Professional Documents

Culture Documents

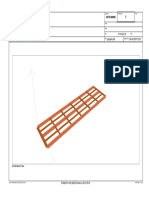

Zone 3 - Wafer Slab Beam Detail C

Zone 3 - Wafer Slab Beam Detail C

Uploaded by

jasekanCopyright:

Available Formats

You might also like

- 2 Plaster Wall SurfaceDocument44 pages2 Plaster Wall SurfaceRobinson ConcordiaNo ratings yet

- Doubly Reinforced BeamDocument8 pagesDoubly Reinforced BeamKARTHIK SGNo ratings yet

- Design of The Low Head Slide Gate: A) Structural SteelDocument17 pagesDesign of The Low Head Slide Gate: A) Structural SteelAlok Sarkar100% (2)

- 23 Feb 2022 Model v9 Beam ForcesDocument2,116 pages23 Feb 2022 Model v9 Beam Forces郑 凯伦 Tey Kai LoonNo ratings yet

- Concrete Beam 1Document2 pagesConcrete Beam 1y2chongNo ratings yet

- 1B4 - 1 230X450 - Critical: Page 1/4 Oscarkonzult 11-Jul-20 11-Jul-20 11-Jul-20Document4 pages1B4 - 1 230X450 - Critical: Page 1/4 Oscarkonzult 11-Jul-20 11-Jul-20 11-Jul-20OscarKonzultNo ratings yet

- Critical BeamDocument16 pagesCritical BeamchristopherNo ratings yet

- FBM06Document4 pagesFBM06Damsha NdahiNo ratings yet

- FLBM13: Proposed Entrepreneurship Centre ADS 001 3 Page 1/2 ABF 14-Oct-23 CM 17-Sep-23 CM 17-Sep-23Document2 pagesFLBM13: Proposed Entrepreneurship Centre ADS 001 3 Page 1/2 ABF 14-Oct-23 CM 17-Sep-23 CM 17-Sep-23Damsha NdahiNo ratings yet

- FBM03Document8 pagesFBM03Damsha NdahiNo ratings yet

- 1B2 - 1 300x400 - Critical: Page 1/2 Legion 5 23/02/2023 23/02/2023 23/02/2023Document2 pages1B2 - 1 300x400 - Critical: Page 1/2 Legion 5 23/02/2023 23/02/2023 23/02/2023Mouris alamamussNo ratings yet

- Weld Stress CalculationsDocument19 pagesWeld Stress CalculationsMichael WaltersNo ratings yet

- Operation Building Design CalculationDocument86 pagesOperation Building Design Calculationthirupathi mookaiahNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Design of Corbels, Brackets and NibsDocument3 pagesDesign of Corbels, Brackets and NibsBrij AkabariNo ratings yet

- BEAM DESIGN-r5Document2 pagesBEAM DESIGN-r5YaserNo ratings yet

- 1) Basic Data: Design of Simply Supported Doubly-Reinforced Beam Using IS 456-2000Document3 pages1) Basic Data: Design of Simply Supported Doubly-Reinforced Beam Using IS 456-2000Khaja100% (1)

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document14 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsNo ratings yet

- RCC DesignDocument39 pagesRCC DesignMariappan .PNo ratings yet

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document8 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Miguel LuqueNo ratings yet

- Design Calculation of Precast WallDocument15 pagesDesign Calculation of Precast WallDustin GrimaresNo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3No ratings yet

- Design of Major Column TiesDocument6 pagesDesign of Major Column TiesMark Brien Vincent YbañezNo ratings yet

- Erp-Reinf Shearwall R1Document6 pagesErp-Reinf Shearwall R1Gunawan Prc2020No ratings yet

- ACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Document14 pagesACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Andy SunjayaNo ratings yet

- Pot Bearing - Fix Bearing DesignDocument2 pagesPot Bearing - Fix Bearing Designtrichandra maharjanNo ratings yet

- TPG OPGW 42 MM Dukong Manggar ZTTDocument4 pagesTPG OPGW 42 MM Dukong Manggar ZTTPalle YulianNo ratings yet

- Problem Double AnglesDocument3 pagesProblem Double AnglesAnthony SupanNo ratings yet

- PurlinDocument2 pagesPurlin2256005No ratings yet

- PC3 QmaxDocument1 pagePC3 QmaxCuong TranNo ratings yet

- Design of Minor Column TiesDocument6 pagesDesign of Minor Column TiesMark Brien Vincent YbañezNo ratings yet

- Footing - Bishan - Stretch D - T-PL1963-BSN-CS-105 - Span 3595 - Footing 800X1500Document3 pagesFooting - Bishan - Stretch D - T-PL1963-BSN-CS-105 - Span 3595 - Footing 800X1500parathasiNo ratings yet

- Strip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNDocument13 pagesStrip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNkushaljp8989No ratings yet

- Design of Steel Strcture, Is-800-2007Document48 pagesDesign of Steel Strcture, Is-800-2007srinivasNo ratings yet

- Aci318-08 Moment Shear Torsion DesignDocument7 pagesAci318-08 Moment Shear Torsion DesignMohammed HanafiNo ratings yet

- say - Use ρmin. Steel yields. #DIV/0! OK sayDocument2 pagessay - Use ρmin. Steel yields. #DIV/0! OK sayryanmikeNo ratings yet

- EC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Document7 pagesEC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Dong LINo ratings yet

- Beam DesignDocument15 pagesBeam Designravi kumarNo ratings yet

- 1.FB - Balkhu - Star Design With Break - 36m Edit Opt 2 - Copy (2) OldDocument32 pages1.FB - Balkhu - Star Design With Break - 36m Edit Opt 2 - Copy (2) OldTriChandra MaharjanNo ratings yet

- SpecificationDocument6 pagesSpecificationMOHAMAD AMIR BIN HALIDNo ratings yet

- Beam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Document4 pagesBeam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Dũng QuangNo ratings yet

- RCC DesignDocument12 pagesRCC DesignRmesh jhaNo ratings yet

- Mathcad - Design On Singly Reinforced T BeamDocument6 pagesMathcad - Design On Singly Reinforced T BeammrnaeemNo ratings yet

- Design of Short Column For Axial Load and MomentDocument5 pagesDesign of Short Column For Axial Load and Momentភារម្យ អេងNo ratings yet

- 06.footing Design Bs 8110 1997Document5 pages06.footing Design Bs 8110 1997QualityControl SorARoonUTTNo ratings yet

- WallcalcDocument31 pagesWallcalcSubhekshya ShresthaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- Kajian Teknis Untuk Perubahan Kabel Feeder Trafo To LVMDPDocument4 pagesKajian Teknis Untuk Perubahan Kabel Feeder Trafo To LVMDPHendrias ari sujarwoNo ratings yet

