocument14 pagesResearch Articlemouka ayiwouoNo ratings yet

- BELLARY HydrologyDocument32 pagesBELLARY HydrologyAshrithNo ratings yet

- Science 3 Q4Document107 pagesScience 3 Q4anon_38051274100% (2)

- UntitledDocument19 pagesUntitledResti PNo ratings yet

- 11 Preservation: Rabab Harweel Power PlantDocument10 pages11 Preservation: Rabab Harweel Power PlantPazhamalairajan KaliyaperumalNo ratings yet

- Steam Utilization in Textile IndustryDocument7 pagesSteam Utilization in Textile IndustryMuddaser83% (6)

- EPA 245.5 HGDocument4 pagesEPA 245.5 HGAarón CespedesNo ratings yet

- Guide To Condensate Polishing - DOWDocument10 pagesGuide To Condensate Polishing - DOWxlxjrv100% (1)

- 8 Good GovernanceDocument4 pages8 Good GovernanceEmilio TaddeiNo ratings yet

- Construction Steps of BuildingDocument5 pagesConstruction Steps of BuildingRK DanishNo ratings yet

- Test Bank For Chemistry For Today General Organic and Biochemistry 8th EditionDocument12 pagesTest Bank For Chemistry For Today General Organic and Biochemistry 8th Editionkristopherpughaqckewzsbr100% (36)

- Soalan 3 The Destruction of The World's Forests Is Inevitable As Our Need For Land and Food GrowsDocument2 pagesSoalan 3 The Destruction of The World's Forests Is Inevitable As Our Need For Land and Food GrowscikgucinaNo ratings yet

- 280 PDFDocument16 pages280 PDFVENKATESHNo ratings yet

- Atlas Группа Izohan Каталог Продуктов Битумные МассыDocument12 pagesAtlas Группа Izohan Каталог Продуктов Битумные Массыtoms4No ratings yet

- Desuperheater Online Program Sizing GuidanceDocument12 pagesDesuperheater Online Program Sizing GuidancebadesharamkNo ratings yet

- Compilation of Plates For Building DesignDocument26 pagesCompilation of Plates For Building DesignAldrin OrigenesNo ratings yet

- Aijn Hygiene CodeDocument53 pagesAijn Hygiene CodeAnilZapateNo ratings yet

- Mining, The Santurban Moor CaseDocument5 pagesMining, The Santurban Moor Caselacoalicionpetrolera100% (1)

- Production of Formaldehyde From MethanolDocument13 pagesProduction of Formaldehyde From MethanolAugusto Mohr Christmann100% (1)

- Waterstops PDFDocument26 pagesWaterstops PDFjmusopoleNo ratings yet

- WQI of River Netravati Using Fuzzy Inference SystemDocument94 pagesWQI of River Netravati Using Fuzzy Inference SystemPRETTY MARYNo ratings yet

- Beaver Lodge Construction Squad - Attenborough - BBC Earth - English (AutoDocument4 pagesBeaver Lodge Construction Squad - Attenborough - BBC Earth - English (AutoAshok KumarNo ratings yet

- Manual Wesen Inox FlatDocument14 pagesManual Wesen Inox FlatRoberto Rodriguez BouzoNo ratings yet

Patente TSP Us 2

Patente TSP Us 2

Uploaded by

Janaina0 ratings0% found this document useful (0 votes)

14 views5 pages1) The document describes a method for producing triple superphosphate fertilizer.

2) It involves mixing ground phosphate rock with concentrated phosphoric acid, which allows the mixture to harden into pellets quickly without drying, avoiding costly and unhealthy processes used previously.

3) The method uses coarsely ground phosphate rock and concentrated acid, making it less expensive than conventional methods while producing a dry, dust-free pelleted product.

Original Description:

Original Title

PATENTE TSP US 2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document describes a method for producing triple superphosphate fertilizer.

2) It involves mixing ground phosphate rock with concentrated phosphoric acid, which allows the mixture to harden into pellets quickly without drying, avoiding costly and unhealthy processes used previously.

3) The method uses coarsely ground phosphate rock and concentrated acid, making it less expensive than conventional methods while producing a dry, dust-free pelleted product.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views5 pagesPatente TSP Us 2

Patente TSP Us 2

Uploaded by

Janaina1) The document describes a method for producing triple superphosphate fertilizer.

2) It involves mixing ground phosphate rock with concentrated phosphoric acid, which allows the mixture to harden into pellets quickly without drying, avoiding costly and unhealthy processes used previously.

3) The method uses coarsely ground phosphate rock and concentrated acid, making it less expensive than conventional methods while producing a dry, dust-free pelleted product.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

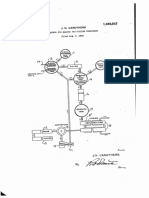

United States Patent Office 2,740,115

Eaterated War. 27, 1956

2,748,115 2

Baumé since if a more ccacentrated acid is employed

METHODS OF PRODUCING TRPLE the mass sets so quickly that it cannot be handled. As

SUPERSPEBSPEACE the result of the conventional operation an extremely

Leroy Henry Facer, Phelps, N. Y., assigno, by mesne moist product results which is not self-drying. After a

5 cure of several days in a large pile this mass is still wet and

assignments, to Glen E. Cooley, Schenectady, N. Y.,

Warren Dungara Foster, Ridgewood, N.J., Halfdan must be kiln dried preferably under continuous agita

Gregersen, New York, N. Y., Magazis . Gregersen, tion. This period of cure is necessary because of the slow

Englewood, N.J., and Dasia S. Lara, New York, N.Y.,

trustees action of a weak acid, its moisture is reduced to 2%

or less and the dry mass which results is composed of

No Drawing. Original application July 9, 1942, Serial O hard lumps of various sizes which thereupon must be

No. 456,324. Divided agad his application April 19, crushed and ground. This dry product creates a large

1951, Serial No. 22,931 amount of irritating dust which is so harmful to all who

7 (Clairs. (C. 7-4) have to handle it in mass that respirators or gas masks

must be continuously used and even so unless precau

As is well known to the practitioners of the fertilizer tions are continuously observed much damage to health

art, the three major products of importance in any com results.

