Professional Documents

Culture Documents

Injection Moulding Process An Overview Ijariie15225

Injection Moulding Process An Overview Ijariie15225

Uploaded by

tou kaiCopyright:

Available Formats

You might also like

- Project Report: Plastic Injection MouldingDocument26 pagesProject Report: Plastic Injection MouldingShubham Kumar JhaNo ratings yet

- Astm D883Document16 pagesAstm D883Anonymous nxfFHG32k100% (7)

- Intro To Plastic Injection Molding EbookDocument43 pagesIntro To Plastic Injection Molding EbookJames Farrugia78% (9)

- Software Instalation R-J2Document213 pagesSoftware Instalation R-J2Marcelo Fiod HasmanNo ratings yet

- Project On Sugarcane BaggasseDocument26 pagesProject On Sugarcane BaggasseV Deepak Kumar75% (4)

- MTE Innovative Project Report Rudransh Khera 2K20 - A18 - 80Document8 pagesMTE Innovative Project Report Rudransh Khera 2K20 - A18 - 80Ayush SinghNo ratings yet

- Compression Moulding Process - An Overview Ijariie11168Document10 pagesCompression Moulding Process - An Overview Ijariie11168ARUN KUMAR KoterimadathilNo ratings yet

- Plastic Injection Training ReportDocument31 pagesPlastic Injection Training ReportsazmsNo ratings yet

- Project Final Year On The Injection Plastic ModuleDocument41 pagesProject Final Year On The Injection Plastic ModuleSajid Zeya100% (1)

- Project Injection Moulding MachineDocument36 pagesProject Injection Moulding MachineSajid ZeyaNo ratings yet

- Prepared By-Chaudhari M.M SVCP (Sinhgad), PUNE (INDIA) Dept. of Mech. EnggDocument39 pagesPrepared By-Chaudhari M.M SVCP (Sinhgad), PUNE (INDIA) Dept. of Mech. EnggMitul patelNo ratings yet

- Blow Mould Tool Design and Manufacturing Process For 1litre Pet BottleDocument10 pagesBlow Mould Tool Design and Manufacturing Process For 1litre Pet BottleSushobhan DasNo ratings yet

- Presentation of Industrial Training In: Li-Tech Electro PlastDocument20 pagesPresentation of Industrial Training In: Li-Tech Electro PlastOM B (RA2011018010046)No ratings yet

- Gear Type Injection MouldingDocument47 pagesGear Type Injection MouldingJohn Ajish50% (2)

- Plastic Injection Molding: Akash Deep.B.N 1SJ03ME121Document20 pagesPlastic Injection Molding: Akash Deep.B.N 1SJ03ME121Maheesaras0% (1)

- Basics of Injection Molding DesignDocument20 pagesBasics of Injection Molding DesignAdeniyiNo ratings yet

- Group 1Document32 pagesGroup 1GemedaNo ratings yet

- Plastic ProcessingDocument35 pagesPlastic ProcessingCIPET KORBA TESTING100% (1)

- Basics of Mold DesignDocument15 pagesBasics of Mold DesignPedro Agirre IturbeNo ratings yet

- Plastic Technology (Uyumluluk Modu)Document72 pagesPlastic Technology (Uyumluluk Modu)Suchetha RajuNo ratings yet

- Energy Efficiency in The Plastics IndustryDocument22 pagesEnergy Efficiency in The Plastics IndustryHans De Keulenaer100% (11)

- What Is Injection Moulding ProcessDocument42 pagesWhat Is Injection Moulding ProcesssadiqusNo ratings yet

- Design and Manufacture of C-Clamp by Injection Molding ProcessDocument6 pagesDesign and Manufacture of C-Clamp by Injection Molding ProcessEng Stephen ArendeNo ratings yet

- Injection MouldingDocument18 pagesInjection MouldingKishore Steve AustinNo ratings yet

- Development of Cost-Effective Injection Molding Machine For Producing Plastic Wares Product Using Recycled Thermoplastic WastesDocument28 pagesDevelopment of Cost-Effective Injection Molding Machine For Producing Plastic Wares Product Using Recycled Thermoplastic WastesGp AlonzoNo ratings yet

- Advances in Injection MoldingDocument15 pagesAdvances in Injection MoldingPranav PatilNo ratings yet

- Final Part.2Document27 pagesFinal Part.2BindhuNo ratings yet

- Basics of Injection Molding DesignDocument12 pagesBasics of Injection Molding DesignGajender MehraNo ratings yet

- Global Academy of Technology: (Accredited by Naac With "A" Grade)Document37 pagesGlobal Academy of Technology: (Accredited by Naac With "A" Grade)James Prajwal PrajuNo ratings yet

- 1.polymer ProcessingDocument23 pages1.polymer Processingafia rahmanNo ratings yet

- Seminar ReportDocument23 pagesSeminar Reportbijithbigb0% (1)

- Introduction To Plastics Processing CIPET.Document55 pagesIntroduction To Plastics Processing CIPET.Pranav DNo ratings yet

- Mt1 Unit 5 NotesDocument11 pagesMt1 Unit 5 NotesvelavansuNo ratings yet

- Plastic InjectionDocument39 pagesPlastic InjectionRishav KumarNo ratings yet

- Design of Injection Mould Tool For Rubber Seal Used in Water HeaterDocument7 pagesDesign of Injection Mould Tool For Rubber Seal Used in Water HeaterAgonafirNo ratings yet

- What Is Plastic?: Manufacturing Processes For PlasticsDocument2 pagesWhat Is Plastic?: Manufacturing Processes For PlasticsJesse Jones SeraspeNo ratings yet

- Gufran Project-1Document60 pagesGufran Project-1Gufran AhmadNo ratings yet

- ARBURG-Examples of Multi Component Mould Designs GB PDFDocument40 pagesARBURG-Examples of Multi Component Mould Designs GB PDFkfaravNo ratings yet

- Module:7 Rapid Tooling 4 Hours SLO: 17: 1.reaction Injection MoldingDocument17 pagesModule:7 Rapid Tooling 4 Hours SLO: 17: 1.reaction Injection MoldingNishanth RajkumarNo ratings yet

- Adm Unit 2Document26 pagesAdm Unit 278956No ratings yet

- Methods, Processes and Equipment Involved in Manufacturing of PlasticDocument34 pagesMethods, Processes and Equipment Involved in Manufacturing of PlasticNiño Gerard JabagatNo ratings yet

- Plastics Processing Technology Lecture 6Document23 pagesPlastics Processing Technology Lecture 6Kyazze SulaimanNo ratings yet

- Lab Report Injection MoldingDocument4 pagesLab Report Injection MoldingMuzamil RazaNo ratings yet

- Project Report Plastic BowlDocument12 pagesProject Report Plastic Bowlmoniket sukhadiaNo ratings yet

- Injection Moulding Lab ReportDocument27 pagesInjection Moulding Lab ReportErnie Yana IINo ratings yet

- PolymersDocument14 pagesPolymersvanshpkotharistudyNo ratings yet

- Packaging AssignmentDocument11 pagesPackaging AssignmentAbhijeetKumar100% (1)

- Hot Runner TechnologyDocument3 pagesHot Runner Technologysuveesh nvNo ratings yet

- Report Injection MouldingDocument11 pagesReport Injection MouldingJilly ArasuNo ratings yet

- Module V - Blow and Transfer Molding ProcessesDocument17 pagesModule V - Blow and Transfer Molding ProcessesAntonius PrakosaNo ratings yet

- Final Report Plastic Injection MoldingDocument38 pagesFinal Report Plastic Injection MoldingshriNo ratings yet

- Polymer Processing HandoutDocument68 pagesPolymer Processing HandoutibraheemNo ratings yet

- Coer Collage Sample Internship FileDocument25 pagesCoer Collage Sample Internship FileHimanshu nirwanNo ratings yet

