Professional Documents

Culture Documents

CBLM 2 Final

CBLM 2 Final

Uploaded by

Mely joy ageasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CBLM 2 Final

CBLM 2 Final

Uploaded by

Mely joy ageasCopyright:

Available Formats

COMPETENCY BASED LEARNING MATERIAL

Sector : AUTOMOTIVE & LAND TRANSPORT

Qualification Title : DRIVING NC II

Unit of Competency : Drive Light Vehicle

Module Title : Driving Light Vehicle

Republic of the Philippines

Technical Education and Skills Development Authority

Region IX, Zamboanga Peninsula

DIPOLOG SCHOOL OF FISHERIES

Olingan, Dipolog City

Tel No. 212-5237 Fax No. (065)212-7248 / dsf_zn9@yahoo.com

APACC Accredited: Certificate No. APACC/1738

HOW TO USE THIS LEARNERS GUIDE

Welcome to the learners for the module: DRIVING LIGHT VEHICLE. This

learner’s guides contain training materials and activities for you to complete.

The unit of competency “Driving Light Vehicle “contains the knowledge, skills and

attitude required for a Driving NC II. It is one of the core modules for National

Certificate Level (NC II)

To complete each learning outcome of the whole module, you are required to go

through a series of learning activities. In each learning outcomes contain Information

Sheets, Operation Sheets, and Task/Job Sheets resource sheets and references

materials for further reading to help you better understand the required activities.

Follow and perform the activities on your own. If you have questions, do not hesitate

to ask assistance from your facilitator/ trainer.

Show to your trainers any certificate of competence from previous training, so

you won’t do the same training again. They may become part of the same training

again. This module was prepared to help you achieved the required competency in

Driving Light Vehicle.

With the aid of these materials you will acquire the competency independently

and at your own pace. Read through the learning guide carefully and talk to your

trainer and agree on how you will fetch organize the training of this unit. Ask for help

from your trainer or to more experienced workmates for their guidance to complete the

activities.

When you feel confident that you have sufficient practice and successfully

completed each element, ask your Trainer to evaluate you. The results of your

assessment will be recorded in your Progress Chart and Accomplishment Chart.

You need to complete this module before you can perform the next module.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 2 of vii

MELY JOY S. AGEAS

DRIVING NC II

COMPETENCY-BASED LEARNING MATERIALS

List of Competencies

No. Unit of Competency Module Title Code

BASIC COMPETENCY

Participate in Participating in 400311210

1. workplace workplace

communication communication

Work in team Working in team 400311211

2. environment environment

Solve/address general Solving/addressing 400311212

3. workplace problems general workplace

problems

Develop career and life Developing career and 400311213

4. decisions life decisions

Contribute to Contributing to 400311214

5. workplace innovation workplace innovation

Present relevant Presenting relevant 400311215

6. information information

Practice occupational Practicing occupational 400311216

safety and health safety and health

7. policies and policies and procedures

procedures

Exercise efficient and Exercising efficient 400311217

effective sustainable and effective

8. practices in sustainable

the workplace practices in

the workplace

Practice Practicing 400311218

9. entrepreneurial skills entrepreneurial skills in

in the workplace the workplace

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 3 of vii

MELY JOY S. AGEAS

COMMON COMPETENCY

1. Apply Appropriate Applying Appropriate ALT723201

1 Sealant/Adhesive Sealant/Adhesive

Move and Position Moving and Positioning ALT723202

2.

Vehicle Vehicle

Perform Mensuration Performing Mensuration ALT311202

3.

and Calculation and Calculation

Read, Interpret and Reading, Interpreting ALT723203

Apply Specifications and Applying

4.

and Manuals Specifications and

Manuals

Use and Apply Using and Applying ALT723204

5.

Lubricant/Coolant Lubricant/Coolant

Perform Shop Performing Shop ALT723205

6.

Maintenance Maintenance

CORE COMPETENCY

Carry Out Minor Carrying Out Minor ALT723348

1. Vehicle Maintenance Vehicle Maintenance

and Servicing and Servicing

2. Drive Light Vehicle Driving Light Vehicle ALT832302

Obey and Observe Obeying and Observing ALT832303

3. Traffic Rules and Traffic Rules and

Regulations Regulations

Implement and Implementing and ALT832304

Coordinate Accident- Coordinate Accident-

4. Emergency Emergency

Procedures Procedures

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 4 of vii

MELY JOY S. AGEAS

MODULE CONTENT

UNIT OF COMPETENCY : Drive

Light Vehicle

MODULE TITLE : Driving Light

Vehicle

MODULE DESCRIPTOR : This

module covers the knowledge,

skills and attitudes

required in cleaning premises

of an accommodation

industry. It includes selection

and set-up of equipment

and materials; cleaning of both wet

and dry areas; and

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 5 of vii

MELY JOY S. AGEAS

maintenance of cleaning equipment

and materials.

UNIT OF COMPETENCY : Drive

Light Vehicle

MODULE TITLE : Driving Light

Vehicle

MODULE DESCRIPTOR : This

module covers the knowledge,

skills and attitudes

required in cleaning premises

of an accommodation

industry. It includes selection

and set-up of equipment

and materials; cleaning of both wet

and dry areas; and

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 6 of vii

MELY JOY S. AGEAS

maintenance of cleaning equipment

and materials.

UNIT OF COMPETENCY : Drive Light Vehicle

MODULE TITLE : Driving Light Vehicle

MODULE DESCRIPTOR : This module covers the knowledge, skills and attitudes

required in cleaning premises of an accommodation industry. It includes

selection and set-up of equipment and materials; cleaning of both wet and dry

areas; and maintenance of cleaning equipment and materials.

NOMINAL DURATION : 80 hours

QUALIFICATION LEVEL : NC II

SUMMARY OF LEARNING OUTCOMES

Upon completion of this module, the trainee would be able to:

L.O 1 Perform light vehicle pre-starting and warm-up

L.O.2 Drive light vehicle

L.O 3 Monitor and maintain vehicle performance

ASSESSMENT CRITERIA

1. Vehicle Inspection is performed as per manufacturer’s specification.

2. Safety harness/devices and tools are check according to the land

transportation office (LTO)/ land transportation franchising and

regulatory board (LTFRB) requirements.

3. Warm up of light vehicle is performed as per manufacturer’s manual.

4. Light vehicle is driven in accordance with traffic rules and

regulations and manufacturer’s instruction.

5. Driving hazards are identified and/or anticipated and avoided or controlled.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 7 of vii

MELY JOY S. AGEAS

COMPETENCY-BASED

LEARNING MATERIALS

DRIVING ( Light Vehicle) NCII

through defensive driving as per

standard operating procedures.

The light vehicle is parked,

shut down and secured in

accordance with

manufacturer’s specifications,

traffic regulations and workplace

procedures.

Passengers and loads are

transported up to the route assigned

and fares are

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 8 of vii

MELY JOY S. AGEAS

collected as per LTFRB regulations.

Driving is performed according

to the restriction and condition

stated in the

official receipt license and within

the occupational health and safety

standards

(OHS).

Out-of line/ anti-car napping

clearance permit is secured as per

traffic rules

and regulations.

Defective or irregular

performance and malfunctions

are monitored and

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 9 of vii

MELY JOY S. AGEAS

reported to the appropriate person/

authority.

Minor vehicle maintenance is

performed in accordance with

manufacturer’s

manual.

