Professional Documents

Culture Documents

Structural Drawings

Structural Drawings

Uploaded by

erniE抖音 AI Mobile Phone Based MovieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Drawings

Structural Drawings

Uploaded by

erniE抖音 AI Mobile Phone Based MovieCopyright:

Available Formats

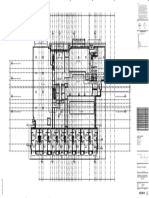

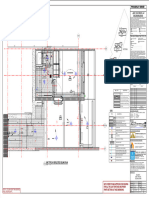

General Notes:

1. USE ONLY FIGURED DIMENSIONS. All dimensions in mm's. Refer to Architect's drawings for

setting out. This drawing is to be read in conjunction with all relevant Architects, subcontractors and

engineers drawings and specifications. Final co-ordination of cladding, drainage, insulation, steelwork,

and other elements is the responsibility of the contractor.

2. All dimensions and levels shown are based on survey drawings. The contractor is to satisfy

themselves that dimensions levels etc are sufficiently accurate to complete construction to the

necessary tolerances. Existing structure to be verified on site by the contractor and any discrepancies

reported immediately to Engineer.

3. Where applicable the contractor is to notify the local H.S.E. area office of the works using form

F10 (rev.) in accordance with the C.D.M. regulations, 2015. A copy of the notification is to be displayed

on site and copied to the Engineer. The client must appoint the Principal Designer and Principal

Contractor and comply with CDM Regulations for all projects: PLAN SE are not the Principal Designer.

The Client must ensure that the Principal Designer issues the Health and Safety File at tender stage,

The Contractor must have a Construction Phase Plan in Place prior to beginning works.

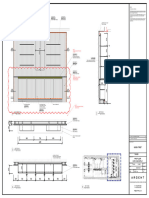

4. Imposed load design to BS6399; Typical Domestic 1.5kN/m²

5. Concrete to be in accordance with BS8110. Concrete for mass concrete foundations to be To FND

3 in accordance with BS8500 (minimum strength 35N/mm², 20mm maximum aggregate size, 75mm

slump and ordinary Portland Cement). Reinforced concrete to be RC28/35 min (previous designation

C35N/mm²) unless noted otherwise.Minimum Cement contents 320kg/m3, Water cement ratio 0.55.2

Cubes to be taken for every 10m3, or every pour, and 1 tested at 28 days with the results provided to

the engineer.

2

(SP-01)

(SP-01)

2No. 50x200

500x100x140 6. Structural steelwork to be in accordance with ADVANCED275JR internally , for high grade steel

C24 Floor Joists

MC Padstone use ADVANCED355JR internally. BS5950 for design detail and workmanship. Steelwork must be

fabricated in accordance with BS EN 1090. Fabricated Steelwork must be provided with a CE Mark,

FPC, RWC and WQMS. All structural work and fire protection to the satisfaction of the Building Control

Officer.

C24 Floor Joists

7. All Steel to be painted: prepared by grit blasting in accordance with BS7079, the standard of

2No. 50x200

Existing wall to surface cleanliness is to Swedish Standard SA2.5. Paint specification to be in accordance with

be removed BS5493. In shop applied high build Red zinc phosphate modified alkyd, to 75 microns. On site,

degrease and touch up as necessary using high build zinc phosphate modified alkyd to 60 microns.

Thicknesses are dry film thicknesses. Steelwork built into cavity to be galvanised inaccordance to EN

ISO 1461 with a minimum 85μm thickness. Site repairs to galvanising to be completed with Cold

2

Galvafroid or similar. Concrete Encased steelwork to have 2 additional site coats of bitumen paint.

