Professional Documents

Culture Documents

Hydro en Aw 1050a

Hydro en Aw 1050a

Uploaded by

Manoranjan MohapatraCopyright:

Available Formats

You might also like

- Sponge Iron PlantDocument11 pagesSponge Iron PlantLi GaryNo ratings yet

- Grinding Wheels, Honing Stones and Turning BitsDocument6 pagesGrinding Wheels, Honing Stones and Turning BitsSamer SalibaNo ratings yet

- Lime Kiln Gasification General - 2012Document18 pagesLime Kiln Gasification General - 2012DiogoNo ratings yet

- Worder & Pandel (Cap Berbec) : X TopoareDocument12 pagesWorder & Pandel (Cap Berbec) : X TopoareFlorinTudose100% (2)

- EurametalTechnic 4Document1 pageEurametalTechnic 4Chirim AinurNo ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- Hydro en Aw 6082Document3 pagesHydro en Aw 6082Velissarios DemetriouNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- RT Duroid 5870 5880 Data Sheet PDFDocument2 pagesRT Duroid 5870 5880 Data Sheet PDFNom MonNo ratings yet

- Commercial Purity Aluminium1050Document1 pageCommercial Purity Aluminium1050HermanNo ratings yet

- Commercial-Purity Aluminium1050Document1 pageCommercial-Purity Aluminium1050SiyabulelaNo ratings yet

- Non Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% MinimumDocument1 pageNon Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% Minimumprivate 2No ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Novatec Premium Ii: Technical Data SheetDocument1 pageNovatec Premium Ii: Technical Data SheetRuben PauwelsNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- Tehnicke Karakteristike Asistal Alu OkapnicaDocument2 pagesTehnicke Karakteristike Asistal Alu OkapnicaDARKO RADICEVICNo ratings yet

- Ultra Soft Thermal Pad: Features ApplicationDocument1 pageUltra Soft Thermal Pad: Features ApplicationMalek Ellouz (Jay)No ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- NEDAL Datasheet-3003Document1 pageNEDAL Datasheet-3003Manoranjan MohapatraNo ratings yet

- TDS HBMDocument1 pageTDS HBMP Singh KarkiNo ratings yet

- Reinz AFM 37 가스켓 TDS (BFP 기본 가스켓) 1Document3 pagesReinz AFM 37 가스켓 TDS (BFP 기본 가스켓) 1Geonung Park (Fall For 2)No ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasNo ratings yet

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasNo ratings yet

- 36NiCrMo16 10083 06 ENG 01Document1 page36NiCrMo16 10083 06 ENG 01Guru Raj9739No ratings yet

- General Description: Coupling: Brown, Blue Pipe Body: Brown, BlueDocument5 pagesGeneral Description: Coupling: Brown, Blue Pipe Body: Brown, Blueharan2000No ratings yet

- 18nicrmo14-6: Steel GradeDocument4 pages18nicrmo14-6: Steel Gradesmith willNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- RT-duroid 6202 Laminate Data SheetDocument2 pagesRT-duroid 6202 Laminate Data SheetAditya Bonnerjee 21BEC0384No ratings yet

- POLYTETRAFLUOROETHYLENE - MAIZEY PTFE - 2021 - EmailDocument2 pagesPOLYTETRAFLUOROETHYLENE - MAIZEY PTFE - 2021 - EmailGustavNo ratings yet

- Sabic Chile Ptfe Hoja TecnicaDocument1 pageSabic Chile Ptfe Hoja Tecnicae.vicente.caballeroNo ratings yet

- Rigid PVCDocument1 pageRigid PVCRND KencanaNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous zBSE9MNo ratings yet

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Document1 pageAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNo ratings yet

- Gb8417domex500mc PDFDocument2 pagesGb8417domex500mc PDFMario MereniNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- Scope: Ferritic Heat-Resistant Steel TK 1.4762Document5 pagesScope: Ferritic Heat-Resistant Steel TK 1.4762Siis IngenieriaNo ratings yet

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81No ratings yet

- Datasheet Wesgo Ceramics Al500Document2 pagesDatasheet Wesgo Ceramics Al500hemanth_85No ratings yet

- GFT Data SheetDocument1 pageGFT Data SheetDasan ThadathilNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- Technical Data Sheet - Burachem Blue 9655 BDocument1 pageTechnical Data Sheet - Burachem Blue 9655 BmunhNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDocument2 pagesKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyNo ratings yet