Vehicle records are

maintained/ updated in

accordance with workplace

procedure

LEARNING OUTCOME NO. 1

Perform Light Vehicle Pre-Starting And Warm-Up

Contents:

1. Parts of Light Vehicle and its Function.

2. Hand Tools.

3. LIGHT Vehicle with some Safety Harness/Devices/Tools of a vehicle

4. Routinely Check-up of a Vehicle

5. LTO/LTFRB Safety Requirements

6. Light Vehicle Pre-starting and Warm-up

Assessment Criteria:

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 10 of vii

MELY JOY S. AGEAS

Vehicle Inspection is performed

as per

manufacturer’s specification.

Safety harness/devices and

tools are check

according to the land transportation

office (LTO)/

1. Vehicle Inspection is performed as per manufacturer’s specification.

2. Safety harness/devices and tools are check according to the land

transportation office (LTO)/ land transportation franchising and regulatory

board (LTFRB) requirements.

3. Warm up of light vehicle is performed as per manufacturer’s manual.

REFERENCES:

Automotive Technology; Tech Manual; 4th Edition; ERJAVEC

Automotive Technology; 4th Edition; ERJAVEC

Toyota Training Manual

Auto Mechanics, Theory and Service By: de Kryger, Kobacik .Bono

Automotive Mechanics; 10th ed. Crouse: Anglin

Internet Websites

Conditions:

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 11 of vii

MELY JOY S. AGEAS

Students/Trainees must be provided

with the

following:

1. WORKPLACE LOCATION:

Equipment

Computer

LCD

2. TOOLS, ACCESSORIES AND

SUPPLIES

Whiteboard

CD

Tapes

3. TRAINING MATERIALS:

Request form

Modules

Students/Trainees must be provided with the following:

1. WORKPLACE LOCATION:

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 12 of vii

MELY JOY S. AGEAS

Equipment

Computer

LCD

2. TOOLS, ACCESSORIES AND SUPPLIES

Whiteboard

3. TRAINING MATERIALS:

Modules

Assessment Method:

1. Written Test

2. Demonstration

Learning Experiences

Learning Outcome 1

Learning Activities Special Instructions

Read information sheet 2.1-1 The focus of this learning outcome is

Read

for you to be able to identify the

traffic lights and Road Signs.

Read Information Sheet and answer

Information self-check. Compare your answers

with the answer key, if you cannot

get all the correct answers please

sheet 2.1-1 read again the information sheet.

Perform Job/Task Sheet and

on

Evaluate your self-using the

Performance Criteria Checklist.

If you feel you are now

Parts of knowledgeable on the content of the

information sheet, you can submit

for trainer evaluation.

Light Vehicle If mastery has been achieved,

submit yourself for Institutional

and its

Assessment.

Function

About Parts of Light Vehicle and its

Function

Answer self-check 2.1-1

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 13 of vii

MELY JOY S. AGEAS

Read Information Sheet 2.1-2

About Hand tools

Answer self-check 2.1-2

Read Information Sheet 2.1-3

about LTO/LTFRB Light Vehicle

with some Safety

Harness/Devices/Tools of a vehicle

Answer self-check 2.1-3

Read Information Sheet 2.1-4

about Routinely Check-up of a

Vehicle (THE BLOWBAGETS)

Answer self-check 2.1-4

Perform Job Sheet 1.1-1 on

LightVehicle Pre-starting and

Warm-up

Perform Observation Checklist1.1-

1 on Light Vehicle Pre-starting and

Warm-up

Information Sheet 2.1-1

Parts of Light Vehicle and its Function

Objectives: After reading this information sheet, the trainee should be able to:

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 14 of vii

MELY JOY S. AGEAS

1. Give the parts of the vehicle and its function.

2. Explain the operation of the speed-control system, and other electrical and

electronic devices.

3. Describe analog and electronic instrument panels, and the operation of the

speedometer and odometer.

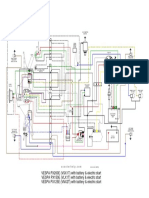

I. Vehicle Lightning

A. Lights

the driver uses electric lightning to provide the illumination or light needed

to safely operate the vehicle. The various lights provide vision and

information to the driver, convenience for passengers, and signals

and warnings to other drivers and pedestrians.

The outside or exterior lights on an automotive include:

1. Two or four headlamps which illuminate the area ahead of the vehicle.

2. Taillights to show red at the rear of the vehicle.

3. Parking light to mark the front of a parked vehicle, and to mark the front of

the vehicle if a headlamp fails.

4. License light too illuminate the license plate on the rear of the vehicle.

5. Side-marker lights on the front

and rear sides of the vehicle to

indicate its

overall length.

6. Turn-signal lights which indicate

an intended change in direction by

flashing

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 15 of vii

MELY JOY S. AGEAS

lights on the side toward which the

turn will be made.

7. Backup lights to illuminate in

back of the car when the

transmission is shifted

into reverse.

8. Emergency flasher or hazard-

warning lights that warn an

approaching driver

of the presence of a vehicular

hazard by flashing all turn-signal

lights together.

5. Side-marker lights on the front and rear sides of the vehicle to indicate its

overall length.

6. Turn-signal lights which indicate an intended change in direction by flashing

lights on the side toward which the turn will be made.

7. Backup lights to illuminate in back of the car when the transmission is

shifted into reverse.

8. Emergency flasher or hazard-warning lights that warn an approaching

driver of the presence of a vehicular hazard by flashing all turn-signal lights

together.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 16 of vii

MELY JOY S. AGEAS

The inside of the car has a variety of interior lights. These include:

1. Instrument-panel lights

2. Warning and indicator lights

3. Courtesy and dome lights—turn on when a door opens. Courtesy and dome

lights are all powered from the fuse panel. They will operate regardless of the

position of the ignition key or headlamp switch.

B. Light Bulbs

Lightning is provided by various sizes and types of light bulbs.

When an electric current flows through a fine wire or filament in the bulb,

the filament gets hot and emits visible light. The bulb may fit into a socket

which forms part of a lamp. The bulb may fit into a socket which forms part

of a lamp. Some bulbs have two filaments. This allows a single bulb to

provide light in two circuits for different purposes. The various

bulbs and lighting circuits usually receive power from the fuse

panel, ignition switch, or headlamp switch.

C. Headlamps

It is the most important lamps for the driver. When switch on, they provide

light ahead of the vehicle. The tungsten filament turns white-hot

when connected to the battery and gives out light. The light is reflected

forward by the curved reflector. Then the light passes through the lens which

arranges it in a pattern to light the road ahead. The sealed beam headlamp is

replaced as a unit.

Many vehicles have halogen headlamps. These emit a whiter and brighter

light than other sealed-beam lights. The halogen headlamp has a smaller

inner bulb filled with halogen gas which protects the tungsten filament. The

outer case is airtight or hermetically sealed. The halogen head

lamp is replaced as a unit.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 17 of vii

MELY JOY S. AGEAS

The most widely used headlamps

are made in four sizes, two round

and two

rectangular The round sizes are

5.75 (146 mm) and 7 inches (178

mm). The

rectangular sizes are 6.5 by 4 inches

(165 by 100 mm) and 7.9 by 5.6

inches

(200 by 142mm). All have the

number the number 1 or 2 molded

into the top

of the lens. Type 1 has one high-

beam filament. Type 2 has two

filaments, one

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 18 of vii

MELY JOY S. AGEAS

for high beam and other for low

beam. The letter H or the word

HALOGEN

appears on the lens of a halogen

headlamp.

The most widely used headlamps are made in four sizes, two round and two

rectangular The round sizes are 5.75 (146 mm) and 7 inches (178 mm). The

rectangular sizes are 6.5 by 4 inches (165 by 100 mm) and 7.9 by 5.6 inches

(200 by 142mm). All have the number the number 1 or 2 molded into the top

of the lens. Type 1 has one high-beam filament. Type 2 has two filaments,

one for high beam and other for low beam. The letter H or the word

HALOGEN appears on the lens of a halogen headlamp.

