Professional Documents

Culture Documents

10 JSA - Cable Drums Installations

10 JSA - Cable Drums Installations

Uploaded by

syed khaja misbhuddinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 JSA - Cable Drums Installations

10 JSA - Cable Drums Installations

Uploaded by

syed khaja misbhuddinCopyright:

Available Formats

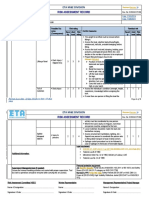

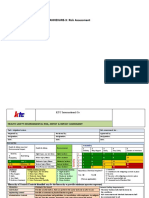

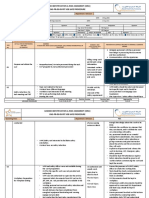

Form – RA 002

JSA – Job Safety Analysis JSA No: 10

SWMS Title: Cable Drums Installations Revision : 000

Submitted by:

Contractor: INFINITI BUILDING SOLUTIONS PVT LTD Prepared by: BALAJI BODA

Contact Name Mr.NAVEEN C Contact Position: PROJECT MANAGER

Contact Signature: Contract Phone No: 0-9989434440

Project Details & JSA Task Description:

M/s. SATTVA KNOWLEDGE CITY PARCEL-II, Location: BUILDING AT Hi-tech CITY,

Project:

HYDERABAD

STORAGE OF THE CABLE DRUMS Bldg/Area

Task / Activity: Level:

Zone/Room

Trades Involved:

Cotton Hand gloves, Hardhat, goggles, Full body

Soft barricading, Warning Lights, Wooden Pad, Harness, Safety shoes, High visibility jackets,

Major Equipment to be used ladder, tagline, Safety Latch, Wheel Choker, List PPE required for this task: welding Aprons, welding face shield, leather

for this task: reverse Horn, Traffic Cones, Road Block hand gloves, fire extinguisher (CO2), Sand/water

*All equipment listed has has been cleared for use on site and is maintained in

accordance with the manufacturers recommendations. buckets.

List any Hazardous

Induction training, Height work training, Hot

Substances, Materials or List Permits to Work required to work training, Manual Handling Training

Dangerous Goods to be used: commence this Task:

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

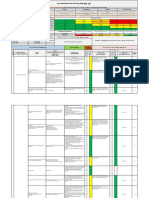

Form – RA 002

Risk Matrix & Ranking

Likelihood / Probability

Level Description of Consequence or Impact Consequence L M U

Likely Moderate Unlikely

H (1) Potential death, permanent disability or major structural failure/damage. Off-site environmental H (1)

1 1 2

(High level of harm) discharge/release not contained and significant long-term environmental harm. (High)

M (2) Potential temporary disability or minor structural failure/damage.

M (2)

(Medium level of On-site environmental discharge/release contained, minor remediation required, short-term 1 2 3

(Medium)

harm) environmental harm.

Incident that has the potential to cause persons to require first aid.

L (3) L (3)

On-site environmental discharge/release immediately contained, minor level clean up with no 2 3 3

(Low level of harm) (Low)

short-term environmental harm.

Level Likelihood / Probability

Likely Could happen frequently

Moderate Could happen occasionally

Unlikely May occur only in exceptional circumstances

Hazards Identification & Control Measures

Risk Class Responsibility

Item Job steps Hazards Controls

Refer risk matrix Who will do it

S.No Break the job down into sequential steps List what can harm you How can you make the job as safe as possible

• Ensure Area should be barricaded by

Barrication Tape Workers

• Ensure Area, Ground Level & over head involved

Lines should be checked

1 Area Preparation • Slip & Trips

• Ensure that Tool Box Task has been given safety in

before starting the work charge, Site

• Ensure that Authorised person to be supervisor

allowed to working area

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

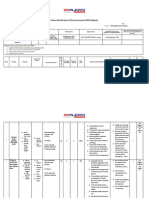

Form – RA 002

Hazards Identification & Control Measures

Risk Class Responsibility

Item Job steps Hazards Controls

Refer risk matrix Who will do it

S.No Break the job down into sequential steps List what can harm you How can you make the job as safe as possible

Person may fall due to We ensure that the Vehicle fitness,

slip or improper license, Crane Boom, Limit, Switches Workers

gripping. fitness, Third Party inspections are involved safety

2 Crane Positioning & Checking Fall from height. checked in charge, Site

Ensure crane Positioning are has been supervisor.

levelled & Compact properly

Ensure overload chart shall be provided

and maintain as per the norms

Ensure that all the oil Leakages shall be

checked Workers

Crane Topple Ensure 300 to 600 kgs shall be lifted and involved safety

tagline shall be provided in charge, site

Follow the load Chart supervisor.

