Professional Documents

Culture Documents

AURETR125 Student AT3

AURETR125 Student AT3

Uploaded by

Kyle ShailenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AURETR125 Student AT3

AURETR125 Student AT3

Uploaded by

Kyle ShailenCopyright:

Available Formats

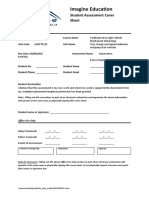

ASSESSMENT TASK 3

Student Version

Test, jump start, remove and replace battery. Rapid

Knowledge Task Task Name

charge battery.

Use this version for students to answer the questions, to mark their answers and give feedback to students.

Section A - Assessment Information

Student name Kyle Shailen

(first name and surname)

Student ID 202118103

Date 30/11/2022

Unit(s) of competency AURETR125 Test, charge and replace batteries and jump-start

(code and title) vehicles

Duration and/or due Students have 60 mins to complete this assessment. Students will be

date provided with the due date when they start this unit.

Student task instructions

This is one of three assessment tasks you need to complete satisfactorily for this unit.

In this task, you will be observed by your assessor completing the following tasks:

Part A – test, jump start and replace a battery

You will test a battery in a vehicle (provided by your assessor) and jump start the vehicle

You will then remove the battery and replace it with another suitable battery.

Part B – Rapid charge a battery

You will rapid charge the battery removed from the vehicle in Part A and test it.

You will be assessed against the criteria listed in the observation checklist in Section B, and

completion of the job card and unshaded sections of the service checklist.

You must complete all criteria satisfactorily to be deemed as meeting requirements for this

task.

©2021 Victorian Automotive Chamber of Commerce (VACC) V1.0 1 of

AURETR125 Test, charge and replace batteries and jump-start vehicles

ASSESSMENT TASK 3

Conditions for assessment

This is an individual assessment; you must complete the task without help except to clarify job

requirements and confirm the location of equipment etc.

You must complete the task safely and, in a work-like manner. If your assessor deems you are

working unsafely, they will stop the assessment, and you will be deemed as not meeting

requirements.

If you believe you have a disability that requires adjustments to this assessment (e.g.,

additional time) discuss this with your assessor before the day of assessment.

You will be assessed as meeting requirements (MR) or further evidence required (FER).

Refer to your training organisation's policy and procedure regarding reassessment if assessed

as further evidence is required.

You can appeal the assessment decision according to your training organisation's assessment

policy and procedure.

Equipment/resources to be provided by the

Equipment/resources students must supply:

RTO or the workplace:

PPE Hard copies of the student version of this

assessment task or access to soft copies,

Own tools (if available) including the job card and service checklist for

this task

Relevant procedures and safety data sheets

A vehicle with a battery that requires charging

Replacement batteries for students to select

Access to workplace procedures, manufacturer

specifications and manuals for the vehicle

Workshop or simulated workshop with the

following tools and equipment

Battery charger for slow/trickle charging

Load testing device

Hydrometer

Multimeter

Jumper leads/pack

Battery terminal cleaning tool

Battery cleaning materials

Battery lifting tool

©2021 Victorian Automotive Chamber of Commerce (VACC) V1.0 2 of

AURETR125 Test, charge and replace batteries and jump-start vehicles

ASSESSMENT TASK 3

Section B - PART A Observation checklist (test, jump-start and replace a battery)

Satisfactory

Marking criteria Comments

Yes No

Pre-Job Tasks

1. Read the job card and accurately

described the requirements to the

☒ ☐

assessor and asks questions for

clarification.

2. Located correct manufacturer procedures

for testing, removing, and replacing and ☒ ☐

cleaning the battery.

3. Wore appropriate PPE, inspected area,

equipment and vehicle for hazards and

☒ ☐

managed any risks before commencing

work.

4. Selected appropriate tools and equipment,

checked they were in working order.

☒ ☐

Inspect and test the battery

5. Safely tested the battery voltage, and load

tested the battery according to

manufacturer procedures and ☒ ☐

specifications and recorded these on the

job card.

6. Safely checked the electrolyte levels and

correctly tested the Specific Gravity (SG)

with a hydrometer, topped up as per ☒ ☐

manufacturer’s specifications and

environmental requirements.

7. Safely inspected the battery case, battery

carrier, battery hold-down, battery cables,

and terminals for faults and damage as per

☒ ☐

workplace procedures. Recorded findings

on the job card and explained findings and

recommendations to the assessor.

Carry out jump-start procedures

8. Correctly and safely connected the jump

leads/pack without causing damage to the

☒ ☐

vehicle, according to the manufacturer’s

specifications and workplace procedures.