Some cars use smaller

rectangular headlamps or

aerodynamically-styled

composite headlamps .These are

made of plastic instead of glass and

have a

replaceable halogen bulb.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 19 of vii

MELY JOY S. AGEAS

Some cars use smaller rectangular headlamps or aerodynamically-

styled composite headlamps .These are made of plastic instead of glass and

have are place able halogen bulb.

The driver selects the beam needed by operating the beam

selector or dimmer switch. It is either on the floor or on the

steering column. Beam selection is made automatically by the automatic

headlamp dimmer system. A defective dimmer switch, or a corroded or loose

dimmer-switch connection, affects both low-beam and both high-beam

filaments. The low beams or high beams may operate normally. However, the

other set of filaments may be dim or fail to operate.

A vehicle with four headlamps has

two type 1 and two type 2

headlamps. For

low- beam driving, one filament in

each type 2 headlamp comes on. On

high

beam, the other filament in the type

2 headlamps comes on along with

thee

single filament in the type 1

headlamps.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 20 of vii

MELY JOY S. AGEAS

A vehicle with four headlamps has two type 1 and two type 2 headlamps. For

low- beam driving, one filament in each type 2 headlamp comes on. On high

beam, the other filament in the type 2 headlamps comes on along with thee

single filament in the type 1 headlamps.

D. Headlamp Switch

The Headlamp Switch controls the operation of the headlamps

and other exterior and interior lights. It connects directly to the battery and

mounts on the instrument panel to left of the steering wheel. The

headlamp switch usually combines a circuit breaker with a three- position

pull switch. It also includes a rotary switch that operates a variable resistor

or rheostat. The three positions of the pull switch are OFF, PARK, and

HEADLAMPS. Pulling the knob to the first detent or PARK position turns on

the parking lights, side-marker lights, and instrumental panel lights. Pulling

the knob to the second detent turns on the headlamps. Clockwise

rotation of the knob varies the instrument-panel lighting from full

bright to dim Rotating the knob fully counterclockwise turns on the

dome light and courtesy lights. Instead of the pull-type headlamp switch,

some cars have three-position rocker switch and a rotating thumbwheel on

the instrument panel.

E. Automatic Headlamp Controls

The automatic headlamp dimmer automatically switches the headlamps from

high to low beam. This occurs when a light sensor senses the headlamps of

an approaching vehicle or the tail-lamps of a vehicle overtaken. The light

sensor triggers a relay that switches beams. When the other car has passed,

the system automatically returns the headlamps to high beam. A

sensitivity control can be set by the driver. This adjusts the light

sensor to the surrounding light.

An automatic on-off headlamp control turns the headlamps on when it gets

dark enough to require light for driving. A light sensor signals the

control module when headlamps are needed. The control then

switches the headlamps on. This system also includes an adjustable time-

delay turn-off. The headlamps will stay on for a short time after the ignition

key is turned off. This is a convenience when exiting the car at night.

F. Turn-Signal Lights

The turn signals permit the driver to signal an intention to turn right or left.

The system includes:

1. A lamp at each front and rear corner of the vehicle.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 21 of vii

MELY JOY S. AGEAS

2. A lever-operated turn-signal switch in the steering column.

3. A flasher which is an automatic-reset circuit breaker.

4. Left- and right- turn indicator lights in the instrument panel.

The turn-signal lever is moved up for right turn and down for a left turn. The

turn-signal switch then completes the circuits to the proper lamps

current flows from the battery through the flasher to the lamps. In the

flasher, the current passes through a thermostatic blade. The resulting heat

causes the thermostatic blade to bend, opening thee flasher contacts. The

blade quickly cools and contacts close. This produces a pulsating voltage

that causes the turn-signal lights to flash.

After completing the turn, the turn movement the steering wheel

automatically cancels the turn signal. The lever moves back to its neutral

position, opening the circuit.

A bulb failure or poor ground may cause the turn signals to work in one

direction but not the other. If no flashing occurs in either direction, check for

a blown fuse or defective flasher.

G. Fiber-optic Lighting

Some cars have as many as 80 light

bulbs. Each bulb can burn out and

fail.

Some components, such as

instrument panels, have many

bulbs close

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 22 of vii

MELY JOY S. AGEAS

together. However, there is little

room behind the instrument panel

for the

bulbs, their sockets, and thee

connecting wiring. One solution is

the use of

printed circuits. Another is the use

of fiber-optic cables.

Fiber-optic cables are made of one

or more transparent glass or plastic

fibers

bundled together parallel to one

another. Each cable formed by the

fiber or

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 23 of vii

MELY JOY S. AGEAS

bundle can conduct light, even

around bends and corners. As light

starts down

thee fiber, the light keeps reflecting

off the internal surfaces of the fiber

with

G. Fiber-optic Lighting

Some cars have as many as 80 light bulbs. Each bulb can burn out and fail.

Some components, such as instrument panels, have many bulbs close

together. However, there is little room behind the instrument panel for the

bulbs, their sockets, and thee connecting wiring. One solution is the use of

printed circuits. Another is the use of fiber-optic cables.

Fiber-optic cables are made of one or more transparent glass or plastic fibers

bundled together parallel to one another. Each cable formed by the fiber or

bundle can conduct light, even around bends and corners. As light starts

down thee fiber, the light keeps reflecting off the internal surfaces of the fiber

with little loss. When the light comes out the other end, it is almost as strong

as when it entered.

There is what we call a fiber-optic lamp monitor system. Fiber-optic cables

run from the lamps to a lamp monitor on top of each front fender.

When the headlamps are on, the lamp monitors show that the lights are

working. If a bulb burns out, its monitor also goes out. This warns the driver

that the lamp has failed.

Another way to use fiber-optics is to run cables from a central light source to

various outlets where light is needed. This allows only one bulb to provide

light at many places. A special arc- discharge bulb provides thee light. It is

smaller and lasts longer than a halogen bulb. Similar to a fluorescent or

neon bulb, there is no filament to burn out. The light appears at each lamp

or outlet only when needed. This system would prevent the failure of many

individual bulbs.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 24 of vii

MELY JOY S. AGEAS

H. Computer Controlled Lighting

In most cars, a separate switch controls each lighting circuit. However, an

electronic-control module or lamp module can control the complete vehicle

lighting system. When the driver operates any switch that controls a lamp

circuit, the switch sends an input signal to tee lamp module. It then turns

the desired lamps on or off. The lamp module provides the intermittent

operation of the hazard-warning and turn-signal lights. No flasher is needed.

In most lighting system a switch supplies voltage to lamps that are

permanently grounded. With computer-controlled lighting, many circuits

operate differently. Voltage is always supplied and a switch or relay provides

the lamp ground. The various lights switches are grouped on the left side of

the steering column in the left switch pod.

I. Distributed Lighting System

The distributed lighting system is a computer-controlled lighting system that

uses the body control module (BCM) as the lamp module. The system

includes nine-solid-state switches or output switching modules (OSM), a

serial data line or bus, and the left switch pod. The BCM controls all

interior and exterior lighting through the switching modules. Each switching

module controls four lamp circuits. Three jumpers divide the power feeds

into three groups. This prevents a module circuit failure from making all

rear or all front lights in operative.

In addition to controlling and monitoring lamp operation, the system

can substitute some lamps for others that have failed. The system includes

two extra or redundant relays. They automatically provide power to the

headlamp (low beam) and left tail lamp if the BCM or the serial data buss

fails. Problems in the distributed lighting system cause a LIGHTING FAULT

message to display. This also sets a lighting-system trouble code which is

stored in the BCM.