plete or mixed fertilizer are nitrogen (N), phosphorus According to the principles set out in my parent ap

(P205), and potash (K2O). The material most widely plication by the use of phosphoric acid more concentrated

used as a source of phosphates, either in a mixed fer than that used in the prior art I am able to make a triple

tilizer or alone, is superphosphate. Superphosphate gen 20 superphosphate of an unusually high degree of avail

erally is made by treating ground phosphate rock with ability and water-extractability without kiln or other

sulphuric or other strong mineral acid in order to con artificial drying. I completely dispense with all of the

vert the phosphate in the rock, which is in a form in expensive specialized apparatus and processes which oth

which it cannot

it can be so used.

be used by the piant, to a form in which ers use in this connection and my product at no point

25 in its development is dusty or harmful to workers. While

In my co-pending parent application, Serial Number other practitioners use excess water to keep their mate

450,324, filed July 9, 1942, of which this application is rial from hardening to a point which prevents it from

a division, I describe and claim other processes all de being readily disintegrated and later dry out this ex

pending upon processing a phosphatic or related com cess water, use an excess of concentrated acid in a first

ponent or crae containing a metailic (minor) element 30 stage thereby securing an intermediate product which can

either by a direct use of materials which conventionally be handled and treated mechanically and then add addi

are either wasted or mist be expensively reprocessed for tional phosphate rock to utilize the excess acid. Since

effective use, or by the use of such materials in a man use concentrated acid it operates quickly without neces

ner to produce at one operation both a major product sity for storage for curing purposes. My end product,

and a minor bit important by-product. As in my par 35 without heating or grinding, is in the form of dry pellets

ent application this invention is particularly concerned from which no dust evolves.

with the maximum utilization of a strong mineral acid Another basis of economy in my process is my use of

or acids in a manner which saves time, cost and mate rock ground no finer than that generally employed for

rials. By the use of the principles of this invention, I ordinary superphosphate. For example, I find that in

avoid processes which are expensive in capital, materials, 40 making these concentrated phosphatic products I can

labor and other operating costs and secure a better prod use phosphate rock ground so that 60% passes through

uct, physically and chemicaliy. a screen with one hundred meshes to the inch. I use all

As is well known in the fertilizer industry, so-called of such rock as it comes from the grinding mechanism,

triple superphosphate, which is a much concentrated not separating the fine from the coarse. Rock for use

product containing from 45% to 48% "available phos 45 in making triple superphosphate is now ordinarily ground

phoric acid' considered as P2O5 of which approximately so that from 80% to 90% passes through a hundred

90% is water-extractable and in the form of mono mesh screen. This fine grinding is an expensive opera

calcium phosphate, is made by acidulating phosphate tion. By this coarse grinding, not only save expense, but

rock with phosphoric acid (HaipO4). in the fertilizer also I slow down the reaction (during this mixing opera

industry, the phosphatic content of a fertilizer has long 50 tion) so that the resulting acidulated mass can be han

been called "phosphoric acid” but in fact it is a phos dled much more readily.

phate sait or salts including more or less free acid and In one illustration of my method of producing my

is stated in terms of P2O5. Except as specifically indi triple superphosphate, divide 813 pounds of ground

cated, however, I herein use the term "phosphoric acid' phosphate rock which I am to use into two parts, for

to mean H3PO4. 55 example one of 713 pounds and the other of 100 pounds.

To secure phosphoric acid, phosphate rock is pre I place the larger quantity of rock in an ordinary super

viously acidulated with sulphuric acid to produce phos phosphate mixing pan or like mixer and add to it 1227

phoric acid and gypsum. The phosphoric acid is washed pounds of phosphoric acid of 87% (or correspondingly

from the gypsum and results in a dilute H3PO4 of ap more if an acid of the concentration of 70% or 75%

proximately 41% or 30 Baumé. An amount of phos 60 is to be substituted) and mix in the ordinary way with

phoric acid up to approximately 2% of the weight of the the application of no extra power. Ordinary (conven

gypsum is left therein after the washing process has been tional) phosphoric acid may be employed or that pro

completed. At least 5% of the phosphoric acid is lost. duced in accordance with the novel method which I have

This dilute acid which results from this process before described in my said parent application and described and

it can be used for making triple superphosphate must be 65 claimed in my copending application Serial Number

concentrated to 60% or 70%-that is, approximately 221,932, filed April 19, 1951, likewise a division thereof.

43 to 50 Baumé. Phosphoric acid is also made by This is purely a mixing operation.

volatization by heat, but this invention is only indirect From the time of completing this first mixing opera

ly concerned with that process.

The conventional method of producing triple super one offorwardly

tion

several

may handle the mass so produced in any

different ways:

phosphate includes the acidulation of phosphate rock with 1. After the mixing operation has been concluded, in

phosphoric acid of no greater concentration than 50 from a minute to two minutes, for example, I may place

2,740,15

s

e.

4.

the mixture in a den where ieave it for a few minutes found that it is often advantageous to make the above

tintil it hardens. This hardening places the mass in a separation of the phosphate rock on the basis of the

Sifiriently plastic condition to be handled as easily as or side of the particles. As before stated, the rock is ground

dinary superphosphate in the den. Then I disintegrate relatively coarsely. It need not be ground finer than

it and pass it while still hot and steaming, although not for 60% to pass through a hundred mesh screen. Such

as hot as ordinary superphosphate, into a pelleting drum separation on the basis of particle size is particularly use

such as that described in my said co-pending parent ap ful when one uses rocks which present particularly diffi

cult problems of digestion. In such cases I apply the

plication. Thereupon as the drum is revolved I add the entire quantity of the acid to the coarse particles and use

additional hundred potands of phosphate rock. At this 0. finer material for the later step. If the characteristics of

time excess acid which I have used in the mixing pan has the rock and degree of grinding used are such as to pro

come to the surface of the particles and immediately

unites with the ground rock which is added. This rock duce noted

materially more than the 14% of fine material above

I add all but this fraction of the fines to the coarse

adheres to the surface and physically absorbs the acid

which thereupon proceeds to react with the tri-calcium 5 rock and apply to it all of the acid. -