9. Correctly and safely started the vehicle, as

per workplace procedures.

☒ ☐

10. Correctly and safely disconnected the ☒ ☐

jump leads/pack without causing damage

to the vehicle according to the

manufacturer’s specifications and

©2021 Victorian Automotive Chamber of Commerce (VACC) V1.0 3 of

AURETR125 Test, charge and replace batteries and jump-start vehicles

ASSESSMENT TASK 3

Satisfactory

Marking criteria

workplace procedures. Comments

Remove and replace battery

11. Correctly connected a battery back-up

device or memory minder to the vehicle as

☒ ☐

per workplace procedures.

12. Correctly and safely disconnected the

battery terminals, removed the battery

☒ ☐

following workplace procedures and

environmental requirements.

13. Selected an appropriate replacement

battery to meet the manufacturers

☒ ☐

specifications.

14. Safely cleaned the battery carrier, hold

down, and terminals using the correct

equipment and cleaning materials, ☒ ☐

according to workplace procedures, SDS

and environmental requirements.

15. Safely and correctly fitted and secured the

replacement battery, following workplace

☒ ☐

procedures.

16. Safely reconnected the battery terminals,

removed the battery back-up device and

☒ ☐

carried out system recalibration procedure

according to manufacturer’s procedures.

Post work tests and job completion

17. Safely tested the vehicle’s charging

system, both loaded and unloaded, as per

☒ ☐

manufacturers specifications and

workplace procedures.

18. Accurately and clearly listed all parts and

materials used, work completed, any

recommendations to the customer on the ☒ ☐

job card and processed it as per workplace

procedures.

19. Completed a final inspection of the vehicle

to ensure it is ready for delivery to the ☒ ☐

customer.

20. Cleaned work area, sorted non-recyclable

and recyclable waste materials, and

disposed of/stored these in the correct ☒ ☐

location according to workplace

procedures.

21. Checked tools and equipment to ensure

they are in working order and stored

☒ ☐

correctly according to workplace

procedures.

©2021 Victorian Automotive Chamber of Commerce (VACC) V1.0 4 of

AURETR125 Test, charge and replace batteries and jump-start vehicles

ASSESSMENT TASK 3

©2021 Victorian Automotive Chamber of Commerce (VACC) V1.0 5 of

AURETR125 Test, charge and replace batteries and jump-start vehicles

ASSESSMENT TASK 3

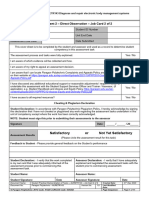

PART B Observation checklist (trickle charge a battery)

Satisfactory

Marking criteria Comments

Yes No

Pre-Job Tasks

1. Inspected area and equipment for hazards

and managed any risks before

☒ ☐

commencing work.

2. Selected appropriate PPE, tools and

equipment, checked they were in working

☒ ☐

order.

Charge the battery (trickle charge)

3. Located technical information from the

☒ ☐

battery or manufacturer.

4. Correctly calculated the charging rate and

time duration to trickle charge the battery

☒ ☐

and proceeded to safely charge battery

and record on job card.

5. Checked the battery charge rate after 10

minutes, reset if required and safely ☒ ☐

continued battery charging.

6. Turned off and disconnected the battery

charger following workplace procedures,

safely rechecked the electrolyte levels and ☒ ☐

topped up as per manufacturer’s

specifications.

Testing and completing the work

7. Safely tested the battery voltage and load

tested according to manufacturer

☒ ☐

procedures.

8. Checked tools and equipment to ensure

they are in working order and stored

☒ ☐

correctly according to workplace

procedures.

9. Completed the work within the time

allocated.

☒ ☐

©2021 Victorian Automotive Chamber of Commerce (VACC) V1.0 6 of

AURETR125 Test, charge and replace batteries and jump-start vehicles

ASSESSMENT TASK 3

Section C - Feedback to Student

Assessment Task Result MR FER

MR - meets requirements FER – further evidence required

☐ ☐

Assessor Feedback to the Student

Assessor Name

Assessor Signature

(confirming they have assessed this work

and are confident this is the students’ own

work)

Date Click or tap to enter a date.

