Professional Documents

Culture Documents

Taco CAF Expansion Tank Install Manual

Taco CAF Expansion Tank Install Manual

Uploaded by

TEMPOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Taco CAF Expansion Tank Install Manual

Taco CAF Expansion Tank Install Manual

Uploaded by

TEMPCopyright:

Available Formats

Instruction Sheet 402-109

CAF Expansion Tanks

SUPERSEDES: December 1, 2014 Effective: June 13, 2022

Plant ID No. 001-5042

D E

WARNING: FAILURE TO COMPLY WITH THESE 1

BEAD LOCATE ON OD OF NOZZLE

INSTRUCTIONS REGARDING THIS PRODUCT CAN

A 012345

OF BAG MUST BE CENTERED BETWEEN

THESE TWO BOLT HOLES TO ENSURE 125 240

PROPER BAG INTERNAL ALIGMENT B

RESULT IN SERIOUS PERSONAL INJURY OR DEATH AND/ C

-20

01-2022

125

OR SEVERE PROPERTY DAMAGE. CAF1000-125

L12345.AB F

5 NAMEPLATE

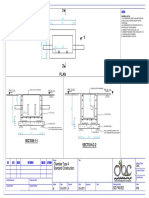

1. Note location of the system connection, charging valve, and the drain plug and labels on the tank.

INFORMATION REQUIRED

Refer to Diagram 1 for location of these tank fittings. FOR FACTORY ASSISTANCE

A. SERIAL NUMBER

2. Carefully remove the shipping plugs in the system connections located at the center of the cover ALLOW A MINIMUM OF 18"

OVER THE COVER FLANGE

B.

C.

NATIONAL REGISTRATION

ASME CERTIFICATION

FOR SYSTEM CONNECTION D. DATE OF MANUFACTURE

flanges. Pause before completely removing to allow any trapped air to escape. There should not INLET/ OUTLET E.

F.

PART NUMBER

CANADA REGISTRATION No.

MARK ON VESSEL

be much, if any, air pressure under the protective covers. 2

6

WARNING: DO NOT REMOVE THE PIPE PLUGS LOCATED ON THE SIDE AND BOTTOM

3

OF THE TANK (TANK DRAINS). THESE PLUGS SHOULD NEVER BE REMOVED UNLESS

NECESSARY AND THEN ONLY AFTER THE AIR PRESSURE IN THE TANK HAS BEEN BLED 4

OFF TO ZERO GAUGE PRESSURE. BEFORE BLEEDING OFF ANY OF THE AIR CHARGE,

ALWAYS REMOVE AND DISCONNECT THE TANK FROM THE SYSTEM. 7 7

(FACTORY USE ONLY)

3. Prior to connecting this tank to the hydronic system the pre-charge pressure within the tank should CAF600 THRU CAF2500 DO NOT PIPE TO DRAIN

be confirmed and if necessary adjusted to equal the minimum system pressure at the tank loca- (FACTORY USE ONLY)

DO NOT PIPE TO DRAIN

tion. This measurement should be taken at the air valve located on the top of the tank. The tank 5

was shipped from the factory with an initial pre-charge of 40 psi at 68 degrees. This may vary with

changes in ambient temperature. Use Diagram 2 (below) - air charge check chart to correct the

value read on the pressure gauge to adjust for changes in the ambient temperature. The fill pres- OPTIONAL

SIGHT GLASS

sure of the system should be indicated on the schedule file or within the job specifications. If not (ADD SUFFIX 'B')

provided in either of these locations consult the design engineer for the proper fill pressure values

prior to installation of this tank. Installation of the tank prior to adjusting the pre-charge can result LIFTING LUG

CAF600 THRU CAF2500

in incorrect pre-charge readings.

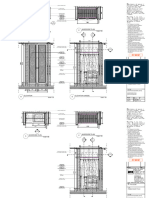

4. The pipe connection to the system may now be made. The piping requirements for flow through

expansion tanks are different from those of single port expansion tanks. Note the Flow Through

Expansion Tank Piping Diagrams. Piping and air elimination devices should be arranged so that air

will not be trapped in the tank, above the tank or in the nozzle. Note that there are 2 recommended

piping arrangements based on flow. If the system flow exceeds the flow rate shown in the chart be-

low, refer to figure 1. A Valve is required in the system to ensure proper flow to the expansion tank.

