Professional Documents

Culture Documents

UTS-2060 SMPR Automatic Direct Test Machine+4

UTS-2060 SMPR Automatic Direct Test Machine+4

Uploaded by

jean-pierre dalyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UTS-2060 SMPR Automatic Direct Test Machine+4

UTS-2060 SMPR Automatic Direct Test Machine+4

Uploaded by

jean-pierre dalyCopyright:

Available Formats

SOIL

Soil Classification

MATERIAL TESTING EQUIPMENT

DIRECT/ RESIDUAL SHEAR

The test covers the determination of consolidated drained shear strength of a soil

Product Code material by direct shear. UTS-2060.SMPR Automatic Direct-Residual Shear Test

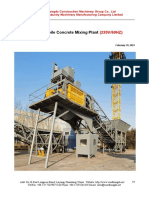

UTS-2060.SMPR Automatic Direct-Residual Shear Machine is motorized and floor mounted. Normal stress is applied to the specimen

Test Machine by utilizing a weight hanger, a lever arm (amplification ratios of 9:1, 10:1 and 11:1)

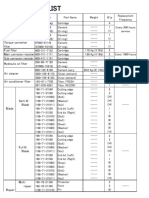

UTS-2065 Shearbox Assembly, 60x60 mm and a vertical loading yoke. Hanger can receive up to 50 kg of weight which is

UTS-2065-07 Cutting Ring, 60x60 mm amplified by the lever arm and transferred to the specimen by the vertical loading

UTS-2065-08 Extrusion Dolly, 60x60 mm yoke as a normal force up to 5 kN (5000 N).

UTS-2066 Shearbox Assembly, Ø 60 mm The machine is supplied with a shearbox bowl that accepts 60 mm square, 100 mm

UTS-2066-07 Cutting Ring, Ø 60 mm square, 60 mm dia. round, 100 mm dia. round and 2.5 inc. dia. round shearboxes.

UTS-2066-08 Extrusion Dolly, Ø 60 mm Shearbox bowl is designed to contain water to inundate the specimen during the test.

UTS-2067 Shearbox Assembly, 100x100 mm The shearbox assemblies consist of rigid upper and lower shearbox frames with

UTS-2067-07 Cutting Ring, 100x100 mm lifting and locking screws, a grooved loading pad, a grooved base plate, porous

UTS-2067-08 Extrusion Dolly, 100x100 mm plates (2 pcs.) and perforated plates (2 pcs.).

UTS-2068 Shearbox Assembly, Ø 100 mm

UTS-2068-07 Cutting Ring, Ø 100 mm Drive unit utilizes a high resolution servomotor and a gear box assembly to ensure

UTS-2068-08 Extrusion Dolly, Ø 100 mm continuously variable transmission of speed in a range from 0.00001 mm-min. to 15

UTS-2069 Shearbox Assembly, Ø 2.5 inch mm-min for both forward and reverse directions. 5 kN load cell is used for load

UTS-2069-07 Cutting Ring, Ø 2.5 inch measurement. 10 x 0.001 mm and 25 x 0.001 mm sensitivity linear potentiometric

UTS-2069-08 Extrusion Dolly, Ø 2.5 inch transducers are used for vertical and horizontal displacement measurements

UTS-2100 Slotted Weight Set, 50 kg respectively. Displacement limits are controlled by limit switch.

(4x10 kg + 1x5 kg + 1x2 kg + 3x1 kg) Shearbox Assemblies, Slotted Weight Sets or Individual Weights and other optional

accessories including cutting ring and extrusion dolly should be ordered separately.