©2021 Victorian Automotive Chamber of Commerce (VACC) V1.0 7 of

AURETR125 Test, charge and replace batteries and jump-start vehicles

You might also like

- AURLTE102 Diagnose and Repair Light Vehicle EnginesDocument29 pagesAURLTE102 Diagnose and Repair Light Vehicle EnginesRoma RajaNo ratings yet

- AURASA102 - AT2 Short AnswerDocument20 pagesAURASA102 - AT2 Short Answers9999923No ratings yet

- AURTTA104 - Assessment 2 Practical Demonstration Tasks - V3Document18 pagesAURTTA104 - Assessment 2 Practical Demonstration Tasks - V3eliezervasconcelos100% (1)

- AURETR130 - Assessment 1 - Written Knowledge Questions - V3Document22 pagesAURETR130 - Assessment 1 - Written Knowledge Questions - V3MUHAMMAD UMAR100% (2)

- Assessment 1 Student Questioning Written Knowledge Assessment AURLTD105 V1Document31 pagesAssessment 1 Student Questioning Written Knowledge Assessment AURLTD105 V1Roma Raja0% (1)

- Diagnose and Repair Compression Ignition Engine Management SystemsDocument60 pagesDiagnose and Repair Compression Ignition Engine Management Systemslittleprayerbyjacks100% (1)

- 29 Aurtta105Document19 pages29 Aurtta105khattarbhoomiNo ratings yet

- Aurttk102 (Wa)Document28 pagesAurttk102 (Wa)ARSHAD TURINo ratings yet

- Assessment Cover Sheet: Student UseDocument11 pagesAssessment Cover Sheet: Student UseARSHAD TURINo ratings yet

- SBM4305-BIS2003 T3 2020 Assessment 3 France Vacancies Project Cost Estimation - 584992893Document1 pageSBM4305-BIS2003 T3 2020 Assessment 3 France Vacancies Project Cost Estimation - 584992893Talha Naseem0% (1)

- AURTTK102 Student Assessment - TheoryDocument9 pagesAURTTK102 Student Assessment - TheoryDeymon Alejandro Pinzon NaranjoNo ratings yet

- Assessment 1 - Questioning - Written Assess AURACA101Document12 pagesAssessment 1 - Questioning - Written Assess AURACA101RomanaIjaz100% (1)

- AURTTA004 Student Assessment Editable pdf2Document39 pagesAURTTA004 Student Assessment Editable pdf2ishworNo ratings yet

- AURLTX103 Student Assessment - ramAN ComDocument22 pagesAURLTX103 Student Assessment - ramAN ComRAMANdeep kaurNo ratings yet

- AURETR012 - Written Knowledge Questions - V2Document25 pagesAURETR012 - Written Knowledge Questions - V2Nikhil Dhawan75% (4)

- Assessment Summary: Student Name: Student IDDocument15 pagesAssessment Summary: Student Name: Student IDAnzel AnzelNo ratings yet

- AnsweredDocument63 pagesAnsweredMohitNo ratings yet

- AURAEA002 - AUR S2 Student Assessment Pack v2.00Document40 pagesAURAEA002 - AUR S2 Student Assessment Pack v2.00SEFRSAED AWWADEQAWE100% (1)

- Aur12 R2.0Document7,618 pagesAur12 R2.02791957No ratings yet

- Scintific CalculatorDocument29 pagesScintific CalculatorAmit Kumar43% (7)

- AURETR125 Student Assessment - Theory v1.1Document10 pagesAURETR125 Student Assessment - Theory v1.1geniveive atanqueNo ratings yet

- AURETR143 Student Assessment 2 Job Card 2.v1.0Document11 pagesAURETR143 Student Assessment 2 Job Card 2.v1.0jjacoba42No ratings yet

- AURETR006 Solder Electrical Wiring and CircuitsDocument108 pagesAURETR006 Solder Electrical Wiring and Circuitsjaredmuge808100% (1)

- AURETR009 Install Vehicle Lighting and Wiring SystemsDocument97 pagesAURETR009 Install Vehicle Lighting and Wiring Systemsjaredmuge808No ratings yet

- AURETR007 KnowledgeAssessmentDocument18 pagesAURETR007 KnowledgeAssessmentMuhammad IrfanNo ratings yet

- Assessment 1 - Questioning: AURTTK102 Use and Maintain Tools and Equipment in An Automotive WorkplaceDocument27 pagesAssessment 1 - Questioning: AURTTK102 Use and Maintain Tools and Equipment in An Automotive WorkplaceARSHAD TURINo ratings yet

- AURETR143 Slideshow.v1.0Document200 pagesAURETR143 Slideshow.v1.0jjacoba42No ratings yet

- Azeem New 2 (1)Document22 pagesAzeem New 2 (1)Ahmad Tarar0% (1)

- AURETR125 - AT2 - Support Document - Job CardDocument4 pagesAURETR125 - AT2 - Support Document - Job CardKyle Shailen100% (1)