- CF4-GRID 8A-D, 8A-D1 Also Refrence For CF-1, CF3, CF2Document4 pagesCF4-GRID 8A-D, 8A-D1 Also Refrence For CF-1, CF3, CF2Parvez KhanNo ratings yet

- Main Component For Two2Document3 pagesMain Component For Two2اسعد الماوريNo ratings yet

- RCBeamOpening v061601Document1 pageRCBeamOpening v061601kevinlow3No ratings yet

- Huchez Winch 10 TonsDocument6 pagesHuchez Winch 10 TonsPhong DuongNo ratings yet

- Column & FootingDocument32 pagesColumn & FootingAmol potdarNo ratings yet

- Design of Beam (Classical Approach) .1Document24 pagesDesign of Beam (Classical Approach) .1Udhasu NayakNo ratings yet

- Fender PileDocument11 pagesFender PileVenkat PalliNo ratings yet

- Dimensionamento Roscas Stub-AcmeDocument13 pagesDimensionamento Roscas Stub-AcmeVítor CarvalhoNo ratings yet

- Zone 14a: Crone Partners Punching Shear For Column C1 BS 25-Dec-2017 1 - 3904 45 460 8 600 0 450 0 0 0Document10 pagesZone 14a: Crone Partners Punching Shear For Column C1 BS 25-Dec-2017 1 - 3904 45 460 8 600 0 450 0 0 0vaideehNo ratings yet

- Beam Detailing Bs 8110 1997Document5 pagesBeam Detailing Bs 8110 1997AhmedAlghzawiNo ratings yet

- Zone 4 - 1VB3a RC Beam Analysis & Design (EN1992)Document18 pagesZone 4 - 1VB3a RC Beam Analysis & Design (EN1992)jasekanNo ratings yet

- RAM Connection Standalone CE ReportDocument2 pagesRAM Connection Standalone CE ReportjasekanNo ratings yet

- Presentation 1Document1 pagePresentation 1jasekanNo ratings yet

- Zone 1 - 1VB1c RC Beam Analysis & Design (EN1992) PDFDocument12 pagesZone 1 - 1VB1c RC Beam Analysis & Design (EN1992) PDFjasekanNo ratings yet

- OutputsDocument13 pagesOutputsjasekanNo ratings yet

- Zone 3 - 1HB65 RC Beam Analysis & Design (EN1992)Document52 pagesZone 3 - 1HB65 RC Beam Analysis & Design (EN1992)jasekanNo ratings yet

- Frame Jase3Document16 pagesFrame Jase3jasekanNo ratings yet

- Common Mistakes For Assignment 3 PDFDocument1 pageCommon Mistakes For Assignment 3 PDFjasekanNo ratings yet

- Envelope (Staadpro)Document10 pagesEnvelope (Staadpro)jasekanNo ratings yet

- Sem-2-AY21xcScSc - TT - For-WebsiteDocument27 pagesSem-2-AY21xcScSc - TT - For-WebsitejasekanNo ratings yet

- Revised Agenda 3Document1 pageRevised Agenda 3jasekanNo ratings yet

- Draft INVITATION 3Document1 pageDraft INVITATION 3jasekanNo ratings yet

- Assignment - DeviDocument10 pagesAssignment - DevijasekanNo ratings yet

- B4C251a-TSD - FlattenedDocument2 pagesB4C251a-TSD - FlattenedjasekanNo ratings yet

- Preprints202111 0327 v1Document39 pagesPreprints202111 0327 v1jasekanNo ratings yet

- Math - T3 - G8 - I, II PP - 2019Document6 pagesMath - T3 - G8 - I, II PP - 2019jasekanNo ratings yet

- Two-Day Preparatory Course For The Chartered Membership Examination of The Institution of Structural Engineers, UkDocument2 pagesTwo-Day Preparatory Course For The Chartered Membership Examination of The Institution of Structural Engineers, UkjasekanNo ratings yet

- 2013 SoilheaveduetopiledrivingDocument20 pages2013 SoilheaveduetopiledrivingjasekanNo ratings yet

- CE5104 Settlement Due To TunnellingDocument114 pagesCE5104 Settlement Due To TunnellingjasekanNo ratings yet

- Em Math g9 I, Iipp 2019Document6 pagesEm Math g9 I, Iipp 2019jasekanNo ratings yet

- Min AxisDocument3 pagesMin AxisjasekanNo ratings yet

- Note 12 Sep 2022Document5 pagesNote 12 Sep 2022jasekanNo ratings yet

- EM - Math - T3 - G9 - I, II PP Ans - 2019Document9 pagesEM - Math - T3 - G9 - I, II PP Ans - 2019jasekanNo ratings yet

- UnknownDocument5 pagesUnknownjasekanNo ratings yet

- Weld Connection - CalculationDocument2 pagesWeld Connection - CalculationjasekanNo ratings yet

- Tuesday, October 20, 2015, 03:28 PMDocument10 pagesTuesday, October 20, 2015, 03:28 PMjasekanNo ratings yet

- Pontoon 13-Oct-15 20-Oct-2015 15:21 Gangway - STD: Job No Sheet No RevDocument6 pagesPontoon 13-Oct-15 20-Oct-2015 15:21 Gangway - STD: Job No Sheet No RevjasekanNo ratings yet

- SSéukaâ Úohd, H Richmond College: M Uq JDR Mílaikh - 2019Document7 pagesSSéukaâ Úohd, H Richmond College: M Uq JDR Mílaikh - 2019jasekanNo ratings yet

- EM - Math - G9 - T3 - I, II PP Ans - 2018Document4 pagesEM - Math - G9 - T3 - I, II PP Ans - 2018jasekanNo ratings yet

- Cantilever Retaining Wall ExampleDocument4 pagesCantilever Retaining Wall ExamplejasekanNo ratings yet

- Topic About Engineering Research PaperDocument6 pagesTopic About Engineering Research Paperscxofyplg100% (1)

- Crane Girder DesignDocument6 pagesCrane Girder Designarzu50% (2)

- CE Board Nov 2020 - RCD - Set 16Document1 pageCE Board Nov 2020 - RCD - Set 16Dale MalazzabNo ratings yet

- Building Construction 2. Masonry: Civil Engineering Materials and ConstructionDocument55 pagesBuilding Construction 2. Masonry: Civil Engineering Materials and ConstructionGautam ChandraNo ratings yet

