Professional Documents

Culture Documents

Rweyq-T Refpipsel 4p347465-1a (1) en

Rweyq-T Refpipsel 4p347465-1a (1) en

Uploaded by

Karmeen RamziOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rweyq-T Refpipsel 4p347465-1a (1) en

Rweyq-T Refpipsel 4p347465-1a (1) en

Uploaded by

Karmeen RamziCopyright:

Available Formats

RWEYQ-T

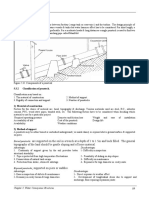

Selection of piping size Example:

Downstream capacity for E=capacity index of unit 1

Determine the proper size referring to following tables and reference Downstream capacity for D=capacity index of unit 1+capacity index of

figure (only for indication). unit 2

Piping between BS unit or refrigerant branch kit and indoor unit: E, G, I

Pipe size for direct connection to indoor unit must be the same as the

B B B connection size of the indoor unit.

a A x C y Piping outer diameter size (mm)

Indoor unit capacity index Suction gas pipe Liquid pipe

D F F

15, 20, 25, 32, 40, 50 12.7 6.4

b 3 3 63, 80, 100, 125 15.9

H I 200 19.1 9.5

c G

250 22.2

E

■ When the equivalent pipe length between outdoor and indoor units

1 2 1 2 1 is 80 m or more, the size of the main liquid pipe must be increased.

1,2 VRV DX indoor unit Depending on the length of the piping, the capacity may drop, but

3 BS unit even in such a case it is possible to increase the size of the main

a,b,c Indoor branch kit pipe.

x,y Multi outdoor unit connection kit

1 2 3 5

INFORMATION

■ In case of heat recovery system:

Use 3 pipes (suction gas, HP/LP gas, liquid). 4

■ In case of heat pump system:

Use 2 pipes (gas and liquid).

In case of gas pipe in heat pump system

Select the piping size in accordance with the suction gas 1 Outdoor unit

piping size. 2 Main pipes

No BS unit can be used in case of heat pump system. 3 Increase only liquid pipe size

4 First refrigerant branch kit

5 Indoor unit

Piping between outdoor unit and (first) refrigerant branch kit: A, B, C Size up

HP Class Liquid size (mm)

Choose from the following table in accordance with the outdoor unit total 8+10 9.5 → 12.7

capacity type, connected downstream. 16 12.7 → 15.9

18+20+24 15.9 → 19.1

Outdoor unit Piping outer diameter size (mm)

26+30 19.1 → 22.2

capacity type

(HP) Suction gas pipe Liquid pipe HP/LP gas pipe

Never increase suction gas pipe and HP/LP gas pipe.

8 19.1 15.9

9.5 ■ The pipe thickness of the refrigerant piping shall comply with the

10 22.2 19.1

applicable legislation. The minimal pipe thickness for R410A piping

16 12.7

28.6 22.2 must be in accordance with the table below.

18+20 15.9

24 Pipe Ø (mm) Minimal thickness t (mm)

34.9 19.1 28.6

26+30 6.4

9.5 0.80

12.7

Piping between refrigerant branch kits: D 15.9 0.99

Piping between refrigerant branch kit and BS unit: F 19.1

0.80

Piping between BS unit and refrigerant branch kit: H 22.2

28.6 0.99

Choose from the following table in accordance with the indoor unit total 34.9 1.21

capacity type, connected downstream. Do not let the connection piping 41.3 1.43

exceed the refrigerant piping size chosen by the general system model name.

■ In case the required pipe sizes (inch sizes) are not available, it is

Indoor unit Piping outer diameter size (mm) also allowed to use other diameters (mm sizes), taken the following

capacity index Suction gas pipe Liquid pipe HP/LP gas pipe into account:

<150 15.9 12.7 - Select the pipe size nearest to the required size.

150≤x<200 19.1 9.5 15.9 - Use the suitable adapters for the change-over from inch

200≤x<290 22.2 to mm pipes (field supply).

19.1

290≤x<420 12.7 In this case, the additional refrigerant calculation has to be adjusted

28.6

420≤x<640 15.9 as mentioned in "Calculating the additional refrigerant charge".

640≤x<920 34.9 28.6

19.1

≥920 41.3

In case of heat pump system (or 2 pipe):

For the gas piping size: select the size of suction gas piping.