It is important to ensure that the flow rate to the tank does not exceed the flow shown in the OPTIONAL

chart below. Taco is not responsible if the flow to the tank exceeds the max flow in tank as 7 ANCHOR CLIPS

(ADD SUFFIX 'A')

shown in the chart below. If the system flow is within the flow rate shown in the chart below, refer DO NOT PIPE TO DRAIN

to figure 2. A valve will not be required in this instance and the precision flow channeling head on

the Flow Through Tank will ensure the proper amount of flow in the tank. 1.

2.

3.

Charging Valve Closure, 1 1/2" NPT

System Connection

Hose Assembly

4. Bag

5. Not all potable water systes will have pumps. A combination shut-off and drain valve should be 5.

6.

ASME Name Plate

Lug(s)

located in the connection piping to provide for tank isolation during the initial hydrostatic test. 7. Sealed 1/2" NPT at Factory - Do not pipe to Drain

Do Not Remove Plug - Removing plug voids tank warranty.

Severe injury of death may result if a factory installed plug

is removed without first isolating the tank from the system

• STANDARD PRODUCT FEATURES WITH 304 SS COVER FOR USE WITH WITH POTABLE and reducing the internal pre-charge pressure to zero psi

at the air valve.

WATER.

• MUST BE INSTALLED IN VERTICAL ORIENTATION.

DIAGRAM 1 – LOCATION OF TANK FITTINGS

• Models certified to NSF/ANSI 61-G are required to be installed on the cold water side of the hot

water heater.

MODEL NUMBER MAX FLOW IN TANK RATE (GPM) CONNECTION SIZE NSF/ANSI 61-G [ P ] OPTION, (EX. P/N CAF90-125P)

Models certified to NSF 61-G are required to be installed

CAF90 TO CAF215 55 1.5" NPT on the cold water side of the hot water heater.

Certified to

CAF300 TO CAF800 80 2" NPT NSF/ANSI/CAN 61-G

CAF900 & CAF2500 200 3" NPT

Diagram 2 - Air Charge Check Chart

Specified Ambient Temperature (°F) How to Use the Chart

Pre Charge

Pressure PSI 1. Determine ambient air temperature where the tank is being checked.

36 44 52 60 68 76 84 92 100

(at 68°F) 2. Locate the specified pre-charge pressure in the left-hand column.

3. Follow across horizontally to the number under the ambient air temperature.

12 10.4 10.8 11.2 11.6 12.0 12.4 12.8 13.2 13.6

4. The number found under step no. 3 is the temperature corrected air charge

pressure in p.s.i. and should agree with the gauge reading observed at the tank.

20 17.9 18.4 18.9 19.5 20.0 20.5 21.1 21.6 22.1

5. If the temperature corrected air charge pressure differs by more than 1 p.s.i.

from the pre-charge pressure specified for the system, then correct it by

30 27.3 28.0 28.6 29.3 30.0 30.7 31.4 32.0 32.7 bleeding pressure through the air charge valve or by adding pressure with an

air compressor.

40 36.7 37.5 38.2 39.2 40.0 40.8 41.6 42.5 43.3

50 46.1 47.1 48.0 49.0 50.0 51.0 52.0 52.9 53.9

60 55.5 56.6 57.7 58.9 60.0 61.1 62.3 63.4 64.5

70 64.9 66.1 67.4 68.7 70.0 71.3 72.6 73.9 75.1

FLOW THROUGH EXPANSION TANK PIPING DIAGRAMS

Typical Installation for Hot Water Recirculation System Where System Flow Exceeds