(SP-01)

8. Unless noted otherwise, steelwork welds to be minimum 6mm fillet weld, all bolts to be grade 8.8

with minimum 16mm diameter. Overall lengths & Connection design is the responsibility of the

152x152x37 UKC

contractor and details where shown are indicative. Where loads are shown on the drawings, V =

Beam 1.6:

New stud wall Factored Shear loads, M = Factored Moments. Connection Calculations & Fabrication details are to be

Span of provided by fabricator to the Engineer prior to fabrication for connection approval and to the Architect

Assumed span

existing joists for setting out approval. Minimum 2M16 per connection and take 75kN tie force, 80kN shear unless

of existing joists

Staircase TBC noted otherwise. Bolt all double beams together with M16 at 600c/c with Spacer tubes. Where

Chimney to be TBC

TBC on site columns sit against masonry bolt back with M16 Resin Anchors at 450c/c staggered either side of

removed flange. Welding to comply with BS EN 288. Site welding if essential to be tested in accordance with

Beam 0.1: 254x254UKC89 the national steelwork specification and results provided to the engineer.

M=50kNm

encased in 100 thick V=130kN Beam 1.1: 254x254UKC89

concrete with D49 wire mesh 9. Contractor MUST provide fabrication drawings & connection calculations to the engineers two

weeks prior to fabrication for approval, final appearance to be agreed with the architect.

(galvanized)

M=50kNm

C3 Column: C3 Column: V=170kN New 50x200 10. Structural timber to be strength class C24, unless noted otherwise, in accordance with BS5268.

C3 Column All double & multiple timbers to be bolted with M10 at450c/c. All new timber in works to be tanalised

203x203x60UKC 203x203x60UKC C24 @300

New wall fully below New wall fully with cut ends treated before fixing. New timber connections to have proprietary galvanised steel fixings.

Joists

Beam 1.3: 254x254UKC89

furfixed into furfixed into Timber to masonry connections by joist hangers unless shown otherwise. Noggings, minimum 38mm

Existing pipe TBC C3 Column width to extend at least 1/2 the depth of the joist, spaced at 1/3 points along joist span.

existing existing 2No.

on site below 2No.

150mm Allow for Bridge valley

timb.trimmers 11. Double up timber joists under all new partition walls and velux windows.

deep Beam over foundation Assumed span rafters

& Block floor detail of existing joists 12. Masonry to be in accordance with BS5628, Class (ii) above DPC and Class (i) ot be used below

TBC Assumed span

1 SP-01 1 1 SP-01 1 1 SP-01 1 DPC's and to chimneys. New brickwork to be carefully bonded to existing. Block bonding is not

by others

SP-01 SP-01 SP-01

Rooflight

of existing joists permitted for exposed masonry brickwork. Block contraction joints required at 6m c/c and brickwork

Existing wall to TBC expansion joints at 12m c/c. Where existing new masonry meets existing masonry stainless steel furfix

be removed 2No. 140x100mm

connections are required. Provide stainless steel EML Bed joint reinforcement two course (150 and

Precast lintels 300 spacing) above and below all new window and door openings. Below DPCS, all masony to the

C1 Column: C1 Column Cranked C1 Column

C1 Column: Frost resistant. Block work below DPC to be sulphate resistant.

203x203x60UKC below point below New 50x150

203x203x60UKC

2No. timb.trimmers C24 @300 13. Padstones, required under all new beam bearing onto masonry, to be 1:1.5:3 mix, (C30). Or PC

Beam 1.2: 254x254UKC89

(To be confirmed by Building

M=60kNm Joists Lintels if noted. 15mm thick Plate can be used with engineers approval.

600mm wide MC footing

founded 1000 mm b.g.l.

V=120kN

Beam 0.2: 254x254UKC89 M=60kNm 14. Dry packing to be to be 2:1 Sand:Cement. Beams over 5m and to all underpins Dry pack to

encased in 100 thick V=120kN contain Fosroc CBex 100. Dry pack to be well rammed in. 48 hours to be left from drypacking to

by others

Rooflight

concrete with D49 wire mesh removal of any temporary supports.