The operation of the distributed lighting system is made possible by

multiplexing. This is the use of one conductor, such as the serial data bus, to

do the job of many wires. A single main-wiring harness simplifies the

electrical system. Because of multiplexing, it has fewer connectors

which improve reliability.

J. Headlamp Aiming

Headlamps must be aimed correctly so the driver can see at night and to

prevent the blinding of approaching drivers. One method is the use of

an aiming screen. Park the car on a level floor, 25 feet (7.6 m) from the

screen. Then the high beam and low beam can be checked.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 25 of vii

MELY JOY S. AGEAS

Adjust the headlamps to provide the specified pattern. There are usually

adjusted by turning vertical-aim and horizontal-aim adjusting screws.

An adapter mounts to the three aiming pads on the headlamp. Some shops

have an optical aimer. It does not touch the headlamp. When using a

headlamp aimer, follow the manufacturer’s operating instructions.

Headlamp-aiming patterns and adjustment are in the vehicle service manual.

Some vehicles have aiming devices built into the headlamp

assembly. A bubble level indicates the proper height (up-and-down)

adjustment as the vertical aim adjusting screws are turned in and out. Other

vehicles also have built-in scales and pointers for horizontal (side-to-side)

adjustment.

Caution:

Halogen bulbs and headlamps get very hot. Do not touch a halogen bulb or

lamp while it is on or shortly after it has been turned-off. Handle the

separately- mounted bulb carefully. It contains gas under pressure. The bulb

may shatter if scratched and dropped. Do not touch the glass envelope. The

oil from your skin may damage it. Keep the bulb out of reach of children.

II. Safety and Signaling

A. Horn and Horn Relay

Most Cars have two horns at the front of the car. Horns are electrically-

operated noise-makers used by the driver to provide a loud warning

signal. Pressing a horn button in the steering wheel or column grounds

thee circuit connecting the battery to the horn relay. This closes contact

points in the relay and connects the horns—through the relay—to the

battery. The electric current then causes a diaphragm in each horn to

vibrate and produce the sound.

B. Vehicular Security Systems

An anti-theft or security alarm system causes the horn to sound and the lights to

flash if someone tries to break into the vehicle. There are several different ways to

trigger the alarm. Typically, the driver sets the alarm by operating a switch when

leaving the vehicle. Then opening or forcing the hood, trunk, tailgate, or any door

triggers the alarm.

Many vehicle security systems include a starter interrupt. This prevents the

starting the engine after any forced entry, even if the ignition switch is by passed.

C. Seat Belts

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 26 of vii

MELY JOY S. AGEAS

Seat Belts restrain the vehicle occupants if there is an accident. After entering the

car, the driver and passengers each fasten a lap or lap-and-shoulder belt. The belt

then helps hold that person in the seat during a collision or rollover. Inertia-

sensitive retractors lock the belt in place when an impact occurs.

A passive restraint provides protection without requiring any action by the driver

or passenger. Two types of passive restraints are air bags and motorized seat

belts. These are front-seat shoulder belts that move into position automatically.

After entering the car and closing the door, the driver turns on the ignition key.

The electric motor then pulls a cable or tape connected to the belt. The belt travels

forward and out of the way when the door opens. In some cars with an air bag on

only the driver’s side, the seatbelt for the front-seat passenger automatically

tightens in a crash. This provides the passenger with additional protection.

D. Air bags

Air bags are also called supplemental inflatable restraints (SIR). They are balloon-

type devices that inflate automatically to protect the driver (and front-passenger in

some vehicles) if a front-end crash occurs. The airbag prevents the occupant from

being thrown forward and injured by striking the steering wheel or wind-shield.

The seat belt and air bag together provide maximum protection against injury in a

collision.

When the ignition key is turned on, the readiness indicator light should come on

for about six seconds. Any other operation of the light indicates a malfunction. The

system is powered directly from the battery. This allows the air bag to inflate with

the ignition key in any position, including OFF and LOCK.

If a front-end crash occurs, two of the four sensors must activate to trigger the air

bag. This helps prevent a short circuit in a sensor or wiring from causing an

unwanted inflation. When the sensors detect a collision, an electric spark below

the inflator in the steering hub ignites a small canister of gas. The gas in turn

ignites the propellant (sodium azide) in the inflator.

The burning propellant creates nitrogen gas. This fills the air bag stored above in

the inflator in the steering wheel hub. As the bag inflates, it pushes through both

the air-cushion container and the steering wheel trim cover. Deployment time,

from impact to full inflation, is about 50 milliseconds (0.050 second) or less.

Some systems include a capacitor that will trigger the system if the battery or

battery cables are damaged by the impact.

E. Air-Bag Replacement

An air bag inflates only once. Then remove the deployed air bag and clean the

inside of the vehicle. This is necessary because of the powder emitted as the air

bag deploys. Install a new air bag module. Follow the air-bag service procedures in

the vehicle service manual.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 27 of vii

MELY JOY S. AGEAS

Caution:

Be careful when working on vehicles with air bags. You could accidentally trigger

thee system. A deploying air bag could injure you if you are not belted in the

normal seated position.

F. Windshield Wipers and Washers

Windshield wipers clean the windshield so the driver can see clearly while driving

in rain or snow. The wiper blades are moved back and forth by linkage connected

to a motor on the firewall in the engine compartment. A switch on the steering

column or instrument pane connects the motor to the ignition switch. The motor

will run when the ignition key is in the ON or ACC position.

The windshield-wiper switch has at least two or three speeds. Many cars have

intermittent windshield wipers. These include an adjustable time delay between

blade movements. The wiper blades will move across and back. Pause, and then

repeat the action.

The windshield washer is a part of the windshield-wiper system. When the driver

presses a button, liquid windshield-washer fluid squirts on the windshield. This

allows the blades to clean more effectively. Some cars have heated wind-shield

washer nozzles. This prevents ice from clogging the small holes in cold weather.

The rear window in some cars has a similar wiper-and washer-system. It works

automatically when the windshield washer operates.

III. Driver Information and Safety

A. Instrument Pane

The instrument panel contains the indicators—gauges, lights, and displays

—the driver needs to operate the car. These are usually grouped

for easy reading by the driver in an instrument cluster. Some driver-

operated controls mount on the instrument panel, or above or

below it in a console/ these include the headlamp switch, heating

and air-conditioning controls and the controls of the radio and tape and

compact-disc player.

Automotive instrumentation may take the form of analog gauges or

electronic displays. Analog gauges show thee condition being monitored by

movement of thee pointer on the gauge. Several analog gauges are group

into an analog instrument cluster. In an electronic cluster, the various

readings and conditions displays a numbers or a bar-graph display. Both

types of the instrument clusters inform the driver of any conditions

including:

1. Vehicle speed

2. Distance traveled

3. Engine temperature

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 28 of vii

MELY JOY S. AGEAS

4. Engine oil pressure

5. Battery charge or discharge

6. Amount of fuel in fuel tank.

Some cars have a hybrid instrument cluster. It includes both analog gauges

and electronic displays, along with other indicating devices and warning

lights. This may illuminate a symbol or a message such as DOOR AJAR or

TAIL LAMPOUT.

B. Head-up Display

Images containing driving information are projected onto the windshield.

The information includes displays of vehicle speed, turn-signal indicators,

high-beam indicator, and low-fuel warning. These images appear

suspended in space near the front bumper. The driver’s eyes do not need to

move from the road or refocus to view this information.

Only certain information from the instrument panel appears in the head-up

display. A warning CHECKGAUGES messages appearing on the windshield

alerts the driver that a gauge on the instrument panel needs attention.