- Training Plan Jonathan StormDocument9 pagesTraining Plan Jonathan StormLiamNo ratings yet

- Inspect & Service Braking SystemsDocument42 pagesInspect & Service Braking SystemsAnonymous VWlCr439No ratings yet

- Assessment 1 - Questioning - Written Assessment - AURETR129Document22 pagesAssessment 1 - Questioning - Written Assessment - AURETR129Sana Siddique100% (1)

- AURAEA002 KnowledgeAssessmentDocument20 pagesAURAEA002 KnowledgeAssessmentMuhammad IrfanNo ratings yet

- Manual Steering System: SectionDocument21 pagesManual Steering System: SectionEduardo ColinNo ratings yet

- Written Knowledge Assessment AURTTA104 V1Document20 pagesWritten Knowledge Assessment AURTTA104 V1madhu8966No ratings yet

- AURAEA002 Student Assessment - Theory V1.1gulsher CompleteDocument10 pagesAURAEA002 Student Assessment - Theory V1.1gulsher CompleteRAMANdeep kaurNo ratings yet

- AURTTB101 LearnersWorkbookDocument36 pagesAURTTB101 LearnersWorkbookMuhammad IrfanNo ratings yet

- AURTTA021 Diagnose Complex System FaultsDocument265 pagesAURTTA021 Diagnose Complex System FaultsAndrés Felipe Huerfano RodríguezNo ratings yet

- Unit 2 - Battery Inspection, Testing, Service, and Jump StartingDocument49 pagesUnit 2 - Battery Inspection, Testing, Service, and Jump StartingBinodSah100% (1)

- 204-00 Ride Height MeasurementDocument4 pages204-00 Ride Height MeasurementAngy SalasNo ratings yet

- Chapter 34 Emission SystemsDocument32 pagesChapter 34 Emission SystemsROSAN YUMANGNo ratings yet

- Aurtta105 Task 1Document19 pagesAurtta105 Task 1Roma Raja0% (1)

- AURLTD005 - Assessment 1 Written Knowledge Question - V2Document34 pagesAURLTD005 - Assessment 1 Written Knowledge Question - V2So BiaNo ratings yet

- AURLTX013 Assessment 2 Practical Demonstration Tasks V2Document14 pagesAURLTX013 Assessment 2 Practical Demonstration Tasks V2Ahmad TararNo ratings yet

- Unit No.7 AURETB002 1Document17 pagesUnit No.7 AURETB002 1faisal nazirNo ratings yet

- AURLTQ102 Student Assessment - Theory Gulshare CDocument15 pagesAURLTQ102 Student Assessment - Theory Gulshare CRAMANdeep kaurNo ratings yet

- AURETR010Document6 pagesAURETR010Muhammad Waseem0% (1)

- Aurltb103 1Document48 pagesAurltb103 1Aniqa ZafiraNo ratings yet

- AUR30620 1 SummaryDocument3 pagesAUR30620 1 SummaryAWAIS ALI UnknownNo ratings yet

- AHT005 AllianceCollegeBrochure PDFDocument44 pagesAHT005 AllianceCollegeBrochure PDFGandum PradityaNo ratings yet

- Service Petrol Fuel SystemsDocument39 pagesService Petrol Fuel SystemsCmon PeteNo ratings yet

- AURETR137Document81 pagesAURETR137Vikramjit singhNo ratings yet

- AURLTB002Document24 pagesAURLTB002tinasokhal1No ratings yet

- Learner Guide - AURLTE002 - Diagnose and Repair Light Vehicle EnginesDocument73 pagesLearner Guide - AURLTE002 - Diagnose and Repair Light Vehicle EnginesAakash100% (1)

- Automotive Repair and MaintenanceDocument19 pagesAutomotive Repair and MaintenanceMarico River Conservation AssociationNo ratings yet

- AURLTD005 Assessment 2 Practical Demonstration Tasks V2Document17 pagesAURLTD005 Assessment 2 Practical Demonstration Tasks V2RomanaIjazNo ratings yet

- Unit 14 Worksheet: Engine Fundamentals Competency Unit: AURTTE004 Inspect and Service EnginesDocument6 pagesUnit 14 Worksheet: Engine Fundamentals Competency Unit: AURTTE004 Inspect and Service EnginesajayNo ratings yet

- Muhammad Farrukh QAMAR - Written TestDocument43 pagesMuhammad Farrukh QAMAR - Written TestRana Muhammad Ashfaq KhanNo ratings yet

- Practical AURAMA005Document36 pagesPractical AURAMA005shahmuzammilNo ratings yet

