Professional Documents

Culture Documents

Lab Report Thermodynamics Exp 3

Lab Report Thermodynamics Exp 3

Uploaded by

QistyCopyright:

Available Formats

You might also like

- Heat Exchanger Lab ReportDocument5 pagesHeat Exchanger Lab ReportJohnConor92% (73)

- N2 Purging PDFDocument5 pagesN2 Purging PDFMohamed AdelNo ratings yet

- Francis TurbineDocument8 pagesFrancis TurbineMohamad HamimyuddinNo ratings yet

- Experiment 4 Turbine CharacteristicsDocument12 pagesExperiment 4 Turbine CharacteristicsChong Ru YinNo ratings yet

- Motors DetailDocument12 pagesMotors Detailhun'bun youmineNo ratings yet

- Pelton Wheel (FINAL) PDFDocument9 pagesPelton Wheel (FINAL) PDFSurendren SurenkkNo ratings yet

- Calculation of Water Column Inertia (T Discharge Q at Outlet of Penstock (After Trifurcation)Document2 pagesCalculation of Water Column Inertia (T Discharge Q at Outlet of Penstock (After Trifurcation)Shahid KhanNo ratings yet

- Design DataDocument29 pagesDesign DatakalyanikishoreNo ratings yet

- Catalog Suflante Kubicek Suprapresiune 2016 05Document28 pagesCatalog Suflante Kubicek Suprapresiune 2016 05Daniela OlteanuNo ratings yet

- Francis TurbineDocument4 pagesFrancis TurbineMuhammad Fauzan Ansari Bin AzizNo ratings yet

- Techanicaldiary 490 MW PDFDocument13 pagesTechanicaldiary 490 MW PDFsauravyadav33No ratings yet

- Experiment # 5: Objective:: Fig: 5.1 (Impulse Turbine)Document7 pagesExperiment # 5: Objective:: Fig: 5.1 (Impulse Turbine)AkramNo ratings yet

- Manual TorquimetroDocument4 pagesManual TorquimetroGabriel ArriazaNo ratings yet

- Centrifugal ExperimentDocument8 pagesCentrifugal ExperimentNizar NanoNo ratings yet

- Yarmouk University Civil Engineering Department Fluid Mechanics and Hydraulic Laboratory CE 354Document7 pagesYarmouk University Civil Engineering Department Fluid Mechanics and Hydraulic Laboratory CE 354Mohammed MigdadyNo ratings yet

- Turbine Fuel Shut Off Valve: Model 4420EDocument11 pagesTurbine Fuel Shut Off Valve: Model 4420EfranmyflamesNo ratings yet

- Lab ManualDocument9 pagesLab ManualMohit SinhaNo ratings yet

- Logsheet Boiler 10-06-2023Document696 pagesLogsheet Boiler 10-06-2023GAMING ChannelNo ratings yet

- NUY90NRa - R290 - 115 - 60Document5 pagesNUY90NRa - R290 - 115 - 60Glorimar RojasNo ratings yet

- Contracorriente Paralelo Ensayo 1 2 3 6 5 4Document6 pagesContracorriente Paralelo Ensayo 1 2 3 6 5 4Digna Bettin CuelloNo ratings yet

- Tecumseh THG1358YLS.Document4 pagesTecumseh THG1358YLS.auyantepuy73100% (1)

- Manual Servicios LG Aruv PDFDocument42 pagesManual Servicios LG Aruv PDFHERIBERTONo ratings yet

- Impulse TurbineDocument13 pagesImpulse TurbineJoy PatelNo ratings yet

- Utilities For EB calculations-DADocument21 pagesUtilities For EB calculations-DAMuataman KhNo ratings yet

- THG1365YLSDocument4 pagesTHG1365YLSRolando LopezNo ratings yet

- Purge With NitrogenDocument5 pagesPurge With NitrogenSurya Kiran KNo ratings yet

- CO2 Compressor PowerDocument4 pagesCO2 Compressor PowerSubrata MukherjeeNo ratings yet

- Component Units 1 2 3 4 5 6: F G F GDocument6 pagesComponent Units 1 2 3 4 5 6: F G F Gbighead3158No ratings yet

- Mis Oct.2021Document18 pagesMis Oct.2021Jacky KaruppaiahNo ratings yet

- Ae2425z FZ1CDocument4 pagesAe2425z FZ1CMageon7No ratings yet

- PeltonDocument10 pagesPeltonNazatul Zuhanis100% (1)

- CPA Electrical Valuation ReportDocument3 pagesCPA Electrical Valuation ReportSatyanarayanareddy AiluriNo ratings yet

- Ciler IspravkaDocument18 pagesCiler IspravkaNevena AksićNo ratings yet

- Reaction Turbine PerformanceDocument12 pagesReaction Turbine PerformanceRIPUDAMAN SINGHNo ratings yet

- Experiment 5: To Obtain The Characteristic Curves of An Axial Flow Impulse Turbine at Different Rotor SpeedDocument15 pagesExperiment 5: To Obtain The Characteristic Curves of An Axial Flow Impulse Turbine at Different Rotor SpeedAbdul Fatir KhanNo ratings yet

- Ae1420z FZ1B PDFDocument8 pagesAe1420z FZ1B PDFMateo AcuñaNo ratings yet

- Chapter 03Document8 pagesChapter 03Gianne Karl AlmarinesNo ratings yet

- Outdoor Unit Specs - Extracted (P1B) - 00006 R0 - OMM-VRF AC Sys. (Samsung)Document112 pagesOutdoor Unit Specs - Extracted (P1B) - 00006 R0 - OMM-VRF AC Sys. (Samsung)eclimaco.snclgroupNo ratings yet

- PUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Document1 pagePUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Bimal DeyNo ratings yet

- Lab No 4Document13 pagesLab No 4Rahim BalouchNo ratings yet

- Optimization of Propane Refrigeration System For Hydrocarbon Dew by Mahmood Moshfeghian On 21 Jul 08.PpDocument22 pagesOptimization of Propane Refrigeration System For Hydrocarbon Dew by Mahmood Moshfeghian On 21 Jul 08.PpRama Krishnan100% (1)

- Duclayan Expt5 PrelimDocument11 pagesDuclayan Expt5 PrelimMarc Steven CaranzoNo ratings yet

- Renewable Energy Sources ProjectsDocument15 pagesRenewable Energy Sources ProjectsnaiaraNo ratings yet

- Fan Calc10Document5 pagesFan Calc10Bùi Hắc HảiNo ratings yet

- Compliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Document5 pagesCompliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Bùi Hắc HảiNo ratings yet

- Compliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Document5 pagesCompliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Bùi Hắc HảiNo ratings yet

- Compliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Document5 pagesCompliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Bùi Hắc HảiNo ratings yet

- Compliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Document5 pagesCompliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)haibhNo ratings yet

- 02 OutputDocument6 pages02 Outputmilos89mfNo ratings yet

- Model:: AE2425Z-GS3CDocument14 pagesModel:: AE2425Z-GS3Candrianimka100% (1)

- Fan Power and Heat CalculatorDocument5 pagesFan Power and Heat CalculatorAnonymous oVRvsdWzfBNo ratings yet

- Fan Pump Calc 10Document5 pagesFan Pump Calc 10Yosses Sang NahkodaNo ratings yet

- Spiral Casing: The Spiral Casing Around The Runner of The Turbine Is Known As Volute Casing. AllDocument9 pagesSpiral Casing: The Spiral Casing Around The Runner of The Turbine Is Known As Volute Casing. AllMuhammad Fauzan Ansari Bin AzizNo ratings yet

- Chiller Plant Equip Log Sheet J Mall August 2016 Group01Document27 pagesChiller Plant Equip Log Sheet J Mall August 2016 Group01Yan's Senora BescoroNo ratings yet

- IEEE9 Model Documentation R0Document13 pagesIEEE9 Model Documentation R0Nando LópezNo ratings yet

- QSD2 QSD28 QSD42 Bosch Bosch Marine 4082012Document2 pagesQSD2 QSD28 QSD42 Bosch Bosch Marine 4082012aleman100% (1)

- Baru - Aux Engine Performance Reports March 2022Document12 pagesBaru - Aux Engine Performance Reports March 2022Dragoș GreceanuNo ratings yet

- Danfoss - NUY70NRa - R290 - 115 - 60Document5 pagesDanfoss - NUY70NRa - R290 - 115 - 60Rubén Darío RojasNo ratings yet

- Addis Ababa Science & Technology University: Collage of Electrical and Mechanical EngineeringDocument10 pagesAddis Ababa Science & Technology University: Collage of Electrical and Mechanical EngineeringNurye NigusNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Certificado de Valvulas K18H010 Mill Test Certificate PDFDocument3 pagesCertificado de Valvulas K18H010 Mill Test Certificate PDFdsoto_108536No ratings yet

- CRV ApplicationsDocument13 pagesCRV ApplicationsMuhammad AdnanNo ratings yet

- Reduced Pressure Backflow Prevention Assembly (RPBA) (Standard ASSE 1013)Document2 pagesReduced Pressure Backflow Prevention Assembly (RPBA) (Standard ASSE 1013)RoNo ratings yet

- H2 Parker PDFDocument44 pagesH2 Parker PDFAlejandro GilNo ratings yet

- Valve Tappet With Guide Block - WBD-IEL-5C0201Document1 pageValve Tappet With Guide Block - WBD-IEL-5C0201tomi100% (1)

- Bqs601 Water Reticulation WorksDocument65 pagesBqs601 Water Reticulation Works2022659706No ratings yet

- Fitting Catalog 1Document47 pagesFitting Catalog 1Denny MahendraNo ratings yet

- Power Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Document46 pagesPower Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Lösky D. PinnockNo ratings yet

- Partes Chiller 30hxc-161 Ry 600 KraftDocument8 pagesPartes Chiller 30hxc-161 Ry 600 KraftANGEL MURILLONo ratings yet

- Turbo Machinery Unit 4: Centrifugal CompressorsDocument12 pagesTurbo Machinery Unit 4: Centrifugal Compressorsram kishor singhNo ratings yet

- Spirajet Spray NozzleDocument2 pagesSpirajet Spray NozzleykozeNo ratings yet

- Types of Valve and SupportDocument22 pagesTypes of Valve and SupportViren ParmarNo ratings yet

- Fire Protection SpecDocument70 pagesFire Protection SpecZezo Abdallah100% (1)

- Fluids HandlingDocument234 pagesFluids HandlingVenkatesh GangadharNo ratings yet

- Ramjet Engine Test Rig: Propulsion Engineering LaboratoryDocument7 pagesRamjet Engine Test Rig: Propulsion Engineering Laboratoryaman guptaNo ratings yet

- Charging of Nitrogen Gas Into AccumulatorDocument1 pageCharging of Nitrogen Gas Into AccumulatorConi Fuenzalida VarelaNo ratings yet

- M15 Gas Turbine Engine: Aviation Training HubDocument197 pagesM15 Gas Turbine Engine: Aviation Training Hubhaider aliNo ratings yet