- Optimization of Injection Molding Manufacturing For Automotive IndustryDocument5 pagesOptimization of Injection Molding Manufacturing For Automotive IndustryJessica AlvarezNo ratings yet

- DesignandFabricationofMini InjectionMouldingMachineforSmall To MediumScalePlasticProcessingDocument10 pagesDesignandFabricationofMini InjectionMouldingMachineforSmall To MediumScalePlasticProcessingMEEN201101002 KFUEITNo ratings yet

- In Jection MouldingDocument21 pagesIn Jection MouldingAbhinandan PatilNo ratings yet

- Injection Molding Manual: Plastic SeriesDocument17 pagesInjection Molding Manual: Plastic SeriesUbaid Ur RehmanNo ratings yet

- Fabrication of Gear Type Injection Moulding AchineDocument29 pagesFabrication of Gear Type Injection Moulding AchineAnonymous ITnkbIEF75% (4)

- Hold Molds Work in Extrusion Blow Molding TechnologyDocument7 pagesHold Molds Work in Extrusion Blow Molding TechnologyNormanBatesNo ratings yet

- Investigate of Parameter Setting in Plastic Injection MoldingDocument28 pagesInvestigate of Parameter Setting in Plastic Injection MoldingKristine de ClaroNo ratings yet

- Interacademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.From EverandInteracademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.No ratings yet

- It 506261347Document12 pagesIt 506261347tou kaiNo ratings yet

- Job Description - Embedded Software Engineer (AUTODocument3 pagesJob Description - Embedded Software Engineer (AUTOtou kaiNo ratings yet

- Toshiba LTO CellDocument5 pagesToshiba LTO Celltou kaiNo ratings yet

- 0054Document1 page0054tou kaiNo ratings yet

- TS 600viDocument2 pagesTS 600vitou kaiNo ratings yet

- 0053Document1 page0053tou kaiNo ratings yet

- 1e. Isolation Sensing: R R R R V 0:002 D 500V R V V V VDocument3 pages1e. Isolation Sensing: R R R R V 0:002 D 500V R V V V Vtou kaiNo ratings yet

- Introduction To Week 4: Cooling SystemDocument3 pagesIntroduction To Week 4: Cooling Systemtou kaiNo ratings yet

- Lco Cgr18650eDocument1 pageLco Cgr18650etou kaiNo ratings yet

- 12 Design of A Variable Stiffness Joint Module To QuiDocument14 pages12 Design of A Variable Stiffness Joint Module To Quitou kaiNo ratings yet

- A Survey of Sensor Planning in Computer VisionDocument19 pagesA Survey of Sensor Planning in Computer Visiontou kaiNo ratings yet

- Using Fuzzy Logic Scheme For Automated Guided Vehicle To Track Following Path Under Various LoadDocument5 pagesUsing Fuzzy Logic Scheme For Automated Guided Vehicle To Track Following Path Under Various Loadtou kaiNo ratings yet

- A Survey On Industrial Vision Systems, Application and ToolsDocument18 pagesA Survey On Industrial Vision Systems, Application and Toolstou kaiNo ratings yet

- 'HVLJQDQG, Psohphqwdwlrqri+Ljk3Huirupdqfh 0Rwlrq&Rqwuroohuiru''Howd5RerwDocument6 pages'HVLJQDQG, Psohphqwdwlrqri+Ljk3Huirupdqfh 0Rwlrq&Rqwuroohuiru''Howd5Rerwtou kaiNo ratings yet

- Application of The Computer Visiion Tecnilogy To Control of Robot ManipulatorDocument6 pagesApplication of The Computer Visiion Tecnilogy To Control of Robot Manipulatortou kaiNo ratings yet

- Computer Vision Using Fuzzy Logic For ManipulatorDocument9 pagesComputer Vision Using Fuzzy Logic For Manipulatortou kaiNo ratings yet

- Implementation of Visionbased Autonomous Mobile Platform To Cont 2018Document6 pagesImplementation of Visionbased Autonomous Mobile Platform To Cont 2018tou kaiNo ratings yet

- E1FLA5 2014 v14n2 136Document9 pagesE1FLA5 2014 v14n2 136tou kaiNo ratings yet

- Visual Servoing in RoboticsDocument2 pagesVisual Servoing in Roboticstou kaiNo ratings yet

- Design and Development of Plastic Wastes Hollow Block Making MachineDocument43 pagesDesign and Development of Plastic Wastes Hollow Block Making MachineRichard ValdezNo ratings yet

- Compression MoldingDocument9 pagesCompression MoldingMadarizc VeryxcNo ratings yet

- HTV Silicone Rubber For Extrusion-AllDocument39 pagesHTV Silicone Rubber For Extrusion-AllJZ HuangNo ratings yet

- Module 15 - UNIT III - PolymersDocument12 pagesModule 15 - UNIT III - PolymersJhess GaliciaNo ratings yet

- Plastic Processing Question Paper 2016Document27 pagesPlastic Processing Question Paper 2016Supreeth Premkumar100% (2)

- Polymer Matrix CompositesDocument84 pagesPolymer Matrix Compositesعلي الشمريNo ratings yet

- Lecture 38. Processing Technologies: 1 .Mixing: Mixing Allows Obtaining A Homogeneous Mixture of PolymerDocument15 pagesLecture 38. Processing Technologies: 1 .Mixing: Mixing Allows Obtaining A Homogeneous Mixture of PolymerSUNILNo ratings yet

- ME8351-Manufacturing Technology-IDocument12 pagesME8351-Manufacturing Technology-IShrinath MPCBNo ratings yet

- Seminar-2 Rubber Compression MoldingDocument11 pagesSeminar-2 Rubber Compression MoldingSwapnil Ahire50% (2)

- App - Chem New MaterialDocument117 pagesApp - Chem New MaterialMadhavarao MaddisettyNo ratings yet

- Composite Written ReportDocument58 pagesComposite Written ReportMaria Cecille Sarmiento GarciaNo ratings yet

- Cetex TC1100Document4 pagesCetex TC1100ninju1No ratings yet

- CH 5 Plastic ProcessingDocument23 pagesCH 5 Plastic ProcessingSahibsartaj Dhaliwal83% (6)

- Rubber Calendering Extrusion MoldingDocument31 pagesRubber Calendering Extrusion MoldingAmyNo ratings yet

- TenCate Chopped Fiber Thermoplastics Compression Molding Technical PaperDocument14 pagesTenCate Chopped Fiber Thermoplastics Compression Molding Technical PaperJohnny 17No ratings yet

- ME8351-Manufacturing Technology-IDocument12 pagesME8351-Manufacturing Technology-IDayon MathewNo ratings yet

- Glossory of CompositeDocument125 pagesGlossory of CompositeIshfaq AhmadNo ratings yet

- Processing Chapter 3 Compression MoldingDocument40 pagesProcessing Chapter 3 Compression MoldingpandalynaNo ratings yet

- Plastic SyllabusDocument11 pagesPlastic SyllabusrajatNo ratings yet

- The Cost of Automotive Polymer CompositesDocument47 pagesThe Cost of Automotive Polymer CompositesIlija Bozovic100% (1)

- A Internship On: Presented by Harsha.G.KDocument19 pagesA Internship On: Presented by Harsha.G.KSunchit LawaniyaNo ratings yet

- Design - Guide Elastomers and ThermoplasticsDocument117 pagesDesign - Guide Elastomers and ThermoplasticsJuan Miguel CalzadaNo ratings yet

- Intro To CE AssignmentDocument16 pagesIntro To CE AssignmentNISA NABILAH MOHD ASRINNo ratings yet

- Objetive QuestionsDocument14 pagesObjetive QuestionsRupesh KamatNo ratings yet

- What Are PolymersDocument51 pagesWhat Are PolymerspatwarcNo ratings yet

- D704-99 (2012) Standard Specification For Melamine-Formaldehyde Molding CompoundsDocument3 pagesD704-99 (2012) Standard Specification For Melamine-Formaldehyde Molding Compoundsjavier perezNo ratings yet

