Professional Documents

Culture Documents

Inspection & Tech - Survey-Pressure Gauge

Inspection & Tech - Survey-Pressure Gauge

Uploaded by

javed iqbal0 ratings0% found this document useful (0 votes)

3 views2 pagesOriginal Title

Inspection & Tech.Survey-Pressure Gauge

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

3 views2 pagesInspection & Tech - Survey-Pressure Gauge

Inspection & Tech - Survey-Pressure Gauge

Uploaded by

javed iqbalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

@iyleoJlg peas auiaill aie] auuugall

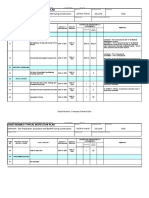

TS Inspection & Technical Survey Est.

C.R. 2050060083 - C.C.No. 120676

Page: 12

180 9001 Certifeation

CERTIFICATE OF CALIBRATION

Certificate No. : 20190526-05N

Customer: AL SYED COMPANY

Address: Dammam, Kingdom of Saudi Arabia

‘This Cerificate of Calibration certifies tha he instrument below has been tasted/calibrated using equipment traceable to NPL, NIST,

‘SASO or other Natonalntemational standards or verfod by ratio type measurements using self calling techniques. Information on

the callraon procass & the results are produced below or are gven inthe fellowing pages of tis document. Al related traceable

documents are on feat ITS (IC Division) and may be examined on request

Instrument Details

Instrument Name : Pressure Gauge

Manufacturer/Brand : Wika

Model/Type : EN837-1

Range/Capacity :0- 360 psi

Resolution 40 psi

Serial No. 10526

Identification No. : Not indicated

Remarks : Passed

Calibration Date : 26 May 2019

Recommended Due Date: 25 November 2019

@)

Nasir Shari

Calibrated By:

QVALITY CONTR

Checked By: CHECKED

QAIac

Signed for and on behatf of

Inspection and Technical Suwvey Est

“Te Measaemnlrevuli parain ory fo the calibaied ineraent athe tine of alban

‘This certiieae & the attached measurement result sheets shall not be reproduced exept in fll without the prio: pemission of TS

P.O. Ba: 8116 - DAMMAM 32436 - Kingdom of Saudi Arabia - Tel.: +966 138376604 - Fak S681 38376605,

www. its-arbia.com

Page? 2

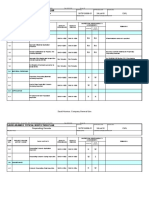

‘Manufacturer: Wika Certificate No, : 20190526-05N

Device Serial Nos 10526 Identification No.: Not indicated

Test Result:

Gauge Set Point | Standard Reading (inereaeing) Standard Reading (Decreasing) | Average! Ear

psi Se Xt a= [= DSi si

0.0 ‘0.0 0.0 0.0, 0.0. 0.0 00) 0.000, 0.000

20.0 30.0 90.0 20.0, 30.0 90.0_| 90.0 90.000 0.000,

180.0 1810 | 181.0 | 180.0 | 180.0_| 179.0 | 190.0 [180.167 0.167

270.0) 271.0 | 2720 | 2700 | 268.0 | 268.0 | 269.0 | 269.833 0.167

360.0, 358.0 | 3590 | 3580 | 368.0 | 359.0 | 3580 | 358.333, =1.667

Uncertainty of Measurement: + 2.0 % of full scale reading at 96% confidence level (k=2)

Condition of Tested Unit

[Within the tolerance on receipt (as found) (Within the tolerance but there is sighi crack on the glass.

[The instrument was adjusted No]

[The instrument was repaired No]

[Within the tolerance on dispatch (as left) Full scale was tested using CM-33 Master with the scope of 0.08%|

Calibration Description and Information

[Test method [The measuring instrument was checked and calibrated atITS Laboratory by using he

reference standards traceable to NIST and/or S|. The test was performed in accordance with

lapplicable formulated procedure based from below standard

[Calibration Procedure |ITS-CLP-O1 EURAMET CG-17,

[Environment's conditions |Temperature 20° 22°C Relative Humidity 60% 210%

[other ‘The readings given are the resulls at the time of testing and do not carry any Implication

regarding the long term stability ofthe instrument.

Reference Standard Used

(Description its > [Cal Due Date [Traceability (Certificate

[Pressure Calibrator icw-30 26 October 2020 | Primary Measurement [2017013621

[Pressure Calibrator icw-s3 28 October 2020_|- lpov70138522

Calibration Technician

-End of certiticate-

FATS-t-002

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Total Station - Leica TS09-3Document2 pagesTotal Station - Leica TS09-3javed iqbalNo ratings yet

- Satip G 115 01Document7 pagesSatip G 115 01javed iqbalNo ratings yet

- Hcs CuringDocument1 pageHcs Curingjaved iqbalNo ratings yet

- Satip A 114 01Document11 pagesSatip A 114 01javed iqbalNo ratings yet

- Satip B 006 01Document11 pagesSatip B 006 01javed iqbalNo ratings yet

- Screed Mix Design Appendix B and CDocument2 pagesScreed Mix Design Appendix B and Cjaved iqbalNo ratings yet

- Atc-Incr # 009Document1 pageAtc-Incr # 009javed iqbalNo ratings yet

- Incr # 09-01-2017Document1 pageIncr # 09-01-2017javed iqbalNo ratings yet

- Atc-Incr # 008Document1 pageAtc-Incr # 008javed iqbalNo ratings yet

- Daily RFI Log (01-Mar-2023)Document1 pageDaily RFI Log (01-Mar-2023)javed iqbalNo ratings yet

- Incr # 15-03-2017Document1 pageIncr # 15-03-2017javed iqbalNo ratings yet

- PhantomPDF UserManualDocument240 pagesPhantomPDF UserManualjaved iqbalNo ratings yet

- Incr # 04-12-2017Document1 pageIncr # 04-12-2017javed iqbalNo ratings yet