- Sant List April-2017Document61 pagesSant List April-2017Javed HasanNo ratings yet

- Hose Reel 308109EN-RDocument40 pagesHose Reel 308109EN-RandraNo ratings yet

- Dosing Pump Series - DDocument2 pagesDosing Pump Series - DKali Dass KMNo ratings yet

- UASB Booster Pressure CalculationDocument143 pagesUASB Booster Pressure CalculationJayakrishnan RadhakrishnanNo ratings yet

- Asahi Wafer Check ValveDocument2 pagesAsahi Wafer Check ValveShaimaa BaataNo ratings yet

- Amman Strategic Reserve Terminal For Petroleum Products: B Issued For Review ABD ABD AMS MADocument11 pagesAmman Strategic Reserve Terminal For Petroleum Products: B Issued For Review ABD ABD AMS MAAbd Al Rahman OmaryNo ratings yet

- 2011 List Price SheetDocument58 pages2011 List Price SheetpressureproNo ratings yet

- 40MF End Suction BrochureDocument4 pages40MF End Suction Brochurerhusseinpos4765No ratings yet

- In-Lab Sharp-Edged Orifice Meter ReportDocument9 pagesIn-Lab Sharp-Edged Orifice Meter ReportLiliane AlameddineNo ratings yet

- Gi-0002 102Document18 pagesGi-0002 102Md Azizul Mawla100% (2)

- 3MS Course NotesDocument84 pages3MS Course NotesJimmy WuNo ratings yet

- Aux Steam Ee 00100 Axs 002Document15 pagesAux Steam Ee 00100 Axs 002anbarasusivaprakasam100% (2)

- Module 1Document45 pagesModule 1shubham GoundadkarNo ratings yet

Lab Report Thermodynamics Exp 3

Lab Report Thermodynamics Exp 3

Uploaded by

QistyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Report Thermodynamics Exp 3

Lab Report Thermodynamics Exp 3

Uploaded by

QistyCopyright:

Available Formats

CONTENTS

ABSTRACT..............................................................................................................................

OBJECTIVES...........................................................................................................................

RESULT....................................................................................................................................

DISCUSSIONS.........................................................................................................................

CONCLUSION AND RECOMMENDATIONS....................................................................

REFERENCES........................................................................................................................

APPENDICES.........................................................................................................................

1 |THERMODYNAMICS LAB REPORT

ABSTRACT

The experiment is conducted to study the effect of the spear valve settings under

varied load conditions. An adjustable spear valve controls the discharge by varying the

diameter of the jet from the nozzle. The centrifugal pump on the base unit supplies water to

the nozzle. Water from the turbine discharges back into the base unit tank and recirculates.

The turbine shaft connects to the base unit dynamometer. This measures torque and speed. By

using turbine we can change one form of energy (kinetic) to other form of energy such as

electricity. These can be achieved when turbines develop torque and shaft power from the

momentum change of fluids –liquid, vapor or gas, which passes through the turbine. To

produce high momentum, a higher velocity of fluid is required therefore differences in

pressure at the inlet and outlet of the turbine can be achieved. The turbine then converts the

energy supplied by the compressed or heated fluid into works that drives electric generators

or transfer power by using shaft. The turbine used are SOLTEQ® Multi Turbine Test Set

(Model: FM 46) consists of a centrifugal pump with controlled motor speed, three

interchangeable sets of Pelton turbine complete with individual casing respectively. The test

set is a self-contained unit comprising two main assemblies, an instrument/control console

and a welded steel base frame, which carries the pump, turbine set and water reservoir tank.

Pressure transmitters are installed on each inlet and outlet of both pump and turbine set to

measure the pressure on the respective locations. A Pelton turbine mounts on the 3 kW pump

and turbine test set base unit. Water from the turbine discharges back into the base unit tank

and recirculates. This measures torque and speed. At the end of this experiment all the data

recorded will be used to calculate power generated, shaft power, turbine input power, motor

efficiency and overall efficiency, then 3 graph will be plotted which is power generated

versus turbine speed for all three opening, turbine motor efficiency versus turbine speed for

all three opening and the turbine overall efficiency versus turbine speed for all three opening.

OBJECTIVES

To study the effect of the spear valve settings under varied load conditions

2 |THERMODYNAMICS LAB REPORT

RESULT

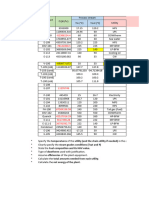

A) FULLY OPENING

1 2 3 4 5 6 7 8 9

Load combination 0 L1 L2 L1+L2 L3 L1+L3 L1+L2+ L4 L5

L3

Pump Inlet PT1 Bar Abs 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75

Pressure

Pump Outlet PT2 Bar Abs 2.63 2.63 2.63 2.63 2.64 2.64 2.64 2.64 2.67

Pressure

Turbine Stage PT3 Bar Abs 2.57 2.57 2.57 2.57 2.57 2.57 2.57 2.57 2.57

1 Pressure

Turbine Stage PT4 Bar Abs 1.82 1.82 1.81 1.81 1.80 1.80 1.81 1.81 1.82

2 Pressure

Water FT Liter/min 162.50 162.60 162.30 162.60 162.50 163.10 162.30 162.00 163.00