- Mould TechnologyDocument71 pagesMould TechnologyS Karthick KeyanNo ratings yet

- Heat Cured ElastomersDocument40 pagesHeat Cured ElastomerslberrierNo ratings yet

Injection Moulding Process An Overview Ijariie15225

Injection Moulding Process An Overview Ijariie15225

Uploaded by

tou kaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injection Moulding Process An Overview Ijariie15225

Injection Moulding Process An Overview Ijariie15225

Uploaded by

tou kaiCopyright:

Available Formats

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

Injection Moulding Process – An Overview

Mayuresh Nitin Madiwale

Graduate Mechanical Engineer, Intern at Amol Enterprises, MIDC Satpur Nashik

ABSTRACT

Injection Moulding process is one of the most commonly used among all plastic processing methods due to its

advantages over other processes. Injection Moulding Process uses high temperature to melt the charge and pressure

to inject molten charge in mould cavity. This paper covers a brief overview of Injection Moulding Process along

with process parameters and their influence; mould design parameters, defects seen in moulded part with their

remedy and latest trends in Injection Moulding Process

Keywords: - Injection Moulding Process, Thermoplastics, Defects and Remedies, Process Parameters, latest

trends.

1. INTRODUCTION

As the demand of plastic products is increasing in the market, the need of supplying more in less time is also

increasing in order to maintain the demand and supply chain. This creates an obligation for manufacturers to reduce

cycle time and to improve quality. Therefore the conditions are approving for Injection Moulding as its production

rate is high, repeatability is high, low production cost, moderate scrap, vast availability of materials as per need and

has ability to produce required surface finish and engraved surfaces.

Manufacturers tend towards “one time setting” of all process parameters and try to achieve their daily production

schedule so as to maintain and improve their competency in the market which is also possible in this process.

Waste in production process is also an important factor that leads to loss in efficiency of manufacturing unit and

financial balance of company. To counter that, the wastage produced in Injection Moulding Process (flash, runners,

gates, defective parts) is recycled (Mostly thermoplastic materials).

The pressure in IM is relatively less than compression moulding (CM) process as it is only useful for injection stage

thereafter full pressure is not required. Thermoplastics are most commonly used material as this group possesses

higher MFI (Melt Flow Index) than that of Thermosets. Thus Thermosets are not suggested to be moulded by this

process and another reason being their inability to re-melt. The process starts with granulated raw material which is

dried in a drier to remove moisture content and to soften the material before moulding. Then the dried raw material

is poured in the hopper of moulding machine from where it moves to the barrel to be melted. After melting, it is then

injected into the mould from nozzle to sprue bush to runner of the part and then finally in the cavity where it

solidifies and takes the shape of cavity. The barrel is maintained at high temperature to melt the plastic while the

mould is maintained at lower temperature to initiate and catalyze solidification by means of running cold water

through mould or by simple air circulation around the mould. The ejection system arranged in the mould facilitates

the ejection safely. Thus the process completes with ejection of moulded part.

1.1 Requirements of Injection Moulding Process

Injection Moulding process requires following:-

1) Raw material

Plastic or Polymer precisely has three main subtypes namely Thermoplastics, Thermosets and Elastomers.

Thermoplastics are recyclable upto certain limit. They can be melted by heating and solidified by cooling.

Polypropylene (PP), Polyethylene (PE), Polystyrene (PS), Vinyl, Acrylic, ABS, Nylon, and Polycarbonate

(PC) are some TP’s used in various applications. On the other hand, Thermosets are not recyclable. They

can be heated to melt only for first time after which they cannot be used again. If heated again, they will

degrade and will be of no use for moulding thereafter. Phenolic, Polyester, Melamine, Urethane, Epoxy,

Alkyd, Diallyl are some TS’s available for various applications. Elastomers group contains polymers with

15225 www.ijariie.com 2238

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

high elasticity. These are also engineering materials used in various applications which require different

processes. Rubber, Butyl, Silicone, Fluorocarbon, Polysulfide, Polysulfide, Neoprene, etc are some

Elastomers used in day to day application.

Thus, Thermoplastics are widely used in Injection Moulding process while Thermosets are moulded by

Compression Moulding process.

Raw Thermoplastic is available in granules, powders, flakes, tapes, pellets or liquids. These are mainly

available in clear or white base colour. To add colour, master batches are added in specific amounts.

Master batches can be pigments or dyes. Raw material is dried in a drier to eliminate the moisture content

in plastic and to soften them before melting.

Fig -1 Raw Material Granules

2) Injection Mould

An accurate and precise mould cavity makes a perfect product. Mould has three main components, Cavity,

Core (Punch) and Ejection system. Cavity is the pocket in mould where molten plastic gets filled and

solidifies. Punch covers the cavity and or makes desired alignment with cavity to produce a hole in product.

Ejector system helps eject the final product from mould. Cavity is on one side of mould hence it is called

cavity half similarly, punch is on one side of mould, so it is called punch half. Ejector system is usually

arranged behind cavity side.

Mould material plays a vital role in accuracy of product. Components of mould that come in direct contact

of plastic such as Punch plate, Cavity plate, Stripper plate are made to withstand heat, pressure and wear-

tear, thus they are made with strong metal alloys such as HDS (Hot Die Steel) or OHNS. Guide pins and

ejector pins are also made with same material. Other parts such as Top plate, Bottom plate, Punch back

plate, Cavity back plate, Ejector plates, and spacers are made with softer material like MS (Mild Steel).

Fig -2 Schematic of Injection Mould

15225 www.ijariie.com 2239

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

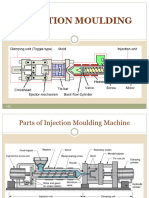

3) Injection Moulding machine

Injection moulding machines are available in two types, Vertical Moulding machines, and Horizontal

Moulding machines. This is distinguished by the direction of molten plastic through which it enters the

mould. Vertical machines usually require less floor space and are used for small light weighted products

while the Horizontal machines require more floor space and are used for heavy and large products. Modern

moulding machines (both vertical and horizontal) usually are fully automatic which theoretically do not

require any attention from workers.

But in practical applications, they are operated as semi automatic machines requiring some attention. E.g.:-

removing product and runners, adjusting various pressures as per need, lubricating the mould if the product

is sticking to it, etc. In Vertical Moulding machines plastic enters the mould through a channel carved

between punch and cavity plates. This method is useful only in Vertical Moulding machines; it does not

require sprue or any auxiliary components. In Horizontal Moulding machines, plastic enters through punch

side through a channel or hole drilled. This requires sprue, locating ring and proper channeling to the

cavity.

Fig -3 Horizontal Injection Moulding Machine

2 PROCESS FLOW

1) Raw material procurement

Raw material in form of granules, sheets, tapes are purchased as per requirement and inspected upon arrival.

Incoming inspection is done to assure that the material bags aren’t tampered with or damaged in any way. Also

the grade and quantity are checked to be sure. Finally it is stored in its appropriate location.

2) Pre-Moulding process

a) Storage

Purchased raw material needs to be stored in a well-ventilated dry place away from direct sunlight and

any heat source. Moisture has a bad impact on moulding process thus it should be away from moisture.

Thus the bags should not be opened until it is needed.

b) Colour mixing

Raw material can be procured in two ways, 1) pre-colored with desired colour code or, 2) clear plastic

and its separate master batch (Colorant). The choice depends on manufacturer or the client. If master

batch is to be added to the clear plastic, it is defined by Let-Down Ratio (LDR) which is the ratio of

master batch to the base material.

E.g.:- If LDR is 3%, master batch is 3 grams per 100 grams of base material.