4PEN347465-1A(1)

You might also like

- Plumber Practice Interprovincial Red Seal ExamDocument40 pagesPlumber Practice Interprovincial Red Seal ExamNick Genese100% (3)

- Module-3.-RECREATION (Laro NG Lahi) 1Document7 pagesModule-3.-RECREATION (Laro NG Lahi) 1Michael Estela Jr.No ratings yet

- The Use of Fixed Stars in AstrologyDocument319 pagesThe Use of Fixed Stars in AstrologyANTHONY WRITER90% (30)

- Philakone's Cryptocurrency Superstar Trading GuideDocument8 pagesPhilakone's Cryptocurrency Superstar Trading GuideJhol AnthonyNo ratings yet

- Test VRF AermecDocument5 pagesTest VRF Aermecemanuel92No ratings yet

- AC FCU Catalogue April 2017Document12 pagesAC FCU Catalogue April 2017Ong MatNo ratings yet

- Erc 00611 enDocument8 pagesErc 00611 enGaurav MaithilNo ratings yet

- Honeywell BK G1.6 G4Document2 pagesHoneywell BK G1.6 G4Mugywara luNo ratings yet

- Logic 24,30,35Document68 pagesLogic 24,30,35Richard DruryNo ratings yet

- Daikin DCH7 SpecsDocument36 pagesDaikin DCH7 SpecsGian Carlos Gonzales ChaconNo ratings yet

- Reem Takrouri PDF - Results PDFDocument5 pagesReem Takrouri PDF - Results PDFريم تكروريNo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- SHPDDocument32 pagesSHPDManuel Alvarez MNo ratings yet

- RITA - Tanque Cilindrico - Alcalinos Diluidos - SPI - David - LongDocument27 pagesRITA - Tanque Cilindrico - Alcalinos Diluidos - SPI - David - LongRoberto Gomez R.No ratings yet

- Refrigeración y Aire AcondicionadoDocument2 pagesRefrigeración y Aire Acondicionadoluisgabrielbuca2246No ratings yet

- Planta ElectricaDocument32 pagesPlanta ElectricaJulian David GonzalezNo ratings yet

- Submittal Data Sheet PCE4 Series 3fasesDocument2 pagesSubmittal Data Sheet PCE4 Series 3fasesgc.ivan.ekNo ratings yet

- PNGF Rooftop 048 350 R410aDocument32 pagesPNGF Rooftop 048 350 R410aRayhan Sayeed100% (1)

- Kingspan Albion Aerocyl Brochure en GBDocument4 pagesKingspan Albion Aerocyl Brochure en GBGeorge PopaNo ratings yet

- Checklist For Separator Cum Storage TankDocument5 pagesChecklist For Separator Cum Storage TankRamalingam PrabhakaranNo ratings yet

- Daikin Paquete ComercialDocument36 pagesDaikin Paquete ComercialAnderson Marquez PaniaguaNo ratings yet

- 1X660 MW WBPDCL Sagardighi TPP Etn. UNIT-5: Condenser Data SheetDocument2 pages1X660 MW WBPDCL Sagardighi TPP Etn. UNIT-5: Condenser Data SheetAyush ChoudharyNo ratings yet

- R Series 1Document4 pagesR Series 1razak shareefNo ratings yet

- 7Document6 pages7Billie CalasanzNo ratings yet

- DBC Commercial: Base Efficiency AC Packaged Rooftop Unit DBC Commercial 15-25 Nominal TonsDocument36 pagesDBC Commercial: Base Efficiency AC Packaged Rooftop Unit DBC Commercial 15-25 Nominal TonsChin Heng LimNo ratings yet

- Manual TCH-240 PDFDocument7 pagesManual TCH-240 PDFRafael Centeno SantanaNo ratings yet

- Concealed Duct Unit (Slim A5 Type) MCAC-VTSM-2018-12Document22 pagesConcealed Duct Unit (Slim A5 Type) MCAC-VTSM-2018-12aa aaNo ratings yet

- 12.1 Why Finned Tube Heat Exchangers?Document18 pages12.1 Why Finned Tube Heat Exchangers?hortalemosNo ratings yet

- RMM Power Distribution & VFD CalculatorDocument12 pagesRMM Power Distribution & VFD CalculatorReymar BanaagNo ratings yet

- Dis de Lineas de TracingDocument2 pagesDis de Lineas de TracingMario CastilloNo ratings yet

- Mid Static Pressure-DUCTEDDocument29 pagesMid Static Pressure-DUCTEDsyed mustafa aliNo ratings yet