Control)

Beam 1.4: 178x102x19UKB

3No. timber trimmers

(galvanized)

Existing foundations TBC

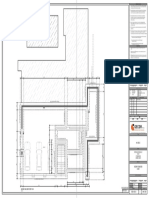

15. The main contractor is to be responsible for the temporary stability of existing structures and

earthworks on the site and adjoining sites, and must take all necessary precautions to safeguard this

3No. timber trimmers

stability. Details of propping/needling, with supporting calculations completed by a suitability qualified

Existing wall to person & method statement to be provided to Engineer prior to commencing works for approval. All

Existing wall Rooflight

be removed 2No. timb.trimmers needles to be design for Span/500 vertically deflection and height over 750 horizontal deflections. All

by others

props to be founded on firm good bearing strata. The contractor should undertake on site jacking of

150mm beams over 6m inserted into existing structures.

by others

deep Beam

Rooflight

16. Existing lintels to be inspected and replaced if showing signs of deterioration.

& Block floor

New 50x200

M=10kNm M=20kNm 17. Existing masonry to be inspected. Where cracked or debonded, repairs are as specified. If repairs

C2 Column: C24 @300

V=15kN V=40kN are not specified contact the engineer. Existing walls to be checked for lateral restraint. If restraint is

150x100x10RHS Beam 1.5: 203x133x25UKB Joists

Existing foundations TBC inadequate provide lateral restraint.

with 8mm bottom plate 2No. timb.trimmers

18. Provide Lateral Restraint straps (1200x30x3) at 1200centres to floors and roof. Provide Holding

Down straps (1200x30x3) at 1200centres roof sole plate.

C2 Column: 600mm wide MC footing C2 Column C2 Column

(SP-10)

(SP-10)

(SP-10)

150x100x10RHS founded 1000 mm b.g.l. below below 19. Use Ancon ST1 Wall ties for new cavity over 75mm. Fix at standard spacing. Less than 75mm

(To be confirmed by Building cavity standard wall ties to be used.

Control)

2

2

ALLOW FOR PILED FOOTING IN CASE OF CLAY

SOIL AND NEARBY TREE. TBC BY CONTRACTOR

AND AGREED WITH BCO.

Beam 1.3

Beam 1.2 Beam 1.1

Beam 1.5 Level TBC on site Level TBC on site - First issue for comments EM 01-09-22

due to existing joists due to staircase

Existing wall to be

removed

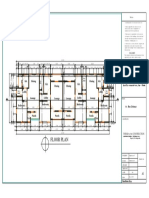

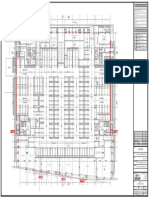

PLAN Structural Engineers

info@planse.co.uk

Existing concrete Existing floor to be

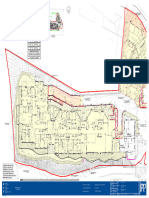

CLIENT:

lowered. TBC on site

slab TBC Thomas

Existing slab

New Beam&Block

floor SITE:

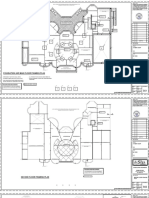

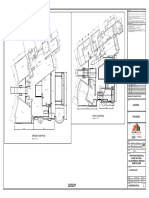

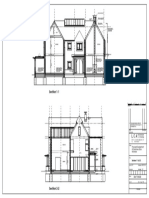

SECTION 1-1 SECTION 2-2 126 Astonville Street

New strip TITLE:

Existing footing Existing footing New strip Existing footing

TBC TBC foundations

foundations

TBC Plans & Sections

Existing footing

FLOOR PLAN TBC

SCALE AT A1: DATE: DRAWN: CHECKED:

SCALE 1:50

1:50 01/09/22 EM FA

PROJECT NO: DRAWING NO: REVISION:

0 1 2 3 4 5

2207 SP-01 -

You might also like

- Restaurant Floor Plan (1st Floor)Document1 pageRestaurant Floor Plan (1st Floor)Ma. Isabel RodriguezNo ratings yet

- Timboon Housing Estate PlansDocument17 pagesTimboon Housing Estate PlansKyra GillespieNo ratings yet

- Face Milling CalculationsDocument7 pagesFace Milling CalculationsShan PinNo ratings yet

- Manning Table: Position Title 1 Shift 2 Shift 3 Shift Total Areas Assigned RemarksDocument5 pagesManning Table: Position Title 1 Shift 2 Shift 3 Shift Total Areas Assigned RemarksSherelyn De Leon TolentinoNo ratings yet