Max Flow in Tank from chart on page 1 Tank Flow - Figure 1

Isolation Backflow By-Pass Cold Hot Isolation Isolation Fixtures

Valve Preventer Valve Water Water Valve Valve

Supply Supply

Relief Isolation

Isolation Isolation

Valve Valve Taco Circulator

Valve Valve

Hot Water Return

Hot Water Supply Line

Union Union

Drain

Valve

Isolation Isolation

Union Valve Valve

Water

Heater

Flow Taco Circulator

Check Hot Water Return Line

Drain

Valve Valve

Taco

CAF Tank

Typical Installation for Hot Water Recirculation System Where System Flow is equal to or less

than Max Flow in Tank from chart on page 1 Tank Flow - Figure 2

Isolation Backflow Isolation Cold Hot Isolation Isolation Fixtures

Valve Preventer Valve Water Water Valve Valve

Supply Supply

Isolation Isolation Relief Isolation

Valve Valve Valve Valve Taco Circulator

Hot Water Return

Hot Water Supply Line

Union Union

Drain

Valve

Isolation Isolation

Union Valve Valve

Water

Heater

Flow Taco Circulator

Check Hot Water Return Line

Drain

Valve Valve

Taco

CAF Tank

LIMITED WARRANTY STATEMENT

Taco, Inc. will repair or replace without charge (at the company’s option) any tive product or part. Taco reserves the right to make changes in details of

commercial pump product or part which is proven defective under normal design, construction, or arrangement of materials of its products without

use within one (1) year from the date of start-up or one (1) year and six (6) notification.

months form date of shipment (whichever occurs first). TACO OFFERS THIS WARRANTY IN LIEU OF ALL OTHER EXPRESS

In order to obtain service under this warranty, it is the responsibility of the WARRANTIES. ANY WARRANTY IMPLIED BY LAW INCLUDING WAR-

purchaser to promptly notify the local Taco stocking distributor or Taco in RANTIES OF MERCHANTABILITY OR FITNESS IS IN EFFECT ONLY

writing and promptly deliver the subject product or part, delivery prepaid, to FOR THE DURATION OF THE EXPRESS WARRANTY SET FORTH IN

the stocking distributor. For assistance on warranty returns, the purchaser THE FIRST PARAGRAPH ABOVE.

may either contact the local Taco stocking distributor or Taco. If the subject THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRAN-

product or part contains no defect as covered in this warranty, the purchaser TIES, EXPRESS OR STATUTORY, OR ANY OTHER WARRANTY OBLI-

will be billed for parts and labor charges in effect at time of factory exam- GATION ON THE PART OF TACO.

ination and repair.

TACO WILL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, INDI-

Any Taco product or part not installed or operated in conformity with Taco RECT OR CONSEQUENTIAL DAMAGES RESULTING FROM THE USE

instructions or which has been subject to misuse, misapplication, the addi- OF ITS PRODUCTS OR ANY INCIDENTAL COSTS OF REMOVING OR

tion of petroleum based fluids or certain chemical additives to the systems, REPLACING DEFECTIVE PRODUCTS.

or other abuse, will not be covered by this warranty.

This warranty gives the purchaser specific rights, and the purchaser may

If in doubt as to whether a particular substance is suitable for use with a have other rights which vary from state to state. Some states do not allow

Taco product or part, or for any application restrictions, consult the limitations on how long an implied warranty lasts or on the exclusion of in-

applicable Taco instruction sheets or contact Taco at [401-942-8000]. cidental or consequential damages, so these limitations or exclusions may

Taco reserves the right to provide replacement products and parts which not apply to you.

are substantially similar in design and functionally equivalent to the defec-

A Taco Family Company

2022

You might also like

- QSC gx7 Rev.d Power Amplifier SCH PDFDocument3 pagesQSC gx7 Rev.d Power Amplifier SCH PDFchris peters100% (3)

- Fre CD 1SNP300190-0200 A1Document1 pageFre CD 1SNP300190-0200 A1luisNo ratings yet

- Amg CHN Temp Da1058Document1 pageAmg CHN Temp Da1058Rahul RajanbabuNo ratings yet

- Delivery Inspection Sheet: (Qa - Section)Document2 pagesDelivery Inspection Sheet: (Qa - Section)EndraNo ratings yet

- Fm-200 Component Description: Cylinder and Valve Assembly 350 LB (158.7 KG) CapacityDocument1 pageFm-200 Component Description: Cylinder and Valve Assembly 350 LB (158.7 KG) Capacityhendrik wibowoNo ratings yet

- Fre CD 1SNP300190-0300 A1Document1 pageFre CD 1SNP300190-0300 A1luisNo ratings yet