Ensure tagline to be provided for both

ends.

Out riggers base plates should be rested Workers

Out rigger failure/ on on the proper & Level Sheet Plates involved safety

soft ground which are placed on the properly levelled in charge, site

and checked ground area.

supervisor.

Truck shall be Placed at 5mt distance for

moving of crane boom. Workers

Slip , Trip & Collapse

Ensure wheel checkers should be involved safety

3 Truck Positions

provided to all wheels in charge, Site

supervisor.

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

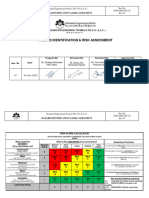

Form – RA 002

Hazards Identification & Control Measures

Risk Class Responsibility

Item Job steps Hazards Controls

Refer risk matrix Who will do it

S.No Break the job down into sequential steps List what can harm you How can you make the job as safe as possible

Ensure check the vehicle fitness, license,

and documents

Ensure third party inspection to be done. Workers

Vehicle Failure

Ensure Slings and D shackles to be involved safety

inspected in charge, site

Ensure nobody should be allowed to the

supervisor.

lifting area

Signal man should give the signal.

The swing area should be clear for the

swing of the boom(360 degrees)

The crane positioning should be done in

such a way that all the adjacent existing

Unloading of Cable drums Hit on adjacent existing

facilities should be out of the crane swing

facilities area.

Ensure that a signal man is allotted to

Slip & trip, cut injuries,

give signal for the crane operator.

Fall of Material & Ensure all oil leakages shall be checked workers involved

4 Ensure no person will stand under the safety in charge,

Persons

suspended load site supervisor.

Lifting Gears Failure Ensure only Skilled & experienced

operators are allowed to operate the

Crane failure

crane.

Improper Operations Ensure that safety orientation is given to

the operators before starting the work.

Only Authorised persons should be

allowed to the working area.

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

Form – RA 002

Hazards Identification & Control Measures

Risk Class Responsibility

Item Job steps Hazards Controls

Refer risk matrix Who will do it

S.No Break the job down into sequential steps List what can harm you How can you make the job as safe as possible

Workers

Suitable ladder provided and ties off with involved,

rope at both ends site

Fall from height & Slip

5 Use full body harness supervisor,

Removing of Slings & Trip

safety in

charge.

JSA Induction Verification. To be signed by all participants in the task prior to commencement.

I have read this SWMS, understand its content and acknowledge its conditions and my responsibilities :

Print Names: Title / Trade Classification Signatures: Dates:

JSA Review & Approval to Proceed.

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

Form – RA 002

Review Date

Status

Rejected Resubmit Approved

Commnets:

This JSA has been reviewed and the works may proceed based on compliance with the requirements outlined in this SWMS , respective permits to work issued, applicable

EH&S legislation, codes and specifications.

Reviewer: Company: Title: Signed: Date: Time:

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

You might also like

- Height Pass and Vertigo Test Report FormatDocument2 pagesHeight Pass and Vertigo Test Report Formatsyed khaja misbhuddin75% (4)

- 19.17 (SWMS) All Work HvacDocument17 pages19.17 (SWMS) All Work Hvacsyed khaja misbhuddinNo ratings yet

- Site Specific Health Safety Environment Plan HvacDocument74 pagesSite Specific Health Safety Environment Plan Hvacsyed khaja misbhuddin100% (1)

- WICKED LibrettoDocument49 pagesWICKED LibrettoCatalina Moreno100% (2)

- Hkdse English Reading全方位實戰神技精讀 主筆記 Sample 1643026918Document23 pagesHkdse English Reading全方位實戰神技精讀 主筆記 Sample 1643026918SupercellNo ratings yet

- YCMOU B.Com SyllabusDocument20 pagesYCMOU B.Com SyllabusPruthviraj PatilNo ratings yet

- Waiting Lines and Qeuing Theory ModelDocument29 pagesWaiting Lines and Qeuing Theory ModelMadeline Gamboa De GuzmanNo ratings yet

- Warehouse AnalyticsDocument62 pagesWarehouse AnalyticsMary Williams100% (1)