- Hs CD 23 00187-Landscpe Layout 2 of 4 - 946589Document1 pageHs CD 23 00187-Landscpe Layout 2 of 4 - 946589api-193778159No ratings yet

- Vivekanand Education Society's College of Architecture: NotesDocument1 pageVivekanand Education Society's College of Architecture: NotesKalpak SurveNo ratings yet

- Stairs For Review - 100536Document1 pageStairs For Review - 100536Owori GeoffreyNo ratings yet

- Res-E02-2202-S-1002 Ground Floor Framing PlanDocument1 pageRes-E02-2202-S-1002 Ground Floor Framing PlanNowshath AliNo ratings yet

- Res-E02-2202-S-1003 1ST Floor Framing PlanDocument1 pageRes-E02-2202-S-1003 1ST Floor Framing PlanNowshath AliNo ratings yet

- PR A TD MLCP FP 201 Basement 2Document1 pagePR A TD MLCP FP 201 Basement 2shaikhtauqeir749No ratings yet

- Van Eden House Plan - Catchment AreaDocument1 pageVan Eden House Plan - Catchment Areadalubuhlencube12345No ratings yet

- Adp-Ksa-Sol-Dwg-El-Td-Det-412 - Stair 1 DetailDocument1 pageAdp-Ksa-Sol-Dwg-El-Td-Det-412 - Stair 1 Detailekhaa.awal1No ratings yet

- Second Floor RCP - R1-Second Floor RCPDocument1 pageSecond Floor RCP - R1-Second Floor RCPIshteyak AlamNo ratings yet

- Floor Plan: Kit. Kit. Dining Dining Lobby Lounge Lounge Bedroom Bedroom Kit. Kit. Dining Dining LobbyDocument1 pageFloor Plan: Kit. Kit. Dining Dining Lobby Lounge Lounge Bedroom Bedroom Kit. Kit. Dining Dining Lobbyamadi4bizNo ratings yet

- Mwaura 03 - 19 Sheet 1Document1 pageMwaura 03 - 19 Sheet 1alexNo ratings yet

- POWERDocument3 pagesPOWERanish.mohanNo ratings yet

- Restaurant Floor Plan 1st Floor - CompressDocument2 pagesRestaurant Floor Plan 1st Floor - CompressCyrus De LeonNo ratings yet

- B14 L3A & 3B Carpark Steel & Perimeter Columns PDFDocument1 pageB14 L3A & 3B Carpark Steel & Perimeter Columns PDFPeter ThomsonNo ratings yet

- Amc Ksa Gam DWG Me CD 5101Document1 pageAmc Ksa Gam DWG Me CD 5101Dan SarmientoNo ratings yet

- Adp-Ksa-Sol-Dwg-El-Td-Det-411 - Railing DetailDocument1 pageAdp-Ksa-Sol-Dwg-El-Td-Det-411 - Railing Detailekhaa.awal1No ratings yet

- 2021 09 20 Garden Mall - A1.02-Plan MezzanineDocument1 page2021 09 20 Garden Mall - A1.02-Plan MezzanineDan SarmientoNo ratings yet

- Electrical Work KeshoDocument1 pageElectrical Work Keshosngunjiri60No ratings yet

- A01.02-D - Assembly ScheduleDocument1 pageA01.02-D - Assembly ScheduleAakanksha Pandit SharmaNo ratings yet

- 05 First FloorDocument1 page05 First FloorAbu Baker DajahNo ratings yet

- HU Hotel Room PDFDocument21 pagesHU Hotel Room PDFshruti00567No ratings yet

- Royale Option 3Document1 pageRoyale Option 3Edmore MukotsanjeraNo ratings yet

- A02.14-D - Overall Floor Plan - Roof PlanDocument1 pageA02.14-D - Overall Floor Plan - Roof PlanAakanksha Pandit SharmaNo ratings yet

- Kanyekanye KZN - School - 2024 - 0112 - Sheet - A103 - Platform 3 - LayoutDocument1 pageKanyekanye KZN - School - 2024 - 0112 - Sheet - A103 - Platform 3 - LayoutTafadzwa MareyaNo ratings yet