- Fm-200 Component Description: Cylinder and Valve Assembly 125 LB (56.7 KG) CapacityDocument1 pageFm-200 Component Description: Cylinder and Valve Assembly 125 LB (56.7 KG) Capacityhendrik wibowoNo ratings yet

- 10-2047 FDDocument52 pages10-2047 FDvinodNo ratings yet

- Easy & Jane Warehouse - 07142022Document14 pagesEasy & Jane Warehouse - 07142022Yong TonghannNo ratings yet

- AD790-A-700-Coordination Drawing - GF 12.12-A700 Part-2Document1 pageAD790-A-700-Coordination Drawing - GF 12.12-A700 Part-2noufal rafiNo ratings yet

- SD-FXI-002 Chamber Sizes and Reinforcing details-TYPE - 4Document1 pageSD-FXI-002 Chamber Sizes and Reinforcing details-TYPE - 4Ali MustafaNo ratings yet

- Footbrakevalve PDFDocument4 pagesFootbrakevalve PDFJason KozminskaNo ratings yet

- Drawing Title Design General NotesDocument25 pagesDrawing Title Design General NotesSaid Ahmed Salem100% (1)

- Description Rev. CHKD Date BYDocument2 pagesDescription Rev. CHKD Date BYsime58No ratings yet

- Gd2.01 Wardrobe DetailDocument4 pagesGd2.01 Wardrobe DetailDeo IvirgaNo ratings yet

- File 1326132307Document1 pageFile 1326132307Rodrigo KrammNo ratings yet

- 1 1 1 027 Evaporator 027-0 Consentrator WT Storage 027-0-41 Firing and Heavy Liquor TanksDocument11 pages1 1 1 027 Evaporator 027-0 Consentrator WT Storage 027-0-41 Firing and Heavy Liquor TanksCarlos Mauricio Guzman ArayaNo ratings yet

- Instruction Manual: Overcurrent Relay Be1-50/51BDocument59 pagesInstruction Manual: Overcurrent Relay Be1-50/51Bandi irawanNo ratings yet

- S S S S: Refer To Sheet Gr-Sl-02 Refer To Sheet Gr-Sl-02 Refer To Sheet Gr-Sl-02 Refer To Sheet Gr-Sl-02Document1 pageS S S S: Refer To Sheet Gr-Sl-02 Refer To Sheet Gr-Sl-02 Refer To Sheet Gr-Sl-02 Refer To Sheet Gr-Sl-02نصر عبدالسلامNo ratings yet

- Py 712 01978 - 0Document1 pagePy 712 01978 - 0Jay ReyesNo ratings yet

- ChemgebraDocument32 pagesChemgebraayazNo ratings yet

- Ei Ad 2 Eidw 24-38 enDocument2 pagesEi Ad 2 Eidw 24-38 enBAO LU GIANo ratings yet

- Exp 4 Cyl Valve Rotative 09 04 11Document4 pagesExp 4 Cyl Valve Rotative 09 04 11Lucas BonilhaNo ratings yet

- 2100 S 40533 - 0 PDFDocument1 page2100 S 40533 - 0 PDFstefano.herradaNo ratings yet

- Ul 2020-07-16-Ex15258-Ex4141, s25, s45, s55, s145 - 400531Document2 pagesUl 2020-07-16-Ex15258-Ex4141, s25, s45, s55, s145 - 400531OETINCA OETINCANo ratings yet

- 2100 S 40535 - 0 PDFDocument1 page2100 S 40535 - 0 PDFstefano.herradaNo ratings yet

- NMR 602 PKGDocument163 pagesNMR 602 PKGRene HebaNo ratings yet

- Platform Karantina Tahap 1Document1 pagePlatform Karantina Tahap 1Gilang WijayaNo ratings yet

- Billymoon House DEDDocument76 pagesBillymoon House DEDagung dwiantaraNo ratings yet

- FILTROS Baldwin Product GuideDocument860 pagesFILTROS Baldwin Product GuideRodolfo LeonNo ratings yet

- Installation Details of Sidewall Elevation SD-009Document1 pageInstallation Details of Sidewall Elevation SD-009John Dave BOSEngineeringNo ratings yet

- Vertical Slide Valve 1-09-03 01Document7 pagesVertical Slide Valve 1-09-03 01Monglafru MogNo ratings yet