Controls allow adjustment of the head-up display brightness and vertic

allocation in the windshield.

C. SPEEDOMETER AND ODOMETER

A speedometer in the instrument cluster shows the driver how the fast the

vehicle is moving. Many speedometers are driven from the transmission

output shaft by a set of gears. Thee driven gear fastens to a flexible shaft or

speedometer cable. It runs from the transmission output shaft to the back

of the speedometer head.

Inside the speedometer, the cable turns a shaft with a small magnetic field

produces a varying pull on the metal ring surrounding the magnet. A pointer

attaches to the metal ring. As magnetic field spins, it causes the ring to

overcome a light spring and swing with the magnetic field. This moves the

pointer which then indicates car

speed. The faster the car speed, the

faster

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 29 of vii

MELY JOY S. AGEAS

the magnet spins, and the farther the

pointer moves.

The odometer records the total

distance the vehicle has traveled. It

is a row of

numbers, usually located in the

speedometer shaft. Its motion

is carried

through the gears to the mileage or

kilometer number rings. These

turn to

show the distance traveled by the

vehicle.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 30 of vii

MELY JOY S. AGEAS

Some vehicles have an

electronically-driven speedometer

and odometer. A

vehicle-speed sensor (VSS) on the

transmission output shaft sends

vehicle

speed signals through wiring

to the speedometer. This

eliminates the

speedometer cable. The speed

signals operate a small electric

stepper motor

which turns the odometer number

rings. Cars with an electronic

instrument

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 31 of vii

MELY JOY S. AGEAS

cluster have a digital speedometer

and odometer display. When the

key is off,

the body control module (BCM)

stores the odometer reading. The

odometer

reading is not lost when the battery

is disconnected.

pointer which then indicates car speed. The faster the car speed, the faster

the magnet spins, and the farther the pointer moves.

The odometer records the total distance the vehicle has traveled. It is a row

of numbers, usually located in the speedometer shaft. Its motion is carried

through the gears to the mileage or kilometer number rings. These turn to

show the distance traveled by the vehicle.

Some vehicles have an electronically-driven speedometer and odometer. A

vehicle-speed sensor (VSS) on the transmission output shaft sends vehicle

speed signals through wiring to the speedometer. This eliminates the

speedometer cable. The speed signals operate a small electric stepper motor

which turns the odometer number rings. Cars with an electronic instrument

cluster have a digital speedometer and odometer display. When the key is

off, the body control module (BCM) stores the odometer reading. The

odometer reading is not lost when the battery is disconnected.

D. Speed-Control System

The cruise control or speed-control system helps the vehicle to automatically

maintain a speed selected by the driver. When set at any speed above

about225 mph [40 kmph], the driver’s foot can be removed from the

accelerator pedal. An actuator motor, vacuum servo then opens and closes

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 32 of vii

MELY JOY S. AGEAS

the throttle, as needed to maintain the speed. However, steep grades up or

down may cause vehicle speed to vary.

Tapping the clutch or brake pedal operates a switch that

disengages the system. Touching the RESUME button or switch causes the

vehicle to return to the former speed setting. Depressing thee accelerator

pedal for passing does not affect the setting. Depressing the accelerator

pedal for passing does not affect the setting. When the pedal is released, the

system returns the vehicle to the preset speed. To disengage and turn off the

speed-control system, move the OFF-ON switch to OFF.

E. Networks and Multiplexing

Some cars have several microprocessors which control the various electronic

systems. One way to reduce duplication and wiring is to have these

controllers communicate with each other. When this happens thee

group of interconnected components and systems becomes a network. For

example, a sensor is wired to one controller. If then shares the information

with all other controllers that require it. The vehicle has fewer sensors, and

the amount of wiring and number of connections is greatly reduced.

F. Other electrical and Electronic Devices

The automobile may contain other electrical and electronic devices in

addition to those already described. These include power seats, power

windows, heated windshield, voice alert systems, voice command systems,

mobile telephones, and electronic navigation systems. Some of these

and other electrical and electronic devices are described below.

1. Electric seat adjusters are motors under the seat that operate by

pushbuttons or levers to move the seat forward and back, or up or down.

Some also change the inclination and shape, or contour, of the seat.

2. The window regulator has a motor in the door that raises or lowers the

window as a switch is operated.

3. The voice alert system uses a computerized voice which says, “The door

is ajar,” “The key is in the ignition lock,” or ‘the headlamps are on. ”These

and other messages inform the driver of conditions that need attention.

4. The voice command system causes the car to respond in some way to a

spoken command. This may be “Tune thee radio,” “Lower thee window,” or

“Dial a phone number.” There are many other voice-command possibilities.

One includes using a voice command to unlock the car door and operate the

ignition instead of using a key.

5. The keyless entry system has a panel of buttons on the driver-side door.

To unlock the door, the buttons must be pressed in the proper order. This

code takes the place of the key. Some keyless entry systems can also be

operated from up to 33 feet [10 m] by a small hand-held transmitter.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 33 of vii

MELY JOY S. AGEAS

Pushing a button on the transmitter will lock all doors, unlock all doors, or

open the trunk. Another button— the PANIC button- acts as a theft

deterrent or anti-theft device. Pushing the panic button with the ignition of

activates the horn and flashes the headlamps.

6. Electronic navigation systems display a map on the instrument panel

which shows the location of the vehicle on the road. The location point

moves on the map as the vehicle travels on the highway. It also shows the

route to the destination. In some systems, a satellite orbiting in space—

22,000 miles [35,400] above the earth—pinpoints vehicle location.

7. Radar braking uses radar to sense how fast a vehicle is closing on the

vehicle ahead. The brakes apply automatically to slow the vehicle if

necessary to maintain a safe distance. Someday radar braking may be

combined with throttle control into intelligent cruise control. This could

keep traffic moving at a preset speed while radar braking maintains safe

intervals between vehicles.

Self- Check 2.1-1

Multiple Choices

Instruction: Choose the letter that correspond the correct answers.

1. ________are electrically-operated noise- makers used by the driver to provide

a loud warning signal.

a. Turn-signal lights c. Windshield wipers

b. Seat Belts d. Horns

2. ____s restrain the vehicle occupants if there is an accident.

a. Turn-signal lights c. Windshield wipers

b. Seat Belts d. Horns

3. _______are balloon-type devices that inflate automatically to protect the

driver(and front-passenger in some vehicles) if a front-end crash occurs.

a. Turn-signal lights c. Windshield wipers

b. Seat Belts d. Air Bags

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 34 of vii

MELY JOY S. AGEAS

4. ______ clean the windshield so the driver can see clearly while driving in rain

or snow.

a. Turn-signal lights c. Horns

b. Seat Belts d. Windshield wipers

5. _____ which indicate an intended change in direction by flashing lights on

the side toward which the turn will be made.

a. Turn-signal lights c. Windshield wipers

b. Seat Belts d. Seat Belts

ANSWER KEY 2.1-1

1. D

2. B

3. D

4. D

5. A

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 35 of vii

MELY JOY S. AGEAS

Information Sheet 2.1-2

Hand Tools

Hand tools

Automotive service work requires a great variety of tools. The proper

tools properly used enable to do a job with safety, speed, and efficiency.

This information sheet covers hand tools. Your hand supplies the

energy to use them. They include striking, turning, gripping, and cutting

tools. They also include tube bending and flaring tools.

A. Striking tools

1. Hammers - a hammer is a hand tool used for striking. The ball-peen

hammer is the one used most in the shop. Grip the hammer on the end of

the handle. Swing it so the hammer face strikes the object or surface

squarely. Avoid hitting the object a tan angle. Use rawhide, plastic, brass,

and rubber hammers to strike easily marred surfaces. A dead blow hammer

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 36 of vii

MELY JOY S. AGEAS

has a hollow head partially filled with small metal shot. This recess

rebounding.

