Professional Documents

Culture Documents

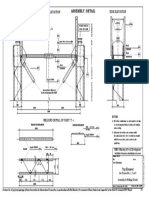

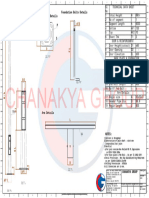

Welding Detail of Part T - L Vertical Legs Assembly Details

Welding Detail of Part T - L Vertical Legs Assembly Details

Uploaded by

saubhagya majhiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Detail of Part T - L Vertical Legs Assembly Details

Welding Detail of Part T - L Vertical Legs Assembly Details

Uploaded by

saubhagya majhiCopyright:

Available Formats

T

WELDING DETAIL OF PART T - l Temporary

FRONT ELEVATION ASSEMBLY 12c

T

Vertical Legs Element

DETAILS 12b SIDE

for Cable

ELEVATION

ELEVATION SIDE ELEVATION hoisting DWG No: 135 T

S-1 12a

S-2 S-3 S-4 S-5 S-6

Rod φ 12 mm

T-lc T-6

T-7

T-7

T-8

T-4 T-10

T-8

240

T-9

T-2 T-9

T-1

T-1

“B”

T-3

Rod φ 12 mm T-3 T-11

T-lb

Angle 65/65/6

T-la

300 300 400

3500

30 240 30 25 350 25

300 400 DETAIL at “A” DETAIL OF PART T-4

10

Angle 65/65/6 1590

T-la Rod φ 12 mm

T-lc

Lacing.

Rod φ 12 mm 6

T-lc

6 Angle 50/50/6 Rod φ 10 mm

T-1a T-1b

6 PLAN 40

Rod φ 12 mm 6

T-lb

“A”

300

r = 70

Angle 65/65/6 4

T-la

WELDING DETAIL OF PART T - 2

FRONT ELEVATION Rod φ 12 mm

T-lb

2505 Lacing.

30 40

70 330 330 330 330 200

1090

Rod φ 10 mm

Angle 50/50/6 T-1b NOTES :

PLAN T-1a HMG / Ministry of Local Development

40 80 1) To obtain uniformity, use of templates and jigs DoLIDAR / Short SpanTrail Bridge Standard

is mandatory for holing bending and welding Bridge Name:

of assembly. No: Span:

r = 70 Steel Drawing:

2) All parts or bundles and packages with

identical parts have to be bundled or marked

Top Element

with the respective part number by the

for Tower No. 4

workshop.

230 400 400 400 400 400 275 Assembly & Welding Details

1590

Date : September 30, 2002 Drawing No. 121N

Produced by Nepal Swiss Association for International Cooperation, in partnership with His Majesty’s Government of Nepal, funded and supported by the Swiss Government (SDC Nepal). 33

You might also like

- Panel Board 520 E34Document1 pagePanel Board 520 E34CADASEDA100% (2)

- Wiring Electrical - AllDocument15 pagesWiring Electrical - AllArief Rakhmad100% (2)

- Engine Control (5S-Fe)Document8 pagesEngine Control (5S-Fe)Toysport Automotive100% (1)

- D C B A F E Distortion Channel: ©2007 LOUD Technologies Inc. All Rights Re Served PWA Guitar Amplifi Er PCB SchematicsDocument3 pagesD C B A F E Distortion Channel: ©2007 LOUD Technologies Inc. All Rights Re Served PWA Guitar Amplifi Er PCB Schematicsgearhead1No ratings yet

- Bosch K-Jet (CIS)Document14 pagesBosch K-Jet (CIS)gjm126No ratings yet

- Assembly Detail: Side Elevation Front ElevationDocument1 pageAssembly Detail: Side Elevation Front ElevationRanjit Kumar ShahNo ratings yet

- Planta Alta ESC. 1: 100 SUP.: 132.43 M2Document1 pagePlanta Alta ESC. 1: 100 SUP.: 132.43 M2Fermín VelascoNo ratings yet

- Guj Conex Floor PlanDocument4 pagesGuj Conex Floor PlanstudioNo ratings yet

- C D G I F H C1 C2 H1: Planta Losa de Planta BajaDocument1 pageC D G I F H C1 C2 H1: Planta Losa de Planta BajaJennerJimenezNo ratings yet

- Op TT412 Tt12a-Tt12c Op186-V04Document1 pageOp TT412 Tt12a-Tt12c Op186-V04Pasindu PriyankaraNo ratings yet

- Legenda / Legend: T-Gi TakengonDocument1 pageLegenda / Legend: T-Gi TakengonBayu Pramana PutraNo ratings yet

- ProfesDocument1 pageProfesAndres Suarez.No ratings yet

- ProfesDocument1 pageProfesAndres Suarez.No ratings yet

- 519-18-TR-2A - 20240405 - 0001 (Commented)Document2 pages519-18-TR-2A - 20240405 - 0001 (Commented)Harish KumarNo ratings yet