- SS DCC3R9Document40 pagesSS DCC3R9Israel ArceoNo ratings yet

- Elkfr 26 GTN 2 YaDocument33 pagesElkfr 26 GTN 2 YaAmin SantanaNo ratings yet

- 150 MW Reheat LP-A1Document4 pages150 MW Reheat LP-A1DeepikaNo ratings yet

- Centrifugal Horizontal Volute Casing Pumps Series NT According To DIN EN 733Document29 pagesCentrifugal Horizontal Volute Casing Pumps Series NT According To DIN EN 733شادي العزبيNo ratings yet

- Air Cooled Heat Exchanger Design Calculator (Estimation) : To ModifyDocument9 pagesAir Cooled Heat Exchanger Design Calculator (Estimation) : To ModifyBilal BhattiNo ratings yet

- Engineering Data HEC v2.4Document17 pagesEngineering Data HEC v2.4Kim WongNo ratings yet

- MANUAL RESUMIDO DE SERVICIO SMMS Serie 2Document18 pagesMANUAL RESUMIDO DE SERVICIO SMMS Serie 2Marcelo RamirezNo ratings yet

- Sumy Npo Oil Gas Catalog EnglDocument47 pagesSumy Npo Oil Gas Catalog Englرائد عبد العزيز فرحانNo ratings yet

- Suppl.B HPK-L - 1136 - 00 - 03 S2-EN - FinalDocument34 pagesSuppl.B HPK-L - 1136 - 00 - 03 S2-EN - FinalJorge VillalobosNo ratings yet

- Ti Orifice enDocument40 pagesTi Orifice enSuparlanNo ratings yet

- Aux 12K 3star PRNDocument6 pagesAux 12K 3star PRNpm9286vNo ratings yet

- MJ8ae 1.28 27DEC16Document1 pageMJ8ae 1.28 27DEC16Glenn IquinNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument31 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- SBD 6479 WaterCalcWorksheet 01 12Document4 pagesSBD 6479 WaterCalcWorksheet 01 12Avinash SharmaNo ratings yet

- SBD-6479 WaterCalcWorksheet 01-12Document4 pagesSBD-6479 WaterCalcWorksheet 01-12Victor ValenciaNo ratings yet

- SBD 6479 WaterCalcWorksheet 01 12Document4 pagesSBD 6479 WaterCalcWorksheet 01 12NghiaNo ratings yet

- SBD-6479 WaterCalcWorksheet 01-12Document4 pagesSBD-6479 WaterCalcWorksheet 01-12Victor ValenciaNo ratings yet

- CSSP Report 1. Project Informa On: 2.1equipment ListDocument5 pagesCSSP Report 1. Project Informa On: 2.1equipment ListPepes HiuuNo ratings yet

- VRV BSVDocument5 pagesVRV BSVignatiusglenNo ratings yet

- Lennox - KHBDocument40 pagesLennox - KHBtquercy.masterNo ratings yet

- V.R.V Indoor Unit Capacity IndexDocument2 pagesV.R.V Indoor Unit Capacity Indexabdullah100% (2)

- DBC Commercial: Base Efficiency Air Conditioner Belt-Drive Packaged Rooftop Unit DBC Commercial 6 Nominal TonsDocument28 pagesDBC Commercial: Base Efficiency Air Conditioner Belt-Drive Packaged Rooftop Unit DBC Commercial 6 Nominal TonsChin Heng LimNo ratings yet

- PCR SvformDocument5 pagesPCR SvformHendrias A.SNo ratings yet

- GRP Piping - Stress AnalysisDocument5 pagesGRP Piping - Stress Analysisghkashyap1No ratings yet

- ICV008H7O7: 1-Way Cassette Indoor UnitDocument2 pagesICV008H7O7: 1-Way Cassette Indoor UnitCarlosNo ratings yet

- ARUM320LTE5Document2 pagesARUM320LTE5jaimegutierrezlinganNo ratings yet

- 5.3.1 General: 5.3 PenstockDocument8 pages5.3.1 General: 5.3 PenstocklijalemNo ratings yet

- Heat Exchanger Set QuestionDocument3 pagesHeat Exchanger Set QuestionPREETOMDEB7No ratings yet

- Article Fitters Notes 4-Way Valve Part 12Document31 pagesArticle Fitters Notes 4-Way Valve Part 12osama alabsiNo ratings yet