Standards

Models for 220-240V 50-60 Hz, 1 ph. UTS-2060.SMPR

ASTM D3080; BS 1377:7; AASHTO T236, TS 1900-2,

CEN-ISO-TS 17892-10 Models for 110-120V, 60Hz, 1ph. UTS-2060.SMPR-N

UTS-2065

UTS-2067 UTS-2068

Accessories of Shear Box Assemblies

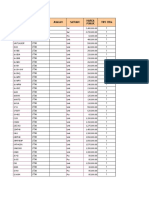

Model of UTS-2065 UTS-2066 UTS-2067 UTS-2068 UTS-2069

Shear Box 60x60 mm Ø:60 mm 100x100 mm Ø:100 mm Ø:2,5 inch

Shear Box UTS-2065-01 UTS-2066-01 UTS-2067-01 UTS-2068-01 UTS-2069-01

Loading Pad UTS-2065-02 UTS-2066-02 UTS-2067-02 UTS-2068-02 UTS-2069-02

Grooved Ret. Plate UTS-2065-03 UTS-2066-03 UTS-2067-03 UTS-2068-03 UTS-2069-03

Porous Plate UTS-2065-04 UTS-2066-04 UTS-2067-04 UTS-2068-04 UTS-2069-04

Perforated Grid UTS-2065-06 UTS-2066-06 UTS-2067-06 UTS-2068-06 UTS-2069-06

The Optional Accessories of UTS-2060 Automatic Direct / Residual Shear Test Machine

Cutting Ring UTS-2065-07 UTS-2066-07 UTS-2067-07 UTS-2068-07 UTS-2069-07

Extrusion Dolly UTS-2065-08 UTS-2066-08 UTS-2067-08 UTS-2068-08 UTS-2069-08 UTS-2069-08 UTS-2069

*2 pcs. supplied with the shear box assemblies

Alternative Slotted Weight Sets of UTS-2100 Individual Slootted Weights

Included Weight Included Weight Included Weight UTS-0382 0,25 kg UTS-0390 5 kg

Product Codes Total Mass (1 kg) (4 kg) (8 kg)

UTS-2102 32 kg 4 3 2 UTS-0384 0,50 kg UTS-0392 10 kg

UTS-2104 64 kg 4 5 5 UTS-0386 1 kg UTS-0394 4 kg

UTS-2106 88 kg 4 5 8 UTS-0388 2 kg UTS-0396 8 kg

SOIL

Soil Classification

MATERIAL TESTING EQUIPMENT

DIRECT/ RESIDUAL SHEAR

U-Touch PRO Control Unit UTEST Software for Direct/Residual Shear Test

for Direct/Residual Shear Test

Utest Direct and Residual Shear Software is developed in accordance with

ASTM D3080, BS 1377:7 and AASHTO T 236 standards to be used with

The U-Touch PRO Control Unit for Direct/Residual Shear Test is

UTS-2060.SMPR Machine.

designed to control the machine to perform direct - residual shear test

Direct residual and shear software consist of two sections. First section is used

acc. to EN, ASTM/AASHTO and BS standards to process. for the consolidation of the sample prior to shear.

The Unit can perform direct - residual shear tests as a stand-alone The second section of the software is capable of performing three different

without the use of a PC or with the USOFT-2060 software and a PC. types of test. The first type moves the machine with the speed determined by

Control of machine, acquisition of load and displacement data in real user until a shear failure occurs. On the second type, the user can set a speed

time are provided by the unit. and a horizontal displacement and the test will continue until the machine

reaches to the set value.

The U-Touch PRO has easy to use menu options. It displays all menu On the last type of test, the machine can be configured for cyclic (multireversal)

option listings simultaneously, allowing the operator to access the operation. In cyclic mode device will advance to the determined distance with

required option quickly to activate that option or enter a numeric value an assigned speed and turn back to the initial (home) position with a different

to set the test parameters and see all the data while the test running. assigned speed, wait for a time for the dissipation of excess pore pressure and

start to the new cycle again.

All these test parameters such

The U-Touch PRO graphic display allows real time Load etc.

as forward-reverse speed,

Displacement or Stress etc. Displacement graph. The advanced distance, cycle number, etc. can

functions for data base management provide an easy navigation of all be defined by the user.

saved data. The test results certificate includes all descriptive The software supports 5

information. Therefore test parameters can be set and details about different normal load values in

the test carried out such as customer details, test type, specimen type, order to calculate cohesion (C)

user info and other information required can be entered and printed out and internal friction angle (Ø)

as well as test reports and graphs. Also, all minor revisions can be values. Prior to the test normal

implemented upon request. The Software calculates both the load value must be entered to the

maximum and resilient shear stress. software.