B. Turning Tools

1. Screwdrivers - Use the proper screwdriver to drive or turn screw.

Screwdrivers are made in a variety of sizes, shapes, and special purpose

designs. The most common type has a single flat blade for driving screws

with slotted heads there are also Torx -head and Phillips-head screws.

Always select a screw driver of the proper types and size for

the job. When using a single-blade screwdriver, the blade shouldcompletely

fill the screw slot. This helps prevent damage to the screw head.

2. Wrenches - long-handled tool with fixed or adjustable jaws. You use a

wrench to turn bolts, nuts, and screws to work on both USC, and metric

fasteners, you need both USC and metric wrenches. A 3/8- to 1-inch USC

set and a 6- to 119-mm metric set will handle most jobs. You need these

sizes in sets of open-end, box, and combination wrenches.

a. Open-end wrench - usually has a jaw opening at a 15degree angle to a

handle. Turn the bolt or nut as far as the space permits. Then flip the

wrench over for further turning of the fastener.

An open-end wrench has a different size on each end. Make sure the wrench

fits snugly against the flats. These are the sides of a nut or bolt head. A

loose fit may break or spring the jaws of the wrench. Springing jaws spread

apart and round off the corners of the hex. This makes use of the proper

wrench more difficult.

Careful:

Never use an open-end wrench to final-tighten a fastener or to free a frozen

fastener. The jaws may spread enough to allow thee wrench to slip. Use a

box wrench or a socket wrench for these jobs.

b. Box-wrench - opening surrounds or “boxes in” the nut or bolt head. An

advantage is that the box will seldom slip off. However, you must lift the box

wrench completely off and then place it back on for each swing. The wrench-

head is thin for use in tight places. The head usually sets at a 15-degree

angle to the body. This provides hand clearance for swinging the wrench.

The most common box wrench has 12 notches or “points” in the head.

This allows turning the fastener if the wrench can swing 30 degrees. A six-

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 37 of vii

MELY JOY S. AGEAS

point box wrench holds better on a nut or bolt but needs a greater swing.

The box wrench has different size openings on each end.

c. Combination wrench - has a box on one end and an opened on the other.

The two ends are usually the same size. The box end is more convenient for

breaking loose or final tightening a nut or bolt. But you must lift the box

completely free after each swing. The open end is more likely to slip off.

However, once the fastener is loose, the open end can turn it faster.

d. Flare-nut wrench - is a special type of combination or boxed wrench. It is

used to attach or loosen a flare nut or tubing nut. The ends of the flare-nut

wrench are thicker than on the wrenches. This helps prevent slipping and

rounding off the points on soft-metal tube fittings. The six-point boxed has

one of the flats cut out. The opening is large enough to slip over the tube.

Careful:

Do not turn the flare nut without holding coupling nut. This will usually

twist and break the metal tube.

e. Adjustable wrench - an adjustable wrench has a

movable jaw that you adjust the fit nuts and bolt heads of various sizes.

Tighten thee jaws against the flats of the nut or bolt before applying a

turning force. Adjustable wrenches are normally used only when applying

relatively light torque. They are not always a strong as fixed jaw wrenches

and maybe damaged if excessive torque is applied.

f. Socket wrenches - the most widely used tools. They are like box wrenches

except that the head or socket is detachable from the handle. You assemble

the socket wrench you need from the socket set in your toolbox.

1. SOCKET. The 12-point socket allows you to turn a bolt or nut in tight spots.

However, if a bolt head or nut has rounded corners or excessive resistance to

turning, thee 120point socket may slip. Use a six point socket for these. The

eight point socket is for turning square heads. These include drain plugs, fill

plugs, and pipe plugs. Deep sockets reach nuts on bolts or studs that are too

long for the standard socket to reach. You remove and install spark plugs with a

spark-plug socket. This is a six-point deep socket with a rubber insert. Thee

insert holds the plug to prevent it from falling out of the socket.

2. HANDLES. Figure 7-8 shows several handles. The ratchet handle has a

mechanism that permits free motion in one direction but lockup in the other.

You select the direction for lockup by moving the reversing lever. Extensions of

various lengths provide access to hard-to-reach bolts or nuts. The universal

joint allows you to turn a nut or bolt while holding the driver at an angle.

Adapters allow you to use a driver with a socket having a different drive size.

Also, various kinds and sizes of screw drivers, Torx drives, Allen wrenches, and

flare- nut wrenches will fit the drivers and adapters.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 38 of vii

MELY JOY S. AGEAS

NOTE:

To work on variety of domestic and imported cars, you need both USC and metric

socket sets.

g. Torque wrench - is basically a special handle for a socket. An indicator on

the torque wrench measures the torque or twisting force. This is the amount

of force applied to a nut or bolt while tightening it. Vehicle service manuals

give the torque specification might be to tighten a bolt to “20 lb. - ft.” this

means to apply a 20 pound pull at a distance of 1 foot from the bolt. Dirty or

damaged threads put a drag on the threads as the bolt or nut is tightened.

This gives a false reading on the torque wrench. It can also result in not

enough tightening. Many torque wrenches read in pound-feet 9lb-ft). Some

read in pound-inches (lb.-in). Use these where you need to accurately apply

a small torque. Twelve pound-inches equals one-pound-foot. The scale on

metric torque wrenches is in kilogram-meters (kg-m), kilogram-centimeters

(kg-cm), or newton-meters (n-m). Newton- meters is the preferred unit. To

convert from USC to newton-meters, multiply pound-feet by 1.35.

h. Torque-Angle Gauge - Tighten torque-to-yield bolts to an initial torque with

a torque wrench. Then final-tighten the bolts by turning them through a

specified angle with a socket wrench. You can easily see a 90-degree turning

angle by watching how a ratchet-handle or breaker-bar moves. For other

angles, use a torque-angle gauge. It accurately measures the turning angle

in degrees. The gauge attaches to the socket driver. The socket attaches to

the gauge. As the handle turns, the degree indicator remains the greatest

angle reached.

C. Gripping tools

1. Pliers - Pliers are hand tools with a pair of adjustable pivoted jaws for

cutting or gripping. There are many styles and sizes of pliers. Combination

slip-joint pliers may have cutting edges at the back of the jaws for wire

cutting. Tongue -and-groove or groove-and-land pliers such as Channel lock

pliers have the tongues or lands to different grooves changes the distance

the jaws can open. The jaws remain parallel at any setting.

Locking pliers such as Vise-Grip pliers have locking jaws. This makes them

useful as pliers, wrenches, clamps, and small vises. Look the jaws by

turning a screw in the end of the handle. This adjusts the size of the

opening. Closing the handles then locks the jaws into place. To release the

jaws, pull the release lever.

Careful:

Never use gripping pliers on hardened steel surfaces. This dulls the pliers’

teeth. Never use pliers on nuts or bolt heads. The pliers may slip and round

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 39 of vii

MELY JOY S. AGEAS

off the edges of the hex. Then a wrench or socket will not fit on the fastener

properly.

2. Pullers - remove parts assembled with an interference fit. This includes

removing gears and hubs from shafts, and bushings from bores or cylinder

liner from engine blocks.

A puller set has many pieces that can fit together to form the puller needed

for the job. There are three basic types of pullers.

D. Cutting Tools

Cutting tools remove metal. They include chisels, hacksaws, files, punches.

Drills, taps, and dies are also cutting tools. Power cutting tools include

grinders, hones, lathes, and boring machine.