It will be understood that in the above operation no

phosphate to form available P2C5, this crystallization

"drying' the pellet throughout, the coating having estab matter how carried out I over-acidulate the phosphate

rock in the first stage. By adding the second quantity

lished the identity of each pellet. The resulting pellet of ground rock, as described and claimed in other em

is of the type described and claimed per se in my co

pending application Serial Number 432,350 filed February 20 bodimentsthis excess

in my said co-pending applications, I absorb

acid and put it to effective use in converting

24, 1942. unavailable P2O5 to an available form, this chemical action

2. Alternatively I may use a screw conveyor to move in itself drying my pellets. By the over-acidulation of

this acidulated mixture directly from the mixing pan to a relatively coarse rock in the first stage, I am able to main

pelleting drum omitting the intermediate step of permitting tain the entire mass in a sufficiently plastic form to be

it to harden to a plastic state in a den. This conveying handled as easily as ordinary superphosphate.

operation need not take over five minutes because by that Particular note should be made of the fact that at no

time the mixture will have set sufficiently so that it can point do I apply external heat. There is no kiln drying

be handled as above; that is, I add the additional one

hundred pounds of phosphate rock late in the pelleting or other form of dehydration. By use of excess acid until

the final stage of the operation, keep the mass suffi

operation and during the revolution of the drum.

3. I may empty a mixing pan into a form such as de 30 ciently add more

plastic so that it can be readily handled. Then I

phosphate rock so that the excess acid is utilized

scribed and claimed in my Patent Number 2,061,567,

dated November 24, 1936. After the mass so emptied pellets are therebyof“dried'

in the production additional phosphatic salts and the

and hardened. At no time is

has hardened in the block which is so formed, I may any appreciable amount of moisture driven off. These

scrape the material from the top of the block in the man 35 pellets when fully cured and ready for use, however, have

ner described and claimed in my Patent Number a moisture content of about five percent, in contrast to

2,213,243, dated September 3, 1940, and place it in the the usual two percent. My process avoids the dustiness

pelleting drum as before. It will be understood that this which has caused so much difficulty in the making and

action is a conveying and disintegrating one. handling of triple superphosphate.

4. Again alternatively inay nix the phosphate rock As is known to those skilled in this art triple super

and phosphoric acid as above in a special movable multi 40

purposed den such as shown in Figure 16 of my said phosphate as conventionally produced is high in free acid,

application, Serial Number 432,350, filed February 25, to such an extent that it is difficult to store in bags for

1942, parent to the parent hereof, and after the mixing more than a few weeks. My triple superphosphate, how

operation has been completed remove the paddles there ever, is both low in free acid and that which does persist

from. After a few minutes of hardening to a plastic state is encased within a pellet the exterior of which is without

the paddles may be again introduced and revolved. They free acid. It will be noted that the freedom from dust

both in my manufacturing operation and in the resulting

will gradually dig their way into the mass and disintegrate product arises from the retention as water of crystalliza

it and pellet it at the same time. After the desired degree tion of the moisture which others drive off by heat, there

of pelleting has been secured I add the additional one by breaking down these crystals by dehydration into an

hundred pounds of ground phosphate rock. 50 noying and harmful dust. The curing period in a large

In all of the four methods described above for handing pile necessary in the conventional operation because of

this material, I may add other fertilizing material either the time taken for the weak acid to become effective

to the pelleting druin in forms 1 to 3 inclusive or to the starts this dehydration of the crystals and the later kiln

special movable den of form 4. in connection with form

4 it will be understood that I prefer to use a plurality of 55 drying The

completes it.

following analysis (Wiley No. 156,397-146) may

movable multi-purposed dens so that the entire operation be taken as typical of my triple superphosphate manu

while on a batch basis may be continuously carried factured in the above manner:

forward. Per cent

The above ratio of about seven parts of rock to be first Moisture at 100 C-------------------------- 5,35

mixed with all of the acid to one part cf rock to be added 60 Total phosphoric acid------------------------ 50.20

later is illustrative and not definitive. As is well known

to those skilled in this art, details of treatinent of each Insoluble phosphoric acid--------------------- .04

shipment and each source of phosphate rock vary in ac Available phosphoric acid.-------------------- 50.16

cordance with particle size and chemical analysis, includ Water soluble phosphoric acid----------------- 49.25

ing factors other than B. P. L. As is made clear through 65 . It will be noted that I secure without the application

out this specification I produce Rn intermediate product of external heat a triple superphosphate which is pal

(after the first mixing and before pelleting), which is

sufficiently plastic to be readily handled. Consequently pably dry. For simplicity in the sub-joined claims I state

that the concentration of the acid is such that no more

this ratio of the one portion of rock to the other portion

will be changed in order always to achieve my charac 70 water in the

is present in the finished product than that required

acidulation reacticn with all of the phosphate

teristic physical consistency. Thus the choice of this exact rock employed to produce superphosphate and to furnish

ratio is a matter more of physical than chemical con substantially all of the water evaporated by the natural

sideration. -

As stated at greater iength in my said co-pending ap heat of reaction and all of the water of crystallization re

plication Serial Number 450,324 parent hereto also have quired by the complete hydration of the end product. It

5 2,740,115

is to be understood, however, that I also seal within 6

each pellet, the exterior surface being dry to the touch, mined quantity of concentrated phosphoric acid with said

an additional amount of moisture, the presence of which Selected major portion of said ground phosphate rock,

is disregarded in the claims. the predetermined amount of concentrated phosphoric

It will be readily understood by those skilled in this acid being the amount sufficient to react with all of the

art that my process as described and claimed herein said predetermined quantity of ground phosphate rock

may be advantageously applied to the manufacture of and in excess of the amount sufficient to react with said