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- BSD - 019 Bulk EarthworksDocument3 pagesBSD - 019 Bulk EarthworksZakkaudin KhanNo ratings yet

- Risk Assessment - Concrete PouringDocument6 pagesRisk Assessment - Concrete Pouringabdullah ashrafNo ratings yet

- Permit To Work FormDocument2 pagesPermit To Work FormNate JamesNo ratings yet

- RA For Fire A68Document11 pagesRA For Fire A68Sajid Shah100% (1)

- RA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsDocument30 pagesRA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsIbrahim EsmatNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- Project EHS KPI - 24 Agustus 2013Document1 pageProject EHS KPI - 24 Agustus 2013Crystin Rotua Hasmi PanjaitanNo ratings yet

- FR - HSE - 061 - en Permit To Work Audit ChecklistDocument2 pagesFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNo ratings yet

- Reinforcement Cutting Bending JSA HSE ProfessionalsDocument1 pageReinforcement Cutting Bending JSA HSE ProfessionalsNoval FebriNo ratings yet

- QHSE DashboardDocument5 pagesQHSE DashboardParure DoréeNo ratings yet

- SAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XDocument13 pagesSAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XWhina R Ayma100% (1)

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- UG RA 006 - Installation of Road BarricadesDocument4 pagesUG RA 006 - Installation of Road BarricadesshamshuddinNo ratings yet

- RA Flushing &Hydro-TestingDocument8 pagesRA Flushing &Hydro-Testingalla malikNo ratings yet

- 5-Star Safety and Health Management System: Risk RegisterDocument3 pages5-Star Safety and Health Management System: Risk RegistersalmanNo ratings yet

- Heat Stress Management PlanDocument4 pagesHeat Stress Management Planthennarasu100% (1)

- 24-Ra Manual HandlingDocument3 pages24-Ra Manual HandlingAsad AyazNo ratings yet

- 07 Manual Excavations & Exposing of Underground FacilitiesDocument6 pages07 Manual Excavations & Exposing of Underground FacilitiesPangky Abasolo100% (1)

- Backfilling and Compaction MVLDocument3 pagesBackfilling and Compaction MVLLawrence adeleke OmisakinNo ratings yet

- Msc-Qhsef-04 Masterlist - Documents and RecordsDocument4 pagesMsc-Qhsef-04 Masterlist - Documents and RecordsAdil Abdulkhader100% (1)

- HSE-RA-031 Back Filling of - Excavation - Rev 0Document9 pagesHSE-RA-031 Back Filling of - Excavation - Rev 0عمروNo ratings yet

- RA - Foundation (Formwork & Reinforcement)Document7 pagesRA - Foundation (Formwork & Reinforcement)abhinav djNo ratings yet

- Lifting Operations Planning Risk Assessment PDFDocument1 pageLifting Operations Planning Risk Assessment PDFulisses costaNo ratings yet

- Safety BoardDocument1 pageSafety BoardsunilNo ratings yet

- 2.8c Risk Assessment - 023 Scaffolding Erection, Dismantling, Modification Rev. July 2019Document9 pages2.8c Risk Assessment - 023 Scaffolding Erection, Dismantling, Modification Rev. July 2019Shah MuzzamilNo ratings yet

- Risk Assessment For FlushingDocument9 pagesRisk Assessment For FlushingABDUL BASITHNo ratings yet

- Site Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkDocument26 pagesSite Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- HSE Inspection Report 148 AttendDocument11 pagesHSE Inspection Report 148 Attendtuan mai vanNo ratings yet

- RiskAssessment For Precast Foundation and Road MarkingDocument13 pagesRiskAssessment For Precast Foundation and Road MarkingAneessh KumarNo ratings yet

- Rock BreakingDocument1 pageRock BreakingGyanendra Narayan NayakNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument13 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- Installation of Cable Trays and LaddersDocument13 pagesInstallation of Cable Trays and LaddersamalNo ratings yet

- 03-F07 Job Safe Procedure Template - DAMMAM - NO. 01Document1 page03-F07 Job Safe Procedure Template - DAMMAM - NO. 01jawad khanNo ratings yet

- HSE-RA-023 Site Establishment - Rev 0Document17 pagesHSE-RA-023 Site Establishment - Rev 0عمروNo ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- Emergency Drill ReportDocument10 pagesEmergency Drill ReportSheri DiĺlNo ratings yet