- Nylon 6Document1 pageNylon 6luuiissNo ratings yet

- ASTM C90700 - CuSn11 - Tin Bronze AlloysDocument1 pageASTM C90700 - CuSn11 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- Kaiser Aluminum 7075 Rod and BarDocument2 pagesKaiser Aluminum 7075 Rod and BarH VNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- Technical Information: Coextruded Biaxially Oriented Polypropylene FilmDocument1 pageTechnical Information: Coextruded Biaxially Oriented Polypropylene FilmAlzena badzlinNo ratings yet

- Acetal Natural Data SheetDocument1 pageAcetal Natural Data SheetvijayNo ratings yet

- General Description: Coupling: Red, Blue Pipe Body: Red, BlueDocument5 pagesGeneral Description: Coupling: Red, Blue Pipe Body: Red, Blueharan2000No ratings yet

- CuZn38Pb2 CW608N ENDocument4 pagesCuZn38Pb2 CW608N ENTaner DemirelNo ratings yet

- PB Unimax English160604152107Document12 pagesPB Unimax English160604152107filipeNo ratings yet

- TDS Siltherm-AluFlex 05-2022Document2 pagesTDS Siltherm-AluFlex 05-2022benjaminNo ratings yet

- Calaumid 612Document1 pageCalaumid 612Sudipta GangopadhyayNo ratings yet

- STC White Paper Zta Zirconia Toughened Alumina 01062021Document4 pagesSTC White Paper Zta Zirconia Toughened Alumina 01062021王柏昆No ratings yet

- Technical Aluminium Alloys LM20 09 05 22Document3 pagesTechnical Aluminium Alloys LM20 09 05 22baskaran.marieNo ratings yet

- Catalog FEEL by THM AgencyDocument68 pagesCatalog FEEL by THM Agencykartika lestariNo ratings yet

- SMAW WeldingDocument259 pagesSMAW Weldingimsovanara5310100% (1)

- Royale Play StuccoDocument2 pagesRoyale Play Stuccosaran100% (1)

- Smaw List of Equipment Tesda-Op-Co-01-F13Document3 pagesSmaw List of Equipment Tesda-Op-Co-01-F13Manilyn GaranganaoNo ratings yet

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiNo ratings yet

- KL HazopDocument4 pagesKL HazopSalahBouzianeNo ratings yet

- Manufacturing of SteelDocument2 pagesManufacturing of SteelSamuel AntobamNo ratings yet

- InkDocument23 pagesInkSaurabh SinghNo ratings yet

- TW-Disposable Masks - W17 UNIDocument7 pagesTW-Disposable Masks - W17 UNICindy FonsecaNo ratings yet

- The Australian Welding Guide PDFDocument220 pagesThe Australian Welding Guide PDFThành Nguyễn Xuân100% (1)

- Corroseal TE 321 Rev 01Document1 pageCorroseal TE 321 Rev 01Ashif AkhtarNo ratings yet

- 10 Types of ValvesDocument7 pages10 Types of ValvesLamar TwitchNo ratings yet

- Electronic PackagingDocument54 pagesElectronic PackagingAdelle Lyn Carlos100% (1)

- Router Repair of Soundboard Cracks: Using The Spurlock Specialty Tools Carbide Router Bit and Router BaseDocument10 pagesRouter Repair of Soundboard Cracks: Using The Spurlock Specialty Tools Carbide Router Bit and Router BaselazarNo ratings yet

- 8.2 Fundamentals of Manufacturing For EngineersDocument13 pages8.2 Fundamentals of Manufacturing For EngineersKhánh ĐàoNo ratings yet

- Laxminarayan Institute of Technology: Placement Record 2020 - 21Document3 pagesLaxminarayan Institute of Technology: Placement Record 2020 - 21Smit patelNo ratings yet

- RJS Pattern Making NewDocument23 pagesRJS Pattern Making NewRam Janm SinghNo ratings yet

- Ucmp First Mid Course FileDocument160 pagesUcmp First Mid Course FileAraveetiCSReddyNo ratings yet

- What Is Difference Between Tempering, Annealing, Normalizing and QuenchingDocument1 pageWhat Is Difference Between Tempering, Annealing, Normalizing and QuenchingMONER MANUSNo ratings yet

- Azud Modular 100 EngDocument2 pagesAzud Modular 100 EngAnonymous nPK85ZFzNo ratings yet

