Professional Documents

Culture Documents

002 - ITP Earthworks - Revision 2.0

002 - ITP Earthworks - Revision 2.0

Uploaded by

randyCopyright:

Available Formats

You might also like

- R07-HC3C05-FET-MTS-ME-0013 Method Statement For Installation of Air CurtainsDocument47 pagesR07-HC3C05-FET-MTS-ME-0013 Method Statement For Installation of Air Curtainslike saddamNo ratings yet

- 003 - ITP Stormwater Drainage - Revision 1.0Document9 pages003 - ITP Stormwater Drainage - Revision 1.0randyNo ratings yet

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Document13 pagesJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinNo ratings yet

- ACLS Study Guide NewDocument35 pagesACLS Study Guide NewNIRANJANA SHALINI100% (1)

- Design Submission Programme - RevisedDocument8 pagesDesign Submission Programme - RevisedUmesgNo ratings yet

- Section 017700 - Closeout ProceduresDocument5 pagesSection 017700 - Closeout ProceduresChase GietterNo ratings yet

- 00-Site InstructionDocument7 pages00-Site InstructionSyed Munawar AliNo ratings yet

- Health and Safety Compliance: Form HDocument1 pageHealth and Safety Compliance: Form HStanley Ng100% (1)

- CribMaster 11 Features - User GuideDocument22 pagesCribMaster 11 Features - User GuidesalurkarNo ratings yet

- Top 20 Countries Found To Have The Most CybercrimeDocument5 pagesTop 20 Countries Found To Have The Most CybercrimeAman Dheer KapoorNo ratings yet

- 004 - ITP Asphalt - Revision 0Document5 pages004 - ITP Asphalt - Revision 0randyNo ratings yet

- Soil Compaction Test ReportDocument7 pagesSoil Compaction Test ReportAkash SharmaNo ratings yet

- ITP - Cable Ladder & Tray InstallationDocument5 pagesITP - Cable Ladder & Tray InstallationGultom Juliana LiliesNo ratings yet

- Traffic Plan - Rev 0Document42 pagesTraffic Plan - Rev 0Dion Alfred EucogcoNo ratings yet

- RNS00001 Fire Protection Systems and EquipmentDocument19 pagesRNS00001 Fire Protection Systems and EquipmentsdonNo ratings yet

- 4 - ExcavtionDocument1 page4 - ExcavtionHSE AmlaakNo ratings yet

- Small Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlocksDocument4 pagesSmall Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlockseleanorNo ratings yet

- MD 216 2500 QD Ix Itp 1001 c01 Itp Hcis Fencing Installation For Ms AdvaconDocument5 pagesMD 216 2500 QD Ix Itp 1001 c01 Itp Hcis Fencing Installation For Ms AdvaconjuberNo ratings yet

- Playbook Mobilisation Phase ChecklistDocument2 pagesPlaybook Mobilisation Phase Checkliststimayo010809No ratings yet

- Part A Memorandum of ProcedureDocument24 pagesPart A Memorandum of ProcedureSyed Umair HashmiNo ratings yet

- DE-QC-IT-S01 (Inspection & Test Plan)Document8 pagesDE-QC-IT-S01 (Inspection & Test Plan)Zainarul Aswad RazaliNo ratings yet

- WIR Ew 0452 A TrenchDocument1 pageWIR Ew 0452 A TrenchBONGNo ratings yet

- Inspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselDocument1 pageInspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselNikki RobertsNo ratings yet

- PATOQ Folder ChecklistDocument1 pagePATOQ Folder Checklistjames alfarasNo ratings yet

- 1f. en - Ditec ALU48 TBO Installation ManualDocument24 pages1f. en - Ditec ALU48 TBO Installation ManualRosemeire MarinelliNo ratings yet

- Quality Assurance/Quality Control Plan: ASARCO - Encycle Facility Asbestos Abatement, Waste Removal, and DemolitionDocument20 pagesQuality Assurance/Quality Control Plan: ASARCO - Encycle Facility Asbestos Abatement, Waste Removal, and DemolitionRen SalazarNo ratings yet

- Inspection & Testing Plan For AggregatesDocument2 pagesInspection & Testing Plan For Aggregatesjerin sam kurian100% (1)

- Cesmp FinalDocument64 pagesCesmp FinalBibek RegmiNo ratings yet

- Appendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementDocument37 pagesAppendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementMohammed AlbayatiNo ratings yet

- QM-099-DP - XXXX Procedure For Concrete Finishing Rev ADocument11 pagesQM-099-DP - XXXX Procedure For Concrete Finishing Rev AGaneshNo ratings yet

- Topic 7 - Civil Engineering Procedure and ContractsDocument53 pagesTopic 7 - Civil Engineering Procedure and ContractsKen MutuiNo ratings yet

- MS 05Document21 pagesMS 05unnicyriacNo ratings yet

- Adtech SWMS - 006 - Non-Destructive Digging (NDD), HydroVac Excavation and PotholingDocument12 pagesAdtech SWMS - 006 - Non-Destructive Digging (NDD), HydroVac Excavation and Potholingpeter MajorNo ratings yet

- Quality Records Control Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00011Document6 pagesQuality Records Control Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00011Meshaal ALBalharithNo ratings yet

- 1 - The Five Causes of Scope CreepDocument8 pages1 - The Five Causes of Scope CreepBruno Nascimento Sé PenhaNo ratings yet

- Construction Project Flow ChartDocument1 pageConstruction Project Flow ChartRuna JullyNo ratings yet