Superphosphate of any desired quantity of P2O5 greater Selected major portion of said phosphate rock, and the

than twenty percent (within the chemical upper limits), concentration of the said phosphoric acid being above

twenty percent being the figure which can readily be 10 about 50 Baumé and sufficiently high to limit and con

reached by the acidulation of phosphate rock by sulphuric trol the amount of water present to that required by com

acid. For simplicity in the sub-joined claims I am using plete reaction of the entire predetermined quantity of

the term "triple superphosphate' to include any super ground phosphate rock and the entire predetermined

phosphate containing a percentage of P2O5 greater than quantity of phosphoric acid, and to furnish water of

that which can be obtained by the directed use of sul 5 crystallization of the triple superphosphate produced

phuric acid. after loss of water evaporated by the natural heat of re

It will be understood that by the above process I se action; disintegrating the mass formed by said mixing

cure a triple superphosphate both of a higher degree of and reaction of said phosphoric acid and said selected

availability than that common at present and also one major portion of said rock to form disintegrated small

particles which are chemically active and over-acidulated;

which has a higher ratio in percent of its available P205 20 Subjecting

in water-extractable form and in addition has the pe to form coalesced said disintegrated small particles to movement

culiar crop-producing capacity which is explained at larger particles of desired size; and

length in my said parent applications. I completely avoid thereafter adding the said minor portion of said prede

the expensive process of kiln drying and the product is termined quantity of ground phosphate rock to coat the

not dusty and harmful to health, 25 said coalesced larger particles, thereby reacting said minor

Although I am presenting for purposes of illustration portion of said ground rock with the said excess quantity

only certain preferred embodiments of my invention it particulateof phosphorictripleacid to form substantially dry, coalesced

superphosphate.

will be readily understood that changes may be made 3. A process of manufacturing particulate triple super

therein within the spirit of my invention and the scope phosphate which comprises: dividing a predetermined

of my broader claims. The advantages of this inven 30 quantity of ground phosphate rock into a selected major

tion will be clear from the above discussion and the ap and a minor portion; mixing and reacting a predeter

pended claims. These advantages include the production

of triple superphosphate of unusually high availability mined quantity of concentrated phosphoric acid with

and water-extractability after a short curing period and said selected major portion of the said ground phosphate

with low free acid, cheaply, simply, without kiln or other phoricrock, the predetermined amount of concentrated phos

artificial drying and without the development of dust. acid being the amount sufficient to react with all

Practice of my invention results in an end product which of the said predetermined quantity of ground phosphate

is pelleted and has the high crop-producing capacity of said rock and in excess of the amount sufficient to react with

the parent of my said parent application. selected major portion of said phosphate rock, and

I claim: 40 the concentration of the said phosphoric acid being be

1. A process of manufacturing triple superphosphate tween about 70% and about 87% acid and sufficiently

in particulate form which comprises: dividing a prede high to limit and control the amount of water present

termined quantity of ground phosphate rock into a se to that required by complete reaction of the entire pre

lected major and a minor portion; mixing and reacting a determined quantity of ground phosphate rock and the

predetermined quantity of concentrated phosphoric acid entire to

predetermined quantity of phosphoric acid, and

furnish water of crystallization of the triple super

with said selected major portion of the said ground phos phosphate produced after loss of water evaporated by

phate rock, the predetermined amount of concentrated

phosphoric acid being the amount sufficient to react with the natural heat of reaction; disintegrating the mass.

all of the said predetermined quantity of ground phos formed by said mixing and reaction of said phosphoric

acid and said selected major portion of said rock to form.

phate rock and in excess of the amount sufficient to react 50 disintegrated

with said selected major portion of said ground phosphate and over-acidulated; small particles which are chemically active

rock, and the concentration of the said phosphoric acid particles to movementsubjecting said disintegrated small

to form coalesced larger particles

being sufficiently high to limit and control the amount

of water present to that required by complete reaction of tion of desired size; and thereafter adding the said minor por

the entire predetermined quantity of ground phosphate 55 rock of said predetermined quantity of ground phosphate

rock and the entire predetermined quantity of phosphoric reacting to coat the said coalesced larger particles, thereby

acid, and to furnish water of crystallization of the triple said excess said minor portion of said ground rock with the

superphosphate produced after loss of water evaporated tially dry, coalesced quantity of phosphoric acid to form substan

by the natural heat of reaction; disintegrating the mass particulate triple superphosphate.

formed by said mixing and reaction of said phosphoric 60 phosphate 4. A process of manufacturing particulate triple super

acid and said selected major portion of said rock to form which comprises: dividing a predetermined

disintegrated Small particles which are chemically active minor quantity of ground phosphate rock into a major and a

and over-acidulated; subjecting said disintegrated small amountportion; mixing said major portion and the entire

particles to movement to form coalesced larger particles 50 Baumé necessary toacid

of phosphoric

form

of the order of more than

triple superphosphate from

of desired size; and thereafter adding the said minor 65 said predetermined quantity of ground phosphate rock

portion of said predetermined quantity of ground phos thereby producing an over-acidulated moist essentially

phate rock to coat the said coalesced larger particles, solid mass which can be readily handled and is disin

thereby reacting said minor portion of said ground rock tegrable in the manner of ordinary superphosphate; dis

with the said excess quantity of phosphoric acid to form integrating said mass into particles; and further process

coalesced particulate triple superphosphate. ing the resulting particles without the addition of external

2. A process of manufacturing particulate triple super heat under conditions avoiding any substantial evapora

phosphate which comprises: dividing a predetermined tion of moisture, and so as to obtain a dry final product,

quantity of ground phosphate rock into a selected major said further processing including adding to the outside

and a minor portion; mixing and reacting a predeter 75 surfaces of the disintegrated particles while still moist

and over-acidulated the said minor portion of said pre

2,740,115 -w 8

7

determined quantity of the phosphate rock thereby caus which comprises dividing groundpelleted

8. A process of manufacturing superphosphate

phosphate rock into a

ing adherence of said added rock to said moist outside major and a minor fraction, mixing said major fraction

surfaces and its chemical bond thereto, the concentration and the entire amount of phosphoric acid necessary to

of the acid being such as to supply not more than the 5 form triple superphosphate from all of said phosphate

amount of water required in the entire acidulation re rock, placing said over-acidulated mixture in a den and

action while furnishing the water evaporated by the natu leaving it there until it hardens into a plastic mass, dis

ral heat of reaction and the amount required to furnish integrating said mass, and while it is still hot and steam

substantially the full aimount of water of crystallization ing passing it to a pelleting drum and pelleting it with

for the completely hydrated yet dry final product. O the addition of said minor fraction of said rock thereby