Flowrate

Pump Speed SP1 Rpm 2000 2000 2000 2000 2000 2000 2003 2003 2003

Pump Torque TQ1 Nm 4.20 4.20 4.20 4.20 4.20 4.20 4.20 4.20 4.20

Pump Power PWR1 kw 2130 2130 2130 2130 2131 2131 2131 2131 2131

Turbine Speed SP2 Rpm 1435 1391 802 784 539 532 431 1334 244

Turbine TQ2 Nm 0.20 0.30 1.10 1.10 1.40 1.40 1.50 0.40 1.60

Torque

Turbine V1 V 73.30 69.60 36.00 35.50 22.20 21.70 16.10 66.30 6.00

Voltage

Turbine I1 A 0.00 0.16 1.93 1.95 2.51 2.51 2.71 0.33 3.03

Current

Power Generated (W) 0.00 11.14 69.48 69.23 55.72 54.47 43.63 21.88 18.18

Shaft Power (W) 30.05 43.70 92.38 90.31 79.02 78.00 67.70 55.88 40.88

Turbine Input Power (W) 45.17 45.19 45.11 45.19 45.17 45.33 45.11 45.03 45.31

Motor Efficiency (%) 66.53 96.70 204.79 199.85 174.94 172.07 150.08 124.10 90.22

Overall Efficiency (%) 0.00 24.65 154.02 153.20 123.36 120.16 96.72 48.59 40.12

3 |THERMODYNAMICS LAB REPORT

B) MIDDLE OPENING

1 2 3 4 5 6 7 8 9

Load combination 0 L1 L2 L1+L2 L3 L1+L3 L1+L2+ L4 L5

L3

Pump Inlet PT1 Bar Abs 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.82

Pressure

Pump Outlet PT2 Bar Abs 2.75 2.75 2.75 2.75 2.75 2.75 2.75 2.75 2.75

Pressure

Turbine Stage PT3 Bar Abs 2.70 2.69 2.69 2.69 2.69 2.69 2.69 2.69 2.69

1 Pressure

Turbine Stage PT4 Bar Abs 2.14 2.14 2.14 2.14 2.14 2.14 2.14 2.13 2.13

2 Pressure

Water FT Liter/min 138.60 139.40 138.30 138.30 138.70 137.80 137.80 137.80 138.40

Flowrate

Pump Speed SP1 Rpm 2003 2003 2003 2003 2003 2003 2003 2003 2003

Pump Torque TQ1 Nm 3.90 3.90 3.90 3.90 3.90 3.90 3.90 3.90 3.90

Pump Power PWR1 kw 2131 2131 2131 2131 2131 2131 2131 2131 2131

Turbine Speed SP2 Rpm 1733 1673 908 886 592 580 468 1600 267

Turbine TQ2 Nm 0.20 0.30 1.20 1.20 1.50 1.50 1.60 0.40 1.70

Torque

Turbine V1 V 88.30 83.30 41.40 39.90 23.80 23.40 17.10 79.50 6.40

Voltage

Turbine I1 A 0.00 0.20 2.10 2.21 2.76 2.77 2.92 0.37 3.32

Current

Power Generated (W) 0.00 16.66 86.94 88.18 65.69 64.82 49.93 29.42 21.25

Shaft Power (W) 36.30 52.56 114.10 111.34 92.99 91.11 78.41 67.02 47.53

Turbine Input Power (W) 38.52 38.75 38.44 38.44 38.55 38.30 38.30 38.30 38.47

Motor Efficiency (%) 94.24 135.64 296.83 289.65 241.22 237.89 204.73 174.99 123.55

Overall Efficiency (%) 0.00 42.99 226.17 229.40 170.40 169.24 130.37 76.81 55.24

4 |THERMODYNAMICS LAB REPORT

C) SMALL OPENING

1 2 3 4 5 6 7 8 9

Load combination 0 L1 L2 L1+L2 L3 L1+L3 L1+L2+L3 L4 L5

Pump Inlet PT1 Bar Abs 1.02 1.02 1.02 1.02 1.02 1.02 1.02 1.02 1.02

Pressure

Pump Outlet PT2 Bar Abs 3.13 3.13 3.13 3.13 3.13 3.13 3.13 3.13 3.13

Pressure

Turbine Stage PT3 Bar Abs 3.09 3.09 3.09 3.09 3.09 3.09 3.09 3.09 3.09

1 Pressure

Turbine Stage PT4 Bar Abs 3.06 3.06 3.06 3.06 3.06 3.06 3.06 3.06 3.06

2 Pressure

Water FT Liter/min 31.30 30.30 30.30 30.50 30.30 30.30 30.60 30.40 30.40

Flowrate

Pump Speed SP1 Rpm 2014 2014 2014 2014 2014 2014 2014 2014 2014

Pump Torque TQ1 Nm 2.40 2.40 2.40 2.40 2.40 2.40 2.40 2.40 2.40

Pump Power PWR1 kw 2132 2132 2132 2131 2131 2131 2131 2131 2131

Turbine Speed SP2 Rpm 600 521 185 177 118 116 92 416 58

Turbine TQ2 Nm 0.10 0.20 0.30 0.30 0.30 0.30 0.30 0.30 0.30

Torque

Turbine V1 V 30.30 26.60 7.80 7.20 3.80 3.80 3.10 19.60 1.10

Voltage

Turbine I1 A 0.00 0.06 0.39 0.39 0.49 0.49 0.51 0.09 0.57

Current

Power Generated (W) 0.00 1.60 3.04 2.81 1.86 1.86 1.58 1.76 0.63

Shaft Power (W) 6.28 10.91 5.81 5.56 3.71 3.64 2.89 13.07 1.82

Turbine Input Power (W) 8.70 8.42 8.42 8.48 8.42 8.42 8.51 8.45 8.45

Motor Efficiency (%) 72.18 129.57 69.00 64.80 44.06 43.23 33.96 154.67 21.54

Overall Efficiency (%) 0.00 19.00 36.10 33.14 22.09 22.09 18.57 20.83 7.46

5 |THERMODYNAMICS LAB REPORT

Graph of Power Generated (W) versus Turbine Speed (Rpm)