- JSA-049 LVS Equipment & Material InstallationDocument10 pagesJSA-049 LVS Equipment & Material InstallationMoaatazz NouisriNo ratings yet

- Hse Bulletin: Cold & FluDocument2 pagesHse Bulletin: Cold & FluRanjan PradhanNo ratings yet

- WRAL Weekly HSE Report 08-01-2024 To - 14-01-2024Document3 pagesWRAL Weekly HSE Report 08-01-2024 To - 14-01-2024sunday abachaNo ratings yet

- Risk Assessment For Ms Installation of Precast BoundrywallDocument11 pagesRisk Assessment For Ms Installation of Precast BoundrywallSajid ShahNo ratings yet

- Focus Audit Temp WorksDocument2 pagesFocus Audit Temp WorksArunKumar GanesanNo ratings yet

- Risk Assesment Fab - Rev-07Document71 pagesRisk Assesment Fab - Rev-07Nikhil PuthiryNo ratings yet

- RA - Blinding ConcreteDocument6 pagesRA - Blinding Concreteabhinav djNo ratings yet

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Document6 pagesSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarNo ratings yet

- Imb SH Hse 0009 01Document64 pagesImb SH Hse 0009 0101095902062ahmedNo ratings yet

- Risk Assessment For Solar Lighting System1Document6 pagesRisk Assessment For Solar Lighting System1hamza ibrahimNo ratings yet

- Simple Dashboard Template Without MacrosDocument5 pagesSimple Dashboard Template Without MacrosvictorNo ratings yet

- HSE Risk Assessment For Hot Work ActivityDocument8 pagesHSE Risk Assessment For Hot Work ActivityDarseen RNo ratings yet

- 01 WI HSE 001 - Risk Assessment BridgesDocument8 pages01 WI HSE 001 - Risk Assessment BridgesMisbah Ul Haq LabeedNo ratings yet

- HSE-RA-059 Mobile Elevating Work Platform Operation - Rev 0Document8 pagesHSE-RA-059 Mobile Elevating Work Platform Operation - Rev 0عمروNo ratings yet

- Soft Cut Saw Operations (Generic) : Job Safety AnalysisDocument1 pageSoft Cut Saw Operations (Generic) : Job Safety AnalysisBorislav VulićNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- RA Excavation For ExcavationDocument13 pagesRA Excavation For ExcavationSasi KumarNo ratings yet

- Lesson Learned RegisterDocument2 pagesLesson Learned Registernasir habibNo ratings yet

- Risk Assement UpdatedDocument10 pagesRisk Assement Updatedashwin0% (1)

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (06) Template SettingDocument13 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (06) Template Settingmohammed tofiqNo ratings yet

- Job Safety AnalysisDocument13 pagesJob Safety Analysissyed khaja misbhuddinNo ratings yet

- Formation of Safety Committee in Phoenix ProjectDocument2 pagesFormation of Safety Committee in Phoenix Projectsyed khaja misbhuddinNo ratings yet

- PPE's Check ListDocument1 pagePPE's Check Listsyed khaja misbhuddinNo ratings yet

- Scissor Lift Safety PlanDocument24 pagesScissor Lift Safety Plansyed khaja misbhuddinNo ratings yet

- HIRA Insullation URCDocument12 pagesHIRA Insullation URCsyed khaja misbhuddinNo ratings yet

- JSA - Scissor - Lift 2023Document4 pagesJSA - Scissor - Lift 2023syed khaja misbhuddinNo ratings yet

- ABS EHS 3 Crane Inspection ChecklistDocument1 pageABS EHS 3 Crane Inspection Checklistsyed khaja misbhuddinNo ratings yet

- Robert Laughton Memo Re Job Safety Analysis - 8-2-17Document29 pagesRobert Laughton Memo Re Job Safety Analysis - 8-2-17syed khaja misbhuddinNo ratings yet

- ABS HIRA For Store ConstructionDocument6 pagesABS HIRA For Store Constructionsyed khaja misbhuddinNo ratings yet

- Urc HIRA Laoding & UnloadingDocument16 pagesUrc HIRA Laoding & Unloadingsyed khaja misbhuddinNo ratings yet

- HIRA URC DUCT InstallationDocument18 pagesHIRA URC DUCT Installationsyed khaja misbhuddinNo ratings yet