- Blinding Concrete Works Method of StatementDocument9 pagesBlinding Concrete Works Method of StatementMohammed Ghareib NasrNo ratings yet

- Derlin Construction Limited Quality Policy Manual: Document HistoryDocument30 pagesDerlin Construction Limited Quality Policy Manual: Document HistoryAdams Bruno100% (1)

- Method Statement Procedure: Revision LogDocument20 pagesMethod Statement Procedure: Revision LogJoyce GordonioNo ratings yet

- Site Mobilization PlanDocument4 pagesSite Mobilization Planshibin kochuNo ratings yet

- Communication Management PlanDocument11 pagesCommunication Management PlanNuwan BandaraNo ratings yet

- Section 7 BOQDocument61 pagesSection 7 BOQayman alnossaryNo ratings yet

- Catch - Up Plan (Sample) : Construction of Flood Control, F.S. Catanico F.S. Catanico, Cugman, CdoDocument1 pageCatch - Up Plan (Sample) : Construction of Flood Control, F.S. Catanico F.S. Catanico, Cugman, CdoJulmie SiarotNo ratings yet

- Ohs-Pr-09-09-F01 (A) Plant and Facility Register and InspectionDocument4 pagesOhs-Pr-09-09-F01 (A) Plant and Facility Register and InspectionSiddiquiNo ratings yet

- Main Building Raft Foundation MS-005 R1Document11 pagesMain Building Raft Foundation MS-005 R1Anonymous kWfNFbNo ratings yet

- DHA KennelDocument1 pageDHA KennelCacique PimientaNo ratings yet

- Construction of MRT Feeder Bus Depot and Related Supporting Buildings and Facilities For The KVMRT Project, SBK LineDocument5 pagesConstruction of MRT Feeder Bus Depot and Related Supporting Buildings and Facilities For The KVMRT Project, SBK LineIkhwan HishamNo ratings yet

- Project Title: Neom Water Transmission System Project Document TransmittalDocument12 pagesProject Title: Neom Water Transmission System Project Document TransmittalMohammad NowfalNo ratings yet

- Section 1 Key QSHE Issues and Risks (Current or Forecast) : KPI Score (Append Every Month's Score Horizontally)Document4 pagesSection 1 Key QSHE Issues and Risks (Current or Forecast) : KPI Score (Append Every Month's Score Horizontally)Syerifaizal Hj. MustaphaNo ratings yet

- 004 MS ITP RA Porland Cement Plaster WorksDocument18 pages004 MS ITP RA Porland Cement Plaster Workslinga2014No ratings yet

- Apprvd. Movilazation of Temporary Site OfficeDocument6 pagesApprvd. Movilazation of Temporary Site OfficeFaisal RazaNo ratings yet

- METHODOLOGY DrainageDocument2 pagesMETHODOLOGY Drainagejef100% (1)

- Quality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakDocument47 pagesQuality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakConnielya AdamNo ratings yet

- ITP - 028 (Lighting Fixtures)Document2 pagesITP - 028 (Lighting Fixtures)mohamed wahebNo ratings yet

- Quality Control Manual Papua New GuineaDocument59 pagesQuality Control Manual Papua New GuineaSmr OnlyNo ratings yet

- ESMPDocument62 pagesESMPMunir HussainNo ratings yet

- Approved Vendor ListDocument1 pageApproved Vendor ListSumit TyagiNo ratings yet

- Business Continuity Management & Disaster Recovery Capabilities in Saudi Arabia ICT BusinessesDocument29 pagesBusiness Continuity Management & Disaster Recovery Capabilities in Saudi Arabia ICT BusinessesAsefa AlemuNo ratings yet

- DRC 000 16540 0055 00 Project Quality PlanDocument41 pagesDRC 000 16540 0055 00 Project Quality PlanSaleem AkhtarNo ratings yet

- Smpling - Storage - Transportation - Installation ProcedureDocument75 pagesSmpling - Storage - Transportation - Installation ProcedurePaddyNo ratings yet

- Kac - CesmpDocument28 pagesKac - Cesmpmahmood100% (1)

- 001 - ITP Clearing - Revision 0Document3 pages001 - ITP Clearing - Revision 0randyNo ratings yet

- Tutorial Problems 1400Document1 pageTutorial Problems 1400randyNo ratings yet

- Tutorial ProblemsDocument1 pageTutorial ProblemsrandyNo ratings yet

- Induction Machines Part2 SolutionsDocument7 pagesInduction Machines Part2 SolutionsrandyNo ratings yet

- 004 - ITP Asphalt - Revision 0Document5 pages004 - ITP Asphalt - Revision 0randyNo ratings yet

- AnswersDocument24 pagesAnswersDeul ErNo ratings yet

- READMEDocument25 pagesREADMENate ClarkNo ratings yet

- Red Hat Jboss Enterprise Application Platform 7.1: Getting Started GuideDocument61 pagesRed Hat Jboss Enterprise Application Platform 7.1: Getting Started Guidesomanath padhyNo ratings yet

- Prof. Gandeza - Review Notes in Civil LawDocument58 pagesProf. Gandeza - Review Notes in Civil LawFlorenz Efren CacatianNo ratings yet

- Pilz PNOZ Sigma PDFDocument16 pagesPilz PNOZ Sigma PDFCristopher Entena100% (1)

- Building SpecificationsDocument5 pagesBuilding Specificationsjologscresencia100% (1)