The normal stress is calculated

according to normal load and

After three runs, the software calculates the cohesion value “c” and

sample size automatically.

shear resistance angle”φ” by using the best straight line fit.

The software supports both

square and round type samples.

Main Features Stress values can be optionally

and automatically calculated as

• Can make the test with displacement control. “standard area” and the

• Real time display of test graph. “corrected area” approach.

• 4 analog channels for load cell and displacement sensor When the test is completed peak

• Calibration function for channels. and residual stress values are

• Programmable digital gain adjustment for load-cell and recorded.

potentiometric sensors, voltage and current transmitters. The normal load versus peak

• Closed-loop PID for steady pace rate. stress pair is used for the

calculation of cohesion and

Consolidation internal friction angle value. At

• 25 pairs of time-vertical displacement values are written to memory. least 3 loading with different

• The vertical displacement value can be tared prior to recording. normal loads are required for

• The analogical channel reading vertical displacement has 260000 this property.

points effective resolution. One can set test speed, axis

• The memory can be exported to PC software. values etc. through the setup of

the software. The results can be

Testing submitted as a report or can be

• 3 different shearing test types can be selected. exported to Microsoft Excel for

advanced reanalyze procedures.

• The machine run with the speed determined by user to the direction See the pages of “General

of shear and stop when the load decreases. Properties of Utest USOFT

Softwares” for detailed

• The machine run with the speed determined by user to the direction of properties of the software.

shear and stop when it reaches to the target horizontal displacement

value which is also determined by the user at the beginnig of the test.

The Automatic Direct Residual Shear Test Machine is

• The machine run with the speed to the direction of shear, after supplied complete with;

reaching to the target displacement, returns and finds the exact initial • Load Cell 5 kN

(HOME) position, waits for the dissipation of excess pore pressure and • Linear Potentiometric Displacement Transducer (10x0.001 mm)

starts to the same procedure again. User can create testing scenarios • Linear Potentiometric Displacement Transducer (25x0.001 mm)

by determining all the parameters of this multi-reversal shearing test • Software

such as test speed, return speed, displacement target, standby time,

and cycle number.

Speed Range 0.00001 to 10,00 mm/min

• By using the control unit, consolidation before shearing tests are Maximum Shear Force 5 kN (5000 N)

possible.

Maximum Vertical Load 0 to 500 N

• The screen displays load, shear stress, horizontal and vertical Horizontal Travel 30 mm

displacements, and τ-Δx graph continuously. Dimensions 450x1250x1200 mm

PLEASE see the pages of “General Properties of U-Touch PRO Control Weight (approx.) 110 kg

Units” for details of the properties of software and hardware. Power 1100 W

You might also like

- Autocad 15X30 Home PlanDocument1 pageAutocad 15X30 Home PlanNawaz KhanNo ratings yet

- 5ton TM PDFDocument600 pages5ton TM PDFJohnathanNo ratings yet

- Brosur PDFDocument3 pagesBrosur PDFEndangRatriSNo ratings yet

- 03-2 UTS-0070 Pocket Dial PenetrometerDocument1 page03-2 UTS-0070 Pocket Dial Penetrometerabdelhamid flittiNo ratings yet

- Practicas Standar KingDocument5 pagesPracticas Standar Kingjesus francoNo ratings yet

- Shakers - CatalogDocument8 pagesShakers - Catalogdéborah_rosales100% (1)

- Uniwash UW Series SpecificationsDocument4 pagesUniwash UW Series Specificationsmairimsp2003No ratings yet

- Blast Pot - Brochure - 1521100590Document1 pageBlast Pot - Brochure - 1521100590sofyanlim2022No ratings yet