- AURETR125 - Assessment 2 - Practical Demonstration - V3Document15 pagesAURETR125 - Assessment 2 - Practical Demonstration - V3nirajan sapkotaNo ratings yet

- EPS Startup Test Procedure - SECDocument45 pagesEPS Startup Test Procedure - SECEng Zaid NawaysehNo ratings yet

- OmniScan PDFDocument482 pagesOmniScan PDFJeganeswaranNo ratings yet

- Autonics PRD Series ManualDocument1 pageAutonics PRD Series ManualArturo CaisaguanoNo ratings yet

- E5118 Sre1-4Document4 pagesE5118 Sre1-4Ravi Kishore BNo ratings yet

- Effect of Initial Strand Slip On The Strength of Hollow-Core SlabsDocument22 pagesEffect of Initial Strand Slip On The Strength of Hollow-Core SlabsKoresh KhalpariNo ratings yet

- Technical Data Sheet For Hilti HIT HY 200Document39 pagesTechnical Data Sheet For Hilti HIT HY 200ValeriuNo ratings yet

- Sending EmailDocument10 pagesSending EmailyprajuNo ratings yet

- Shear Wall Moment-Curvature RelationshipDocument16 pagesShear Wall Moment-Curvature RelationshipEric CastilloNo ratings yet

- 2089-WAOC AD 2-1 SD AD 2-6Document6 pages2089-WAOC AD 2-1 SD AD 2-6Verdy TariganNo ratings yet

- Resume FresherDocument2 pagesResume Freshersweet2shineNo ratings yet

- Pre Feasibility Report For Welspun Iron & Steel Pvt. LimitedDocument25 pagesPre Feasibility Report For Welspun Iron & Steel Pvt. LimitedkalaiNo ratings yet

- Energization and Tie in Plan: ObjectiveDocument5 pagesEnergization and Tie in Plan: ObjectiveNajmul QamarNo ratings yet

- Option H2 Modbus Communication CGC 400 4189340865 UKDocument42 pagesOption H2 Modbus Communication CGC 400 4189340865 UKMarco OlivettoNo ratings yet

- Pile Lateral Capacity Design (Brom's Method) ExampleDocument3 pagesPile Lateral Capacity Design (Brom's Method) ExampleTariqul IslamNo ratings yet

- Literature Supplement: Form No.: 160.00-M1 (LS03) 801Document2 pagesLiterature Supplement: Form No.: 160.00-M1 (LS03) 801Azar TajNo ratings yet

- Professional Engineers Board Singapore Pe Exam Guides (Reference) by Ies AcademyDocument2 pagesProfessional Engineers Board Singapore Pe Exam Guides (Reference) by Ies AcademyKevin HuangNo ratings yet

- Preliminary Tech. Doc. OG120C TG 5Document17 pagesPreliminary Tech. Doc. OG120C TG 5Михаил Гуляев100% (2)

- CP Stands-D53+D57+D58Document10 pagesCP Stands-D53+D57+D58Carlos LourençoNo ratings yet

- Brake ChamberDocument59 pagesBrake ChamberKanesh MaheshNo ratings yet

- HuDocument126 pagesHuAttila TothNo ratings yet

- Technical Specifications: Motor GraderDocument8 pagesTechnical Specifications: Motor GraderHerry ArsevenNo ratings yet

- NCPWBDocument8 pagesNCPWBfraemddNo ratings yet

- Comparing Steganography AlgorithmsDocument31 pagesComparing Steganography AlgorithmsBakir JawadNo ratings yet

- CKT08 PDFDocument46 pagesCKT08 PDFShivam MishraNo ratings yet

- Pump Clinic 43Document3 pagesPump Clinic 43fnahas_bhNo ratings yet

- PublicationDocument17 pagesPublicationJosé de SousaNo ratings yet

- Ansi Hi 1.1 1.2 2000 Centrifugal PumpsDocument74 pagesAnsi Hi 1.1 1.2 2000 Centrifugal Pumps김규백100% (1)

- 3600CE ManualDocument92 pages3600CE Manualيوسف عامرNo ratings yet

- vnx.su дачия 1304-1305-1307 пикап ENGINE-F8QDocument620 pagesvnx.su дачия 1304-1305-1307 пикап ENGINE-F8Qcvn2No ratings yet

- Class 150 LB: Pipe Flange Data Lap Hub Drilling Data WeightDocument1 pageClass 150 LB: Pipe Flange Data Lap Hub Drilling Data WeightHugo Marcelo Valdivia AguileraNo ratings yet