1. Color code system:-

The colorant is defined by many color matching systems one of which is RAL value .E.g.:-

RAL 7032 – Pebble grey, RAL 1004 – Golden yellow

RAL is a European color matching system which defines colors for paint, coatings and plastics.

The RAL color standard is administrated by the RAL Deutsches Institut für Gütesicherung und

Kennzeichnung. 'RAL' is the abbreviation of 'Reichs-Ausschuß für Lieferbedingungen und

15225 www.ijariie.com 2240

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

Gütesicherung'. This name can be translated in English as 'National Commission for

Delivery Terms and Quality Assurance'. [1]

c) Drying

After mixing of colorant pigment or granules, the batch is dried in a Blow Drier. This process removes

the moisture content from the plastic. This can also be done in a low temperature furnace.

Fig -4 Hopper Drier [4]

3) Moulding process

a) Shot size

In each cycle, a specific amount of plastic is injected into the mould. This amount depends upon the

weight of part to be moulded and runner system used in moulding. Extra material in small quantities is

always helpful in ensuring the complete filling of cavity.

E.g.:- a part is weighing 50 grams, and runner system is weighing 2 grams, then the shot size is 10+2

=12 grams

b) Homogenization

Plastic granules from hopper are fed into the barrel of injection moulding. The screw in the barrel mixes

the plastic thoroughly, this ensures proper color as per requirement and the color is homogenized for the

entire batch. After one cycle is completed, the barrel screw turns while moving backwards filling the shot

and homogenizing the color simultaneously in this process.

c) Melting

Heaters attached at various points on the barrel melts the plastic. Ceramic, MICA band, induction coil

heaters are some types of heaters used in injection moulding process. Modern moulding machines have 5

point heaters, four on the barrel and one on the nozzle.

d) Pressurizing

The screw is then fed linearly pressurizing the charge in the barrel. As the screw moves towards the

nozzle, the pressure increases because the nozzle area is far less than the barrel cross-sectional area. The

pressure can be controlled with changing the pressure of hydraulic system.

e) Injecting

Pressurized charge moves with high velocity as it passes the nozzle and enters the sprue bush. The

internal aperture of sprue bush is tapered to facilitate the easy removal of runner after the solidification of

part. This also helps in reducing the jet velocity and increasing pressure similar to a venturi.

15225 www.ijariie.com 2241

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

f) Solidification

After complete filling of cavity, the plastic starts to solidify as the mould temperature is significantly

lower than the barrel. Also the mould temperature can be controlled by using external aid such as water

cooling system.

g) Ejection

After complete solidification, the part is ejected or “De-moulded” from the mould. There can be in-built

ejection system which is most widely used in practice or there can be external ejection system such as

“Pneumatic Ejection” which requires compressed air supply.

Various types of ejection systems include:-

I. Pin ejection

II. Sleeve ejection

III. Stripper plate ejection

a. Ejection pin operated

b. Side ejection

IV. Blade ejection

V. Pneumatic ejection (Air ejection)

Fig -5 Pneumatic Ejection System Schematic

4) Post-Moulding process

a) De-flashing

Flash/ Burr are difficult to eliminate. Thus the parts are deflashed. Operator removes the flash present on

the edges of the part and also removes the runner attached to the parts. This can be done when next cycle

is underway so as to eliminate further processing time.

b) Conditioning

Post Moulding Conditioning is a process required by some polymer types like Polyamide (Nylon), Acetal

and composites like Glass filled Nylon. These polymers absorb water from atmosphere. Water is a

plasticizer of these polymers and is necessary for dimensional and structural stability. The time it takes to

absorb moisture from atmosphere and attain equilibrium can be few days, weeks or even months. Thus

conditioning is necessary as soon as the part is ejected. Standard procedure suggests the conditioning in

water at 80-85º C for at least an hour.

c) Storage

After above steps are carried out, parts are dried again if there is moisture present and stored in a well

ventilated, dry room before it can be shipped to the customer.

15225 www.ijariie.com 2242

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

3. PROCESS PARAMETERS

There are various process parameters that control the operations. Also Mould design plays a significant role in

quality of part moulded. Following are some process parameters:-

I. Melt temperature

It is the temperature of the melted plastic. If the temperature is low, the plastic will not evenly melt and

may get stuck in the nozzle or gate area. If too high, it will degrade during the cycle and will evaporate the

moisture trapped and will be prone to trapped air bubbles.

II. Injection pressure

It is the pressure applied by plunger on the charge. If too high, it will show flow marks in the part and if too

low, the mould cavity will not fill completely.

III. Ejection pressure

It is the pressure applied by the ejector rod on the ejection system and on the part ultimately. If too low,

part will take longer to leave the cavity. If too high, the part will get deformed and may get scored by the

walls of cavity.

IV. Back pressure

It is the pressure applied on the screw on the way to collect new material from hopper. For proper

homogenization, this pressure should be controlled properly.

V. Screw RPM

It is the speed in revolutions per minute for the screw while it mixes the material for homogenization. If the

speed is low, the material may not mix properly causing colour defects. If too high, it will mix unnecessary

air in the material causing blow holes.

VI. Charge mass

It is the quantity of material imported in the barrel from hopper. This quantity should be equal to the mass

of part, runner system and little bit extra to ensure complete filling of cavity. More quantity will affect the

part as it will create flash. Less material will lead to short shot.

VII. Hold time / cooling time

It is the time for which the mould is kept closed after injection is complete. During this time, the part

solidifies inside the cavity. If this time is less, the part will not solidify completely and will get deformed on

removal. If it is more than required, it will increase cycle time.

VIII. Fill time

It is the time for which the injection is carried out. If enough time is not provided, it will cause incomplete

filling of cavity. If more, it will cause more material to get inside cavity causing excessive flash.

IX. Injection speed

It is the jet velocity of molten plastic. If it is more, it will cause flow pattern on part, which is a problem

when part is transparent. To avoid this runner design can be made such that it will not let high velocity jet

to go inside cavity.

X. Ejection speed

It is the speed by which the ejection system will operate. If the speed is more than requirement, it will cause

deformation on part. If the speed is less it will increase the overall cycle time of moulding.

XI. Clamping force

It is the force applied by the machine on the mould halves for proper sealing of mould. If less, it may leave

gap between the mould plates where material will get filled and flashes would occur. If too high, it will

cause damage to the hydraulics of machine and the mould surfaces.

15225 www.ijariie.com 2243

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

4. MOULD DESIGN PARAMETERS

These are the parameters to be considered while designing the mould. These parameters affect the part quality as

well.

I. Number of gates

Number of gates in a product influences its mechanical properties as well as the cycle time. If more than

one gate is present in the part, there will be weld line created compulsorily. There can be no such part

moulded with a number of gates and no weld line. And when weld line gets created, the structural rigidity

will be compromised specifically when the part is to be used where loads will be applied. To reduce this,

the gates should be placed such that the weld line will be on non critical areas of the part. However the

cycle time will be reduced dramatically when there is more than one gate.

II. Gate size

If there is obligation that number of gates cannot be made and the cycle time should be less, then increasing

the gate size can to the trick. More cross sectional area of gate means fast filling of part but much larger

portion of part needs to be trimmed of when runner system is being cut. Thus size of gate should be

appropriate such that final part does not look shabby on gate location.

III. Part’s geometric complexity

Geometric complexity of part matters a lot when moulding is being done. A very complex part will take

more time in mould design and manufacturing and hence will cost more. So it should be clear that the part

when designed for a specific condition should be less complex and easy to mould.

IV. Mould material

For a long run mould material should be capable of handling loads, abrasion and wear and tear. A very

simple mould which will not be used for mass production can be made from mild steel which is cheap as

well as capable for handling load for short duration. On the other hand, most moulds are made with harder

materials such as P20, OHNS, and HDS which perform excellent in long runs. However, more durable

metal alloys come with more cost. Thus the trick used by majority of mould makers is using harder and

durable alloys in most critical areas i.e. the core inserts, cavity inserts, cavity plate and stripper plate.