- A Hybrid Intrution Detection Approach Based On Deep LearningDocument16 pagesA Hybrid Intrution Detection Approach Based On Deep LearningVictor KingbuilderNo ratings yet

- 01.1. RPS MSDM MM 2021Document10 pages01.1. RPS MSDM MM 2021anang setiawanNo ratings yet

- Consumer Redress: Fair Trade Enforcement BureauDocument47 pagesConsumer Redress: Fair Trade Enforcement BureauMaria LovesongorNo ratings yet

- Ibabm-Ddcs-Monitor v1.8 en A4Document26 pagesIbabm-Ddcs-Monitor v1.8 en A4Deepak PatelNo ratings yet

- Amendment of Information, Formal Vs SubstantialDocument2 pagesAmendment of Information, Formal Vs SubstantialNikkoCataquiz100% (3)

- Hotel Administration and Management Network - AbstractDocument3 pagesHotel Administration and Management Network - AbstractMehadi Hasan RoxyNo ratings yet

- Dqs259 Assignment 2_question [Mar-Aug 2024]Document12 pagesDqs259 Assignment 2_question [Mar-Aug 2024]CrackedCoreNo ratings yet

- Superbad (Film) - Wikipedia, The Free EncyclopediaDocument87 pagesSuperbad (Film) - Wikipedia, The Free Encyclopediaresearcher911No ratings yet

- Draft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleDocument2 pagesDraft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleRica Carmel Lanzaderas100% (3)

- Essentials of Marketing Research 4th Edition Hair Test Bank DownloadDocument22 pagesEssentials of Marketing Research 4th Edition Hair Test Bank Downloademmanuelmabelnjt7nn100% (35)

- Product Specifications Product Specifications: HWXX HWXX - 6516DS1 6516DS1 - VTM VTMDocument2 pagesProduct Specifications Product Specifications: HWXX HWXX - 6516DS1 6516DS1 - VTM VTMcesarbayonaNo ratings yet

- Kirch GroupDocument13 pagesKirch GroupStacy ChackoNo ratings yet

- Pumba Cap 3 2022Document15 pagesPumba Cap 3 2022adityakamble070103No ratings yet

- Unit 1 - Identifying A Problem PDFDocument16 pagesUnit 1 - Identifying A Problem PDFZanko FitnessNo ratings yet

- Minerals Potential - Minerals Law of Lao PDRDocument44 pagesMinerals Potential - Minerals Law of Lao PDRkhamsone pengmanivongNo ratings yet

- Accounting Q&ADocument6 pagesAccounting Q&AIftikharNo ratings yet

- Criteria For Master Teacher: (With Additional Proposed Documents and The Specific Points As Support To Other Criteria)Document19 pagesCriteria For Master Teacher: (With Additional Proposed Documents and The Specific Points As Support To Other Criteria)Dennis ReyesNo ratings yet

- Braille Actuator Report MAJORDocument32 pagesBraille Actuator Report MAJORSwapnil BeheraNo ratings yet

- Lownds CFPB 2 of 3Document1,098 pagesLownds CFPB 2 of 3Judicial Watch, Inc.No ratings yet

- AmbaniDocument14 pagesAmbaniShimoni ShahNo ratings yet

- A Framework For Improving Advertising Creative Using Digital MeasurementDocument15 pagesA Framework For Improving Advertising Creative Using Digital MeasurementMs Mariia MykhailenkoNo ratings yet

002 - ITP Earthworks - Revision 2.0

002 - ITP Earthworks - Revision 2.0

Uploaded by

randyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

002 - ITP Earthworks - Revision 2.0

002 - ITP Earthworks - Revision 2.0

Uploaded by

randyCopyright:

Available Formats

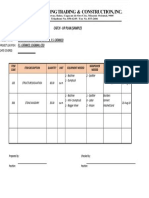

Inspection and Test Plan (ITP)

Project Number and Name: AMPOL Lytton Refinery Future Fuels Project Bulk Earthworks & Pavements

Inspection Title:

Earthworks

Lot Number: Dates of Work:

Lot Location/Area: Lot Owner: Lachlan Ferguson

Revision Description of Changes Date of Issue

0 Initial Issue 24/04/2023

1 FYFE References Incorporated 11/05/2023

2 FYFE OPW Drawing Updates 25/05/2023

Lot Record Requirements

Type Description Item Reference No.

Hold Point Documentation 1.1

Hold Point Inductions 1.2

Hold Point IFC Pavement Design 1.6

Hold Point Material Approval 1.7

Witness Point Clearing and Grubbing 2.1

Witness Point Disposal of Material 2.4

Hold Point Structural Excavation 3.2

Hold Point Rock Excavation 3.3

Hold Point Subgrade Inspection / Proof Roll 4.4

Witness Point Geotechnical Engineer Supervision 5.1

Sign-Off

Name: Signature: Date:

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 1 of 12

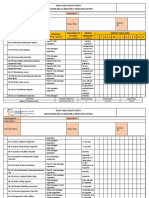

Inspection and Test Plan (ITP)

Hold Points/ Verification Sign

Inspection/ Clause

Item Work Step Witness Conformance Criteria Frequency Date

Points Test Method Reference Kent/Geo

BMD

Engineer

1.0 Preliminary Requirements

Prior to

SWMS to be submitted prior to permit being

1.1 Documentation Hold Point establishment Submission

issued.

on site

All personnel are required to complete an Prior to

1.2 Inductions Hold Point Ampol or Kent induction, BMD induction and establishment Induction

an on-site familiarisation. on site

All workers onsite are required to be signed

onto the Ampol or Kent permit provided by

Kent, attend the pre-starts and toolbox talks

and to be wearing the appropriate PPE as

1.3 Site Establishment required. As Required Visual Inspection

BMD JHA/JSEA cards to be completed and

kept on hand.