- 2021 09 20 Garden Mall-A10.04-Typical Details - ScreenDocument1 page2021 09 20 Garden Mall-A10.04-Typical Details - ScreenDan SarmientoNo ratings yet

- BA BA' BB BC BD BE BF BG BH BJ BK BL BM BN BP BQ BR: General NotesDocument1 pageBA BA' BB BC BD BE BF BG BH BJ BK BL BM BN BP BQ BR: General NotesAditya HegdeNo ratings yet

- Res-e02-2202-S-1008 Upper Roof Floor Framing PlanDocument1 pageRes-e02-2202-S-1008 Upper Roof Floor Framing PlanNowshath AliNo ratings yet

- Res-e02-2202-S-1008 Upper Roof Floor Framing PlanDocument1 pageRes-e02-2202-S-1008 Upper Roof Floor Framing PlanNowshath AliNo ratings yet

- 6QS Id (26) 1 02Document1 page6QS Id (26) 1 02amirice70No ratings yet

- BeamsDocument1 pageBeamsamanyaNo ratings yet

- 00 Basement Foundation LayoutDocument1 page00 Basement Foundation LayoutrendaninNo ratings yet

- Laxcon Developments: Cardiff 029 2052 8140 London 0207 138 3560 Wrexham 01978 357 887 WWW - Lawray.co - UkDocument1 pageLaxcon Developments: Cardiff 029 2052 8140 London 0207 138 3560 Wrexham 01978 357 887 WWW - Lawray.co - Ukrajen raghwaniNo ratings yet

- A02.05-D - Overall Floor Plan - Mech. Mezzanine & TH LVL 02Document1 pageA02.05-D - Overall Floor Plan - Mech. Mezzanine & TH LVL 02Aakanksha Pandit SharmaNo ratings yet

- A02.10-D - Overall Floor Plan - Level 07Document1 pageA02.10-D - Overall Floor Plan - Level 07Aakanksha Pandit SharmaNo ratings yet

- Structural Drawings 10 Kenny CT - 20240308 StructureDocument5 pagesStructural Drawings 10 Kenny CT - 20240308 StructuretigzzlopesNo ratings yet

- Specs 1Document1 pageSpecs 1mohammedpetiwalaNo ratings yet

- Context Plan: 55 Charles Street EastDocument1 pageContext Plan: 55 Charles Street EastCassie MillerNo ratings yet

- FS0654-DOD-XX-00-DR-P-4002 - Ground Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-00-DR-P-4002 - Ground Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

- FS0654-DOD-XX-00-DR-P-4001 - Ground Floor Domestic Water Services Sheet 1 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-00-DR-P-4001 - Ground Floor Domestic Water Services Sheet 1 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

- Lobby Floor Plan (Ground)Document1 pageLobby Floor Plan (Ground)Ma. Isabel RodriguezNo ratings yet

- Pdch14-Gaj-Dwg-000-Xxx-Arc-31701-Pdf (T00) - Aluminium Louver Door Screen Typical DetailsDocument1 pagePdch14-Gaj-Dwg-000-Xxx-Arc-31701-Pdf (T00) - Aluminium Louver Door Screen Typical DetailsZaido Al HalabiNo ratings yet

- Basement 4 1:150: Lettabe Area Usable Decks & Terrace Common InfrastructureDocument12 pagesBasement 4 1:150: Lettabe Area Usable Decks & Terrace Common InfrastructureKay EMNo ratings yet

- St-Nerf-20 Basement Floor PlanDocument1 pageSt-Nerf-20 Basement Floor Planmhazarath murariNo ratings yet

- Layout and Details of Structural Modification in LPG Filling YardDocument1 pageLayout and Details of Structural Modification in LPG Filling Yardiscco isccoNo ratings yet

- First Floor Plan - Joy GalleryDocument1 pageFirst Floor Plan - Joy Gallerysushil aroraNo ratings yet

- Van Eden House Plan - Floor PlansDocument1 pageVan Eden House Plan - Floor Plansdalubuhlencube12345No ratings yet