2000

1800

1600

1400

1200

1000

800

Turbine Speed (Rpm)

600

400

200

0

Fully Opening Middle Opening Small Opening

Turbine Speed (Rpm) Power Generated (W)

Graph 1: Power generated (W) versus Turbine Speed (Rpm)

6 |THERMODYNAMICS LAB REPORT

Graph Turbine Motor Efficiency (%) versus Turbine Speed (Rpm)

2000

1800

1600

1400

1200

1000

Turbine Speed (Rpm)

800

600

400

200

0

Fully Opening Middle Opening Small Opening

Turbine Speed (Rpm) Turbine Motor Efficiency (%)

Graph 2: Turbine motor efficiency (%) versus turbine speed (Rpm)

7 |THERMODYNAMICS LAB REPORT

Graph of Turbine Overall Efficiency (%) versus Turbine Speed (Rpm)

2000

1800

1600

1400

1200

1000

Turbine Speed (Rpm)

800

600

400

200

0

Fully Opening Middle Opening Small Opening

Turbine Speed (Rpm) Turbine Overall Efficiency (%)

Graph 3: Turbine overall efficiency (%) versus turbine speed (Rpm)

8 |THERMODYNAMICS LAB REPORT

DISCUSSIONS

Based on the result obtained, the experiment was successful. This experiment is

using impulse turbine to study the effect of adjusting the spear valve settings under varied

load conditions. Turbine is a machine where the process of open system occurs. This

experiment is related to First Law of Thermodynamics where heat is a form of energy, and

thermodynamic processes are therefore subject to the principle of conservation of energy.

This means that heat energy cannot be created or destroyed. It can, however, be transferred

from one location to another and converted to and from other forms of energy (Lucas, 2015).

There are three types of setting on spear valve. The difference is in the diameter or the

size of the jet on the nozzle. We use fully, middle and small opening of spear valve to analyse

the efficiency of the turbine. We used water as a medium to operate the Multi Turbine Test

Set. Water flowrate is increasing from small opening to fully opening or from larger

diameter to small diameter of the nozzle. Because when the area of the nozzle is larger, the

flow of the water become easier and flowrate is increasing. Besides that, the pressure of the

pump in fully opening is lower than in middle and small opening. This is because of the

pressure is inversely proportional with area.

According to the table of data, each load combinations have constant value of

pressure in inlet pump and outlet pump and also at turbine stage 1 and stage 2. All of type

opening has a higher pressure at outlet pump compared to inlet pump. Meanwhile pressure at

turbine stage 1 and stage 2 at fully opening of spear valve has a larger different ( ± 0.77 )

between them. In middle opening result, there are ± 0.06 differences and in small opening is

± 0.03 differences. In conclusion, the size of nozzle at middle opening or small opening could

be flow at steady state.

Graph 1 is present the relationship between the power generated (W) and turbine

speed (rpm). All of type opening has zero value when there is no load exerted. Then, power

generated fully opening and middle opening increasing from load combination 1 to 5.

Meanwhile, small opening is increasing until load combination 4. Each type of opening has

zero value for turbine current during the 1st load combination and increasing until load

combination 9. When 8th load combination, turbine shown smaller value of current and higher

turbine voltage. Power generated is affected by the turbine current and voltage value. The

9 |THERMODYNAMICS LAB REPORT

higher the turbine voltage (smaller turbine current), the higher the power generated by the

turbine. The turbine speed for all type of settings is decreasing from load combination 1st to

9th but at 8th load combination the turbine speed increasing then it decreases at 9 th load

combination. At fully opening, turbine speed at 8th load combination (L4 ) is 1334 rpm, middle

opening is 1600 rpm and small opening is 416 rpm.

Then, graph 2 is graphically presented the relationship between the turbine motor

efficiency and turbine speed. Turbine motor efficiency is the ratio of shaft power and turbine

power input. Turbine power input is proportional with water flowrate. The higher the water

flowrate, the larger the turbine input power. Meanwhile shaft power is proportional with

turbine torque and turbine speed. The higher the turbine torque, the higher the shaft power.

According to the result of motor efficiency, shaft power has higher value compared to turbine

input power. Middle opening shown the highest motor efficiency at load combination 3 (L2),

296.83% also same with fully opening with 204.79%. Compared to small opening at load

combination 2 (L1) with 129.57%. Turbine torque at middle opening has larger value

compared to fully opening and middle opening.

Graph 3 is shown the relationship between turbine overall efficiency and turbine

speed. Overall efficiency is the summarize of the turbine work or heat transfer at maximum.

Based on the ratio of power generated (output) to turbine power input. Basically, we produce

or deliver higher value of output than input. Middle opening shown the highest overall

efficiency at load combination 4 ( L1 +L2), 229.4%. Compared to fully opening and small

opening at load combination 3 (L2) 154.02% and 36.10% respectively.

In conclusion, middle opening is the most suitable for turbine to generate. This is

because of its angle and the distance of the nozzle to jet the water to turbine blades. At

middle opening, the position of nozzle is equal or balance for water to flow out. To get a

better result for generate the turbine, the spear valve supposed have same different of distance

between fully, middle and small opening. From this, we can see clearly the differences

between the turbine works at different size of nozzle. Ensure you fill in the tank with 70% of

its height. It is important so the turbine can operate.