- Wieland Coaxial Heat Exchangers WKC WKEDocument6 pagesWieland Coaxial Heat Exchangers WKC WKElabasom379No ratings yet

- Aspen Exchanger Design and Rating Plate V10: DescriptionDocument10 pagesAspen Exchanger Design and Rating Plate V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Exploring BeagleBone: Tools and Techniques for Building with Embedded LinuxFrom EverandExploring BeagleBone: Tools and Techniques for Building with Embedded LinuxRating: 4 out of 5 stars4/5 (2)

- Himani Bhasin: 4631, Danforth Drive, Richmond, BC V6x2x5 Career ObjectiveDocument4 pagesHimani Bhasin: 4631, Danforth Drive, Richmond, BC V6x2x5 Career ObjectiveCharubhasinNo ratings yet

- 1 Nature and Characteristics of PoliticsDocument36 pages1 Nature and Characteristics of PoliticsHaziq RiduanNo ratings yet

- ISO 3834-6 Documents RequiredDocument3 pagesISO 3834-6 Documents RequiredEdilson SantosNo ratings yet

- High Speed Centrifugal Spray DryerDocument8 pagesHigh Speed Centrifugal Spray DryerHilyaNo ratings yet

- Number PatternDocument14 pagesNumber PatternSolehah Roslan100% (1)

- DME Lecture Notes - Module 1Document37 pagesDME Lecture Notes - Module 1maanwarNo ratings yet

- Instruction ManualDocument462 pagesInstruction ManualCaraluaNo ratings yet

- Extra WorksDocument4 pagesExtra WorksNuwan AththanayakaNo ratings yet

- Aspek Hukum Pada Profesi Akuntan Publik: Wisnu WijayantoDocument16 pagesAspek Hukum Pada Profesi Akuntan Publik: Wisnu WijayantoDettia fitriNo ratings yet

- 183211053-Arynaa Azzahra-Biographical - Historical Criticism, To His Coy MistressDocument3 pages183211053-Arynaa Azzahra-Biographical - Historical Criticism, To His Coy Mistressryn hanakuro33% (3)

- Megashor Metric - Rev H - Email VersionDocument93 pagesMegashor Metric - Rev H - Email VersionEstebanLopezNo ratings yet

- Genral Final With New Questions To READDocument83 pagesGenral Final With New Questions To READRobin HillsonNo ratings yet

- Retention of Removable Partial DentureDocument45 pagesRetention of Removable Partial DentureKarlaNo ratings yet

- Android-Based Classroom Monitoring System For Teacher Using QR Code TechnologyDocument12 pagesAndroid-Based Classroom Monitoring System For Teacher Using QR Code TechnologyAkmad Ali AbdulNo ratings yet

- 10 1108 - Bij 03 2023 0131Document19 pages10 1108 - Bij 03 2023 0131Teguh SetiawanNo ratings yet

- Iv STD ScienceDocument2 pagesIv STD SciencePradeepNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechaneeshNo ratings yet

- Chapter Review Guide QuestionsDocument1 pageChapter Review Guide QuestionsRick RanteNo ratings yet

- Srend Manual WRF InstallDocument5 pagesSrend Manual WRF InstallisraelmpNo ratings yet

- 9239 04 Outline Proposal FormDocument2 pages9239 04 Outline Proposal FormbonalambokNo ratings yet

- Extra HOTS: Chapter 9: Probability of Combined EventDocument2 pagesExtra HOTS: Chapter 9: Probability of Combined EventSnow TownNo ratings yet

- Learjet45 VersofinalDocument111 pagesLearjet45 VersofinalBlueOneGaussNo ratings yet

- Introduction To Modelling PDFDocument329 pagesIntroduction To Modelling PDFclaudiuteodorNo ratings yet

- E-Commerce Product Rating Based On Customer Review MiningDocument4 pagesE-Commerce Product Rating Based On Customer Review MiningNitish KumarNo ratings yet

- Booklet N219 REV JAN 2018 PDFDocument10 pagesBooklet N219 REV JAN 2018 PDFGuntara WigunaNo ratings yet

- Applied Ergonomics: Nora Balfe, Sarah Sharples, John R. WilsonDocument13 pagesApplied Ergonomics: Nora Balfe, Sarah Sharples, John R. WilsonDian Palupi RestuputriNo ratings yet

- Test PaperDocument8 pagesTest PaperGim SiewNo ratings yet