Service location to ascertain and mark on the

ground the position of all underground service

1.4 Service Location All Areas Visual Inspection

and structures within the limits of the work and

within 10m beyond the limits of work.

All site survey control to be developed and

confirmed prior to setting out structures and

1.5 Survey Setout and Control pavements. All survey Setout to be in All Areas

accordance with the Drawings and Australian

Standards for survey.

The IFC pavement designs from the Principal FYFE - CIVIL

1.6 IFC Pavement Design Hold Point Contractor / Company are required prior to All Areas Documentation TYPICAL

the import or placement of fill material. DETAILS

All import material fill results are required to be

submitted to the Principal Contractor / Document

All Materials

Company for approval prior to work Submission

commencement. FYFE - CIVIL

1.7 Material Approval Hold Point TYPICAL

All geotextiles material reports are required to DETAILS

be submitted to the Principal Contractor / Document

All Materials

Company for approval prior to work Submission

commencement.

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 2 of 12

Hold Points/ Verification Sign

Inspection/ Clause

Item Work Step Witness Conformance Criteria Frequency Date

Points Test Method Reference Kent/Geo

BMD

Engineer

2.0 Clearing & Stripping

All areas within the works that are to be

excavated, filled, or otherwise developed shall

be cleared and grubbed – no clearing shall be STD

2.1 Clearing and Grubbing Witness Point done beyond the site boundaries. All Areas Visual Inspection 40.06.Q.004

The tree stumps and roots are to be removed CL.3.2

to a depth greater than 300mm, surface is to

be ploughed to a depth greater than 150mm.

The topsoil shall be stripped (min. 200mm or

as stated on the Drawings) from areas under STD

the main structures, footings, buildings, roads, 40.06.Q.004

hardstands, and other areas as specified on CL.3.3

Zone 1-4,7: the Drawings.

Topsoil Stripping XY21024-18-

The tree roots, large stones, rubbish, etc. shall

2.2 be removed from the topsoil and stockpiled at All Areas Visual Inspection Y30-5002

the location designated by the Principal CL7.1.3

Contractor / Company

FYFE - CIVIL

Heavy Duty Asphalt Pavement:

Zone 5&6: TYPICAL

Existing topsoil is to be stripped under the DETAILS

Topsoil Stripping

heavy-duty asphalt pavement type.

Medium Duty Crushed Rock Pavement,

Heavy Duty Crushed Rock Pavement &

Zone 5&6: Light Duty Crushed Rock Pavement: FYFE - CIVIL

2.3 All Areas Visual Inspection TYPICAL

Grass Slashing The existing topsoil layer is to remain in-situ. DETAILS

All surface vegetation is to be slashed and

mown down to stubble.

The excavated material that is not used in the

work shall be stockpiled at the location All excavated STD

2.4 Disposal of Material Witness Point

designated by the Principal Contractor / material 40.06.Q.004

Company

3.0 Excavation

All excavation and filling shall be made to the

lines, grades and elevations shown on the

All Areas Survey

Drawings and in accordance with AMPOL

Excavation Procedure PROC 4.10.02.001. STD

3.1 Excavation and Fill

Geotechnical 40.06.Q.004 CL4

Any excess excavation to pipe and cable Testing

trenches shall be backfilled with Type 1 fill As Required

material. STD 40.06.Q.004

CL4.5.1

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 3 of 12

Hold Points/ Verification Sign

Inspection/ Clause

Item Work Step Witness Conformance Criteria Frequency Date

Points Test Method Reference Kent/Geo

BMD

Engineer

All excavations below founding depth of

footings shall be backfilled with 10MPa As Required Concrete Testing

concrete.

If rock is encountered over part of the base of Visual Inspection /

a pipe or cable trench excavation, then it shall Geotechnical STD

be removed to a depth of at least 150mm Testing

3.2 Structural Excavation Hold Point As Required 40.06.Q.004

below the underside of pipe or cable trench.

STD 40.06.Q.004 CL4.2

The over-excavated area shall be backfilled

with Type 1 fill and compacted as directed. CL4.5.1

The Subcontractor (BMD) is to notify the

Principal Contractor / Company & a

suitable qualified Geotechnical Engineer

upon discovery of rock material to:

1. Determine if the rock complies with STD

3.3 Rock Excavation Hold Point the definition as specified in Figure As Required Visual Inspection 40.06.Q.004

1, & CL4.3

2. Provide the Subcontractor (BMD)

with a direction excavate the rock

using approved methods and

procedures.

4.0 Subgrade

The Subcontractor (BMD) is to conduct

subgrade CBR testing and provide the results

to the Principal Contractor / Company & a FYFE - CIVIL

All Subgrade Geotechnical

4.1 Subgrade In-situ CBR Testing suitable qualified Geotechnical Engineer for TYPICAL

Surfaces Testing

assessment. DETAILS

A minimum 2% CBR is required.

In areas where topsoil is stripped (i.e. Zone

1-4,7 & Zone 5&6 with Heavy Duty Asphalt FYFE - CIVIL

Pavement) As per Figure Geotechnical TYPICAL

4.2 Subgrade Testing DETAILS

The upper 150mm of subgrade is to be 2 Testing

compacted to achieve 98% standard NOTE 3

compaction.