10 |THERMODYNAMICS LAB REPORT

CONCLUSION AND RECOMMENDATIONS

As a conclusion, the experiment was successfully done based on the

observation and data that we have collected. The difference of diameter or size of the jet on

the nozzle influenced the water flowrate. We have used 3 types of opening in this Impulse

Turbine experiment which are fully opening, middle opening and also small opening of spear

valve to analyse the efficiency of the impulse turbine. The medium or fluid that we used to

operate the SOLTEQ® Multi Turbine Test Set ( Model: FM 46 ) is water or denoted as H 2O.

The Multi Turbine Set is more than capable to perform experiments on mechanical power

out, hydraulic power in, hydraulic efficiency and also specific speed. Water flowrate value

that we recorded is higher when we used small opening compared to fully opening or larger

diameter of nozzle compared to small diameter of the nozzle. That is currently because when

the area of the nozzle is larger, the flow of the water become easier and flowrate is

increasing. Other than that, the pressure of the pump in fully opening is lower than in middle

and small opening. This experiment shows that the pressure inside the nozzle is inversely

proportional with area of the nozzle. The size of nozzle at middle opening or small opening

could be flow at steady state. The higher the turbine voltage (smaller turbine current), the

higher the power generated by the turbine. This can be proved by the formula of Power =

Current x Voltage. The turbine speed for all type of settings is decreasing from load

combination 1st to 9th but at 8th load combination the turbine speed increasing then it

decreases at 9th load combination. Turbine power input is proportional with water flowrate.

The higher the water flowrate, the larger the turbine input power. Meanwhile shaft power is

proportional with turbine torque and turbine speed. The higher the turbine torque, the higher

the shaft power. According to the result of motor efficiency, shaft power has higher value

compared to turbine input power. Last but not least, middle opening is the most suitable for

turbine to generate. This is because of its angle and the distance of the nozzle to jet the water

to turbine blades. At middle opening, the position of nozzle is equal or balance for water to

flow out. To get a better result for generate the turbine, the spear valve supposed have same

different of distance between fully, middle and small opening. The recommendations that we

can suggest is we must to wait at least one minute before we turn off the load switch to make

sure the system achieve stability before we recorded the data from the impulse turbine.

11 |THERMODYNAMICS LAB REPORT

REFERENCES

Lucas, J. (2015, May 19). What Is the First Law of Thermodynamics? Retrieved from Life

Science: https://www.livescience.com/50881-first-law-thermodynamics.html

Darling, D. (n.d.). impulse turbine. Retrieved from

https://www.daviddarling.info/encyclopedia/I/AE_impulse_turbine.html

Robertson, J.A. and Crowe, C.T. (1993). Engineering Fluid Mechanics, 5th edition, Houghton

Mifflin, Boston, MA.

White, F.M. (1994). Fluid Mechanics, 3rd edition, McGraw-Hill, Inc., New York, NY.

12 |THERMODYNAMICS LAB REPORT

APPENDICES

Sample calculation:

1. Power Generated

P = IV

Based on the fully opening result L1,

P = (O.16)(69.60)

= 11.14 W

2. Shaft Power

2 πNT

Pshaft =

60

Based on the fully opening result L1,

2 π (1391)(0.30)

Pshaft =

60

Pshaft = 43.70 W

3. Turbine Input Power

Pturbine.input = Pgage x Q

= (pgh) x Q

Based on the fully opening result L1,

3 3

162.5l 1 min 1000 cm 1m

Pturbine.input = (1000)(9.81)(1.70) x × × × 6 3

min 60s 1l 10 cm

= 45.19 W

13 |THERMODYNAMICS LAB REPORT

4. Motor Efficiency

P shaft

nmotor = x 100%

P turbine .input

Based on the fully opening result L1,

43.70

nmotor = x 100%

45.19

=96.70%

5. Overall Efficiency

P generated

Noverall = x 100%

P turbine .input

Based on the fully opening result L1,

11.14

Noverall = x 100%

45.19

=24.65%

14 |THERMODYNAMICS LAB REPORT

You might also like

- Heat Exchanger Lab ReportDocument5 pagesHeat Exchanger Lab ReportJohnConor92% (73)

- N2 Purging PDFDocument5 pagesN2 Purging PDFMohamed AdelNo ratings yet

- Francis TurbineDocument8 pagesFrancis TurbineMohamad HamimyuddinNo ratings yet

- Experiment 4 Turbine CharacteristicsDocument12 pagesExperiment 4 Turbine CharacteristicsChong Ru YinNo ratings yet

- Motors DetailDocument12 pagesMotors Detailhun'bun youmineNo ratings yet

- Pelton Wheel (FINAL) PDFDocument9 pagesPelton Wheel (FINAL) PDFSurendren SurenkkNo ratings yet

- Calculation of Water Column Inertia (T Discharge Q at Outlet of Penstock (After Trifurcation)Document2 pagesCalculation of Water Column Inertia (T Discharge Q at Outlet of Penstock (After Trifurcation)Shahid KhanNo ratings yet

- Design DataDocument29 pagesDesign DatakalyanikishoreNo ratings yet

- Catalog Suflante Kubicek Suprapresiune 2016 05Document28 pagesCatalog Suflante Kubicek Suprapresiune 2016 05Daniela OlteanuNo ratings yet

- Francis TurbineDocument4 pagesFrancis TurbineMuhammad Fauzan Ansari Bin AzizNo ratings yet

- Techanicaldiary 490 MW PDFDocument13 pagesTechanicaldiary 490 MW PDFsauravyadav33No ratings yet