- Short Col DesignDocument17 pagesShort Col DesignBhavin ShahNo ratings yet

- Types of Bridges: Main Structure Coinciding With Deck LineDocument21 pagesTypes of Bridges: Main Structure Coinciding With Deck Lineshna jabarNo ratings yet

- Introducing Two Most Common Types of Shear Walls and Their Construction MethodsDocument6 pagesIntroducing Two Most Common Types of Shear Walls and Their Construction MethodsVictor OmotoriogunNo ratings yet

- Structural Integrity in The Design of Precast Prestressed Concrete StructuresDocument11 pagesStructural Integrity in The Design of Precast Prestressed Concrete StructuresMohamed AyoubNo ratings yet

- SDPL CH 148-160 Shuttering Design For Girder-Layout-23Document1 pageSDPL CH 148-160 Shuttering Design For Girder-Layout-23Sudeep JoshiNo ratings yet

- BMW Center Show Room Final-01Document43 pagesBMW Center Show Room Final-01QC MEPNo ratings yet

- Staad QuizDocument3 pagesStaad QuizKenneth NaguitNo ratings yet

- 12 Chapter 5Document21 pages12 Chapter 5MEERA04No ratings yet

- RCC94 Two-Way Slabs (Tables)Document3 pagesRCC94 Two-Way Slabs (Tables)Mohammad Twaha JaumbocusNo ratings yet

- SFD & BMDDocument21 pagesSFD & BMDSayan ChowdhuryNo ratings yet

- BCE-UNIT-2 Components of BuilDocument84 pagesBCE-UNIT-2 Components of Builviveksp99No ratings yet

- Analysis of Beam (Longitudinal Frames)Document44 pagesAnalysis of Beam (Longitudinal Frames)Anissah ManialaNo ratings yet

- Detail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)Document1 pageDetail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)sathiyanNo ratings yet

- Calculate Quantities of Materials For Concrete - Cement, Sand, AggregatesDocument7 pagesCalculate Quantities of Materials For Concrete - Cement, Sand, Aggregatesvenkateswara rao pothinaNo ratings yet

- Ductile Detailing Useful ReferencesDocument6 pagesDuctile Detailing Useful ReferencesMandar NadgaundiNo ratings yet

- Expansion Joint Checklist: Waterproofing Membrane System Trafficability Fire RatingDocument1 pageExpansion Joint Checklist: Waterproofing Membrane System Trafficability Fire RatingDavid Alexander Calderón ArreguiNo ratings yet

- 2003 EWS X440 Product Guide-GlulamDocument32 pages2003 EWS X440 Product Guide-GlulamVinícius Da Cunha FerreiraNo ratings yet

- Member Code: Dyntek Pte. LTDDocument1 pageMember Code: Dyntek Pte. LTDHerbert BishopNo ratings yet

- Design Timber Structures Using Eurocode 5Document119 pagesDesign Timber Structures Using Eurocode 5margitorsi100% (2)

- Chemical Admixtures For Concrete: ACI 212.3R-04Document30 pagesChemical Admixtures For Concrete: ACI 212.3R-04josel_ortizcNo ratings yet

- Basics of Post Installed Rebar Connections: 1 ApplicationsDocument33 pagesBasics of Post Installed Rebar Connections: 1 ApplicationsHaitham KayyaliNo ratings yet

- Basement ExcavationDocument4 pagesBasement ExcavationAnonymous U6pIEKQghNo ratings yet

- WikiEngineer - Structural - Pinned-Roller Shear & Moment DiagramsDocument8 pagesWikiEngineer - Structural - Pinned-Roller Shear & Moment DiagramsBogdanBNo ratings yet

- Banglo Pahang Estimate BQDocument37 pagesBanglo Pahang Estimate BQHazim ZakariaNo ratings yet

Zone 3 - Wafer Slab Beam Detail C

Zone 3 - Wafer Slab Beam Detail C

Uploaded by

jasekanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zone 3 - Wafer Slab Beam Detail C

Zone 3 - Wafer Slab Beam Detail C

Uploaded by

jasekanCopyright:

Available Formats

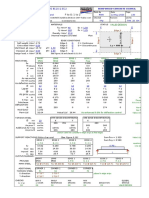

Project Job Ref.

Structure Sheet no.

Wafer Slab Beam Detail C Page 1/10

Chk'd by App'd by

1B1409

Static Design Summary

1B1409 - 1 700x800 - Critical

Design summary bending top

Region 1 2 3

Analysis 3D Building Analysis 3D Building Analysis 3D Building Analysis

Combination 4 1 3

MEd 1128.5 kNm 0.0 kNm 1117.9 kNm

d 740.4 mm 740.4 mm 740.4 mm

d2 50.0 mm 50.0 mm 50.0 mm

K / K' 0.51 0.00 0.50

z 663.8 mm 0.0 mm 664.6 mm

Ast,reqd 3910 mm2 0 mm2 3868 mm2

Aswa,reqd 0 mm2 0 mm2 0 mm2

AslT,reqd 0 mm 2

0 mm 2

0 mm2

As2,reqd 0 mm 2

0 mm 2

0 mm2

Astt,reqd 3910 mm2 0 mm2 3868 mm2

As,min 745 mm2 0 mm2 745 mm2

Ast,prov 3436 mm 2

3436 mm 2

3436 mm2

Top bars 7H25 7H25 7H25

Design summary bending bottom

Region 1 2 3

Analysis 3D Building Analysis 3D Building Analysis 3D Building Analysis

Combination 3 3 3

MEd 0.0 kNm 460.6 kNm 0.0 kNm

d 750.0 mm 750.0 mm 750.0 mm

d2 59.6 mm 59.6 mm 59.6 mm

K / K' 0.00 0.20 0.00

z 0.0 mm 712.5 mm 0.0 mm

Ast,reqd 0 mm2 1487 mm2 0 mm2

Aswa,reqd 1487 mm2 0 mm2 1487 mm2

AslT,reqd 0 mm 2

0 mm 2

0 mm2

As2,reqd 0 mm 2

0 mm 2

0 mm2

Astt,reqd 1487 mm 2

1487 mm 2

1487 mm2

As,min 755 mm2 755 mm2 755 mm2

Ast,prov 1885 mm2 1885 mm2 1885 mm2

Bottom bars 6H20 6H20 6H20

Deflection check - L / d = 9.600 < 54.298 -

Design summary shear and torsion

Region Left Centre Right

Length 1.800 m 3.600 m 1.800 m

Analysis 3D Building Analysis 3D Building Analysis 3D Building Analysis

Combination 4 3 3

VEd 1160.8 kN 554.0 kN 1000.6 kN

VRd,max 1599.6 kN 1599.6 kN 1599.6 kN

VRd,c 179.8 kN 179.8 kN 179.8 kN

Asws,reqd 1603 mm2/m 765 mm2/m 1382 mm2/m

Asw,min,reqd 593 mm /m 2

593 mm /m 2

593 mm2/m

Asw,prov 4712 mm /m 2

4712 mm /m 2

4712 mm2/m

TEd 0.56 kNm 0.57 kNm 0.57 kNm

TRd,max 403.11 kNm 403.11 kNm 403.11 kNm

TRd,c 151.74 kNm 151.74 kNm 151.74 kNm

Aswt,reqd 0 mm2/m 0 mm2/m 0 mm2/m

Links 6H10-100 6H10-100 6H10-100

Tekla Structural Designer, version: 23.2.1.1

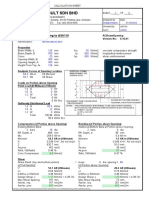

Project Job Ref.