In areas where topsoil is stripped (i.e. Zone

1-4,7 & Zone 5&6 with Heavy Duty Asphalt All Areas with

FYFE - CIVIL

Pavement) Stripped

4.3 Subgrade Preparation TYPICAL

Topsoil

The subgrade is to be prepared in accordance DETAILS

Surfaces

with TMR MRTS04.

Subgrade Inspection / Proof After all excavations have been made, the All Subgrade Visual Inspection / STD

4.4 Hold Point

Roll subgrade surface shall be presented to the Areas with Proof Roll 40.06.Q.004

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 4 of 12

Hold Points/ Verification Sign

Inspection/ Clause

Item Work Step Witness Conformance Criteria Frequency Date

Points Test Method Reference Kent/Geo

BMD

Engineer

Principal Contractor / Company & a Stripped CL 4.2.1 & CL

suitable qualified Geotechnical Engineer to Topsoil 4.4

visually assess the subgrade surface for Surfaces

perceptible surface deformation by FYFE - COVER

undertaking proof rolling to: SHEET

1. Ensure the subgrade is suitable for

the placement of fill, OR

2. Provide the Subcontractor (BMD)

with direction and details to perform

additional subgrade treatment.

5.0 Filling

Medium Duty Crushed Rock Pavement,

Heavy Duty Crushed Rock Pavement &

Light Duty Crushed Rock Pavement:

The Subcontractor, BMD, is to engage a

suitably qualified Geotechnical Engineer to

witness and approve the (1) combi-grid and (2)

crushed rock starer layer preparation works. All Pavement

The Geotechnical Engineer is to visually Areas where

Geotechnical Engineer Visual Inspection /

5.1 Witness Point assess the subgrade surface for perceptible the Topsoil

Supervision Proof Roll

surface deformation by undertaking proof Remained In-

rolling to: situ

1. Ensure the subgrade is suitable for

the placement of fill, OR

2. (b) Provide the Subcontractor

(BMD) with direction and details to

perform additional subgrade

treatment.

The fill material shall be placed and spread in

STD

uniform near-horizontal layers, which do not

5.2 Placing Fill All Areas Visual Inspection 40.06.Q.004

exceed the thickness specified for the various

CL4.5 &CL4.8

grades of fill listed in the STD 40.06.Q.004.

The Subcontractor (BMD) is required to

achieve compaction testing results in the

following order:

1. Compaction testing requirements

listed in the FYFE CIVIL DETAILS STD

As per Figure Geotechnical

5.3 Compaction of Fill DRAWING 40.06.Q.004

2 Testing

a. A1 Structural Fill @ 98% CL4.4

standard compaction.

b. Rock Starter Layer @

98% standard

compaction; &

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 5 of 12

Hold Points/ Verification Sign

Inspection/ Clause

Item Work Step Witness Conformance Criteria Frequency Date

Points Test Method Reference Kent/Geo

BMD

Engineer

c. Type 2.3 @ 100%

standard compaction.

2. Compaction testing requirements

listed individually in ITP Section 5.0

Material Requirements

5.0 Material Requirements

Material shall be placed in layers not STD

Fill Material - Type 1 (Site Geotechnical

5.1 exceeding 200mm uncompacted thickness 40.06.Q.004

Cohesive Soil) Testing

and compacted to comply with Clause 4.9. CL4.5.1

Type 2 fill shall possess the following

characteristics:

1) Liquid limit (Max): 40%

2) Plasticity Index (Max):20%

3) Particle grading within the following

limits:

AS Sieve Size Percentage

Passing Sieve STD

Fill Material - Type 2 Geotechnical

5.2 Allowable Range 40.06.Q.004

(Imported Cohesive Soil) Testing

CL4.5.2

13.2mm 100

9.5mm 60-90

0.6mm 0-10

Material shall be placed in layers not

exceeding 200mm uncompacted thickness

and compacted to comply with Clause 4.9.

Type 3 fill shall possess the following

characteristics:

STD

Fill Material - Type 3 (Crushed Geotechnical

5.3 40.06.Q.004

Rock - Road Base Course) Testing

CL4.5.3

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 6 of 12

Hold Points/ Verification Sign

Inspection/ Clause

Item Work Step Witness Conformance Criteria Frequency Date

Points Test Method Reference Kent/Geo

BMD

Engineer

Particle grading within the following limits:

AS Sieve Size Percentage

Passing Sieve

Allowable Range

26.5mm 100

19mm 87-100

9.5mm 67-87

4.75mm 50-70

2.36mm 36-52

0.425mm 14-24

0.075mm 7-16

Material shall be placed in layers not

exceeding 150mm compacted thickness and

compacted to at least 98% relative compaction

(modified).

Type 4 fill shall possess the following

characteristics:

AS Sieve Size Percentage

Passing Sieve

Allowable Range

2mm 100 STD

Geotechnical

5.4 Fill Material - Type 4 (Sand) 40.06.Q.004

0.07mm 5 Testing

CL4.5.4

Material shall be used in accordance with

Clause 4.8 (placement of fill). Layers are not to

exceed 200mm uncompacted thickness and

compacted to comply with Clause 4.7.2.