- 77 1006 SafetyReliefValveDocument8 pages77 1006 SafetyReliefValverahul soniNo ratings yet

- Sly Venturi ScrubberDocument2 pagesSly Venturi Scrubberzguy360No ratings yet

- Introduction To Micro Nanofabrication PDFDocument39 pagesIntroduction To Micro Nanofabrication PDFGauri DalviNo ratings yet

- E e en N Na A Af F Fix Ix Ix: Tile AdhesiveDocument2 pagesE e en N Na A Af F Fix Ix Ix: Tile Adhesiveریحان مغلNo ratings yet

- Itp For Pipes CS<CSDocument1 pageItp For Pipes CS<CSSuraj ShettyNo ratings yet

- 1556320638TDS - SN-501 100 RTV Neutral Silicone SealantDocument2 pages1556320638TDS - SN-501 100 RTV Neutral Silicone SealantLawrence LauNo ratings yet

Hydro en Aw 1050a

Hydro en Aw 1050a

Uploaded by

Manoranjan MohapatraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydro en Aw 1050a

Hydro en Aw 1050a

Uploaded by

Manoranjan MohapatraCopyright:

Available Formats

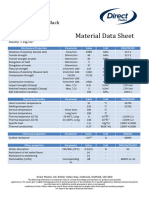

Technical datasheet - Extruded products

Alloy EN AW-1050A [Al99.5]

The 1xxx series are essentially pure with a minimum of 99% aluminum content by weight. The series are non-heat treatable but

can be work hardened. Alloy 1050 has a minimum purity of 99.5% aluminum and it can be extruded into profiles, rods, bars and

tubes.

This alloy offers very good corrosion resistance and displays excellent forming, welding, brazing and finishing characteristics.

Typical applications include chemical and food handling equipment, as well as containers for food, pharmaceuticals and liquids.

Typical Applications

• Heat exchanger tubing • Medical and chemical equipment • Cable sheating

• Electrical conductors • Pharmaceutical containers • Food handling equipment

Chemical Composition 1

Si Fe Cu Mn Mg Cr Zn Ti Pb Others Al

Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max Each Tot Min

0.25 0.40 0.05 0.05 0.05 0.07 0.05 0.03 99.50

1 Chemical composition in weight-% according to EN-573-3:2013

Mechanical Properties 2

HBW c

Wall thickness Rp0,2 Rm A A50mm

Temper TYPICAL

t [mm] [MPa] [MPa] [%] [%]

VALUE

Fa, H112 all 20 60 25 23 20

2 Properties according to EN 755-2:2016 for extruded profile, minimum values unless else specified.

a F temper: properties are for information only.

c Brinell hardness values are for information only.

Temper Designations 4

As fabricated.

F This designation applies to the products of shaping processes in which no special control over thermal conditions or

strain-hardening is employed. For this temper there is no mechanical property limits specified.

Annealed.

O This designation applies to products which are annealed to obtain the lowest strength temper.

H112 Strain hardened temper via the extrusion process to develop minimum property requirements

4 Temper designations according to EN 515:1993

Physical Properties 5

Coefficient of

Modulus of Modulus of Thermal Specific Heat Electrical

Melting Range Density linear

Temper Elasticity Rigidity Conductivity Capacity Resistivity

[°C] [g/cm3] expansion

[GPa] [GPa] [W/m⋅K] [J/kg⋅K] [nΩm]

[10-6K-1]

69 26 645 - 658 2.70 229 901 28 23.5

5 Reference: MNC Handbok nr 12, version 2, SIS, 1989. Typical properties at room temperature 20°C

Hydro Innovation & Technology, Finspång, Sweden 1/1 Hydro 1050A – 10/2018

You might also like

- Sponge Iron PlantDocument11 pagesSponge Iron PlantLi GaryNo ratings yet

- Grinding Wheels, Honing Stones and Turning BitsDocument6 pagesGrinding Wheels, Honing Stones and Turning BitsSamer SalibaNo ratings yet

- Lime Kiln Gasification General - 2012Document18 pagesLime Kiln Gasification General - 2012DiogoNo ratings yet

- Worder & Pandel (Cap Berbec) : X TopoareDocument12 pagesWorder & Pandel (Cap Berbec) : X TopoareFlorinTudose100% (2)