5. A process of manufacturing superphosphate which utilizing all of the acidic component of said mass and

comprises grinding phosphate rock into relatively coarse causing the

and fine particles, mixing the coarse particles and the en palpably drypellets to pass from a palpably moist to a

tire amount of phosphoric acid necessary to form triple then unused acid and the

state by

the

chemical reaction between the

freshly added rock by which

superphosphate from all of said phosphate rock thereby almost all of the free moisture present at the beginning

producing an over-acidulated liquid-containing plastic of the pelleting operation becomes water of crystalliza

mass winich can be readily handled, the concentration of tion thereby assuring the integrity of the pellets thereafter.

the acid being such that no more water is present than 9. A process of manufacturing a pelleted superphos

that required in the acidulation reaction with all of the phate which comprises dividing ground phosphate rock

phosphate rock employed to produce superphosphate and 20 into a majorand a minor fraction, mixing said major

to furnish substantially all of the water evaporated by fraction and the entire amount of phosphoric acid neces

the natural heat of reaction and all of the water of crystal sary to form-triple superphosphate from all of said phos

Iization required by complete hydration of the end prod phate rock, disintegrating said mixture after it has hard

uct, and thereafter mixing with said mass said fine par ened into a plastic mass, and pelleting it while it is still

ticles of the phosphate rock thereby utilizing all of the hot and steaming with the addition of said minor frac

acidic component of said mass, thereby combining the tion of said rock thereby utilizing all of the acidic com

remaining free acid and the last added phosphate rock ponent of said mass and causing the pellets to pass from

as superphosphate and converting the entire mass to a a palpably moist to a palpably dry state by the chemical

dry6.and non-coalescent

A process condition. superphosphate which reaction between the then unused acid and the freshly

of manufacturing added rock by which almost all of the free moisture

comprises grinding phosphate rock so that substantially 30 present

sixty percent thereof is relatively fine and the remainder comes water at the beginning of the pelleting operation be

of crystallization thereby. assuring the in

relatively coarse, mixing the coarse particles and the en tegrity of the pellets

tire amount of phosphoric acid necessary to form triple thereafter.

superphosphate from all of said phosphate rock thereby 10. A process of manufacturing pelleted triple super

producing an over-acidulated liquid-containing plastic phosphate which comprises dividing ground phosphate

mass which can be readily handled, the concentration of rock into a major portion and a minor portion, said major

the acid being such that no more water is present than portion being sufficient in amount so that when it has

that required in the acidulation reaction with all of the been mixed with the entire amount of phosphoric acid

phosphate rock employed to produce Superphosphate and necessary to form triple superphosphate from all of said

to furnish substantially all of the water evaporated by phosphate rock it will produce an over-acidulated liquid

the natural heat of reaction and all of the water of crystal

containing plastic mass which can be readily handled,

lization required by complete hydration of the end prod the concentration of the acid being such that no more

uct, and thereafter mixing with said mass said fine par

water is present than that required in the acidulation

ticles of the phosphate rock thereby utilizing all of the reaction with all of the phosphate rock employed to

acidic component of said mass, thereby combining the produce Superphosphate and to furnish substantially all

of the water evaporated by the natural heat of reaction

remaining free acid and the last added phosphate rock as and all of the water of crystallization required by com

superphosphate and converting the entire mass to a dry plete hydration of the end product, mixing said major

and non-coalescent condition.

7. A process of manufacturing particulate triple super portion

and

and all of said acid, mixing said mass so formed

said minor portion of the phosphate rock, and re

phosphate which comprises dividing a predetermined 50 volving said mass upon itself to form pellets, said second

quantity of ground phosphate rock into a major and a portion of said rock being sufficient in amount so that

minor portion, mixing said major portion and the entire the pellets are coated and remaining free acid combined

amount of phosphoric acid of the order of more than as superphosphates and the pellets converted to a dry and

50 Baumé necessary to form triple superphosphate from non-coalescent condition.

said predetermined quantity of ground phosphate rock 53 11. A process of manufacturing a pelleted superphos

thereby producing an over-acidulated moist essentially phate which comprises dividing ground phosphate rock

solid mass which can be readily handled and is disia into a major fraction and a minor fraction, mixing said

tegrable in the manner of ordinary superphosphate, dis major fraction with the entire amount of phosphoric acid

integrating said mass into particles, and further process ile:ressary to form superphosphate from all of said rock,

ing the resulting particles without the addition of external and further processing the resulting mass without the addi

heat under conditions avoiding any substantial evapora tion of heat under conditions avoiding any substantial

tion of moisture and so as to obtain a dry final product, evaporation and so as to obtain a dry final product, the

said further processing including adding to the outside concentration of the acid being such as to supply not

surfaces of the disintegrated particles while still moist R more than the amount of water required in the acidulation

and over-acidulated the said minor portion of said pre 5 reaction of all of said phosphate rock and evaporated

determined quantity of the phosphate rock thereby calls by the natural heat of reaction and the amount required

ing adherence of said added rock to said moist outside to furnish substantially the full amount of water of

surfaces and its chemical bond thereto, the concentration crystallization for the completely hydrated final product,

of the acid being between about 70% and about 87% said further processing including conveying said mixture

acid and being such as to supply not more than the to a rotatable drum, said conveying operation being of

amount of water required in the entire acidulation re

action while furnishing the water evaporated by the natu abecomes

length sufficient so that the said over-acidulated mass

plastic during it, placing said plastic mass and

ral heat of reaction and the amount required to furnish said minor fraction of said phosphate rock in said drum

substantially the full amount of water of crystallization is and revolving said drum to form pellets thereby utilizing

for the completely hydrated yet dry final product.