Structure Sheet no.

Page 2/10

Chk'd by App'd by

1B1409 - 2 700x800 - Critical

Design summary bending top

Region 1 2 3

Analysis 3D Building Analysis 3D Building Analysis 3D Building Analysis

Combination 4 1 3

MEd 1014.5 kNm 0.0 kNm 1025.0 kNm

d 740.4 mm 740.4 mm 740.4 mm

d2 50.0 mm 50.0 mm 50.0 mm

K / K' 0.46 0.00 0.46

z 672.4 mm 0.0 mm 671.7 mm

Ast,reqd 3470 mm2 0 mm2 3510 mm2

Aswa,reqd 0 mm2 0 mm2 0 mm2

AslT,reqd 0 mm 2

0 mm 2

0 mm2

As2,reqd 0 mm 2

0 mm 2

0 mm2

Astt,reqd 3470 mm2 0 mm2 3510 mm2

As,min 745 mm2 0 mm2 745 mm2

Ast,prov 3436 mm 2

3436 mm 2

3436 mm2

Top bars 7H25 7H25 7H25

Design summary bending bottom

Region 1 2 3

Analysis 3D Building Analysis 3D Building Analysis 3D Building Analysis

Combination 4 4 4

MEd 0.0 kNm 406.3 kNm 0.0 kNm

d 750.0 mm 750.0 mm 750.0 mm

d2 59.6 mm 59.6 mm 59.6 mm

K / K' 0.00 0.18 0.00

z 0.0 mm 712.5 mm 0.0 mm

Ast,reqd 0 mm2 1312 mm2 0 mm2

Aswa,reqd 1312 mm2 0 mm2 1312 mm2

AslT,reqd 0 mm 2

0 mm 2

0 mm2

As2,reqd 0 mm 2

0 mm 2

0 mm2

Astt,reqd 1312 mm2 1312 mm2 1312 mm2

As,min 755 mm2 755 mm2 755 mm2

Ast,prov 1885 mm2 1885 mm2 1885 mm2

Bottom bars 6H20 6H20 6H20

Deflection check - L / d = 9.600 < 85.913 -

Design summary shear and torsion

Region Left Centre Right

Length 1.800 m 3.600 m 1.800 m

Analysis 3D Building Analysis 3D Building Analysis 3D Building Analysis

Combination 4 3 3

VEd 906.2 kN 511.0 kN 909.3 kN

VRd,max 1599.6 kN 1599.6 kN 1599.6 kN

VRd,c 179.8 kN 179.8 kN 179.8 kN

Asws,reqd 1251 mm2/m 705 mm2/m 1256 mm2/m

Asw,min,reqd 593 mm /m 2

593 mm /m 2

593 mm2/m

Asw,prov 4712 mm /m 2

4712 mm /m 2

4712 mm2/m

TEd 0.12 kNm 0.12 kNm 0.12 kNm

TRd,max 403.11 kNm 403.11 kNm 403.11 kNm

TRd,c 151.74 kNm 151.74 kNm 151.74 kNm

Aswt,reqd 0 mm /m2

0 mm /m 2

0 mm2/m

Links 6H10-100 6H10-100 6H10-100

1B1409 - 3 700x800 - Critical

Design summary bending top

Tekla Structural Designer, version: 23.2.1.1

Project Job Ref.

Structure Sheet no.

Page 3/10

Chk'd by App'd by

Region 1 2 3

Analysis 3D Building Analysis 3D Building Analysis 3D Building Analysis

Combination 4 1 3

MEd 1172.5 kNm 0.0 kNm 1126.6 kNm

d 740.4 mm 740.4 mm 740.4 mm

d2 50.0 mm 50.0 mm 50.0 mm

K / K' 0.53 0.00 0.51

z 660.4 mm 0.0 mm 664.0 mm

Ast,reqd 4083 mm2 0 mm2 3903 mm2

Aswa,reqd 0 mm2 0 mm2 0 mm2

AslT,reqd 0 mm2 0 mm2 0 mm2

As2,reqd 0 mm 2

0 mm 2

0 mm2

Astt,reqd 4083 mm 2

0 mm 2

3903 mm2

As,min 745 mm 2

0 mm 2

745 mm2

Ast,prov 3436 mm 2

3436 mm 2

3436 mm2

Top bars 7H25 7H25 7H25

Design summary bending bottom

Region 1 2 3

Analysis 3D Building Analysis 3D Building Analysis 3D Building Analysis

Combination 4 4 4

MEd 0.0 kNm 485.5 kNm 0.0 kNm

d 750.0 mm 750.0 mm 750.0 mm

d2 59.6 mm 59.6 mm 59.6 mm

K / K' 0.00 0.21 0.00

z 0.0 mm 712.5 mm 0.0 mm

Ast,reqd 0 mm2 1567 mm2 0 mm2

Aswa,reqd 1567 mm2 0 mm2 1567 mm2

AslT,reqd 0 mm2 0 mm2 0 mm2

As2,reqd 0 mm2 0 mm2 0 mm2

Astt,reqd 1567 mm 2

1567 mm 2

1567 mm2

As,min 755 mm 2

755 mm 2

755 mm2

Ast,prov 1885 mm 2

1885 mm 2

1885 mm2

Bottom bars 6H20 6H20 6H20

Deflection check - L / d = 9.767 < 47.653 -

Design summary shear and torsion

Region Left Centre Right

Length 1.831 m 3.663 m 1.831 m

Analysis 3D Building Analysis 3D Building Analysis 3D Building Analysis

Combination 4 3 3

VEd 1044.5 kN 473.2 kN 1135.4 kN

VRd,max 1599.6 kN 1599.6 kN 1599.6 kN

VRd,c 179.8 kN 179.8 kN 179.8 kN

Asws,reqd 1442 mm2/m 653 mm2/m 1568 mm2/m

Asw,min,reqd 593 mm2/m 593 mm2/m 593 mm2/m

Asw,prov 4712 mm2/m 4712 mm2/m 4712 mm2/m

TEd 0.42 kNm 0.42 kNm 0.42 kNm

TRd,max 403.11 kNm 403.11 kNm 403.11 kNm

TRd,c 151.74 kNm 151.74 kNm 151.74 kNm

Aswt,reqd 0 mm2/m 0 mm2/m 0 mm2/m

Links 6H10-100 6H10-100 6H10-100

Regional code: Singapore (Eurocode), design code: SS EN 1992-1-1 + Singapore NA (2004)

Static Design Calculations

1B1409 - 1 700x800 - Critical

Longitudinal Bars - Critical

Tekla Structural Designer, version: 23.2.1.1

Project Job Ref.