- 9946Z - 0657-SP-SL-PL-C-G20-001 (P3) - Proposed Levels Plan (Sheet 1 of 2)Document1 page9946Z - 0657-SP-SL-PL-C-G20-001 (P3) - Proposed Levels Plan (Sheet 1 of 2)jmdavies.isNo ratings yet

- Iten Arch 17 10 2023Document15 pagesIten Arch 17 10 2023SAMUEL MUMO KIOKONo ratings yet

- Ras-Albar Hospital Ga Plan - Operationroom - 02Document1 pageRas-Albar Hospital Ga Plan - Operationroom - 02Hajer AshrafNo ratings yet

- Civil Works CW05 R1 (Submission Drawings 16.03.22)Document1 pageCivil Works CW05 R1 (Submission Drawings 16.03.22)Joel AganNo ratings yet

- Neighbor'S Plot - : Sheet No Rev No R0Document1 pageNeighbor'S Plot - : Sheet No Rev No R0jibeesh cmNo ratings yet

- Harden Zone Mark Up MPSHD Hi Ar DWG A 1601Document1 pageHarden Zone Mark Up MPSHD Hi Ar DWG A 1601Saiful IslamNo ratings yet

- 07 - 11. ITB-2023-45343 VAC Drawing PDFDocument7 pages07 - 11. ITB-2023-45343 VAC Drawing PDFxuseen maxamedNo ratings yet

- Floor Plan and Roof PlanDocument1 pageFloor Plan and Roof PlanAnotida Tuna ManganyeNo ratings yet

- CCDC NTL Ar Una1 RCP 01Document1 pageCCDC NTL Ar Una1 RCP 01ericka.mir401No ratings yet

- Yatta Foundation RevDocument1 pageYatta Foundation RevKevin Lil'Vokez MulimaNo ratings yet

- 2024-04-17 Drawing 00 LocationPlanDocument1 page2024-04-17 Drawing 00 LocationPlanerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- pPYqnlFGTC2UMT6pBejw - 3004-101 Proposed PlansDocument1 pagepPYqnlFGTC2UMT6pBejw - 3004-101 Proposed PlanserniE抖音 AI Mobile Phone Based MovieNo ratings yet

- SEC - TE - 01A - Sections 1 and 2Document1 pageSEC - TE - 01A - Sections 1 and 2erniE抖音 AI Mobile Phone Based MovieNo ratings yet

- XXhQ9jVCQTie08fxmmJW - 3004-001 Existing PlansDocument1 pageXXhQ9jVCQTie08fxmmJW - 3004-001 Existing PlanserniE抖音 AI Mobile Phone Based MovieNo ratings yet

- 2024-04-17 Drawing 01 Full Proposed&AltDocument1 page2024-04-17 Drawing 01 Full Proposed&AlterniE抖音 AI Mobile Phone Based MovieNo ratings yet

- 2023-00-00 Thermal Windpost TWP2 AnconDocument8 pages2023-00-00 Thermal Windpost TWP2 AnconerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Steel Ridge Beam DetailDocument1 pageSteel Ridge Beam DetailerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- 2023-00-00 Uk SuppliersdatabaseDocument40 pages2023-00-00 Uk SuppliersdatabaseerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- 2023-00-00 Channel Bolt Fixings AnconDocument20 pages2023-00-00 Channel Bolt Fixings AnconerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- 2023-07-15 StructuralDrawingsDocument1 page2023-07-15 StructuralDrawingserniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Structural DrawingsDocument1 pageStructural DrawingserniE抖音 AI Mobile Phone Based MovieNo ratings yet

- StructuralDrawings - (2) - Calcs#1Document52 pagesStructuralDrawings - (2) - Calcs#1erniE抖音 AI Mobile Phone Based MovieNo ratings yet

- ELE - TE - 02B - Side ElevationsDocument1 pageELE - TE - 02B - Side ElevationserniE抖音 AI Mobile Phone Based MovieNo ratings yet

- 2018-00-00 - BarnConversion - Structural SurveyDocument18 pages2018-00-00 - BarnConversion - Structural SurveyerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- JacksonChan SampleDocument1 pageJacksonChan SampleerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- David SharpeDocument9 pagesDavid SharpeerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Purlins Hiprafters OldProjectDocument1 pagePurlins Hiprafters OldProjecterniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Fatma Mohamed Mohamed - Research 2Document1 pageFatma Mohamed Mohamed - Research 2Fatma MHNo ratings yet