- ELEV. +/-6201 ELEV. +/ - 6101: A-001.G Detail Side View Pev-250Document1 pageELEV. +/-6201 ELEV. +/ - 6101: A-001.G Detail Side View Pev-250herri christantoNo ratings yet

- Serviceable: ComponentDocument1 pageServiceable: ComponentFemi AgbanaNo ratings yet

- Detail 02 Eave Gutter With Protruding Roof Detail 01-A Ridge Detail Saddle RoofDocument1 pageDetail 02 Eave Gutter With Protruding Roof Detail 01-A Ridge Detail Saddle Roofmin miniNo ratings yet

- 55e FDS 1741Document14 pages55e FDS 1741Enrique PinedaNo ratings yet

- XAL-53 Explosion Proof Pull Station PDFDocument2 pagesXAL-53 Explosion Proof Pull Station PDFSANTONo ratings yet

- XAL-53 Explosion Proof Pull StationDocument2 pagesXAL-53 Explosion Proof Pull StationRICHI0% (1)

- GC 1Document1 pageGC 1Karthik NNo ratings yet

- PhasesDocument55 pagesPhasesJunior Rojas PerezNo ratings yet

- WC 1Document1 pageWC 1Karthik NNo ratings yet

- Purchase Specification Group: VFD Engineering A4 - 12: Page 00 of 24Document46 pagesPurchase Specification Group: VFD Engineering A4 - 12: Page 00 of 24kajale.shrikantNo ratings yet

- D113R1202 DRW07 PDFDocument1 pageD113R1202 DRW07 PDFSP6H-18 Yap JRNo ratings yet

- Canadian Solar Datasheet BiHiKu6 CS6Y MB AG v1.1 enDocument2 pagesCanadian Solar Datasheet BiHiKu6 CS6Y MB AG v1.1 enviagi81No ratings yet

- Service ManualDocument3 pagesService Manualyomismooo32No ratings yet

- Drawing MDB SMDB PDFDocument32 pagesDrawing MDB SMDB PDFjaimonjoyNo ratings yet

- Gd2.08 Dado DetailDocument3 pagesGd2.08 Dado DetailDeo IvirgaNo ratings yet

- Issued For Construction: Panel MV UnigearDocument4 pagesIssued For Construction: Panel MV UnigearIrfan MaulanaNo ratings yet

- Shop Drawing Submittal: Project: Project No. Client: Consultant: Contractor: 20-373-DS-ARC-PE-21Document129 pagesShop Drawing Submittal: Project: Project No. Client: Consultant: Contractor: 20-373-DS-ARC-PE-21Ernest NavarroNo ratings yet

- Assembly Instructions For Cable Gland: 121 Industrial General PurposeDocument2 pagesAssembly Instructions For Cable Gland: 121 Industrial General PurposerhomadonaNo ratings yet

- A' F Legends & Abbreviations: Description SymbolDocument1 pageA' F Legends & Abbreviations: Description SymbolGANESHNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Isolated Inverter Platform (Enhanced Protection) : 1NST2 1NST2 1NST2Document7 pagesIsolated Inverter Platform (Enhanced Protection) : 1NST2 1NST2 1NST2Ehsan HabibNo ratings yet

- Cascade 55F-FDS-B221R0Document14 pagesCascade 55F-FDS-B221R0garaguainamo11No ratings yet

- SR200 Electrical PDFDocument5 pagesSR200 Electrical PDFAnonymous Hd32bhq100% (4)

- La B843PDocument102 pagesLa B843PAgus ApriyantoNo ratings yet

- Oil Tank Metering: GIS - Insulation Is Sf6 Gas Oil Tank Hermetically SealedDocument1 pageOil Tank Metering: GIS - Insulation Is Sf6 Gas Oil Tank Hermetically SealedMahyar MashayekhiNo ratings yet

- 4.FSD C22048 Ele 101Document1 page4.FSD C22048 Ele 101mhazarath murariNo ratings yet

- Carver Px1450 Px-Series Rev.c AmplifierDocument9 pagesCarver Px1450 Px-Series Rev.c Amplifieradrianvelazquezjarv15No ratings yet