- EurametalTechnic 4Document1 pageEurametalTechnic 4Chirim AinurNo ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- Hydro en Aw 6082Document3 pagesHydro en Aw 6082Velissarios DemetriouNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- RT Duroid 5870 5880 Data Sheet PDFDocument2 pagesRT Duroid 5870 5880 Data Sheet PDFNom MonNo ratings yet

- Commercial Purity Aluminium1050Document1 pageCommercial Purity Aluminium1050HermanNo ratings yet

- Commercial-Purity Aluminium1050Document1 pageCommercial-Purity Aluminium1050SiyabulelaNo ratings yet

- Non Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% MinimumDocument1 pageNon Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% Minimumprivate 2No ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Novatec Premium Ii: Technical Data SheetDocument1 pageNovatec Premium Ii: Technical Data SheetRuben PauwelsNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- Tehnicke Karakteristike Asistal Alu OkapnicaDocument2 pagesTehnicke Karakteristike Asistal Alu OkapnicaDARKO RADICEVICNo ratings yet

- Ultra Soft Thermal Pad: Features ApplicationDocument1 pageUltra Soft Thermal Pad: Features ApplicationMalek Ellouz (Jay)No ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- NEDAL Datasheet-3003Document1 pageNEDAL Datasheet-3003Manoranjan MohapatraNo ratings yet

- TDS HBMDocument1 pageTDS HBMP Singh KarkiNo ratings yet

- Reinz AFM 37 가스켓 TDS (BFP 기본 가스켓) 1Document3 pagesReinz AFM 37 가스켓 TDS (BFP 기본 가스켓) 1Geonung Park (Fall For 2)No ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasNo ratings yet

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasNo ratings yet

- 36NiCrMo16 10083 06 ENG 01Document1 page36NiCrMo16 10083 06 ENG 01Guru Raj9739No ratings yet

- General Description: Coupling: Brown, Blue Pipe Body: Brown, BlueDocument5 pagesGeneral Description: Coupling: Brown, Blue Pipe Body: Brown, Blueharan2000No ratings yet

- 18nicrmo14-6: Steel GradeDocument4 pages18nicrmo14-6: Steel Gradesmith willNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- RT-duroid 6202 Laminate Data SheetDocument2 pagesRT-duroid 6202 Laminate Data SheetAditya Bonnerjee 21BEC0384No ratings yet

- POLYTETRAFLUOROETHYLENE - MAIZEY PTFE - 2021 - EmailDocument2 pagesPOLYTETRAFLUOROETHYLENE - MAIZEY PTFE - 2021 - EmailGustavNo ratings yet

- Sabic Chile Ptfe Hoja TecnicaDocument1 pageSabic Chile Ptfe Hoja Tecnicae.vicente.caballeroNo ratings yet

- Rigid PVCDocument1 pageRigid PVCRND KencanaNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous zBSE9MNo ratings yet

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Document1 pageAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNo ratings yet

- Gb8417domex500mc PDFDocument2 pagesGb8417domex500mc PDFMario MereniNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- Scope: Ferritic Heat-Resistant Steel TK 1.4762Document5 pagesScope: Ferritic Heat-Resistant Steel TK 1.4762Siis IngenieriaNo ratings yet

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81No ratings yet

- Datasheet Wesgo Ceramics Al500Document2 pagesDatasheet Wesgo Ceramics Al500hemanth_85No ratings yet

- GFT Data SheetDocument1 pageGFT Data SheetDasan ThadathilNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- Technical Data Sheet - Burachem Blue 9655 BDocument1 pageTechnical Data Sheet - Burachem Blue 9655 BmunhNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDocument2 pagesKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyNo ratings yet

- Nylon 6Document1 pageNylon 6luuiissNo ratings yet

- ASTM C90700 - CuSn11 - Tin Bronze AlloysDocument1 pageASTM C90700 - CuSn11 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- Kaiser Aluminum 7075 Rod and BarDocument2 pagesKaiser Aluminum 7075 Rod and BarH VNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- Technical Information: Coextruded Biaxially Oriented Polypropylene FilmDocument1 pageTechnical Information: Coextruded Biaxially Oriented Polypropylene FilmAlzena badzlinNo ratings yet

- Acetal Natural Data SheetDocument1 pageAcetal Natural Data SheetvijayNo ratings yet

- General Description: Coupling: Red, Blue Pipe Body: Red, BlueDocument5 pagesGeneral Description: Coupling: Red, Blue Pipe Body: Red, Blueharan2000No ratings yet