- OGF-B-23-4-001 - Reg. Longitudinal and Cross Section - Darft 8-05-23-Model PDFDocument1 pageOGF-B-23-4-001 - Reg. Longitudinal and Cross Section - Darft 8-05-23-Model PDFA oppositeNo ratings yet

- Gama ING 6Document1 pageGama ING 6mbidNo ratings yet

- 05 - Reinforcement Details of D-S Sloping Barrels For SyphonDocument1 page05 - Reinforcement Details of D-S Sloping Barrels For SyphonLearningSupport by Ejaz shaikhNo ratings yet

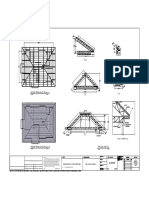

- Truss Detail - 094434Document1 pageTruss Detail - 094434Leo Manuel Ejudo CorderoNo ratings yet

- Traffic Direction: Mounting Bracket TDC-MB 1Document1 pageTraffic Direction: Mounting Bracket TDC-MB 1Ryyette AguirreNo ratings yet

- Discontinued: TMT1HNCR Series Reliance Commercial Line Manual Toilet Flush Valve, Exposed 1.6 GPFDocument2 pagesDiscontinued: TMT1HNCR Series Reliance Commercial Line Manual Toilet Flush Valve, Exposed 1.6 GPFSharrife JNo ratings yet

- ATS624 Four-Relay Expander Installation SheetDocument14 pagesATS624 Four-Relay Expander Installation SheetFredNo ratings yet

- 113-05-0102 FOUNDATION DETAILS FOR DG WATER TRANSFER PUMPS-ModelDocument1 page113-05-0102 FOUNDATION DETAILS FOR DG WATER TRANSFER PUMPS-ModelShanmuganathan ShanNo ratings yet

- Wiring Diagram ATS 135Document5 pagesWiring Diagram ATS 135Septian Pandjie100% (1)

- Wiring Diagram ATS 25kva AtyS-Revisi1Document5 pagesWiring Diagram ATS 25kva AtyS-Revisi1Andira ElectrikNo ratings yet

- PFD Acetone From Isopropyl AlcoholDocument1 pagePFD Acetone From Isopropyl AlcoholNabila Rizki Amalia100% (1)

- Shimano EV-FD-C101-E, C102 Altus Top Swing Front DerailleurDocument1 pageShimano EV-FD-C101-E, C102 Altus Top Swing Front DerailleurxjcaiNo ratings yet

- UmedaDocument1 pageUmedaRuby Jean RosalNo ratings yet

- Pre Twa1500 Whx2000Document1 pagePre Twa1500 Whx2000Anderson DiamantinoNo ratings yet

- Grounding System Rasc Emas 5-Jan-2021Document1 pageGrounding System Rasc Emas 5-Jan-2021Nat WutthivongthanakornNo ratings yet

- MD031-TTK-ZZ-0G-DR-M-AUXL-1002 - MD3.1 Data Hall Groud Floor Leak Detection System (Aerial) - A1-AerialDocument1 pageMD031-TTK-ZZ-0G-DR-M-AUXL-1002 - MD3.1 Data Hall Groud Floor Leak Detection System (Aerial) - A1-AerialssiNo ratings yet

- For Vogt Power Intl Inc Amata Abpr4, Thailand Assembly & Details Hot Flange Assembly GT Outlet Transition Duct & EjDocument1 pageFor Vogt Power Intl Inc Amata Abpr4, Thailand Assembly & Details Hot Flange Assembly GT Outlet Transition Duct & EjprasongNo ratings yet

- Selec: Mechanical Installation Terminal ConnectionsDocument1 pageSelec: Mechanical Installation Terminal ConnectionsPasindu PriyankaraNo ratings yet

- Q-07 Domae: General NotesDocument1 pageQ-07 Domae: General NotesrosaNo ratings yet

- Wiring Panel MCC PT. INL (Revisi) PT. DEXA ENERGY MEDANDocument6 pagesWiring Panel MCC PT. INL (Revisi) PT. DEXA ENERGY MEDANDede JuwandaNo ratings yet

- Ast eDocument2 pagesAst ejulio cesarNo ratings yet

- Manuals qnd-7080r Qno-7080r qnv-7080r 180608 enDocument54 pagesManuals qnd-7080r Qno-7080r qnv-7080r 180608 enMinh TuNo ratings yet

- New T.V.L Building: Senior High School BuildingDocument1 pageNew T.V.L Building: Senior High School Buildingbernie evaristo bacsaNo ratings yet

- Tree Planting 11 12 21Document2 pagesTree Planting 11 12 21silbapan27No ratings yet

- Hitachi cdh-l32s02 SCHDocument12 pagesHitachi cdh-l32s02 SCHMario BorgiattinoNo ratings yet