V. Runner design

An effective runner design leads to effective parts, less consumption of time and less wastage of plastic in

runners. There are several runner system designs the mould makers can choose as per the requirement. A

two cavity mould will require a simple Y-Balance system assuming each part has one gate. The care should

be taken that when more than one part is to be moulded, the effective length of runner from sprue should be

same for all parts. This will ensure that same time is required for all parts to be filled with same pressure

and velocity of melted plastic.

VI. Mould temperature

Mould temperature plays a vital role in solidification stage in moulding. The temperature control of mould

is hence necessary and controlled with care. More than required temperature will result in poor

solidification with deformed part at ejection. Too low temperature will solidify the plastic in the runner

system much prior it reaches the cavity. This will not only be good for part, but will also be bad for the

moulding machine as it will create excess pressure in the barrel and on the screw plunger.

Mould temperature control depends on type of moulding as well. Injection moulding requires mould

cooling whereas compression moulding requires mould heating. For cooling, air cooled moulds are most

conventional and cheap method but is in affective for large moulds. Water cooled system are used in large

moulds with much improved performance than that of air cooled but requires complex channels carved

inside the moulds which is time consuming and costly.

VII. Air vent location and size

Air vent is a necessary element in the mould. The air trapped in cavity needs to be rejected as the cavity

gets filled with molten plastic. It is seen in practice that air gets trapped in an area far away from gate

location. This is due to the air compressibility. Molten plastic pushes the air towards the far end and cannot

15225 www.ijariie.com 2244

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

compress it further causing bubble. Thus air vents are located in such areas if cavity is large. In small

moldings, the “clearance fit” provided on ejection rods is sufficient to let the air escape. The gap should be

in a range of 0.02 to 0.03 mm.

VIII. Mould opening/closing speed

This is the speed of mould operation. If the mould closing speed is too high, the collision of plates will

affect the part quality and will also lead to wear and tear of mould itself. If the opening speed is too high,

there will be fluctuations in quality and also a high probability of surface scratches on part. Modern

moulding machines are programmed considering this and have the speed variation in three stages. In first

stage the speed is slow, followed by a fast second stage and again slow stage at end.

5. DEFECTS FOUND IN INJECTION MOULDING PROCESS AND THEIR REMEDIES

There are many defects that can be encountered while moulding. This is because the process has many variables that

have implications on the final part quality. It’s hence important to know the potential defects and the way to

eliminate or at least reduce them. Following some defects that can be usually seen and can be avoided by some easy

tricks and techniques are discussed.

Table -1 Defect and their remedies in moulding.

Sr.

Defect Remedy

no

1 Short shot Increase injection pressure or

injection time. Increase shot size

by proper calculation

2 Flow lines Increase injection temperature or

decrease injection pressure.

Change gate location if jet is

abruptly gets stopped in cavity

3 Flash Decrease injection pressure or

change mould design to have less

gaps in cavity

15225 www.ijariie.com 2245

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

4 Blow holes/ air bubble trapped Increase injection pressure or add

air vents in mould

5 Warpage Induce slow cooling of part after

solidification or place weight on

parts to reduce the effect.

6 Surface scratches Apply lubricant spray on cavity

surface to reduce the effect.

7 Distortion Increase solidification time or

decrease mould temperature.

Reduce ejection speed and

ejection pressure

8 Colour inclusion Proper purging of plastic after

production

15225 www.ijariie.com 2246

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

9 Thermal cracking Usually occurs in initial cycles,

increase mould temperature

10 Blow holes Proper air vents required. Slow

down screw rotation speed to

reduce air inclusion

6. LATEST TRENDS IN INJECTION MOULDING

I. IML (In Mould Labeling)

In mould labeling is a part of In-Mould Decoration process which eliminates labeling time and the process

after the moulding is done. The process is carried out by placing the labels to be put on part placed inside

the cavity even before plastic is injected. The process is suitable for mass production. The most common

example is: - Ice-cream boxes with labels on all four sides.

Fig -6 In-Mould Labeling Process

II. Stack Moulds

This is advancement in conventional injection moulds. Conventional mould has only one mould face while

stack moulds have number of mould faces. The mould is divided into three parts. One side is the injecting

end which has sprue bush in it. The central core has two faces and both faces have cavities. And third side

is a supporting part which is used to open and close the mould.

One other type of stack mould has a rotating central core. This core has four moulding faces which rotate

around its central axis. Due to this rotation, a new face is exposed to the injecting side after a cycle is

15225 www.ijariie.com 2247

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

completed. This increases the productivity as no time is wasted in removing the part. Then next cycle is

underway, previous part is already facing away from injecting end thus part can be removed without

stopping the machine for long time.

Fig -7 Stack Mould – Mould Closed – Injection Done Fig -8 Stack Mould – Mould Open – Part Ejection

Fig -9 Rotating Cube Stack Mould

III. Micro Moulding

Micro-molding is a highly specialized manufacturing process that produces extremely small, high-precision

thermoplastic parts and components with micron tolerances. The process starts in a tooling department

where a mold is created that has a cavity in the shape of the part desired. Thermoplastic or resin is rapidly

injected into the cavity, creating the component or part at high speed

Part sizes in micron scale that too in high precision and accuracy is possible in Micro Moulding. Part

dimensions below 1mm with complex shapes and intricate patterns are maintained by this process. This

process can be single shot or two shot. Two shot micro moulding refers to use of two types of plastic

injected into cavity at same time.

IV. Bio Degradable Plastics in Injection moulding [2]

Traditional plastics do not decompose easily or rather take years to do so. Biodegradable plastic is a

variety that can decompose naturally in the environment. Fermentation of canola oil or sugar can produce a

polymer that decomposes under the right temperature and humidity conditions.

This makes biodegradable plastic especially well-suited for items and products which will be discarded

after one use.

The most common types of biodegradable plastic resins used in plastic injection molding include:

1. Thermoplastic Starch-based Plastics (TPS)

2. Polyhydroxyalkanoates (PHA)

3. Polylactic Acid (PLA)

4. Polybutylene Succinate (PBS)

5. Polycaprolactone (PCL)

15225 www.ijariie.com 2248

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

V. Gas Assisted Moulding [3]

The basic concept of the gas-assisted molding process is quite similar to regular injection

moulding process. In this gas-assisted molding, the plastic material is melted with the help of extruder

barrel and injected into the mold cavities like the regular injection moulding process but only up to

70%~80% of the mold volume. Plastic melts in contact with the mold walls begins to solidify and nitrogen

gas is injected into the mold through strategically designed and placed gas channels, providing pressure that

pushes the plastic material into the mold extremities and finally the molded part is ejected like the regular

injection molding process.

VI. Moulding of Structural Foam [4]

The Structural Foam Process is a low pressure injection molding process where an inert gas is introduced

into melted polymer for the purpose of reducing density and hence weight of the finished product.

Structural foam molded products have cellular cores surrounded by rigid, integral skins. Foaming agent

(NI, CO2 or CBA) is introduced into the polymer melt stream, creating a homogenous mixture of polymer

and gas. The mixture is short-shot injected through nozzles into the mold in a volume that is less than the

amount required to mold a solid part. Injection pressure and expansion of the polymer/gas mixture fills the

mold. A porous skin is formed when the melt contacts the cold surface of the mold. The expanding

polymer/gas mixture forms the cellular core.

Fig -10 Injection of Structural Foam Along With Plastic

VII. Use of Robotics In Injection Moulding [5]

Robots are made to do things which are either too difficult for humans or too labour intensive and time

consuming. Robots can handle these chores easily and relieve worker’s extra work which in turn improves

productivity. Highly repetitive actions are tedious to do and also can cause fatigue to workers. This is why

robotics in injection moulding process can be pain reducer. Machine tending – loading and unloading of

moulded parts from machine to further processes is the best area for robotic automation. In market there are

various types of robots available from which a few are discussed below.