2,740,115

all of the acidic component of said mass, the pellets no more water is present thanOthat required in the acidu

being dried by the chemical reaction between the then lation reaction with all of the phosphate rock employed

unused acid and the freshly added rock. to produce superphosphate and to furnish substantially

12. A process of manufacturing superphosphate which all

comprises dividing ground phosphate rock into a major andofalltheofwater evaporated by the natural heat of reaction

the water of crystallization required by com

and a minor fraction, mixing said major fraction and the plete hydration of the end product, said first portion of

entire amount of phosphoric acid necessary to form triple said rock being sufficient in amount so that when all of

Superphosphate from ail of said phosphate rock, pouring

Successive mixtures so formed into successive layers in said acid is added thereto it reduces said rock to a mate

rial which considered in its totality has the characteristics

a form thereby creating a block of over-acidulated super 0. of

phosphate, removing the form, scraping material from ingmoist sand, adding said acid to said first portion, agitat

the top of the block and conveying it to a pelleting drum, said the mass so formed to produce pellets and adding

such scraping and conveying operation being effective masssecond during

portion of said rock to said last mentioned

a later portion of said agitation said second

to place in said drum disintegrated plastic material, and portion of said rock being sufficient in amount so that

mixing said material and said minor fraction of said 5 the pellets are coated and remaining free acid combined

phosphate rock.

13. A process of manufacturing triple superphosphate as superphosphate and the pellets converted to a dry and

non-coalescent condition.

which comprises dividing ground phosphate rock into a 16. A process of manufacturing a pelleted mixed super

k major and a minor fraction, placing in a container said

major fraction and the entire amount of phosphoric acid

necessary to form triple superphosphate from all of said

phosphatic fertilizer which comprises dividing ground

phosphate rock into a major and minor fraction, mixing

phosphate rock, introducing paddles into said container said major fraction and the entire amount of phosphoric

thereby mixing the mass, after such mixing has been acid necessary to form triple superphosphate from all

completed removing said paddles and leaving the mix of said phosphate rock, placing said over-acidulated mix

ture untreated until it has become plastic, re-introducing 25 ture in a den and leaving it there until it hardens into

said paddles into said container and revolving them in a plastic mass, disintegrating said mass, thereupon adding

order to form pellets, introducing into said container said another fertilizer material to said mass, and while the

minor fraction of said phosphate rock and continuing mixture so formed is still hot and steaming from said

such agitation so that the pellets are coated whereby they original mixture of phosphate rock and phosphoric acid

are dried by chemical reaction between the freshly added passing the combined mixture to a pelleting drum and

rock and the then unused acid. pelleting it with the addition of said minor fraction of said

14. A process of manufacturing a pelleted superphos rock thereby utilizing all of the acidic component of said

mass and causing the pellets to pass from a palpably moist

phate of relatively high phosphatic content which com to

prises separating ground phosphate rock into a first por theathen palpably dry state by the chemical reaction between

tion and a second portion, said first portion including almost allunused acid and the freshly added rock by which

of the free moisture present at the beginning

relatively coarse rock particles and said second portion of the pelleting operation becomes water of crystalliza

consisting only of relatively fine rock particles, mixing tion thereby assuring the integrity of the pellets there

said first portion with an acid solution which contains after.

an acid of phosphorus in an amount sufficient to acidu 17. A process of manufacturing a complete pelleted

late said entire amount of said rock, the concentration 40 mixed

of the acid being such that no more water is present than groundsuperphosphatic fertilizer which comprises dividing

phosphate rock into a major and minor fraction,

that required in the acidulation reaction with all of the mixing said major fraction and the entire amount of phos

phosphate rock employed to produce superphosphate phoric acid necessary to form triple superphosphate from

and to furnish substantially all of the water evaporated

by the natural heat of reaction and all of the water of 45 itallhas

of said phosphate rock, disintegrating said mixture after

hardened into a plastic mass, and thereupon adding

crystallization required by complete hydration of the end nitrogen-bearing and potash-bearing fertilizer materials

product, said first portion of said rock being sufficient in and pelleting the resulting mixture while it is still hot and

amount so that when all of said acid is added thereto steaming from the original mixture of acid and rock with

it reduces said rock to a material which considered in its the addition of said minor fraction of said rock late in the

totality has the characteristics of moist sand, adding said 50 pelleting operation, thereby utilizing all of the acidic com

acid to said first portion, agitating the mass so formed ponent of said mass and causing the pellets to pass from a

to produce pellets and adding said second portion of said palpably moist to a palpably dry state by the chemical

rock to said last mentioned mass during a later portion

of said agitation, said second portion of said rock being reaction between the then unused acid and the freshly

added rock by which almost all of the free moisture pres

sufficient in amount so that the pellets are coated and ent

remaining free acid combined as superphosphate and waterat ofthecrystallization

beginning of the pelleting operation becomes

thereby assuring the integrity of

the pellets converted to a dry non-coalescent condition.

15. A process of manufacturing a pelleted superphos the pellets thereafter.

phate of relatively high phosphatic content which com References Cited in the file of this patent

prises separating ground phosphate rock into a first por 60

tion and a second portion, said first portion including UNITED STATES PATENTS

relatively coarse rock particles and a second portion con 389,566 Glaser ---------------- Sept. 18, 1888

sisting only of relatively fine rock particles, the ratio of 1,146,222 Wilson et al. ------------ July 13, 1915

said first portion to said second portion being of the 1916,114 Ober et al. ------------- June 27, 1933

order of seven to one, mixing said first portion with an 65 2,061,567 Facer ----------------- Nov. 24, 1936

acid solution which contains an acid of phosphorus in 2,106,223 Nordengren ------------- Jan. 25, 1938

an amount sufficient to acidulate said entire amount of 2,136,793 Gabeler et al.----------- Nov. 15, 1938

said rock, the concentration of the acid being such that

You might also like

- SSS 2 E-Note 3rd Term ChemistryDocument61 pagesSSS 2 E-Note 3rd Term ChemistryDave Blessed83% (6)

- O&M ManualDocument255 pagesO&M ManualSanjeev Kumar DasNo ratings yet

- United States Patent (191: Macdonald 145) Feb. 25, 1975Document4 pagesUnited States Patent (191: Macdonald 145) Feb. 25, 1975Javier Alejandro Rodriguez MelgozaNo ratings yet

- Afault and 4-Motov: March 13, 1962 B. C. Bigot 3,025,152Document4 pagesAfault and 4-Motov: March 13, 1962 B. C. Bigot 3,025,152Dikul BrahmbhattNo ratings yet