- Experiment # 5: Objective:: Fig: 5.1 (Impulse Turbine)Document7 pagesExperiment # 5: Objective:: Fig: 5.1 (Impulse Turbine)AkramNo ratings yet

- Manual TorquimetroDocument4 pagesManual TorquimetroGabriel ArriazaNo ratings yet

- Centrifugal ExperimentDocument8 pagesCentrifugal ExperimentNizar NanoNo ratings yet

- Yarmouk University Civil Engineering Department Fluid Mechanics and Hydraulic Laboratory CE 354Document7 pagesYarmouk University Civil Engineering Department Fluid Mechanics and Hydraulic Laboratory CE 354Mohammed MigdadyNo ratings yet

- Turbine Fuel Shut Off Valve: Model 4420EDocument11 pagesTurbine Fuel Shut Off Valve: Model 4420EfranmyflamesNo ratings yet

- Lab ManualDocument9 pagesLab ManualMohit SinhaNo ratings yet

- Logsheet Boiler 10-06-2023Document696 pagesLogsheet Boiler 10-06-2023GAMING ChannelNo ratings yet

- NUY90NRa - R290 - 115 - 60Document5 pagesNUY90NRa - R290 - 115 - 60Glorimar RojasNo ratings yet

- Contracorriente Paralelo Ensayo 1 2 3 6 5 4Document6 pagesContracorriente Paralelo Ensayo 1 2 3 6 5 4Digna Bettin CuelloNo ratings yet

- Tecumseh THG1358YLS.Document4 pagesTecumseh THG1358YLS.auyantepuy73100% (1)

- Manual Servicios LG Aruv PDFDocument42 pagesManual Servicios LG Aruv PDFHERIBERTONo ratings yet

- Impulse TurbineDocument13 pagesImpulse TurbineJoy PatelNo ratings yet

- Utilities For EB calculations-DADocument21 pagesUtilities For EB calculations-DAMuataman KhNo ratings yet

- THG1365YLSDocument4 pagesTHG1365YLSRolando LopezNo ratings yet

- Purge With NitrogenDocument5 pagesPurge With NitrogenSurya Kiran KNo ratings yet

- CO2 Compressor PowerDocument4 pagesCO2 Compressor PowerSubrata MukherjeeNo ratings yet

- Component Units 1 2 3 4 5 6: F G F GDocument6 pagesComponent Units 1 2 3 4 5 6: F G F Gbighead3158No ratings yet

- Mis Oct.2021Document18 pagesMis Oct.2021Jacky KaruppaiahNo ratings yet

- Ae2425z FZ1CDocument4 pagesAe2425z FZ1CMageon7No ratings yet

- PeltonDocument10 pagesPeltonNazatul Zuhanis100% (1)

- CPA Electrical Valuation ReportDocument3 pagesCPA Electrical Valuation ReportSatyanarayanareddy AiluriNo ratings yet

- Ciler IspravkaDocument18 pagesCiler IspravkaNevena AksićNo ratings yet

- Reaction Turbine PerformanceDocument12 pagesReaction Turbine PerformanceRIPUDAMAN SINGHNo ratings yet

- Experiment 5: To Obtain The Characteristic Curves of An Axial Flow Impulse Turbine at Different Rotor SpeedDocument15 pagesExperiment 5: To Obtain The Characteristic Curves of An Axial Flow Impulse Turbine at Different Rotor SpeedAbdul Fatir KhanNo ratings yet

- Ae1420z FZ1B PDFDocument8 pagesAe1420z FZ1B PDFMateo AcuñaNo ratings yet

- Chapter 03Document8 pagesChapter 03Gianne Karl AlmarinesNo ratings yet

- Outdoor Unit Specs - Extracted (P1B) - 00006 R0 - OMM-VRF AC Sys. (Samsung)Document112 pagesOutdoor Unit Specs - Extracted (P1B) - 00006 R0 - OMM-VRF AC Sys. (Samsung)eclimaco.snclgroupNo ratings yet

- PUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Document1 pagePUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Bimal DeyNo ratings yet

- Lab No 4Document13 pagesLab No 4Rahim BalouchNo ratings yet

- Optimization of Propane Refrigeration System For Hydrocarbon Dew by Mahmood Moshfeghian On 21 Jul 08.PpDocument22 pagesOptimization of Propane Refrigeration System For Hydrocarbon Dew by Mahmood Moshfeghian On 21 Jul 08.PpRama Krishnan100% (1)

- Duclayan Expt5 PrelimDocument11 pagesDuclayan Expt5 PrelimMarc Steven CaranzoNo ratings yet

- Renewable Energy Sources ProjectsDocument15 pagesRenewable Energy Sources ProjectsnaiaraNo ratings yet

- Fan Calc10Document5 pagesFan Calc10Bùi Hắc HảiNo ratings yet

- Compliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Document5 pagesCompliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Bùi Hắc HảiNo ratings yet

- Compliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Document5 pagesCompliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Bùi Hắc HảiNo ratings yet

- Compliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Document5 pagesCompliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Bùi Hắc HảiNo ratings yet

- Compliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)Document5 pagesCompliant Compliant: Use To Determine Fan Efficiency Use To Find Fan Heat Penalty (In - WTR.)haibhNo ratings yet

- 02 OutputDocument6 pages02 Outputmilos89mfNo ratings yet

- Model:: AE2425Z-GS3CDocument14 pagesModel:: AE2425Z-GS3Candrianimka100% (1)

- Fan Power and Heat CalculatorDocument5 pagesFan Power and Heat CalculatorAnonymous oVRvsdWzfBNo ratings yet

- Fan Pump Calc 10Document5 pagesFan Pump Calc 10Yosses Sang NahkodaNo ratings yet