Structure Sheet no.

Page 4/10

Chk'd by App'd by

Top: 0.000 - 1.800 - Critical

3D Building Analysis - Critical

4 STR3.1-1.35G+1.5Q+1.5RQ+EHFDir1+ - Critical

Tension steel utilization ratio Astt,reqd / Ast,prov = 1.138

Provided tension bars: 7H25

Fail

Compression steel utilization ratio As2,reqd / As2,prov = 0.000

Provided compression bars: 6H20

Pass

Bottom: 0.000 - 1.080 - Critical

3D Building Analysis - Critical

3 STR1-1.35G+1.5Q+1.5RQ - Critical

Tension steel utilization ratio Astt,reqd / Ast,prov = 0.789

Provided tension bars: 6H20

Pass

Compression steel utilization ratio As2,reqd / As2,prov = 0.000

Provided compression bars: 7H25

Pass

Tekla Structural Designer, version: 23.2.1.1

Project Job Ref.

Structure Sheet no.

Page 5/10

Chk'd by App'd by

Deflection Check - Critical

Beam width bw = 700.0 mm

Effective depth in region d = 750.0 mm

Effective span length Leff = 8.400 m

Concrete cylinder strength fck = 28.000 N/mm2

Steel characteristic yield strength fyk = 500.0 N/mm2

f1 f1 = 1.000

f2 f2 = MIN[ 1 , 7 / Leff ] = 0.833

f3 f3 = 1.500

Required tension steel area for bending in region Ast,reqd = 1487 mm2

Required compression steel area for bending in region As2,reqd = 0 mm2

Supplied tension steel area Ast,prov = MIN[ Ast,prov,region , f3 × Ast,reqd ] = 1885 mm2

Reference reinforcement ratio ρ0 = fck / 1000 = 0.005

Required tension reinforcement ratio ρ = MAX[ Ast,reqd / (bw × d) , ρ0 / 100 ] = 0.003

Required compression reinforcement ratio ρ' = As2,reqd / (bw × d) = 0.000

Structural system factor Kss = 1.300

Maximum allowable span/effective depth ratio (L / d)max = Kss × f1 × f2 × (11 + (1.5 × fck × (ρ0 / ρ)) + (3.2 × fck × ((ρ0 / ρ) - 1)1.5)) × 500 × Ast,prov / (fyk × Ast,reqd) = 54.298 EN 1992-1-1:2004 Section 7.4.2

Clear span length L = 7.200 m

Actual span/effective depth ratio L / d = 9.600

Deflection check: L / d ≤ (L / d)max

Pass

Tekla Structural Designer, version: 23.2.1.1

Project Job Ref.

Structure Sheet no.

Page 6/10

Chk'd by App'd by

Shear Links - Critical

0.000 - 1.800 - Critical

3D Building Analysis - Critical

4 STR3.1-1.35G+1.5Q+1.5RQ+EHFDir1+ - Critical

Link Checks - Critical

Link utilization ratio (Asw / s)reqd / (Asw / s)prov =

0.340

Pass

1B1409 - 2 700x800 - Critical

Longitudinal Bars - Critical

Top: 5.400 - 7.200 - Critical

3D Building Analysis - Critical

3 STR1-1.35G+1.5Q+1.5RQ - Critical

Tension steel utilization ratio Astt,reqd / Ast,prov = 1.022

Provided tension bars: 7H25

Fail

Compression steel utilization ratio As2,reqd / As2,prov = 0.000

Provided compression bars: 6H20

Pass

Bottom: 0.000 - 1.080 - Critical

3D Building Analysis - Critical

4 STR3.1-1.35G+1.5Q+1.5RQ+EHFDir1+ - Critical

Tension steel utilization ratio Astt,reqd / Ast,prov = 0.696

Provided tension bars: 6H20

Pass

Compression steel utilization ratio As2,reqd / As2,prov = 0.000

Provided compression bars: 7H25

Pass

Tekla Structural Designer, version: 23.2.1.1

Project Job Ref.

Structure Sheet no.

Page 7/10

Chk'd by App'd by

Deflection Check - Critical

Beam width bw = 700.0 mm

Effective depth in region d = 750.0 mm

Effective span length Leff = 8.400 m

Concrete cylinder strength fck = 28.000 N/mm2

Steel characteristic yield strength fyk = 500.0 N/mm2

f1 f1 = 1.000

f2 f2 = MIN[ 1 , 7 / Leff ] = 0.833

f3 f3 = 1.500

Required tension steel area for bending in region Ast,reqd = 1312 mm2

Required compression steel area for bending in region As2,reqd = 0 mm2

Supplied tension steel area Ast,prov = MIN[ Ast,prov,region , f3 × Ast,reqd ] = 1885 mm2

Reference reinforcement ratio ρ0 = fck / 1000 = 0.005

Required tension reinforcement ratio ρ = MAX[ Ast,reqd / (bw × d) , ρ0 / 100 ] = 0.002

Required compression reinforcement ratio ρ' = As2,reqd / (bw × d) = 0.000

Structural system factor Kss = 1.500

Maximum allowable span/effective depth ratio (L / d)max = Kss × f1 × f2 × (11 + (1.5 × fck × (ρ0 / ρ)) + (3.2 × fck × ((ρ0 / ρ) - 1)1.5)) × 500 × Ast,prov / (fyk × Ast,reqd) = 85.913 EN 1992-1-1:2004 Section 7.4.2

Clear span length L = 7.200 m

Actual span/effective depth ratio L / d = 9.600

Deflection check: L / d ≤ (L / d)max

Pass

Tekla Structural Designer, version: 23.2.1.1

Project Job Ref.

Structure Sheet no.