- CuZn38Pb2 CW608N ENDocument4 pagesCuZn38Pb2 CW608N ENTaner DemirelNo ratings yet

- PB Unimax English160604152107Document12 pagesPB Unimax English160604152107filipeNo ratings yet

- TDS Siltherm-AluFlex 05-2022Document2 pagesTDS Siltherm-AluFlex 05-2022benjaminNo ratings yet

- Calaumid 612Document1 pageCalaumid 612Sudipta GangopadhyayNo ratings yet

- STC White Paper Zta Zirconia Toughened Alumina 01062021Document4 pagesSTC White Paper Zta Zirconia Toughened Alumina 01062021王柏昆No ratings yet

- Technical Aluminium Alloys LM20 09 05 22Document3 pagesTechnical Aluminium Alloys LM20 09 05 22baskaran.marieNo ratings yet

- Catalog FEEL by THM AgencyDocument68 pagesCatalog FEEL by THM Agencykartika lestariNo ratings yet

- SMAW WeldingDocument259 pagesSMAW Weldingimsovanara5310100% (1)

- Royale Play StuccoDocument2 pagesRoyale Play Stuccosaran100% (1)

- Smaw List of Equipment Tesda-Op-Co-01-F13Document3 pagesSmaw List of Equipment Tesda-Op-Co-01-F13Manilyn GaranganaoNo ratings yet

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiNo ratings yet

- KL HazopDocument4 pagesKL HazopSalahBouzianeNo ratings yet

- Manufacturing of SteelDocument2 pagesManufacturing of SteelSamuel AntobamNo ratings yet

- InkDocument23 pagesInkSaurabh SinghNo ratings yet

- TW-Disposable Masks - W17 UNIDocument7 pagesTW-Disposable Masks - W17 UNICindy FonsecaNo ratings yet

- The Australian Welding Guide PDFDocument220 pagesThe Australian Welding Guide PDFThành Nguyễn Xuân100% (1)

- Corroseal TE 321 Rev 01Document1 pageCorroseal TE 321 Rev 01Ashif AkhtarNo ratings yet

- 10 Types of ValvesDocument7 pages10 Types of ValvesLamar TwitchNo ratings yet

- Electronic PackagingDocument54 pagesElectronic PackagingAdelle Lyn Carlos100% (1)

- Router Repair of Soundboard Cracks: Using The Spurlock Specialty Tools Carbide Router Bit and Router BaseDocument10 pagesRouter Repair of Soundboard Cracks: Using The Spurlock Specialty Tools Carbide Router Bit and Router BaselazarNo ratings yet

- 8.2 Fundamentals of Manufacturing For EngineersDocument13 pages8.2 Fundamentals of Manufacturing For EngineersKhánh ĐàoNo ratings yet

- Laxminarayan Institute of Technology: Placement Record 2020 - 21Document3 pagesLaxminarayan Institute of Technology: Placement Record 2020 - 21Smit patelNo ratings yet

- RJS Pattern Making NewDocument23 pagesRJS Pattern Making NewRam Janm SinghNo ratings yet

- Ucmp First Mid Course FileDocument160 pagesUcmp First Mid Course FileAraveetiCSReddyNo ratings yet

- What Is Difference Between Tempering, Annealing, Normalizing and QuenchingDocument1 pageWhat Is Difference Between Tempering, Annealing, Normalizing and QuenchingMONER MANUSNo ratings yet

- Azud Modular 100 EngDocument2 pagesAzud Modular 100 EngAnonymous nPK85ZFzNo ratings yet

- 77 1006 SafetyReliefValveDocument8 pages77 1006 SafetyReliefValverahul soniNo ratings yet

- Sly Venturi ScrubberDocument2 pagesSly Venturi Scrubberzguy360No ratings yet

- Introduction To Micro Nanofabrication PDFDocument39 pagesIntroduction To Micro Nanofabrication PDFGauri DalviNo ratings yet

- E e en N Na A Af F Fix Ix Ix: Tile AdhesiveDocument2 pagesE e en N Na A Af F Fix Ix Ix: Tile Adhesiveریحان مغلNo ratings yet

- Itp For Pipes CS<CSDocument1 pageItp For Pipes CS<CSSuraj ShettyNo ratings yet

- 1556320638TDS - SN-501 100 RTV Neutral Silicone SealantDocument2 pages1556320638TDS - SN-501 100 RTV Neutral Silicone SealantLawrence LauNo ratings yet