1. 3-Axis Robots | Top Entry Robots

Part picking, In-Mold Decorating (IMD), In-Mold Labeling (IML), Insert Loading, Inspection,

Stacking and Palletizing are some of the processes that can be done with this type of robot. These

are used on Horizontal Plastic Injection Molding Machines (top entry automation applications)

and applications requiring higher speed.

2. 6-Axis Robots | Articulated Robots

Flexible automation on both Horizontal and Vertical Plastic Injection Molding Machines is done

with these robots. Larger working envelope and flexibility in upstream and downstream processes

are the advantages of Articulated Robots.

3. Collaborative Robots (Cobots)

The name itself suggests the function of the robot. Collaborative work of robot with humans is the

primary advantage of this type. Workers can work safely alongside these robots. Also

programming of these robots is way simpler than traditional robots. While traditional robots

require an engineer to write the codes for a certain movement to be done, cobots can be easily

programmed just by moving the arm in desired location and it will remember the movement. This

not only makes working alongside easier but also safer.

15225 www.ijariie.com 2249

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

4. 4-Axis SCARA Robots

Selective Compliant Assembly Robot Arm - 4-axis robots typically work in Plastic Injection

Molding automation applications for loading and unloading Vertical Injection Molding machines.

They have a circular work envelope with flexibility. These can work with other robots such as 3

axis or 6 axis robots for work sharing and high precision automation.

5. Side Entry Robots

Side entry robots are single axis robots that perform a specific application. They are capable of

extreme high speed applications such as placing decorations / labels for In-Mold Decorating

(IMD) / In-Mold Labeling (IML) and part removal.

6. Servo Sprue Pickers

Servo Sprue Pickers are simple pick-and-place robotic devices used for sprue removal or part and

runner separation in plastic injection molding automation. All three axes i.e. X, Y, and Z axis are

servo driven for maximum flexibility and programmability. A simple hand held pendant is enough

to move the robot in desired location with great flexibility and simplicity. Servo sprue pickers are

also capable for pre-staging above the mold. This minimizes cycle time. They are flexible

allowing for deposit on both sides of the injection molding machine - runners out on one side and

parts out on the other.

1). 3-Axis Robots | Top Entry Robots 3). Collaborative Robots (Cobots)

2). 6-Axis Robots |

Articulated Robots

5). Side Entry Robots

6). Servo Sprue Pickers

4). 4-Axis SCARA Robots

VIII. Hot Runner Injection System

Hot Runner System is a subtype of Runner-less Moulds. This system is effective in eliminating

the use of cold runners which are then required to trim after moulding. This not only saves the

material from wasting but also saves extra effort and time required after moulding is done. Most

modern mass production houses use Hot Runner system as it reduces effort and time even though

it requires more initial cost. Advantages of Hot Runner system are – shorter cycle time, easier to

use, lesser sing marks, flexible design options and balanced melt flow. Automation in

manufacturing is possible as no after trimming is required.

15225 www.ijariie.com 2250

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

Fig -11 Hot Runner System Schematic

IX. Injection – Compression Moulding (ICM)

As the name suggests, this process is conjunction of two moulding processes namely injection

and compression moulding. This is a special application moulding process. Usually insert

moulding (Moulding of a part with a preformed component – often metal component – loaded

into cavity where it is then overmoulded with plastic) is carried out. These inserts are to be placed

such a way that they do not fall before moulding thus this process is preferred. This process

requires special machines and mould design. Also there is no runner system expected hence

usually has Hot Runner System employed.

Fig -12 Injection of Plastic Material in Cavity Fig -13 Compression of Plastic in Cavity

X. Collapsible Core Moulding

For Internal threads or to induce an undercut in a part, without using split moulds, collapsible

cores are used. These cores operate such that internal threads or any other features that are to be

moulded on inner surface of part has becomes much easier. The faces expand when an actuator

rod is inserted and collapse when it is removed.

Fig -14 Collapsible Cores

Fig -15 Schematic of Collapsible Core

7. CONCLUSIONS

To produce any plastic component in less time while not compromising with quality, Injection Moulding Process

should be implemented. Numerous combinations of surface finish, material, shape, size, and colour can be made

possible by this process.

15225 www.ijariie.com 2251

Vol-7 Issue-4 2021 IJARIIE-ISSN(O)-2395-4396

Many organizations have started using non conventional mould designs such as stack moulds and automation

techniques such as robots to increase production. Modern analysis tools are also used before the actual process is

underway. This benefit in accurate representations of processes and corrective operations needed. This also helps in

saving large finances and time which were consumed during conventional trial and error method.

By controlling the process parameters, mould design parameters and using latest trending methods mentioned above,

the process can be used at its best.

7. ACKNOWLEDGEMENT

I acknowledge all the staff, employees and management of Amol Enterprises, MIDC Satpur, Nashik for their kind

support and guiding me to be capable enough to complete this paper.

8. REFERENCES

[1] https://en.wikipedia.org/wiki/RAL_colour_standard

[2] https://www.stelray.com/biodegradable-plastics-for-injection-plastic-molding/

[3] https://dienamics.com.au/blog/what-is-gas-assisted-injection-

moulding/#:~:text=The%20basic%20process%20of%20Gas,mould%20is%20about%2070%25%20full.

[4] https://www.wilmingtonmachinery.com/structural-foam-injection-molding-process/

[5] https://www.rnaautomation.com/blog/robotics-in-injection-moulding/

Books Referred:-

[1] Dominick V. Rosato, Donald V. Rosato, “Injection Molding Handbook”, CBS Publishers & Distributors,

ISBN 8123913648, 9788123913643, year – 200

[2] Georg Menges, Walter Michaeli, Paul Mohren, “How to Make Injection Molds”, Hanser Publishers, Munich,

eISBN: 978-3-446-40180-8 Print ISBN: 978-3-446-21256-5, year - 2001

Image References:-

[1] Fig -1 https://is2.ecplaza.com/ecplaza2/products/b/bb/bb8/1092135576/supla-synthetic-raw.jpg

[2] Fig -3 http://haitianpm.com/en/products/haitian-mars-series-ma/#ma5300iii-front

[3] Fig -4 https://image.made-in-china.com/2f0j00TnUEDiWFverQ/Plastic-Pellets-Hopper-Dryer-for-Injection-

Molding-Machine.jpg

[4] Fig -5 https://www.plasticmoulds.net/ejection-system-plastic-mold.html

[5] Fig -6 https://www.arion.asia/wp-content/uploads/2020/10/IMD-Process.jpg

[6] Fig -7, 8 https://www.evcoplastics.com/processes/stack-molds

[7] Fig -9 https://www.plasticstoday.com/new-turns-multicomponent-mold-revolution

[8] Fig -10 https://www.wilmingtonmachinery.com/structural-foam-injection-molding-process/

[9] Fig -11 https://www.smlease.com/wp-content/uploads/2017/11/Hot-Runner-Vs-Cold-Runner-System.png

[10] Fig -12, 13 Georg Menges, Walter Michaeli, Paul Mohren, “How to Make Injection Molds”, Hanser

Publishers, Munich, eISBN: 978-3-446-40180-8 Print ISBN: 978-3-446-21256-5, year – 2001, page no:- 594

[11] Fig -14 https://cdn.genalpha.com/2/images/rt-cores-cat.jpg

[12] Fig -15 https://ars.els-cdn.com/content/image/1-s2.0-S0890695599000966-gr4.gif

BIOGRAPHY

Mayuresh Nitin Madiwale

Graduate Mechanical Engineer,

Intern at Amol Enterprises, MIDC Satpur Nashik

15225 www.ijariie.com 2252

You might also like

- Project Report: Plastic Injection MouldingDocument26 pagesProject Report: Plastic Injection MouldingShubham Kumar JhaNo ratings yet