Page 8/10

Chk'd by App'd by

Shear Links - Critical

5.400 - 7.200 - Critical

3D Building Analysis - Critical

3 STR1-1.35G+1.5Q+1.5RQ - Critical

Link Checks - Critical

Link utilization ratio (Asw / s)reqd / (Asw / s)prov =

0.266

Pass

1B1409 - 3 700x800 - Critical

Longitudinal Bars - Critical

Top: 0.000 - 1.831 - Critical

3D Building Analysis - Critical

4 STR3.1-1.35G+1.5Q+1.5RQ+EHFDir1+ - Critical

Tension steel utilization ratio Astt,reqd / Ast,prov = 1.188

Provided tension bars: 7H25

Fail

Compression steel utilization ratio As2,reqd / As2,prov = 0.000

Provided compression bars: 6H20

Pass

Bottom: 0.000 - 1.099 - Critical

3D Building Analysis - Critical

4 STR3.1-1.35G+1.5Q+1.5RQ+EHFDir1+ - Critical

Tension steel utilization ratio Astt,reqd / Ast,prov = 0.831

Provided tension bars: 6H20

Pass

Compression steel utilization ratio As2,reqd / As2,prov = 0.000

Provided compression bars: 7H25

Pass

Tekla Structural Designer, version: 23.2.1.1

Project Job Ref.

Structure Sheet no.

Page 9/10

Chk'd by App'd by

Deflection Check - Critical

Beam width bw = 700.0 mm

Effective depth in region d = 750.0 mm

Effective span length Leff = 8.400 m

Concrete cylinder strength fck = 28.000 N/mm2

Steel characteristic yield strength fyk = 500.0 N/mm2

f1 f1 = 1.000

f2 f2 = MIN[ 1 , 7 / Leff ] = 0.833

f3 f3 = 1.500

Required tension steel area for bending in region Ast,reqd = 1567 mm2

Required compression steel area for bending in region As2,reqd = 0 mm2

Supplied tension steel area Ast,prov = MIN[ Ast,prov,region , f3 × Ast,reqd ] = 1885 mm2

Reference reinforcement ratio ρ0 = fck / 1000 = 0.005

Required tension reinforcement ratio ρ = MAX[ Ast,reqd / (bw × d) , ρ0 / 100 ] = 0.003

Required compression reinforcement ratio ρ' = As2,reqd / (bw × d) = 0.000

Structural system factor Kss = 1.300

Maximum allowable span/effective depth ratio (L / d)max = Kss × f1 × f2 × (11 + (1.5 × fck × (ρ0 / ρ)) + (3.2 × fck × ((ρ0 / ρ) - 1)1.5)) × 500 × Ast,prov / (fyk × Ast,reqd) = 47.653 EN 1992-1-1:2004 Section 7.4.2

Clear span length L = 7.325 m

Actual span/effective depth ratio L / d = 9.767

Deflection check: L / d ≤ (L / d)max

Pass

Tekla Structural Designer, version: 23.2.1.1

Project Job Ref.

Structure Sheet no.

Page 10/10

Chk'd by App'd by

Shear Links - Critical

5.494 - 7.325 - Critical

3D Building Analysis - Critical

3 STR1-1.35G+1.5Q+1.5RQ - Critical

Link Checks - Critical

Link utilization ratio (Asw / s)reqd / (Asw / s)prov =

0.333

Pass

Tekla Structural Designer, version: 23.2.1.1

You might also like

- 2 Plaster Wall SurfaceDocument44 pages2 Plaster Wall SurfaceRobinson ConcordiaNo ratings yet

- Doubly Reinforced BeamDocument8 pagesDoubly Reinforced BeamKARTHIK SGNo ratings yet

- Design of The Low Head Slide Gate: A) Structural SteelDocument17 pagesDesign of The Low Head Slide Gate: A) Structural SteelAlok Sarkar100% (2)

- 23 Feb 2022 Model v9 Beam ForcesDocument2,116 pages23 Feb 2022 Model v9 Beam Forces郑 凯伦 Tey Kai LoonNo ratings yet

- Concrete Beam 1Document2 pagesConcrete Beam 1y2chongNo ratings yet

- 1B4 - 1 230X450 - Critical: Page 1/4 Oscarkonzult 11-Jul-20 11-Jul-20 11-Jul-20Document4 pages1B4 - 1 230X450 - Critical: Page 1/4 Oscarkonzult 11-Jul-20 11-Jul-20 11-Jul-20OscarKonzultNo ratings yet

- Critical BeamDocument16 pagesCritical BeamchristopherNo ratings yet

- FBM06Document4 pagesFBM06Damsha NdahiNo ratings yet

- FLBM13: Proposed Entrepreneurship Centre ADS 001 3 Page 1/2 ABF 14-Oct-23 CM 17-Sep-23 CM 17-Sep-23Document2 pagesFLBM13: Proposed Entrepreneurship Centre ADS 001 3 Page 1/2 ABF 14-Oct-23 CM 17-Sep-23 CM 17-Sep-23Damsha NdahiNo ratings yet

- FBM03Document8 pagesFBM03Damsha NdahiNo ratings yet

- 1B2 - 1 300x400 - Critical: Page 1/2 Legion 5 23/02/2023 23/02/2023 23/02/2023Document2 pages1B2 - 1 300x400 - Critical: Page 1/2 Legion 5 23/02/2023 23/02/2023 23/02/2023Mouris alamamussNo ratings yet

- Weld Stress CalculationsDocument19 pagesWeld Stress CalculationsMichael WaltersNo ratings yet

- Operation Building Design CalculationDocument86 pagesOperation Building Design Calculationthirupathi mookaiahNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Design of Corbels, Brackets and NibsDocument3 pagesDesign of Corbels, Brackets and NibsBrij AkabariNo ratings yet

- BEAM DESIGN-r5Document2 pagesBEAM DESIGN-r5YaserNo ratings yet

- 1) Basic Data: Design of Simply Supported Doubly-Reinforced Beam Using IS 456-2000Document3 pages1) Basic Data: Design of Simply Supported Doubly-Reinforced Beam Using IS 456-2000Khaja100% (1)

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document14 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsNo ratings yet

- RCC DesignDocument39 pagesRCC DesignMariappan .PNo ratings yet

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document8 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Miguel LuqueNo ratings yet

- Design Calculation of Precast WallDocument15 pagesDesign Calculation of Precast WallDustin GrimaresNo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3No ratings yet

- Design of Major Column TiesDocument6 pagesDesign of Major Column TiesMark Brien Vincent YbañezNo ratings yet

- Erp-Reinf Shearwall R1Document6 pagesErp-Reinf Shearwall R1Gunawan Prc2020No ratings yet

- ACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Document14 pagesACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Andy SunjayaNo ratings yet

- Pot Bearing - Fix Bearing DesignDocument2 pagesPot Bearing - Fix Bearing Designtrichandra maharjanNo ratings yet

- TPG OPGW 42 MM Dukong Manggar ZTTDocument4 pagesTPG OPGW 42 MM Dukong Manggar ZTTPalle YulianNo ratings yet

- Problem Double AnglesDocument3 pagesProblem Double AnglesAnthony SupanNo ratings yet

- PurlinDocument2 pagesPurlin2256005No ratings yet

- PC3 QmaxDocument1 pagePC3 QmaxCuong TranNo ratings yet

- Design of Minor Column TiesDocument6 pagesDesign of Minor Column TiesMark Brien Vincent YbañezNo ratings yet

- Footing - Bishan - Stretch D - T-PL1963-BSN-CS-105 - Span 3595 - Footing 800X1500Document3 pagesFooting - Bishan - Stretch D - T-PL1963-BSN-CS-105 - Span 3595 - Footing 800X1500parathasiNo ratings yet

- Strip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNDocument13 pagesStrip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNkushaljp8989No ratings yet

- Design of Steel Strcture, Is-800-2007Document48 pagesDesign of Steel Strcture, Is-800-2007srinivasNo ratings yet

- Aci318-08 Moment Shear Torsion DesignDocument7 pagesAci318-08 Moment Shear Torsion DesignMohammed HanafiNo ratings yet

- say - Use ρmin. Steel yields. #DIV/0! OK sayDocument2 pagessay - Use ρmin. Steel yields. #DIV/0! OK sayryanmikeNo ratings yet

- EC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Document7 pagesEC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Dong LINo ratings yet

- Beam DesignDocument15 pagesBeam Designravi kumarNo ratings yet

- 1.FB - Balkhu - Star Design With Break - 36m Edit Opt 2 - Copy (2) OldDocument32 pages1.FB - Balkhu - Star Design With Break - 36m Edit Opt 2 - Copy (2) OldTriChandra MaharjanNo ratings yet

- SpecificationDocument6 pagesSpecificationMOHAMAD AMIR BIN HALIDNo ratings yet

- Beam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Document4 pagesBeam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Dũng QuangNo ratings yet

- RCC DesignDocument12 pagesRCC DesignRmesh jhaNo ratings yet

- Mathcad - Design On Singly Reinforced T BeamDocument6 pagesMathcad - Design On Singly Reinforced T BeammrnaeemNo ratings yet

- Design of Short Column For Axial Load and MomentDocument5 pagesDesign of Short Column For Axial Load and Momentភារម្យ អេងNo ratings yet

- 06.footing Design Bs 8110 1997Document5 pages06.footing Design Bs 8110 1997QualityControl SorARoonUTTNo ratings yet

- WallcalcDocument31 pagesWallcalcSubhekshya ShresthaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- Kajian Teknis Untuk Perubahan Kabel Feeder Trafo To LVMDPDocument4 pagesKajian Teknis Untuk Perubahan Kabel Feeder Trafo To LVMDPHendrias ari sujarwoNo ratings yet

- CF4-GRID 8A-D, 8A-D1 Also Refrence For CF-1, CF3, CF2Document4 pagesCF4-GRID 8A-D, 8A-D1 Also Refrence For CF-1, CF3, CF2Parvez KhanNo ratings yet

- Main Component For Two2Document3 pagesMain Component For Two2اسعد الماوريNo ratings yet

- RCBeamOpening v061601Document1 pageRCBeamOpening v061601kevinlow3No ratings yet

- Huchez Winch 10 TonsDocument6 pagesHuchez Winch 10 TonsPhong DuongNo ratings yet

- Column & FootingDocument32 pagesColumn & FootingAmol potdarNo ratings yet

- Design of Beam (Classical Approach) .1Document24 pagesDesign of Beam (Classical Approach) .1Udhasu NayakNo ratings yet

- Fender PileDocument11 pagesFender PileVenkat PalliNo ratings yet

- Dimensionamento Roscas Stub-AcmeDocument13 pagesDimensionamento Roscas Stub-AcmeVítor CarvalhoNo ratings yet

- Zone 14a: Crone Partners Punching Shear For Column C1 BS 25-Dec-2017 1 - 3904 45 460 8 600 0 450 0 0 0Document10 pagesZone 14a: Crone Partners Punching Shear For Column C1 BS 25-Dec-2017 1 - 3904 45 460 8 600 0 450 0 0 0vaideehNo ratings yet

- Beam Detailing Bs 8110 1997Document5 pagesBeam Detailing Bs 8110 1997AhmedAlghzawiNo ratings yet

- Zone 4 - 1VB3a RC Beam Analysis & Design (EN1992)Document18 pagesZone 4 - 1VB3a RC Beam Analysis & Design (EN1992)jasekanNo ratings yet

- RAM Connection Standalone CE ReportDocument2 pagesRAM Connection Standalone CE ReportjasekanNo ratings yet

- Presentation 1Document1 pagePresentation 1jasekanNo ratings yet

- Zone 1 - 1VB1c RC Beam Analysis & Design (EN1992) PDFDocument12 pagesZone 1 - 1VB1c RC Beam Analysis & Design (EN1992) PDFjasekanNo ratings yet

- OutputsDocument13 pagesOutputsjasekanNo ratings yet

- Zone 3 - 1HB65 RC Beam Analysis & Design (EN1992)Document52 pagesZone 3 - 1HB65 RC Beam Analysis & Design (EN1992)jasekanNo ratings yet

- Frame Jase3Document16 pagesFrame Jase3jasekanNo ratings yet

- Common Mistakes For Assignment 3 PDFDocument1 pageCommon Mistakes For Assignment 3 PDFjasekanNo ratings yet

- Envelope (Staadpro)Document10 pagesEnvelope (Staadpro)jasekanNo ratings yet

- Sem-2-AY21xcScSc - TT - For-WebsiteDocument27 pagesSem-2-AY21xcScSc - TT - For-WebsitejasekanNo ratings yet

- Revised Agenda 3Document1 pageRevised Agenda 3jasekanNo ratings yet

- Draft INVITATION 3Document1 pageDraft INVITATION 3jasekanNo ratings yet

- Assignment - DeviDocument10 pagesAssignment - DevijasekanNo ratings yet

- B4C251a-TSD - FlattenedDocument2 pagesB4C251a-TSD - FlattenedjasekanNo ratings yet

- Preprints202111 0327 v1Document39 pagesPreprints202111 0327 v1jasekanNo ratings yet