1. Chisels - is a cutting tool with a single cutting edge. There are various

sizes and shapes of chisels. Striking the chisel with a hammer makes the

chisel cut metal. Hold the chisel with one hand and the hammer in the

other. Hit the end of the chisel squarely holding the chisel in a chisel holder

or smooth-jaw locking pliers will protect your hand.

Caution:

Always wear eye protection when using a chisel. Never use a chisel with a

mushroomed head. When the hammer strikes the head, a piece could fly off.

The flying metal could cut you or injure an unprotected eye.

2. Hacksaw - is basically an adjustable metal frame that holds a steel saw

blade. The blade is replaceable and has from14 to 32 teeth per inch. Cutting

occurs on the forward stroke as you push the blade across the metal. The

teeth act like tiny chisels and cut off fine shavings or chips. Select a blade

with the proper number teeth per inch for the job. The teeth must be close

enough so at least two teeth are cutting. Teeth that are too close together

clog and stop cutting. The hacksaw blade for general cutting has 18 teeth

per inch.

3. Files - are used for cutting and shaping metal. They have many cutting

edges or teeth. When the cuts are far apart, there are only a few per inch.

This is rough-or coarse-cut file. When the cuts are close together, the file is

a smooth or dead-smooth file. A single-cut file has a series of sharp blades.

A double-cut file has a second series cut at an angle to the first. This creates

a series of sharp teeth. Various sizes and cuts of round, half-round, flat, and

triangular files are used during automotive service work. Always use a

handle with a file. Tapping the end of the handle on the bench tightens the

file in the handle. Keep the file teeth clean with a file card. It has short stiff-

wire bristles that remove chips and dirt from the teeth.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 40 of vii

MELY JOY S. AGEAS

4. Punches - are used to knock out rivets and pins. They also align parts for

the assembly. To remove a rivet, grind off the rivet head. Or cut it off with a

chisel. Mark spots where holes are to be drilled with a center punch. The

punch mark keeps the drill bit centered as it starts cutting you can use the

center punch to mark parts before they are disassembled .Align the punch

marks to reassemble the parts in the same position.

5. Twist drills (Drill bits) - are tools for making holes. The material being

drilled determines the preferred shape of the cutting edges that form the

point. The grooves along the body carry the chips out of the hole. A hand-

held air or electric drill motor, or a drill press, drives the drill bit.

6. Taps and Dies - tap-and-die sets are for cutting USC and metric threads.

Taps cut inside the threads. To tap a hole, determine the thread size needed.

Refer to a tap drill chart and select the size of drill bit required. The hole

made by the specified tap drill will be the proper diameter for tapping.

Dies cut outside threads on rods diestock holds the die. Chamfer or bevel the

rod end so the die starts easily. The basic procedure is the same for both

taps and dies. Apply cutting the lubricant to the surface. Then begin thread

cutting. After every two turns, back off the tap or die and apply more

lubricant.

Self Check 2.1-2

Multiple Choices

Instruction:

Choose the letter that correspond the correct answer.

1. ___are long-handled tool with fixed or adjustable jaws.

a. screw driver c. Hammer

b. Wrenches d. Pliers.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 41 of vii

MELY JOY S. AGEAS

2._____ is a hand tool used for striking.

a. Hammer c. screw driver

b. Wrenches d. Pliers

3. Use the proper ____ to drive or turn screw.

a. screw driver c. Hammer

b. Wrenches d. Pliers

4.____are hand tools with a pair of adjustable pivoted jaws for cutting or

gripping.

a. Pliers c. Hammer

b. Wrenches d. screw driver

5._______are used to knock out rivets and pins.

a. Punches c. Hammer

b. Wrenches d. screw driver

Answer Key 2.1-2

1. B

2. A

3. A

4. A

5. A

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 42 of vii

MELY JOY S. AGEAS

Information Sheet 2.1-3

LTO/LTFRB Light vehicle with Some Safety Harness/

Devices/Tools of a Vehicle

Objectives:

After reading the information sheet, the trainee should be able to:

1. Enumerate Examples of Light Vehicle

2. Give some safety harness/devices/tools of a vehicle

A .Light vehicle

1. Private car

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 43 of vii

MELY JOY S. AGEAS

2. Owner type Jeepney

3. Taxicab

4. Public Utility Jeepney

B. Some Safety Harness/ devices/ tools of a vehicle

1. Seat belt - a strong strap or harness designed to keep the wearer securely

in a seat in a vehicle or aircraft.

2. Early Warning device - advance notice that something, especially

something dangerous or threatening, is going to happen.

E.W.D orange must be set in front the vehicle at least 5meter away

E.W.D red must be set at the back of the vehicle at least 5meter away

3. Hand tools

a. Wrench - a hand or power tool with fixed or movable jaws, used to seize,

turn, or twist objects such as nuts and bolts

b. Pliers - a hand tool with two hinged arms ending in jaws that are closed

by hand pressure to grip something

c. Screwdrivers - a tool for driving screws that consists of a handle or power

tool with a metal rod shaped at the tip to fit into the head of a screw

d. Early warning Device

e. Jack - a portable device that uses a mechanical or hydraulic lifting

system to raise heavy objects, especially cars, a short distance

f. Spare tires - rubber edging for wheel kept in case of emergency.

4. Flashlights - emergency lighting device

5. Consumable Materials and spare parts such as”

a. Rags - a small piece or scrap of usually old or unwanted clothused for

cleaning, polishing, or applying liquid substance.

b. Fan Belt - a continuous belt that turns a fan, especially oneturning the

cooling fan in the engine of a motor vehicle

c. Wheel cap - a wheel in a vehicle that is connected by way of the steering

column to the steering gear and is turned to change direction.

d. Fuse - an electrical safety device containing a piece of a metal that melts

if the current running through it exceeds a particular level, thereby

breaking the circuit.

e. Electrical Tape

f. Brake Fluid - a liquid or gas put in brake.

g. Motor oil - oil put in the engine

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 44 of vii

MELY JOY S. AGEAS

Self-Check 2.1-3

Enumeration

Instruction:

Enumerate the following.

A. Light vehicle

B. Some Safety Harness/ devices/ tools of a vehicle

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 45 of vii

MELY JOY S. AGEAS

Answer Key 2.1-3

Model Answer

A. Light vehicle

1. Private car

2. Owner type Jeepney

3. Taxicab

4. Public Utility Jeepney

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 46 of vii

MELY JOY S. AGEAS

B. Some Safety Harness/ devices/ tools of a vehicle

1. Seat belt - a strong strap or harness designed to keep the wearer securely

in a seat in a vehicle or aircraft.

2. Early Warning device - advance notice that something, especially

something dangerous or threatening, is going to happen.

E.W.D orange must be set in front the vehicle at least 5meter away

E.W.D red must be set at the back of the vehicle at least 5meter away

3. Hand tools

g. Wrench - a hand or power tool with fixed or movable jaws, used to seize,

turn, or twist objects such as nuts and bolts

h. Pliers - a hand tool with two hinged arms ending in jaws that are closed

by hand pressure to grip something

i. Screwdrivers - a tool for driving screws that consists of a handle or power

tool with a metal rod shaped at the tip to fit into the head of a screw

j. Early warning Device

k. Jack - a portable device that uses a mechanical or hydraulic lifting

system to raise heavy objects, especially cars, a short distance

l. Spare tires - rubber edging for wheel kept in case of emergency.