- Lecture 35 PDFDocument8 pagesLecture 35 PDFabderrahimn100% (1)

- Processing Phosphates For Use in The Fertilizer IndustryDocument4 pagesProcessing Phosphates For Use in The Fertilizer IndustrydzungNo ratings yet

- Paten Sulfur Mixer PDFDocument7 pagesPaten Sulfur Mixer PDFLily DianaNo ratings yet

- Us 4501724Document7 pagesUs 4501724DARWIN STALIN ALCACIEGA PILCONo ratings yet

- Phosphate Fertilizer Plants: Industry Description and PracticesDocument4 pagesPhosphate Fertilizer Plants: Industry Description and PracticesGbl BplNo ratings yet

- United States Patent Office: Patented Nov. 5, 1966Document6 pagesUnited States Patent Office: Patented Nov. 5, 1966Alexander Franco CastrillonNo ratings yet

- Us 2179174Document5 pagesUs 2179174Pat22 22patNo ratings yet

- SSPDocument11 pagesSSPMuhammad AmjadNo ratings yet

- Unite Sites Fret (19) : DahlinDocument3 pagesUnite Sites Fret (19) : Dahlintrinh xuan hiepNo ratings yet

- The Phosphates Processing Handbook PDFDocument29 pagesThe Phosphates Processing Handbook PDFJulian CadenaNo ratings yet

- History of Fluorine Recovery ProcessesDocument21 pagesHistory of Fluorine Recovery ProcessesFajar Zona100% (1)

- United States Patent Office.: This Invention Is Based Upon The DiscovDocument2 pagesUnited States Patent Office.: This Invention Is Based Upon The Discovchoi yoojungNo ratings yet

- United States Patent Office: Tion, It Will Be Understood To Have Been Calculated AsDocument2 pagesUnited States Patent Office: Tion, It Will Be Understood To Have Been Calculated Asthan zawNo ratings yet

- US4610862Document6 pagesUS4610862محمد عليNo ratings yet

- Other Phosphate Fertilizers - Part 1: Enriched SuperphosphateDocument10 pagesOther Phosphate Fertilizers - Part 1: Enriched SuperphosphatetegararazaqNo ratings yet

- History of Fluorine Recovery ProcessesDocument21 pagesHistory of Fluorine Recovery ProcessesmahaNo ratings yet

- US3416887Document6 pagesUS3416887khairulNo ratings yet

- J. N. CarothersDocument4 pagesJ. N. CarothershaviedNo ratings yet

- Articulo Patente 4Document4 pagesArticulo Patente 4AgentesteveNo ratings yet

- United States Patent ToDocument8 pagesUnited States Patent ToAwat MuhammadNo ratings yet

- United States: Patent OfficeDocument3 pagesUnited States: Patent OfficefredyNo ratings yet

- United States Patent Office: 2 Claims. (CI. 71-29)Document2 pagesUnited States Patent Office: 2 Claims. (CI. 71-29)Fernando Nieto OchoaNo ratings yet

- Int4D Ustrlal: and Engineering ChemistryDocument11 pagesInt4D Ustrlal: and Engineering Chemistryاحمد الدلالNo ratings yet

- Triple Superphosphate PDFDocument6 pagesTriple Superphosphate PDFsukhmaniNo ratings yet

- US3936501Document3 pagesUS3936501qaim abbasNo ratings yet

- Process For The Production of Sucrose Esters of Fatty AcidsDocument5 pagesProcess For The Production of Sucrose Esters of Fatty AcidsHarry CortezNo ratings yet

- PhosphaticDocument35 pagesPhosphaticSafyan ManzoorNo ratings yet

- 2000 Ifa Neworleans GobbitDocument14 pages2000 Ifa Neworleans GobbitFajar ZonaNo ratings yet

- Phosphate Beneficiation Process - Mineral Processing - MetallurgyDocument13 pagesPhosphate Beneficiation Process - Mineral Processing - MetallurgyTulika PaulNo ratings yet

- III Sem ICTDocument56 pagesIII Sem ICToctoviancletusNo ratings yet

- Pilot-Plant Development Ofthe Foam Distribution Process For Production OF Wet-Process PhosphoricDocument5 pagesPilot-Plant Development Ofthe Foam Distribution Process For Production OF Wet-Process PhosphoricIngrid ContrerasNo ratings yet

- Us 2427642Document2 pagesUs 2427642SatyamSahuNo ratings yet

- III Sem ICTDocument20 pagesIII Sem ICToctoviancletusNo ratings yet

- Guy H BuchananDocument4 pagesGuy H BuchananVizzy VishalNo ratings yet

- United States Patent (19) : Story Et AlDocument14 pagesUnited States Patent (19) : Story Et Alahmed khaledNo ratings yet

- Under The Guidance Of: Project Report On P Neutralisation of Gypsum in Phosphoric Acid PlantDocument18 pagesUnder The Guidance Of: Project Report On P Neutralisation of Gypsum in Phosphoric Acid PlantsurendraNo ratings yet

- Fosfato Simple 2Document4 pagesFosfato Simple 2Jose CortezNo ratings yet

- Us4643848 Fumaric RosinDocument5 pagesUs4643848 Fumaric RosinPudien MuhamadNo ratings yet

- Es Patent Office IDocument7 pagesEs Patent Office IShandy ArmandoNo ratings yet

- Inorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyDocument37 pagesInorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyMohamed AbdelaalNo ratings yet

- By 22-Le: April 8, 1969 J. S. Sproul Etal 3,437,434Document6 pagesBy 22-Le: April 8, 1969 J. S. Sproul Etal 3,437,434Cris AcevedoNo ratings yet

- Us 4315763Document11 pagesUs 4315763Thusith WijayawardenaNo ratings yet

- US3689216Document5 pagesUS3689216PABLO URIZ CEREZONo ratings yet

- Removal of Fluorine From Wet Process Phosphoric AcidDocument2 pagesRemoval of Fluorine From Wet Process Phosphoric AcidAdios ANo ratings yet

- Becker Pierre. - Phosphates and Phosphoric Acid - Raw Materials, Technology and Economics of The Wet Process. 1983Document301 pagesBecker Pierre. - Phosphates and Phosphoric Acid - Raw Materials, Technology and Economics of The Wet Process. 1983احمد العنزيNo ratings yet