- Math - T3 - G8 - I, II PP - 2019Document6 pagesMath - T3 - G8 - I, II PP - 2019jasekanNo ratings yet

- Two-Day Preparatory Course For The Chartered Membership Examination of The Institution of Structural Engineers, UkDocument2 pagesTwo-Day Preparatory Course For The Chartered Membership Examination of The Institution of Structural Engineers, UkjasekanNo ratings yet

- 2013 SoilheaveduetopiledrivingDocument20 pages2013 SoilheaveduetopiledrivingjasekanNo ratings yet

- CE5104 Settlement Due To TunnellingDocument114 pagesCE5104 Settlement Due To TunnellingjasekanNo ratings yet

- Em Math g9 I, Iipp 2019Document6 pagesEm Math g9 I, Iipp 2019jasekanNo ratings yet

- Min AxisDocument3 pagesMin AxisjasekanNo ratings yet

- Note 12 Sep 2022Document5 pagesNote 12 Sep 2022jasekanNo ratings yet

- EM - Math - T3 - G9 - I, II PP Ans - 2019Document9 pagesEM - Math - T3 - G9 - I, II PP Ans - 2019jasekanNo ratings yet

- UnknownDocument5 pagesUnknownjasekanNo ratings yet

- Weld Connection - CalculationDocument2 pagesWeld Connection - CalculationjasekanNo ratings yet

- Tuesday, October 20, 2015, 03:28 PMDocument10 pagesTuesday, October 20, 2015, 03:28 PMjasekanNo ratings yet

- Pontoon 13-Oct-15 20-Oct-2015 15:21 Gangway - STD: Job No Sheet No RevDocument6 pagesPontoon 13-Oct-15 20-Oct-2015 15:21 Gangway - STD: Job No Sheet No RevjasekanNo ratings yet

- SSéukaâ Úohd, H Richmond College: M Uq JDR Mílaikh - 2019Document7 pagesSSéukaâ Úohd, H Richmond College: M Uq JDR Mílaikh - 2019jasekanNo ratings yet

- EM - Math - G9 - T3 - I, II PP Ans - 2018Document4 pagesEM - Math - G9 - T3 - I, II PP Ans - 2018jasekanNo ratings yet

- Cantilever Retaining Wall ExampleDocument4 pagesCantilever Retaining Wall ExamplejasekanNo ratings yet

- Topic About Engineering Research PaperDocument6 pagesTopic About Engineering Research Paperscxofyplg100% (1)

- Crane Girder DesignDocument6 pagesCrane Girder Designarzu50% (2)

- CE Board Nov 2020 - RCD - Set 16Document1 pageCE Board Nov 2020 - RCD - Set 16Dale MalazzabNo ratings yet

- Building Construction 2. Masonry: Civil Engineering Materials and ConstructionDocument55 pagesBuilding Construction 2. Masonry: Civil Engineering Materials and ConstructionGautam ChandraNo ratings yet

- Short Col DesignDocument17 pagesShort Col DesignBhavin ShahNo ratings yet

- Types of Bridges: Main Structure Coinciding With Deck LineDocument21 pagesTypes of Bridges: Main Structure Coinciding With Deck Lineshna jabarNo ratings yet

- Introducing Two Most Common Types of Shear Walls and Their Construction MethodsDocument6 pagesIntroducing Two Most Common Types of Shear Walls and Their Construction MethodsVictor OmotoriogunNo ratings yet

- Structural Integrity in The Design of Precast Prestressed Concrete StructuresDocument11 pagesStructural Integrity in The Design of Precast Prestressed Concrete StructuresMohamed AyoubNo ratings yet

- SDPL CH 148-160 Shuttering Design For Girder-Layout-23Document1 pageSDPL CH 148-160 Shuttering Design For Girder-Layout-23Sudeep JoshiNo ratings yet

- BMW Center Show Room Final-01Document43 pagesBMW Center Show Room Final-01QC MEPNo ratings yet

- Staad QuizDocument3 pagesStaad QuizKenneth NaguitNo ratings yet

- 12 Chapter 5Document21 pages12 Chapter 5MEERA04No ratings yet

- RCC94 Two-Way Slabs (Tables)Document3 pagesRCC94 Two-Way Slabs (Tables)Mohammad Twaha JaumbocusNo ratings yet

- SFD & BMDDocument21 pagesSFD & BMDSayan ChowdhuryNo ratings yet

- BCE-UNIT-2 Components of BuilDocument84 pagesBCE-UNIT-2 Components of Builviveksp99No ratings yet

- Analysis of Beam (Longitudinal Frames)Document44 pagesAnalysis of Beam (Longitudinal Frames)Anissah ManialaNo ratings yet

- Detail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)Document1 pageDetail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)sathiyanNo ratings yet

- Calculate Quantities of Materials For Concrete - Cement, Sand, AggregatesDocument7 pagesCalculate Quantities of Materials For Concrete - Cement, Sand, Aggregatesvenkateswara rao pothinaNo ratings yet

- Ductile Detailing Useful ReferencesDocument6 pagesDuctile Detailing Useful ReferencesMandar NadgaundiNo ratings yet

- Expansion Joint Checklist: Waterproofing Membrane System Trafficability Fire RatingDocument1 pageExpansion Joint Checklist: Waterproofing Membrane System Trafficability Fire RatingDavid Alexander Calderón ArreguiNo ratings yet

- 2003 EWS X440 Product Guide-GlulamDocument32 pages2003 EWS X440 Product Guide-GlulamVinícius Da Cunha FerreiraNo ratings yet

- Member Code: Dyntek Pte. LTDDocument1 pageMember Code: Dyntek Pte. LTDHerbert BishopNo ratings yet

- Design Timber Structures Using Eurocode 5Document119 pagesDesign Timber Structures Using Eurocode 5margitorsi100% (2)

- Chemical Admixtures For Concrete: ACI 212.3R-04Document30 pagesChemical Admixtures For Concrete: ACI 212.3R-04josel_ortizcNo ratings yet

- Basics of Post Installed Rebar Connections: 1 ApplicationsDocument33 pagesBasics of Post Installed Rebar Connections: 1 ApplicationsHaitham KayyaliNo ratings yet

- Basement ExcavationDocument4 pagesBasement ExcavationAnonymous U6pIEKQghNo ratings yet

- WikiEngineer - Structural - Pinned-Roller Shear & Moment DiagramsDocument8 pagesWikiEngineer - Structural - Pinned-Roller Shear & Moment DiagramsBogdanBNo ratings yet

- Banglo Pahang Estimate BQDocument37 pagesBanglo Pahang Estimate BQHazim ZakariaNo ratings yet