- Types of RaftersDocument3 pagesTypes of RaftersJeriza AquinoNo ratings yet

- Jumbo Firewall 63/120: System: Brand: Thickness: Fire PropertiesDocument1 pageJumbo Firewall 63/120: System: Brand: Thickness: Fire PropertiesWaltonNo ratings yet

- Milling Presentation (2010)Document42 pagesMilling Presentation (2010)meseraabdiNo ratings yet

- CNC G Codes and M Codes - 9-4-24Document4 pagesCNC G Codes and M Codes - 9-4-24Dr RAMESH KUMAR ANo ratings yet

- 02 Epl Lab Manual - 2017-18Document93 pages02 Epl Lab Manual - 2017-18jvanandhNo ratings yet

- ShopNotes Issue 42 PDFDocument32 pagesShopNotes Issue 42 PDFbenigno100% (1)

- Detail Ukuran Aktual Kamar No.2119 (Dengan Balkon)Document1 pageDetail Ukuran Aktual Kamar No.2119 (Dengan Balkon)Arkaan PerbawaNo ratings yet

- 112 - Dwi Rizky Rosilila - UNIT3 - EssayDocument11 pages112 - Dwi Rizky Rosilila - UNIT3 - EssayDwi Rizky RosililaNo ratings yet

- Easy Outdoor Sofa From 2x4s and Two Power ToolsDocument8 pagesEasy Outdoor Sofa From 2x4s and Two Power ToolsGustavo Eduardo Romero CamarenaNo ratings yet

- M18CCS66 Product ManualDocument12 pagesM18CCS66 Product Manualcbturtle10No ratings yet

- Hand Arm Vibration ChartDocument2 pagesHand Arm Vibration ChartSophie-Louise MercedesNo ratings yet

- Architect Philippines - English - Tagalog Construction TermsDocument3 pagesArchitect Philippines - English - Tagalog Construction TermsJohn Rae R. DomingoNo ratings yet

- Homemade Wood Lathe: InstructablesDocument10 pagesHomemade Wood Lathe: InstructablesBruno MirandaNo ratings yet

- Design Elements RoofDocument2 pagesDesign Elements Roofcrizel100% (1)

- Tsugami B0125-126 Mark III Focus Brochure-3Document5 pagesTsugami B0125-126 Mark III Focus Brochure-3Hermansyah EmirNo ratings yet

- Newland WPC CatalogueDocument11 pagesNewland WPC CatalogueRaven VergaraNo ratings yet

- 28sqm Scheme 3 ModelsDocument16 pages28sqm Scheme 3 ModelsNico CiprianoNo ratings yet

- Using A Dividing HeadDocument12 pagesUsing A Dividing HeadQadeer Ishaq0% (1)

- Checklist For Tiles FlooringDocument2 pagesChecklist For Tiles FlooringKishoreNo ratings yet

- Poarr L45Document16 pagesPoarr L45slohariNo ratings yet

- Workshop Technology Chapter 1 Hand ToolsDocument74 pagesWorkshop Technology Chapter 1 Hand ToolsPencil neck75% (8)

- Module 3 - RoofsDocument8 pagesModule 3 - RoofsSreelakshmi G100% (1)

- Formica Pocket Directory 2015 enDocument160 pagesFormica Pocket Directory 2015 enAnonymous JyjVdROGNo ratings yet

- Accomplishment Works With Highlighted Keyplan & PhotosDocument8 pagesAccomplishment Works With Highlighted Keyplan & PhotosChristelle Marie Aquino BeroñaNo ratings yet

- B NG Giá Makita Maktec 2017Document44 pagesB NG Giá Makita Maktec 2017BINH NGUYENNo ratings yet

- B FSRTC BLDG and C and S Works1517Document418 pagesB FSRTC BLDG and C and S Works1517Wan IkkhuwaeNo ratings yet

- Framing - House ConstructionDocument64 pagesFraming - House Construction오상진100% (1)