- Astm D883Document16 pagesAstm D883Anonymous nxfFHG32k100% (7)

- Intro To Plastic Injection Molding EbookDocument43 pagesIntro To Plastic Injection Molding EbookJames Farrugia78% (9)

- Software Instalation R-J2Document213 pagesSoftware Instalation R-J2Marcelo Fiod HasmanNo ratings yet

- Project On Sugarcane BaggasseDocument26 pagesProject On Sugarcane BaggasseV Deepak Kumar75% (4)

- MTE Innovative Project Report Rudransh Khera 2K20 - A18 - 80Document8 pagesMTE Innovative Project Report Rudransh Khera 2K20 - A18 - 80Ayush SinghNo ratings yet

- Compression Moulding Process - An Overview Ijariie11168Document10 pagesCompression Moulding Process - An Overview Ijariie11168ARUN KUMAR KoterimadathilNo ratings yet

- Plastic Injection Training ReportDocument31 pagesPlastic Injection Training ReportsazmsNo ratings yet

- Project Final Year On The Injection Plastic ModuleDocument41 pagesProject Final Year On The Injection Plastic ModuleSajid Zeya100% (1)

- Project Injection Moulding MachineDocument36 pagesProject Injection Moulding MachineSajid ZeyaNo ratings yet

- Prepared By-Chaudhari M.M SVCP (Sinhgad), PUNE (INDIA) Dept. of Mech. EnggDocument39 pagesPrepared By-Chaudhari M.M SVCP (Sinhgad), PUNE (INDIA) Dept. of Mech. EnggMitul patelNo ratings yet

- Blow Mould Tool Design and Manufacturing Process For 1litre Pet BottleDocument10 pagesBlow Mould Tool Design and Manufacturing Process For 1litre Pet BottleSushobhan DasNo ratings yet

- Presentation of Industrial Training In: Li-Tech Electro PlastDocument20 pagesPresentation of Industrial Training In: Li-Tech Electro PlastOM B (RA2011018010046)No ratings yet

- Gear Type Injection MouldingDocument47 pagesGear Type Injection MouldingJohn Ajish50% (2)

- Plastic Injection Molding: Akash Deep.B.N 1SJ03ME121Document20 pagesPlastic Injection Molding: Akash Deep.B.N 1SJ03ME121Maheesaras0% (1)

- Basics of Injection Molding DesignDocument20 pagesBasics of Injection Molding DesignAdeniyiNo ratings yet

- Group 1Document32 pagesGroup 1GemedaNo ratings yet

- Plastic ProcessingDocument35 pagesPlastic ProcessingCIPET KORBA TESTING100% (1)

- Basics of Mold DesignDocument15 pagesBasics of Mold DesignPedro Agirre IturbeNo ratings yet

- Plastic Technology (Uyumluluk Modu)Document72 pagesPlastic Technology (Uyumluluk Modu)Suchetha RajuNo ratings yet

- Energy Efficiency in The Plastics IndustryDocument22 pagesEnergy Efficiency in The Plastics IndustryHans De Keulenaer100% (11)

- What Is Injection Moulding ProcessDocument42 pagesWhat Is Injection Moulding ProcesssadiqusNo ratings yet

- Design and Manufacture of C-Clamp by Injection Molding ProcessDocument6 pagesDesign and Manufacture of C-Clamp by Injection Molding ProcessEng Stephen ArendeNo ratings yet

- Injection MouldingDocument18 pagesInjection MouldingKishore Steve AustinNo ratings yet

- Development of Cost-Effective Injection Molding Machine For Producing Plastic Wares Product Using Recycled Thermoplastic WastesDocument28 pagesDevelopment of Cost-Effective Injection Molding Machine For Producing Plastic Wares Product Using Recycled Thermoplastic WastesGp AlonzoNo ratings yet

- Advances in Injection MoldingDocument15 pagesAdvances in Injection MoldingPranav PatilNo ratings yet

- Final Part.2Document27 pagesFinal Part.2BindhuNo ratings yet

- Basics of Injection Molding DesignDocument12 pagesBasics of Injection Molding DesignGajender MehraNo ratings yet

- Global Academy of Technology: (Accredited by Naac With "A" Grade)Document37 pagesGlobal Academy of Technology: (Accredited by Naac With "A" Grade)James Prajwal PrajuNo ratings yet

- 1.polymer ProcessingDocument23 pages1.polymer Processingafia rahmanNo ratings yet

- Seminar ReportDocument23 pagesSeminar Reportbijithbigb0% (1)

- Introduction To Plastics Processing CIPET.Document55 pagesIntroduction To Plastics Processing CIPET.Pranav DNo ratings yet

- Mt1 Unit 5 NotesDocument11 pagesMt1 Unit 5 NotesvelavansuNo ratings yet

- Plastic InjectionDocument39 pagesPlastic InjectionRishav KumarNo ratings yet

- Design of Injection Mould Tool For Rubber Seal Used in Water HeaterDocument7 pagesDesign of Injection Mould Tool For Rubber Seal Used in Water HeaterAgonafirNo ratings yet

- What Is Plastic?: Manufacturing Processes For PlasticsDocument2 pagesWhat Is Plastic?: Manufacturing Processes For PlasticsJesse Jones SeraspeNo ratings yet

- Gufran Project-1Document60 pagesGufran Project-1Gufran AhmadNo ratings yet

- ARBURG-Examples of Multi Component Mould Designs GB PDFDocument40 pagesARBURG-Examples of Multi Component Mould Designs GB PDFkfaravNo ratings yet

- Module:7 Rapid Tooling 4 Hours SLO: 17: 1.reaction Injection MoldingDocument17 pagesModule:7 Rapid Tooling 4 Hours SLO: 17: 1.reaction Injection MoldingNishanth RajkumarNo ratings yet

- Adm Unit 2Document26 pagesAdm Unit 278956No ratings yet

- Methods, Processes and Equipment Involved in Manufacturing of PlasticDocument34 pagesMethods, Processes and Equipment Involved in Manufacturing of PlasticNiño Gerard JabagatNo ratings yet

- Plastics Processing Technology Lecture 6Document23 pagesPlastics Processing Technology Lecture 6Kyazze SulaimanNo ratings yet

- Lab Report Injection MoldingDocument4 pagesLab Report Injection MoldingMuzamil RazaNo ratings yet

- Project Report Plastic BowlDocument12 pagesProject Report Plastic Bowlmoniket sukhadiaNo ratings yet

- Injection Moulding Lab ReportDocument27 pagesInjection Moulding Lab ReportErnie Yana IINo ratings yet

- PolymersDocument14 pagesPolymersvanshpkotharistudyNo ratings yet

- Packaging AssignmentDocument11 pagesPackaging AssignmentAbhijeetKumar100% (1)

- Hot Runner TechnologyDocument3 pagesHot Runner Technologysuveesh nvNo ratings yet

- Report Injection MouldingDocument11 pagesReport Injection MouldingJilly ArasuNo ratings yet

- Module V - Blow and Transfer Molding ProcessesDocument17 pagesModule V - Blow and Transfer Molding ProcessesAntonius PrakosaNo ratings yet

- Final Report Plastic Injection MoldingDocument38 pagesFinal Report Plastic Injection MoldingshriNo ratings yet

- Polymer Processing HandoutDocument68 pagesPolymer Processing HandoutibraheemNo ratings yet

- Coer Collage Sample Internship FileDocument25 pagesCoer Collage Sample Internship FileHimanshu nirwanNo ratings yet

- Optimization of Injection Molding Manufacturing For Automotive IndustryDocument5 pagesOptimization of Injection Molding Manufacturing For Automotive IndustryJessica AlvarezNo ratings yet

- DesignandFabricationofMini InjectionMouldingMachineforSmall To MediumScalePlasticProcessingDocument10 pagesDesignandFabricationofMini InjectionMouldingMachineforSmall To MediumScalePlasticProcessingMEEN201101002 KFUEITNo ratings yet