- Shearscan2 Pneumatic Direct Residual ShearDocument2 pagesShearscan2 Pneumatic Direct Residual ShearYves DeshommesNo ratings yet

- Section 7-Parts List - HFC-227ea Design Manua - Rev ADocument4 pagesSection 7-Parts List - HFC-227ea Design Manua - Rev AasmaNo ratings yet

- Compatible Puller Stud and Hydraulic Cylinder Capacity Chart (0599, 7000, 7562)Document5 pagesCompatible Puller Stud and Hydraulic Cylinder Capacity Chart (0599, 7000, 7562)Odai AlsaafinNo ratings yet

- Import Saldoawal ItemDocument21 pagesImport Saldoawal ItemCekasCGNo ratings yet

- Aggregate: Testing EquipmentsDocument12 pagesAggregate: Testing EquipmentsMorched TounsiNo ratings yet

- Applimotion UTS Motor Kits DatasheetDocument2 pagesApplimotion UTS Motor Kits DatasheetElectromateNo ratings yet

- Wear Parts ListDocument2 pagesWear Parts ListAgus DaniNo ratings yet

- Civil Engineering Instruments Cement Concrete Instruments Aggregates Instruments Bitumen Asphalt Equipments Shrinkage Limit SetDocument4 pagesCivil Engineering Instruments Cement Concrete Instruments Aggregates Instruments Bitumen Asphalt Equipments Shrinkage Limit SetAdeel RasheedNo ratings yet

- Versalift VST5000Document2 pagesVersalift VST5000adalberto veigaNo ratings yet

- In Situ CBR Test ApparatusDocument3 pagesIn Situ CBR Test Apparatusdiana aznanNo ratings yet

- Wp-Content Themes Magnificent Manual Horizon VAC100 EA4Document8 pagesWp-Content Themes Magnificent Manual Horizon VAC100 EA4linuxcadNo ratings yet

- Hal PrintDocument1 pageHal Printhenry yuman darmawanNo ratings yet

- NC Tool StorageDocument6 pagesNC Tool StorageabhayiimcNo ratings yet

- Extraction: Technical SpecificationsDocument1 pageExtraction: Technical SpecificationsDilhara WickramaarachchiNo ratings yet

- 02-1 - Roundslings Chapter - LR PDFDocument20 pages02-1 - Roundslings Chapter - LR PDFMichaelNo ratings yet

- Utc-4713g SLPDocument2 pagesUtc-4713g SLPMomar DiengNo ratings yet

- Previous Page: Presses Soup ShapesDocument22 pagesPrevious Page: Presses Soup ShapesKunwar Apoorva SinghNo ratings yet

- ARC 23281A en US FactSheet Main 01Document2 pagesARC 23281A en US FactSheet Main 01Pedido VentasNo ratings yet

- Series 2000: Pneumatic Diaphragm ActuatorDocument10 pagesSeries 2000: Pneumatic Diaphragm ActuatorAyman RiyadhNo ratings yet

- Compacted Road Base and Subbase Soils: Density-Water Content Relationship Automatic Mechanical CompactorDocument1 pageCompacted Road Base and Subbase Soils: Density-Water Content Relationship Automatic Mechanical CompactorTopina RahimNo ratings yet

- Brochure SP (H) 20-100 ENGDocument16 pagesBrochure SP (H) 20-100 ENGYokesh JagadeshNo ratings yet

- Testing Equipments: Field Inspection & SamplingDocument32 pagesTesting Equipments: Field Inspection & SamplingMorched Tounsi100% (1)

- Hydrostatic System - Test and AdjustDocument26 pagesHydrostatic System - Test and AdjustRajan Mullappilly100% (1)

- European Aviation Safety Agency: Easa Type-Certificate Data SheetDocument9 pagesEuropean Aviation Safety Agency: Easa Type-Certificate Data SheetAlberto CisnerosNo ratings yet