- The FEECO Phosphates Processing HandbookDocument33 pagesThe FEECO Phosphates Processing HandbookThe EAKNo ratings yet

- Us 2600253Document5 pagesUs 2600253Michael Kang'eriNo ratings yet

- SuperphosphateDocument12 pagesSuperphosphateSusbsisvNo ratings yet

- High Performance Oilfield Scale InhibitorsDocument27 pagesHigh Performance Oilfield Scale InhibitorsRégis OngolloNo ratings yet

- Process For Producing Granular Triple Superphosphate: F. DunbarDocument5 pagesProcess For Producing Granular Triple Superphosphate: F. DunbarOscar SobradosNo ratings yet

- 21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8Document14 pages21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8kaldjdsjkaNo ratings yet

- Us4117092 Phosphoric Acid Recovery by Solvent ExtractionDocument5 pagesUs4117092 Phosphoric Acid Recovery by Solvent ExtractionM.zuhair asifNo ratings yet

- H3PO4Document23 pagesH3PO4Leo Edrik Cortez VidalNo ratings yet

- US3347627Document3 pagesUS3347627Nuttapong JongjitsatitmunNo ratings yet

- United States Patent (19) : PistoriusDocument5 pagesUnited States Patent (19) : Pistoriusmasood kblNo ratings yet

- Sulphuric AcidDocument9 pagesSulphuric AcidHasnat AhmadNo ratings yet

- Farm Gardening with Hints on Cheap Manuring: Quick Cash Crops and How to Grow ThemFrom EverandFarm Gardening with Hints on Cheap Manuring: Quick Cash Crops and How to Grow ThemNo ratings yet

- The Handbook of Soap ManufactureFrom EverandThe Handbook of Soap ManufactureRating: 3 out of 5 stars3/5 (1)

- Processes 11 01753Document25 pagesProcesses 11 01753JanainaNo ratings yet

- Phosphoric Acid AspenDocument14 pagesPhosphoric Acid AspenJanaina0% (1)

- The Treatment of Waste Gas From Fertilizer Production - An Industrial CaseDocument10 pagesThe Treatment of Waste Gas From Fertilizer Production - An Industrial CaseJanainaNo ratings yet

- MAP ReferenciaDocument4 pagesMAP ReferenciaJanainaNo ratings yet

- MT1 BiomesDocument20 pagesMT1 BiomesBaby Hazel RamirezNo ratings yet

- MENA Reference MBR Durrat Al BahreinDocument2 pagesMENA Reference MBR Durrat Al BahreinNermeen ElmelegaeNo ratings yet

- Solar StillDocument18 pagesSolar StillJORDAN MALLARINo ratings yet

- Ostenberg RossDocument24 pagesOstenberg RossidigitiNo ratings yet

- P1 88thminutesDocument42 pagesP1 88thminutesVaishnavi JayakumarNo ratings yet

- Research ArticleDocument14 pagesResearch Articlemouka ayiwouoNo ratings yet

- BELLARY HydrologyDocument32 pagesBELLARY HydrologyAshrithNo ratings yet

- Science 3 Q4Document107 pagesScience 3 Q4anon_38051274100% (2)

- UntitledDocument19 pagesUntitledResti PNo ratings yet

- 11 Preservation: Rabab Harweel Power PlantDocument10 pages11 Preservation: Rabab Harweel Power PlantPazhamalairajan KaliyaperumalNo ratings yet

- Steam Utilization in Textile IndustryDocument7 pagesSteam Utilization in Textile IndustryMuddaser83% (6)

- EPA 245.5 HGDocument4 pagesEPA 245.5 HGAarón CespedesNo ratings yet

- Guide To Condensate Polishing - DOWDocument10 pagesGuide To Condensate Polishing - DOWxlxjrv100% (1)

- 8 Good GovernanceDocument4 pages8 Good GovernanceEmilio TaddeiNo ratings yet

- Construction Steps of BuildingDocument5 pagesConstruction Steps of BuildingRK DanishNo ratings yet

- Test Bank For Chemistry For Today General Organic and Biochemistry 8th EditionDocument12 pagesTest Bank For Chemistry For Today General Organic and Biochemistry 8th Editionkristopherpughaqckewzsbr100% (36)

- Soalan 3 The Destruction of The World's Forests Is Inevitable As Our Need For Land and Food GrowsDocument2 pagesSoalan 3 The Destruction of The World's Forests Is Inevitable As Our Need For Land and Food GrowscikgucinaNo ratings yet

- 280 PDFDocument16 pages280 PDFVENKATESHNo ratings yet

- Atlas Группа Izohan Каталог Продуктов Битумные МассыDocument12 pagesAtlas Группа Izohan Каталог Продуктов Битумные Массыtoms4No ratings yet

- Desuperheater Online Program Sizing GuidanceDocument12 pagesDesuperheater Online Program Sizing GuidancebadesharamkNo ratings yet

- Compilation of Plates For Building DesignDocument26 pagesCompilation of Plates For Building DesignAldrin OrigenesNo ratings yet

- Aijn Hygiene CodeDocument53 pagesAijn Hygiene CodeAnilZapateNo ratings yet

- Mining, The Santurban Moor CaseDocument5 pagesMining, The Santurban Moor Caselacoalicionpetrolera100% (1)

- Production of Formaldehyde From MethanolDocument13 pagesProduction of Formaldehyde From MethanolAugusto Mohr Christmann100% (1)

- Waterstops PDFDocument26 pagesWaterstops PDFjmusopoleNo ratings yet

- WQI of River Netravati Using Fuzzy Inference SystemDocument94 pagesWQI of River Netravati Using Fuzzy Inference SystemPRETTY MARYNo ratings yet

- Beaver Lodge Construction Squad - Attenborough - BBC Earth - English (AutoDocument4 pagesBeaver Lodge Construction Squad - Attenborough - BBC Earth - English (AutoAshok KumarNo ratings yet

- Manual Wesen Inox FlatDocument14 pagesManual Wesen Inox FlatRoberto Rodriguez BouzoNo ratings yet