- PowerPoint Presentation+Document12 pagesPowerPoint Presentation+Khlouda HamadaNo ratings yet

- Geography Notes Part 1Document19 pagesGeography Notes Part 1Airfa MNo ratings yet

- Do The Right Thing 1989Document95 pagesDo The Right Thing 1989Juan Carlos Torres LizarazoNo ratings yet

- SilSter168rev2012.02.21 BRN BladDocument2 pagesSilSter168rev2012.02.21 BRN BladBatam CompanyNo ratings yet

- Report - A4 ColourDocument19 pagesReport - A4 ColourrajsedasariNo ratings yet

- vh3373 EnglishDocument12 pagesvh3373 EnglishtonNo ratings yet

- Sohail Ahmed - ResumeDocument5 pagesSohail Ahmed - ResumenomNo ratings yet

- Giz Grey Water Recycling and Reuse 2011Document94 pagesGiz Grey Water Recycling and Reuse 2011v adamNo ratings yet

- Ee Revise With Me Mega Session DetailsDocument7 pagesEe Revise With Me Mega Session DetailsGayatriramanaNo ratings yet

- Mixing: by DR Eng. Kinfe Kassa Arba Minch Institute of Technology Arba Minch University April 2017Document42 pagesMixing: by DR Eng. Kinfe Kassa Arba Minch Institute of Technology Arba Minch University April 2017Belete DestawNo ratings yet

- Iran's Water ResourcesDocument14 pagesIran's Water Resourcesleatishia.0817No ratings yet

- Nelson Mwangi NjihiaDocument9 pagesNelson Mwangi NjihianemwanjiNo ratings yet

- AssignmentDocument9 pagesAssignmentSanjayNo ratings yet

- GW - Paper On Evaluation of GWDocument24 pagesGW - Paper On Evaluation of GWershadNo ratings yet

- MEP Drawing List - KalalgodaDocument2 pagesMEP Drawing List - KalalgodasarangaNo ratings yet

- Bereket Jilo Thesis Proposal 2023Document49 pagesBereket Jilo Thesis Proposal 2023labemanza03No ratings yet

- Project Work of ChemistryDocument14 pagesProject Work of ChemistryBipul RazzNo ratings yet

- A1Document1 pageA1Mark Allan RojoNo ratings yet

- Assessment of Urban Storm Water Drainage System Using StormDocument106 pagesAssessment of Urban Storm Water Drainage System Using Stormchalie mollaNo ratings yet

- Performance of Irrigation: An Assessment at Different Scales in EthiopiaDocument14 pagesPerformance of Irrigation: An Assessment at Different Scales in Ethiopiahabtamu fentaNo ratings yet

- Section I. Demographic Questions: Section II. Drinking WaterDocument4 pagesSection I. Demographic Questions: Section II. Drinking WaterKurt NicolasNo ratings yet

- Bilge and Ballast System Layout - Procedure For Ship Service SystemsDocument5 pagesBilge and Ballast System Layout - Procedure For Ship Service SystemsharimecNo ratings yet

- Executed WorksDocument3 pagesExecuted WorksDevendra ChandakNo ratings yet

- Project Report PRJ00026570Document5 pagesProject Report PRJ00026570SanamNo ratings yet

- Hydraulic Machines MR Raman GahlautDocument44 pagesHydraulic Machines MR Raman GahlautEyob AdNo ratings yet

- RS606 TB0066-02Document2 pagesRS606 TB0066-02Sebiha Mohamed LamineNo ratings yet

- Comprehensive Development Plan (CDP) Map For Berhampur Development Plan Area (BDPA)Document97 pagesComprehensive Development Plan (CDP) Map For Berhampur Development Plan Area (BDPA)Sweety MohantyNo ratings yet

- Dam Break Analysis of Mullaperiyar Dam Using HEC-RASDocument8 pagesDam Break Analysis of Mullaperiyar Dam Using HEC-RASIJRASETPublicationsNo ratings yet

- Foundations Summer 2023 FinalDocument44 pagesFoundations Summer 2023 Finalmarcoaieta1951No ratings yet

- BLD307 Newly CompiledDocument85 pagesBLD307 Newly CompiledAbdulazeez Habeebllah OlaitanNo ratings yet