4. Flashlights - emergency lighting device

5. Consumable Materials and spare parts such as”

h. Rags - a small piece or scrap of usually old or unwanted cloth used for

cleaning, polishing, or applying liquid substance.

i. Fan Belt - a continuous belt that turns a fan, especially one turning the

cooling fan in the engine of a motor vehicle

j. Wheel cap - a wheel in a vehicle that is connected by way of the steering

column to the steering gear and is turned to change direction.

k. Fuse - an electrical safety device containing a piece of a metal that melts

if the current running through it exceeds a particular level, thereby

breaking the circuit.

l. Electrical Tape

m. Brake Fluid - a liquid or gas put in brake.

n. Motor oil - oil put in the engine

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 47 of vii

MELY JOY S. AGEAS

Information Sheet 2.1-4

Routinely Checks on Vehicle Component(THE BLOWBAGETS}

Objective:

After reading the information, the trainee should be able to perform routinely

checks on vehicle component (THE BLOWBAGETS}.

T - Tires – is a ring shaped component that surrounds a wheel’s rim to transfer a

vehicle’s load from the axles through the wheel to the ground and to provide

traction on the surface traveled over.

The Following must be checked:

a. Uneven sidewall wear, down to fabric plies, due to significant under-inflation

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 48 of vii

MELY JOY S. AGEAS

H– Horn – is a sound making device that can be equipped to motor vehicles,

buses, bicycles, trains and other type of vehicles. The vehicle operator uses the

horn to warn others of vehicle approach or presence. Or to call attention to

some hazards. The following must be checked:

a. Check the relay connecting to the battery.

E– Engine – is a machine designed to convert one form into mechanical energy.

Heat engines burn a fuel to create heat which is then used to do work.

The following must be checked”

a. Engine oil

b. ATF

c. Brake Fluid

d. Fan Belt

B-Battery - The cars source of electrical energy. It supplies direct current to the

electrical Components an electro chemical device for storing energy in chemical

form so that it can be released as electricity for cranking the engine and powering

the electrical load.

The following must be checked

a. Clamps and cables

b. Battery solution

c. Cracks

d. Under charge

e. Terminal corrosion

f. Sulfation

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 49 of vii

MELY JOY S. AGEAS

L- Light- The lighting system of a vehicle inside and outside of the car is either

automatic or manually operated or switch by the driver.

a. Headlight - the main lighting system of a vehicle

b. Signal light-use to indicate right turn or left turn

c. Stop light- use to indicate slow down or stopping

d. Back up light- use to indicate vehicle backing up

e. High beam indicator- use to indicate high beam of headlight

f. Horn

g. Fuses and relays

h. Wires and cables

i. switches

O - Oil- Is to prevent friction between moving parts of the engine by supplying an

adequate amount of oil

Tasks

To cool the engine components

To provide seal between sliding contact components

To clean internal parts of the engine

Motor oil, gear oil, and A.T.F

W- Water -Is place in the radiator where cooling takes place.

A. Cooling System Flush

Overheating in engines is often caused by a poorly performing cooling system. This

can lead to a lack of performance or worse, the potential failure of your engine and

transmission resulting in expensive repair bills. Our Cooling System Flush is

designed to safely break down and remove rust and scale deposits from

the cooling system. This specialty service then replaces up to 95% of the old

coolant and refills the system with quality, long life fluid. Specialty conditioning

treatment is added to help maintain the cooling system in optimum condition.

KEY ITEMS:

Check radiator for damage or leaks

Check hoses and thermostat operation

Drain and flush cooling system

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 50 of vii

MELY JOY S. AGEAS

Refill radiator with coolant and conditioner

Pressure test cooling system and test for leak

B – Brakes - A brake is a mechanical device that inhibits motion by absorbing

energy from a moving system. It is used for slowing or stopping a moving vehicle,

wheel, axle, or to prevent its motion, most often accomplished by means of

friction.

A –Air- mixture of gases that composes the atmosphere surrounding Earth. Air is

the life sustaining of vehicle tire and must always be checked before running the

vehicle.

The following must be checked.

a. Tire pressure

Tire Service

Why is it important?

Tires may wear differently depending on their position on the vehicle, your

driving style and the condition of your suspension. Regularly rotating your tires

can evenly distribute their wear — helping you get the most miles out of your tires

while maximizing traction on all four wheels.

What is the service?

Changing the position of the tires on your vehicle is according to your vehicle and

tire manufacturers’ recommended rotation pattern.

Benefit to you:

Tire Rotation Service – Helps maximize the life span of your tires.

G- Gas – Natural gas vehicle (NGV) is an alternative fuel vehicle that uses

compressed natural gas (CNG) or liquefied natural gas (LNG). Natural gas vehicles

should not be confused with vehicles powered by LPG (mainly propane), which is a

fuel with a fundamentally different composition.

-Especially during long drives, a full gas tank is important. Imagine how

troublesome it would be if you run out of fuel while you’re stuck in traffic or

driving along the road where a gas station is nowhere in sight.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 51 of vii

MELY JOY S. AGEAS

E- Early Warning Device -a device that signals the occurrence of some

undesirable event.

4 reasons why carrying an Early Warning Device:

1. Safety - EWD is designed for safety purposes. It warns other motorists that

there’s a stalled vehicle ahead, which could lessen the odds of an accident.

2. Road Courtesy - Placing EWD won’t just keep you safe when you pull over to the

side but, it will also protect the approaching motorists. In this way, you are

being courteous towards other road users, and at the same time, you are

promoting road safety.

3. Responsible Car Owner - If all of us are responsible car owners or drivers, car-

related accidents could be reduced to a minimum. Be a responsible driver by

practicing road safety and courtesy. As such, you should always have the

essential tools inside your car – especially the EWD.

4. Required by the Law - Yes, it is required by the law. The Memorandum Circular

No. VPT-2012-1609 or the Revised Rules on the Implementation of the

Early Warning Device Requirement states that EWD is a mandatory accessory

for all motor vehicles, except motorcycles and tricycles. The memorandum goes

on by stating that “a pair of EWD…shall be carried at all times.” So, you might

want to buy EWD right now if you still don’t have one inside your car.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 52 of vii

MELY JOY S. AGEAS

T-Tools – a device or implement, especially one held in the hand, used to carry

out a particular function, any instrument or simple piece of equipment that you

hold in your hands and use to do a particular kind of work.

S- Self -Human error is the leading cause of road accidents. Accident Recording

and Analysis System cites fatigue, sleepiness, drunkenness, and medical problems

like asthma and dizziness as examples.

The following must be checked

1. Check yourself! If you’re sick, dizzy, tired, sleepy, or drunk, you better let

somebody else take over the steering wheel.

2. Also, check your documents before you hit the road. Your driver’s license, LTO

registration papers, and proof of car insurance should be within reach when you

get pulled over on your road trip.

Self-Check 2.1-4

A. True or False

Instruction: Write T if the statement is correct and f if the statement is False.

1. Overheating in engines is often caused by a poorly performing cooling system.

2. It is highly recommended to check your oil twice a month.

3. The lighting system of a vehicle inside and outside of the car is either automatic

or manually operated or switch by the driver.

4. Changing the position of the tires on your vehicle is according to

your vehicle and tire manufacturers’ recommended rotation pattern.

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 53 of vii

MELY JOY S. AGEAS

5. Air is the life sustaining of vehicle tire and must always be checked before

running the vehicle.

B. Enumeration

1. Vehicle components routinely to be checked

2. Components must be checked on the Battery

3. Components must be checked on Light

Answer Key 2.1-4

A. True or False

1. T

2. T

3. T

4. T

5. T

B. Enumeration

1. Vehicle components routinely to be checked

Date Developed: Document No.

September 2023

DRIVING NC II

Developed by: Pag 54 of vii

MELY JOY S. AGEAS

T – Tires

H – Horn

E – Engine

B – Battery