- In Jection MouldingDocument21 pagesIn Jection MouldingAbhinandan PatilNo ratings yet

- Injection Molding Manual: Plastic SeriesDocument17 pagesInjection Molding Manual: Plastic SeriesUbaid Ur RehmanNo ratings yet

- Fabrication of Gear Type Injection Moulding AchineDocument29 pagesFabrication of Gear Type Injection Moulding AchineAnonymous ITnkbIEF75% (4)

- Hold Molds Work in Extrusion Blow Molding TechnologyDocument7 pagesHold Molds Work in Extrusion Blow Molding TechnologyNormanBatesNo ratings yet

- Investigate of Parameter Setting in Plastic Injection MoldingDocument28 pagesInvestigate of Parameter Setting in Plastic Injection MoldingKristine de ClaroNo ratings yet

- Interacademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.From EverandInteracademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.No ratings yet

- It 506261347Document12 pagesIt 506261347tou kaiNo ratings yet

- Job Description - Embedded Software Engineer (AUTODocument3 pagesJob Description - Embedded Software Engineer (AUTOtou kaiNo ratings yet

- Toshiba LTO CellDocument5 pagesToshiba LTO Celltou kaiNo ratings yet

- 0054Document1 page0054tou kaiNo ratings yet

- TS 600viDocument2 pagesTS 600vitou kaiNo ratings yet

- 0053Document1 page0053tou kaiNo ratings yet

- 1e. Isolation Sensing: R R R R V 0:002 D 500V R V V V VDocument3 pages1e. Isolation Sensing: R R R R V 0:002 D 500V R V V V Vtou kaiNo ratings yet

- Introduction To Week 4: Cooling SystemDocument3 pagesIntroduction To Week 4: Cooling Systemtou kaiNo ratings yet

- Lco Cgr18650eDocument1 pageLco Cgr18650etou kaiNo ratings yet

- 12 Design of A Variable Stiffness Joint Module To QuiDocument14 pages12 Design of A Variable Stiffness Joint Module To Quitou kaiNo ratings yet

- A Survey of Sensor Planning in Computer VisionDocument19 pagesA Survey of Sensor Planning in Computer Visiontou kaiNo ratings yet

- Using Fuzzy Logic Scheme For Automated Guided Vehicle To Track Following Path Under Various LoadDocument5 pagesUsing Fuzzy Logic Scheme For Automated Guided Vehicle To Track Following Path Under Various Loadtou kaiNo ratings yet

- A Survey On Industrial Vision Systems, Application and ToolsDocument18 pagesA Survey On Industrial Vision Systems, Application and Toolstou kaiNo ratings yet

- 'HVLJQDQG, Psohphqwdwlrqri+Ljk3Huirupdqfh 0Rwlrq&Rqwuroohuiru''Howd5RerwDocument6 pages'HVLJQDQG, Psohphqwdwlrqri+Ljk3Huirupdqfh 0Rwlrq&Rqwuroohuiru''Howd5Rerwtou kaiNo ratings yet

- Application of The Computer Visiion Tecnilogy To Control of Robot ManipulatorDocument6 pagesApplication of The Computer Visiion Tecnilogy To Control of Robot Manipulatortou kaiNo ratings yet

- Computer Vision Using Fuzzy Logic For ManipulatorDocument9 pagesComputer Vision Using Fuzzy Logic For Manipulatortou kaiNo ratings yet

- Implementation of Visionbased Autonomous Mobile Platform To Cont 2018Document6 pagesImplementation of Visionbased Autonomous Mobile Platform To Cont 2018tou kaiNo ratings yet

- E1FLA5 2014 v14n2 136Document9 pagesE1FLA5 2014 v14n2 136tou kaiNo ratings yet

- Visual Servoing in RoboticsDocument2 pagesVisual Servoing in Roboticstou kaiNo ratings yet

- Design and Development of Plastic Wastes Hollow Block Making MachineDocument43 pagesDesign and Development of Plastic Wastes Hollow Block Making MachineRichard ValdezNo ratings yet

- Compression MoldingDocument9 pagesCompression MoldingMadarizc VeryxcNo ratings yet

- HTV Silicone Rubber For Extrusion-AllDocument39 pagesHTV Silicone Rubber For Extrusion-AllJZ HuangNo ratings yet

- Module 15 - UNIT III - PolymersDocument12 pagesModule 15 - UNIT III - PolymersJhess GaliciaNo ratings yet

- Plastic Processing Question Paper 2016Document27 pagesPlastic Processing Question Paper 2016Supreeth Premkumar100% (2)

- Polymer Matrix CompositesDocument84 pagesPolymer Matrix Compositesعلي الشمريNo ratings yet

- Lecture 38. Processing Technologies: 1 .Mixing: Mixing Allows Obtaining A Homogeneous Mixture of PolymerDocument15 pagesLecture 38. Processing Technologies: 1 .Mixing: Mixing Allows Obtaining A Homogeneous Mixture of PolymerSUNILNo ratings yet

- ME8351-Manufacturing Technology-IDocument12 pagesME8351-Manufacturing Technology-IShrinath MPCBNo ratings yet

- Seminar-2 Rubber Compression MoldingDocument11 pagesSeminar-2 Rubber Compression MoldingSwapnil Ahire50% (2)

- App - Chem New MaterialDocument117 pagesApp - Chem New MaterialMadhavarao MaddisettyNo ratings yet

- Composite Written ReportDocument58 pagesComposite Written ReportMaria Cecille Sarmiento GarciaNo ratings yet

- Cetex TC1100Document4 pagesCetex TC1100ninju1No ratings yet

- CH 5 Plastic ProcessingDocument23 pagesCH 5 Plastic ProcessingSahibsartaj Dhaliwal83% (6)

- Rubber Calendering Extrusion MoldingDocument31 pagesRubber Calendering Extrusion MoldingAmyNo ratings yet

- TenCate Chopped Fiber Thermoplastics Compression Molding Technical PaperDocument14 pagesTenCate Chopped Fiber Thermoplastics Compression Molding Technical PaperJohnny 17No ratings yet

- ME8351-Manufacturing Technology-IDocument12 pagesME8351-Manufacturing Technology-IDayon MathewNo ratings yet

- Glossory of CompositeDocument125 pagesGlossory of CompositeIshfaq AhmadNo ratings yet

- Processing Chapter 3 Compression MoldingDocument40 pagesProcessing Chapter 3 Compression MoldingpandalynaNo ratings yet

- Plastic SyllabusDocument11 pagesPlastic SyllabusrajatNo ratings yet

- The Cost of Automotive Polymer CompositesDocument47 pagesThe Cost of Automotive Polymer CompositesIlija Bozovic100% (1)

- A Internship On: Presented by Harsha.G.KDocument19 pagesA Internship On: Presented by Harsha.G.KSunchit LawaniyaNo ratings yet

- Design - Guide Elastomers and ThermoplasticsDocument117 pagesDesign - Guide Elastomers and ThermoplasticsJuan Miguel CalzadaNo ratings yet

- Intro To CE AssignmentDocument16 pagesIntro To CE AssignmentNISA NABILAH MOHD ASRINNo ratings yet

- Objetive QuestionsDocument14 pagesObjetive QuestionsRupesh KamatNo ratings yet

- What Are PolymersDocument51 pagesWhat Are PolymerspatwarcNo ratings yet

- D704-99 (2012) Standard Specification For Melamine-Formaldehyde Molding CompoundsDocument3 pagesD704-99 (2012) Standard Specification For Melamine-Formaldehyde Molding Compoundsjavier perezNo ratings yet

- Mould TechnologyDocument71 pagesMould TechnologyS Karthick KeyanNo ratings yet

- Heat Cured ElastomersDocument40 pagesHeat Cured ElastomerslberrierNo ratings yet