- Hoyt AMMETERDocument3 pagesHoyt AMMETERDayanna MorenoNo ratings yet

- WHRH BrochureDocument4 pagesWHRH BrochureJade AlexanderNo ratings yet

- Kent BrochureDocument2 pagesKent BrochureRob Marks (Imaus Kahmeur)No ratings yet

- Tubo MecanicoDocument3 pagesTubo MecanicoRca Maquinas EngenhariaNo ratings yet

- Precision Torque PDFDocument18 pagesPrecision Torque PDFAndres HernandezNo ratings yet

- Prensas Accu-Tek Touch Ele InternationalDocument4 pagesPrensas Accu-Tek Touch Ele InternationalMarcos González MaldonadoNo ratings yet

- Shakers SPECDocument2 pagesShakers SPECRajavelu PerumalNo ratings yet

- Otsukatec Super Cubical BrochureDocument11 pagesOtsukatec Super Cubical BrochureMostar NNo ratings yet

- Capacities and Specs - (08-2003) - Us-EnDocument50 pagesCapacities and Specs - (08-2003) - Us-EnChristian Bedoya50% (2)

- Shockwave IsolatorDocument2 pagesShockwave IsolatorojangurenNo ratings yet

- Potain MR615Document16 pagesPotain MR615Jhony Espinoza Perez0% (1)

- Ammann Av26-2 01Document8 pagesAmmann Av26-2 01RAFAEL RIBEIRONo ratings yet

- COMETTO CATALOGO MSPE 297x210 08 2017 EN MailDocument24 pagesCOMETTO CATALOGO MSPE 297x210 08 2017 EN MailHermon PakpahanNo ratings yet

- 049 2 Prosp E260DS4 3 DS5 3 EngDocument4 pages049 2 Prosp E260DS4 3 DS5 3 EngRolandas GaudėšiusNo ratings yet

- 3G TransmitterDocument10 pages3G TransmitterazfahaidarNo ratings yet

- KAT Tracker - Seam TrackerDocument4 pagesKAT Tracker - Seam TrackerAlessandro sergio de souzaNo ratings yet

- Пакер Тулз Каталог На АнглийскомDocument78 pagesПакер Тулз Каталог На АнглийскомarbNo ratings yet

- YHZS75 Mobile Concrete Mixing Plant - (220V-60HZ)Document5 pagesYHZS75 Mobile Concrete Mixing Plant - (220V-60HZ)DelioNo ratings yet

- Replacement Wear Parts For Komatsu MachineryDocument24 pagesReplacement Wear Parts For Komatsu MachineryAntonio Pastor Alberola100% (3)

- MODEL 2500QM MODEL 2500QM: AC Auto For Over - Arm Moving Device Is AvailableDocument1 pageMODEL 2500QM MODEL 2500QM: AC Auto For Over - Arm Moving Device Is AvailablearjunkoppalNo ratings yet

- A200C Spare PartsLlistDocument15 pagesA200C Spare PartsLlistAndres RiveraNo ratings yet

- Tool Kit KACDocument81 pagesTool Kit KACMeyerNo ratings yet

- BURSTING TESTERS BROCHURE SinglePages (FINAL) 091416Document6 pagesBURSTING TESTERS BROCHURE SinglePages (FINAL) 091416felix bazanNo ratings yet

- C InstalDocument170 pagesC InstalklemencicvinkoNo ratings yet

- ISO Easyset Setting ToolDocument2 pagesISO Easyset Setting ToolRizky WahyuNo ratings yet

- Side Discharge Buckets: S S L M T L C T L C W LDocument2 pagesSide Discharge Buckets: S S L M T L C T L C W LDietz LaNo ratings yet

- Hydraulic Pump Test and Adjust PDFDocument22 pagesHydraulic Pump Test and Adjust PDFservhiperu100% (1)

- Batteryspecs PDFDocument12 pagesBatteryspecs PDFMarcel BaqueNo ratings yet

- Multi-Head Self-Attention Transformer For Dogecoin Price PredictionDocument6 pagesMulti-Head Self-Attention Transformer For Dogecoin Price PredictionThu GiangNo ratings yet