Type 5 fill shall possess the following

characteristics:

Fill Material - Type 5 (Crushed STD

Geotechnical

5.5 Rock - Road Sub-Base 40.06.Q.004

Testing

Course) CL4.5.5

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 7 of 12

Hold Points/ Verification Sign

Inspection/ Clause

Item Work Step Witness Conformance Criteria Frequency Date

Points Test Method Reference Kent/Geo

BMD

Engineer

Particle grading within the following limits:

AS Sieve Size Percentage

Passing Sieve

Allowable Range

75mm 100

37.5mm 90-100

19mm 80-100

4.75mm 42-76

2.36mm 30-60

0.425mm 14-28

0.075mm 7-16

Material shall be placed in layers not

exceeding 150mm compacted thickness and

compacted to at least 95% relative

compaction(modified).

Class 2.3 Material The Class 2.3 Material is to comply with the FYFE - CIVIL

As per Figure Geotechnical

5.6 MRTS-05 - Section 7.2 Type 2 Unbound TYPICAL

MRTS 05 3 Testing

Material (excerpts on Page 12-13). DETAILS

The minimum size pieces shall be 75mm and STD

5.7 Rock Pitching thickness when places shall not exceed As Required Visual Inspection 40.06.Q.004

150mm. CL4.5.7

6.0 Construction Tolerances

Vertical tolerance from design levels: STD

All Areas Survey

• +/-30mm 40.06.Q.004 CL4

6.1 Top Surfaces

Vertical difference from straight edge: STD

All Areas Survey

• 50mm in 10m 40.06.Q.004 CL4

Vertical tolerance from design levels: STD

6.2 Batters All Areas Survey

• +/- 50 mm 40.06.Q.004 CL4

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 8 of 12

Figure 1: Rock Definition (Extracted from AMPOL Earthworks Specification - Table 1 - Definitions)

Figure 2: Testing Frequencies (Extracted from AMPOL Earthworks Specification - Table 8 - Testing Fill Guide)

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 9 of 12

Figure 3: Source and Product Testing for Class 2.3 Material (Extracted from MRTS05 - Table A2)

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 10 of 12

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 11 of 12

[BMS Doc ID]

Rev. 0 (19/02/2020) Page 12 of 12

You might also like

- R07-HC3C05-FET-MTS-ME-0013 Method Statement For Installation of Air CurtainsDocument47 pagesR07-HC3C05-FET-MTS-ME-0013 Method Statement For Installation of Air Curtainslike saddamNo ratings yet

- 003 - ITP Stormwater Drainage - Revision 1.0Document9 pages003 - ITP Stormwater Drainage - Revision 1.0randyNo ratings yet

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Document13 pagesJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinNo ratings yet

- ACLS Study Guide NewDocument35 pagesACLS Study Guide NewNIRANJANA SHALINI100% (1)

- Design Submission Programme - RevisedDocument8 pagesDesign Submission Programme - RevisedUmesgNo ratings yet

- Section 017700 - Closeout ProceduresDocument5 pagesSection 017700 - Closeout ProceduresChase GietterNo ratings yet

- 00-Site InstructionDocument7 pages00-Site InstructionSyed Munawar AliNo ratings yet

- Health and Safety Compliance: Form HDocument1 pageHealth and Safety Compliance: Form HStanley Ng100% (1)

- CribMaster 11 Features - User GuideDocument22 pagesCribMaster 11 Features - User GuidesalurkarNo ratings yet

- Top 20 Countries Found To Have The Most CybercrimeDocument5 pagesTop 20 Countries Found To Have The Most CybercrimeAman Dheer KapoorNo ratings yet

- 004 - ITP Asphalt - Revision 0Document5 pages004 - ITP Asphalt - Revision 0randyNo ratings yet

- Soil Compaction Test ReportDocument7 pagesSoil Compaction Test ReportAkash SharmaNo ratings yet

- ITP - Cable Ladder & Tray InstallationDocument5 pagesITP - Cable Ladder & Tray InstallationGultom Juliana LiliesNo ratings yet

- Traffic Plan - Rev 0Document42 pagesTraffic Plan - Rev 0Dion Alfred EucogcoNo ratings yet

- RNS00001 Fire Protection Systems and EquipmentDocument19 pagesRNS00001 Fire Protection Systems and EquipmentsdonNo ratings yet

- 4 - ExcavtionDocument1 page4 - ExcavtionHSE AmlaakNo ratings yet

- Small Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlocksDocument4 pagesSmall Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlockseleanorNo ratings yet

- MD 216 2500 QD Ix Itp 1001 c01 Itp Hcis Fencing Installation For Ms AdvaconDocument5 pagesMD 216 2500 QD Ix Itp 1001 c01 Itp Hcis Fencing Installation For Ms AdvaconjuberNo ratings yet

- Playbook Mobilisation Phase ChecklistDocument2 pagesPlaybook Mobilisation Phase Checkliststimayo010809No ratings yet

- Part A Memorandum of ProcedureDocument24 pagesPart A Memorandum of ProcedureSyed Umair HashmiNo ratings yet

- DE-QC-IT-S01 (Inspection & Test Plan)Document8 pagesDE-QC-IT-S01 (Inspection & Test Plan)Zainarul Aswad RazaliNo ratings yet

- WIR Ew 0452 A TrenchDocument1 pageWIR Ew 0452 A TrenchBONGNo ratings yet

- Inspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselDocument1 pageInspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselNikki RobertsNo ratings yet

- PATOQ Folder ChecklistDocument1 pagePATOQ Folder Checklistjames alfarasNo ratings yet