- Compensation Policy - ABS HRCDocument4 pagesCompensation Policy - ABS HRCsyed khaja misbhuddinNo ratings yet

- 19.17 (SWMS) All Work HVAC URCDocument15 pages19.17 (SWMS) All Work HVAC URCsyed khaja misbhuddinNo ratings yet

- HIRA Electrical Works HRC 002Document7 pagesHIRA Electrical Works HRC 002syed khaja misbhuddinNo ratings yet

- Weekly EHS StatisticsDocument1 pageWeekly EHS Statisticssyed khaja misbhuddinNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- JSA - Lifting Shifting PhoenixDocument5 pagesJSA - Lifting Shifting Phoenixsyed khaja misbhuddinNo ratings yet

- Enhancing With Multi ThreadingDocument38 pagesEnhancing With Multi Threadingra_po_1No ratings yet

- 4357r 85 PDFDocument14 pages4357r 85 PDFFred PrzNo ratings yet

- AFFLE - Investor Presentation - FY21Document19 pagesAFFLE - Investor Presentation - FY21Abhishek MurarkaNo ratings yet

- V.1 Comment Opposiiton To Defendant's Motion For Extension of Time To File AnswerDocument2 pagesV.1 Comment Opposiiton To Defendant's Motion For Extension of Time To File AnswerRhows Buergo100% (1)

- DSA Weekly PlanDocument3 pagesDSA Weekly PlanJatin0% (1)

- Polarization DensityDocument8 pagesPolarization DensityAshwin BalajiNo ratings yet

- 042 Myrmidon (Elf Class)Document3 pages042 Myrmidon (Elf Class)VikshadeNo ratings yet

- Variable Pitch Fan System - If EquippedDocument3 pagesVariable Pitch Fan System - If EquippedEVER DAVID SAAVEDRA HUAYHUANo ratings yet

- Certificate of Eligibility: VA Loan Number State Loan Amount Date of Loan Entitlement Charged StatusDocument1 pageCertificate of Eligibility: VA Loan Number State Loan Amount Date of Loan Entitlement Charged Statuswoodstracy19No ratings yet

- FT096 20191112 Iso A4Document64 pagesFT096 20191112 Iso A4Jeff Zeitlin100% (4)

- ECO FONE Report Structure From RoehamptonDocument23 pagesECO FONE Report Structure From RoehamptonfinastefanNo ratings yet

- Rama 2Document3 pagesRama 2Ramasubba ReddyNo ratings yet

- Molykote® P-37 Datasheet Eng PDFDocument2 pagesMolykote® P-37 Datasheet Eng PDFBib GmzNo ratings yet

- Proxmox Mail Gateway 5.1 Datasheet PDFDocument4 pagesProxmox Mail Gateway 5.1 Datasheet PDFRey TmoNo ratings yet

- Is It Worth Dropping One More Year For GATE - QuoraDocument6 pagesIs It Worth Dropping One More Year For GATE - QuoraRaJu SinGhNo ratings yet

- DAA 2020 Week 06 Assignment 02Document6 pagesDAA 2020 Week 06 Assignment 02NikileshNo ratings yet

- CPD Using The Ecsa Electronic System For Entering Records: WWW - Ecsa.co - ZaDocument5 pagesCPD Using The Ecsa Electronic System For Entering Records: WWW - Ecsa.co - ZaBen MudoziNo ratings yet

- 350-01015-00, Center AirDocument50 pages350-01015-00, Center AirlordofwarNo ratings yet

- Investing Basics Bonds Student V52Document5 pagesInvesting Basics Bonds Student V52nikola.zyszkiewiczNo ratings yet

- sjp810m Manual BookDocument12 pagessjp810m Manual BookMegNo ratings yet

- Unisab III Engineering - 2009 06Document293 pagesUnisab III Engineering - 2009 06Marildo CominNo ratings yet

- Adolescent Health and Development Program - Department of Health WebsiteDocument4 pagesAdolescent Health and Development Program - Department of Health WebsiteJL CalvinNo ratings yet

- Cr02a 8Document7 pagesCr02a 8Heriberto Flores AmpieNo ratings yet

- TITT - Consultancy Services - Prod OpsDocument74 pagesTITT - Consultancy Services - Prod OpsWale OyeludeNo ratings yet

- Data Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeDocument10 pagesData Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeRisa RidmaNo ratings yet