- Nri 2022Document262 pagesNri 2022Dimitris VgNo ratings yet

- r520 Spec SheetDocument2 pagesr520 Spec SheetBirla VargheseNo ratings yet

- Geographic Information SystemDocument17 pagesGeographic Information Systemupayarakhmat6711No ratings yet

- Design Secure & Compliant Roles For Oracle ERP & HCM CloudDocument33 pagesDesign Secure & Compliant Roles For Oracle ERP & HCM CloudRajvirNo ratings yet

- FlutterDocument1 pageFlutterYouth Zoom100% (1)

- Package Robper': March 27, 2016Document32 pagesPackage Robper': March 27, 2016jaimeNo ratings yet

- Database Management System PDFDocument228 pagesDatabase Management System PDFPrateek RaizadaNo ratings yet

- Geography - AE - AEE - Civil Engineering Handwritten Notes (CivilEnggForAll - Com) PDFDocument220 pagesGeography - AE - AEE - Civil Engineering Handwritten Notes (CivilEnggForAll - Com) PDFMANJUNo ratings yet

- Vmware Vsphere With Ontap Best Practices: Netapp SolutionsDocument36 pagesVmware Vsphere With Ontap Best Practices: Netapp SolutionsSenthilkumar MuthusamyNo ratings yet

- Cymatics Keys ManualDocument5 pagesCymatics Keys ManualGousto Mix OfficialNo ratings yet

- ML AlgorithmsDocument2 pagesML AlgorithmshemaNo ratings yet

- SOP For Raw Material ReleaseDocument4 pagesSOP For Raw Material ReleaseSolomonNo ratings yet

- Data Aire Dap4 Modbus TCP/IP Protocol Integration InstructionsDocument27 pagesData Aire Dap4 Modbus TCP/IP Protocol Integration InstructionscarlosNo ratings yet

- Broadly, There Are 3 Types of Machine Learning Algorithms.Document33 pagesBroadly, There Are 3 Types of Machine Learning Algorithms.hbk.hariharanNo ratings yet

- 1st PUC Computer Lab Manual-2023Document69 pages1st PUC Computer Lab Manual-2023rishabh.rukmangadhaNo ratings yet

- Chinese Wall Security Model Buzulan and TeleghinDocument13 pagesChinese Wall Security Model Buzulan and TeleghinLoryQa LoryNo ratings yet

- Instant Recovery With Write-Ahead LoggingDocument5 pagesInstant Recovery With Write-Ahead LoggingFrozenade McForsakenNo ratings yet

- CS-3035 (ML) - CS Mid March 2023Document3 pagesCS-3035 (ML) - CS Mid March 2023Jaideep SharmaNo ratings yet

- Pythontest 2Document35 pagesPythontest 2Monisha arumugamNo ratings yet

- Arduino Based Smart Home Security System: October 2019Document6 pagesArduino Based Smart Home Security System: October 2019Neel ModiNo ratings yet

- Winshuttle MDG Ebook ENDocument15 pagesWinshuttle MDG Ebook ENVenkata Ramana GottumukkalaNo ratings yet

- RSHH Qam13 Module 01 PDFDocument16 pagesRSHH Qam13 Module 01 PDFSteven PurnomoNo ratings yet

- Assertions PDFDocument16 pagesAssertions PDFSpritual ThoughtsNo ratings yet

- Updating Exadata Database Server SoftwareDocument15 pagesUpdating Exadata Database Server SoftwareΒαγγέλης ΟικονομοπουλοςNo ratings yet

- SSC CGL Syllabus 34c11371Document28 pagesSSC CGL Syllabus 34c11371HaridigitalNo ratings yet

- Corner ColumnDocument12 pagesCorner ColumnKelvine IjejiNo ratings yet

- Huawei HyperClone Technical White Paper PDFDocument14 pagesHuawei HyperClone Technical White Paper PDFMenganoFulanoNo ratings yet

- European Patent PDFDocument2 pagesEuropean Patent PDFDanNo ratings yet