- 1f. en - Ditec ALU48 TBO Installation ManualDocument24 pages1f. en - Ditec ALU48 TBO Installation ManualRosemeire MarinelliNo ratings yet

- Quality Assurance/Quality Control Plan: ASARCO - Encycle Facility Asbestos Abatement, Waste Removal, and DemolitionDocument20 pagesQuality Assurance/Quality Control Plan: ASARCO - Encycle Facility Asbestos Abatement, Waste Removal, and DemolitionRen SalazarNo ratings yet

- Inspection & Testing Plan For AggregatesDocument2 pagesInspection & Testing Plan For Aggregatesjerin sam kurian100% (1)

- Cesmp FinalDocument64 pagesCesmp FinalBibek RegmiNo ratings yet

- Appendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementDocument37 pagesAppendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementMohammed AlbayatiNo ratings yet

- QM-099-DP - XXXX Procedure For Concrete Finishing Rev ADocument11 pagesQM-099-DP - XXXX Procedure For Concrete Finishing Rev AGaneshNo ratings yet

- Topic 7 - Civil Engineering Procedure and ContractsDocument53 pagesTopic 7 - Civil Engineering Procedure and ContractsKen MutuiNo ratings yet

- MS 05Document21 pagesMS 05unnicyriacNo ratings yet

- Adtech SWMS - 006 - Non-Destructive Digging (NDD), HydroVac Excavation and PotholingDocument12 pagesAdtech SWMS - 006 - Non-Destructive Digging (NDD), HydroVac Excavation and Potholingpeter MajorNo ratings yet

- Quality Records Control Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00011Document6 pagesQuality Records Control Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00011Meshaal ALBalharithNo ratings yet

- 1 - The Five Causes of Scope CreepDocument8 pages1 - The Five Causes of Scope CreepBruno Nascimento Sé PenhaNo ratings yet

- Construction Project Flow ChartDocument1 pageConstruction Project Flow ChartRuna JullyNo ratings yet

- Blinding Concrete Works Method of StatementDocument9 pagesBlinding Concrete Works Method of StatementMohammed Ghareib NasrNo ratings yet

- Derlin Construction Limited Quality Policy Manual: Document HistoryDocument30 pagesDerlin Construction Limited Quality Policy Manual: Document HistoryAdams Bruno100% (1)

- Method Statement Procedure: Revision LogDocument20 pagesMethod Statement Procedure: Revision LogJoyce GordonioNo ratings yet

- Site Mobilization PlanDocument4 pagesSite Mobilization Planshibin kochuNo ratings yet

- Communication Management PlanDocument11 pagesCommunication Management PlanNuwan BandaraNo ratings yet

- Section 7 BOQDocument61 pagesSection 7 BOQayman alnossaryNo ratings yet

- Catch - Up Plan (Sample) : Construction of Flood Control, F.S. Catanico F.S. Catanico, Cugman, CdoDocument1 pageCatch - Up Plan (Sample) : Construction of Flood Control, F.S. Catanico F.S. Catanico, Cugman, CdoJulmie SiarotNo ratings yet

- Ohs-Pr-09-09-F01 (A) Plant and Facility Register and InspectionDocument4 pagesOhs-Pr-09-09-F01 (A) Plant and Facility Register and InspectionSiddiquiNo ratings yet

- Main Building Raft Foundation MS-005 R1Document11 pagesMain Building Raft Foundation MS-005 R1Anonymous kWfNFbNo ratings yet

- DHA KennelDocument1 pageDHA KennelCacique PimientaNo ratings yet

- Construction of MRT Feeder Bus Depot and Related Supporting Buildings and Facilities For The KVMRT Project, SBK LineDocument5 pagesConstruction of MRT Feeder Bus Depot and Related Supporting Buildings and Facilities For The KVMRT Project, SBK LineIkhwan HishamNo ratings yet

- Project Title: Neom Water Transmission System Project Document TransmittalDocument12 pagesProject Title: Neom Water Transmission System Project Document TransmittalMohammad NowfalNo ratings yet

- Section 1 Key QSHE Issues and Risks (Current or Forecast) : KPI Score (Append Every Month's Score Horizontally)Document4 pagesSection 1 Key QSHE Issues and Risks (Current or Forecast) : KPI Score (Append Every Month's Score Horizontally)Syerifaizal Hj. MustaphaNo ratings yet

- 004 MS ITP RA Porland Cement Plaster WorksDocument18 pages004 MS ITP RA Porland Cement Plaster Workslinga2014No ratings yet

- Apprvd. Movilazation of Temporary Site OfficeDocument6 pagesApprvd. Movilazation of Temporary Site OfficeFaisal RazaNo ratings yet

- METHODOLOGY DrainageDocument2 pagesMETHODOLOGY Drainagejef100% (1)

- Quality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakDocument47 pagesQuality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakConnielya AdamNo ratings yet

- ITP - 028 (Lighting Fixtures)Document2 pagesITP - 028 (Lighting Fixtures)mohamed wahebNo ratings yet

- Quality Control Manual Papua New GuineaDocument59 pagesQuality Control Manual Papua New GuineaSmr OnlyNo ratings yet

- ESMPDocument62 pagesESMPMunir HussainNo ratings yet

- Approved Vendor ListDocument1 pageApproved Vendor ListSumit TyagiNo ratings yet

- Business Continuity Management & Disaster Recovery Capabilities in Saudi Arabia ICT BusinessesDocument29 pagesBusiness Continuity Management & Disaster Recovery Capabilities in Saudi Arabia ICT BusinessesAsefa AlemuNo ratings yet