- Spiral Casing: The Spiral Casing Around The Runner of The Turbine Is Known As Volute Casing. AllDocument9 pagesSpiral Casing: The Spiral Casing Around The Runner of The Turbine Is Known As Volute Casing. AllMuhammad Fauzan Ansari Bin AzizNo ratings yet

- Chiller Plant Equip Log Sheet J Mall August 2016 Group01Document27 pagesChiller Plant Equip Log Sheet J Mall August 2016 Group01Yan's Senora BescoroNo ratings yet

- IEEE9 Model Documentation R0Document13 pagesIEEE9 Model Documentation R0Nando LópezNo ratings yet

- QSD2 QSD28 QSD42 Bosch Bosch Marine 4082012Document2 pagesQSD2 QSD28 QSD42 Bosch Bosch Marine 4082012aleman100% (1)

- Baru - Aux Engine Performance Reports March 2022Document12 pagesBaru - Aux Engine Performance Reports March 2022Dragoș GreceanuNo ratings yet

- Danfoss - NUY70NRa - R290 - 115 - 60Document5 pagesDanfoss - NUY70NRa - R290 - 115 - 60Rubén Darío RojasNo ratings yet

- Addis Ababa Science & Technology University: Collage of Electrical and Mechanical EngineeringDocument10 pagesAddis Ababa Science & Technology University: Collage of Electrical and Mechanical EngineeringNurye NigusNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Certificado de Valvulas K18H010 Mill Test Certificate PDFDocument3 pagesCertificado de Valvulas K18H010 Mill Test Certificate PDFdsoto_108536No ratings yet

- CRV ApplicationsDocument13 pagesCRV ApplicationsMuhammad AdnanNo ratings yet

- Reduced Pressure Backflow Prevention Assembly (RPBA) (Standard ASSE 1013)Document2 pagesReduced Pressure Backflow Prevention Assembly (RPBA) (Standard ASSE 1013)RoNo ratings yet

- H2 Parker PDFDocument44 pagesH2 Parker PDFAlejandro GilNo ratings yet

- Valve Tappet With Guide Block - WBD-IEL-5C0201Document1 pageValve Tappet With Guide Block - WBD-IEL-5C0201tomi100% (1)

- Bqs601 Water Reticulation WorksDocument65 pagesBqs601 Water Reticulation Works2022659706No ratings yet

- Fitting Catalog 1Document47 pagesFitting Catalog 1Denny MahendraNo ratings yet

- Power Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Document46 pagesPower Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Lösky D. PinnockNo ratings yet

- Partes Chiller 30hxc-161 Ry 600 KraftDocument8 pagesPartes Chiller 30hxc-161 Ry 600 KraftANGEL MURILLONo ratings yet

- Turbo Machinery Unit 4: Centrifugal CompressorsDocument12 pagesTurbo Machinery Unit 4: Centrifugal Compressorsram kishor singhNo ratings yet

- Spirajet Spray NozzleDocument2 pagesSpirajet Spray NozzleykozeNo ratings yet

- Types of Valve and SupportDocument22 pagesTypes of Valve and SupportViren ParmarNo ratings yet

- Fire Protection SpecDocument70 pagesFire Protection SpecZezo Abdallah100% (1)

- Fluids HandlingDocument234 pagesFluids HandlingVenkatesh GangadharNo ratings yet

- Ramjet Engine Test Rig: Propulsion Engineering LaboratoryDocument7 pagesRamjet Engine Test Rig: Propulsion Engineering Laboratoryaman guptaNo ratings yet

- Charging of Nitrogen Gas Into AccumulatorDocument1 pageCharging of Nitrogen Gas Into AccumulatorConi Fuenzalida VarelaNo ratings yet

- M15 Gas Turbine Engine: Aviation Training HubDocument197 pagesM15 Gas Turbine Engine: Aviation Training Hubhaider aliNo ratings yet

- Sant List April-2017Document61 pagesSant List April-2017Javed HasanNo ratings yet

- Hose Reel 308109EN-RDocument40 pagesHose Reel 308109EN-RandraNo ratings yet

- Dosing Pump Series - DDocument2 pagesDosing Pump Series - DKali Dass KMNo ratings yet

- UASB Booster Pressure CalculationDocument143 pagesUASB Booster Pressure CalculationJayakrishnan RadhakrishnanNo ratings yet

- Asahi Wafer Check ValveDocument2 pagesAsahi Wafer Check ValveShaimaa BaataNo ratings yet

- Amman Strategic Reserve Terminal For Petroleum Products: B Issued For Review ABD ABD AMS MADocument11 pagesAmman Strategic Reserve Terminal For Petroleum Products: B Issued For Review ABD ABD AMS MAAbd Al Rahman OmaryNo ratings yet

- 2011 List Price SheetDocument58 pages2011 List Price SheetpressureproNo ratings yet

- 40MF End Suction BrochureDocument4 pages40MF End Suction Brochurerhusseinpos4765No ratings yet

- In-Lab Sharp-Edged Orifice Meter ReportDocument9 pagesIn-Lab Sharp-Edged Orifice Meter ReportLiliane AlameddineNo ratings yet

- Gi-0002 102Document18 pagesGi-0002 102Md Azizul Mawla100% (2)

- 3MS Course NotesDocument84 pages3MS Course NotesJimmy WuNo ratings yet

- Aux Steam Ee 00100 Axs 002Document15 pagesAux Steam Ee 00100 Axs 002anbarasusivaprakasam100% (2)

- Module 1Document45 pagesModule 1shubham GoundadkarNo ratings yet