- DRC 000 16540 0055 00 Project Quality PlanDocument41 pagesDRC 000 16540 0055 00 Project Quality PlanSaleem AkhtarNo ratings yet

- Smpling - Storage - Transportation - Installation ProcedureDocument75 pagesSmpling - Storage - Transportation - Installation ProcedurePaddyNo ratings yet

- Kac - CesmpDocument28 pagesKac - Cesmpmahmood100% (1)

- 001 - ITP Clearing - Revision 0Document3 pages001 - ITP Clearing - Revision 0randyNo ratings yet

- Tutorial Problems 1400Document1 pageTutorial Problems 1400randyNo ratings yet

- Tutorial ProblemsDocument1 pageTutorial ProblemsrandyNo ratings yet

- Induction Machines Part2 SolutionsDocument7 pagesInduction Machines Part2 SolutionsrandyNo ratings yet

- 004 - ITP Asphalt - Revision 0Document5 pages004 - ITP Asphalt - Revision 0randyNo ratings yet

- AnswersDocument24 pagesAnswersDeul ErNo ratings yet

- READMEDocument25 pagesREADMENate ClarkNo ratings yet

- Red Hat Jboss Enterprise Application Platform 7.1: Getting Started GuideDocument61 pagesRed Hat Jboss Enterprise Application Platform 7.1: Getting Started Guidesomanath padhyNo ratings yet

- Prof. Gandeza - Review Notes in Civil LawDocument58 pagesProf. Gandeza - Review Notes in Civil LawFlorenz Efren CacatianNo ratings yet

- Pilz PNOZ Sigma PDFDocument16 pagesPilz PNOZ Sigma PDFCristopher Entena100% (1)

- Building SpecificationsDocument5 pagesBuilding Specificationsjologscresencia100% (1)

- A Hybrid Intrution Detection Approach Based On Deep LearningDocument16 pagesA Hybrid Intrution Detection Approach Based On Deep LearningVictor KingbuilderNo ratings yet

- 01.1. RPS MSDM MM 2021Document10 pages01.1. RPS MSDM MM 2021anang setiawanNo ratings yet

- Consumer Redress: Fair Trade Enforcement BureauDocument47 pagesConsumer Redress: Fair Trade Enforcement BureauMaria LovesongorNo ratings yet

- Ibabm-Ddcs-Monitor v1.8 en A4Document26 pagesIbabm-Ddcs-Monitor v1.8 en A4Deepak PatelNo ratings yet

- Amendment of Information, Formal Vs SubstantialDocument2 pagesAmendment of Information, Formal Vs SubstantialNikkoCataquiz100% (3)

- Hotel Administration and Management Network - AbstractDocument3 pagesHotel Administration and Management Network - AbstractMehadi Hasan RoxyNo ratings yet

- Dqs259 Assignment 2_question [Mar-Aug 2024]Document12 pagesDqs259 Assignment 2_question [Mar-Aug 2024]CrackedCoreNo ratings yet

- Superbad (Film) - Wikipedia, The Free EncyclopediaDocument87 pagesSuperbad (Film) - Wikipedia, The Free Encyclopediaresearcher911No ratings yet

- Draft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleDocument2 pagesDraft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleRica Carmel Lanzaderas100% (3)

- Essentials of Marketing Research 4th Edition Hair Test Bank DownloadDocument22 pagesEssentials of Marketing Research 4th Edition Hair Test Bank Downloademmanuelmabelnjt7nn100% (35)

- Product Specifications Product Specifications: HWXX HWXX - 6516DS1 6516DS1 - VTM VTMDocument2 pagesProduct Specifications Product Specifications: HWXX HWXX - 6516DS1 6516DS1 - VTM VTMcesarbayonaNo ratings yet

- Kirch GroupDocument13 pagesKirch GroupStacy ChackoNo ratings yet

- Pumba Cap 3 2022Document15 pagesPumba Cap 3 2022adityakamble070103No ratings yet

- Unit 1 - Identifying A Problem PDFDocument16 pagesUnit 1 - Identifying A Problem PDFZanko FitnessNo ratings yet

- Minerals Potential - Minerals Law of Lao PDRDocument44 pagesMinerals Potential - Minerals Law of Lao PDRkhamsone pengmanivongNo ratings yet

- Accounting Q&ADocument6 pagesAccounting Q&AIftikharNo ratings yet

- Criteria For Master Teacher: (With Additional Proposed Documents and The Specific Points As Support To Other Criteria)Document19 pagesCriteria For Master Teacher: (With Additional Proposed Documents and The Specific Points As Support To Other Criteria)Dennis ReyesNo ratings yet

- Braille Actuator Report MAJORDocument32 pagesBraille Actuator Report MAJORSwapnil BeheraNo ratings yet

- Lownds CFPB 2 of 3Document1,098 pagesLownds CFPB 2 of 3Judicial Watch, Inc.No ratings yet

- AmbaniDocument14 pagesAmbaniShimoni ShahNo ratings yet

- A Framework For Improving Advertising Creative Using Digital MeasurementDocument15 pagesA Framework For Improving Advertising Creative Using Digital MeasurementMs Mariia MykhailenkoNo ratings yet

![Dqs259 Assignment 2_question [Mar-Aug 2024]](https://imgv2-1-f.scribdassets.com/img/document/747277161/149x198/98cbcf6efd/1719923930?v=1)