- ZYHBDocument30 pagesZYHBGio GNo ratings yet

- Amd 001 S.A R4 2Document1 pageAmd 001 S.A R4 2Yoto SoN FirstNo ratings yet

- 2R2T RmuDocument1 page2R2T RmuNurholis SetiawanNo ratings yet

- 6mtr T Bracket PoleDocument1 page6mtr T Bracket PoledseshireddyNo ratings yet

- S-15A Detail of CanopyDocument1 pageS-15A Detail of CanopygoldieNo ratings yet

- INSTRUMENT HOUSING - Type XD-I80dieDocument2 pagesINSTRUMENT HOUSING - Type XD-I80dieNaveedullah AwanNo ratings yet

- MTB Nlu3: Chú Thích Sàn Hoàn ThiệnDocument1 pageMTB Nlu3: Chú Thích Sàn Hoàn ThiệnHoàng NamNo ratings yet

- 00 Nivel 4 120322Document2 pages00 Nivel 4 120322Francisco Haros MattusNo ratings yet

- Wiring Diagram ATS 25kva AtyS-Revisi1 PDFDocument5 pagesWiring Diagram ATS 25kva AtyS-Revisi1 PDFtri faela musthofa100% (2)

- 04 - Reinforcement Details of U-S Sloping Barrels For SyphonDocument1 page04 - Reinforcement Details of U-S Sloping Barrels For SyphonLearningSupport by Ejaz shaikhNo ratings yet

- Ax 063Document1 pageAx 063Al Fakhamah LiftsNo ratings yet

- Student 1 19 Student 2 19 Student 3 20 Student 4 19 Student 5 20 Student 6 20 Student 7 20 Student 8 20 Student 9 19 Student 1 20Document2 pagesStudent 1 19 Student 2 19 Student 3 20 Student 4 19 Student 5 20 Student 6 20 Student 7 20 Student 8 20 Student 9 19 Student 1 20Joy IbarrientosNo ratings yet

- GSW - Información Técnica-Sportage2001SocketsDocument8 pagesGSW - Información Técnica-Sportage2001SocketsAndersonNo ratings yet

- B Bga144Document1 pageB Bga144Yargen GonzalezNo ratings yet

- Ca 9700Document1 pageCa 9700Anonymous BSjaUstLNo ratings yet

- G.A Cane Feeder Table - R5Document1 pageG.A Cane Feeder Table - R5Babiker ElrasheedNo ratings yet

- New Kitchen (13!11!23Document1 pageNew Kitchen (13!11!23Vicky simplemanNo ratings yet

- Front Elevation Side Elevation General Arrangement: SaddleDocument1 pageFront Elevation Side Elevation General Arrangement: SaddleRanjit Kumar ShahNo ratings yet

- Fog 1500 FT Service Manual V 2Document4 pagesFog 1500 FT Service Manual V 2Silverio SogorbNo ratings yet

- Tray Filler WiringDiagramPg1Document1 pageTray Filler WiringDiagramPg1Alexandre Werneck SilvaNo ratings yet

- Concerto Madrigalesco RV129 - VivaldiDocument11 pagesConcerto Madrigalesco RV129 - VivaldiAmauri Cristóbal100% (1)

- MIDAS/Civil: Project TitleDocument9 pagesMIDAS/Civil: Project Titlesaubhagya majhiNo ratings yet

- MIDAS/Civil: Project TitleDocument5 pagesMIDAS/Civil: Project Titlesaubhagya majhiNo ratings yet

- 29-72 Superstructure - PagenumberDocument44 pages29-72 Superstructure - Pagenumbersaubhagya majhiNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCDocument2 pages(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCsaubhagya majhiNo ratings yet

- Ope Type Left SoilDocument1 pageOpe Type Left Soilsaubhagya majhiNo ratings yet

- RB Up WCFDocument2 pagesRB Up WCFsaubhagya majhiNo ratings yet

- Beam DesignDocument11 pagesBeam Designsaubhagya majhiNo ratings yet

- WGC DownstreamDocument2 pagesWGC Downstreamsaubhagya majhiNo ratings yet

- WT DW1Document3 pagesWT DW1saubhagya majhiNo ratings yet

- LB Up WCFDocument2 pagesLB Up WCFsaubhagya majhiNo ratings yet

- RB DW WCFDocument2 pagesRB DW WCFsaubhagya majhiNo ratings yet

- Municipality, Jaleshwor, Province No. 2: Cost EstimateDocument2 pagesMunicipality, Jaleshwor, Province No. 2: Cost Estimatesaubhagya majhiNo ratings yet

- LB DW WCFDocument2 pagesLB DW WCFsaubhagya majhiNo ratings yet

- Open Type Right SoilDocument1 pageOpen Type Right Soilsaubhagya majhiNo ratings yet

- Chapter 12Document11 pagesChapter 12saubhagya majhiNo ratings yet

- φ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationDocument1 pageφ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationsaubhagya majhiNo ratings yet

- 44 9nconDocument1 page44 9nconsaubhagya majhiNo ratings yet

- Section at A-A, 1:50: 40 Cable Elevation 120 40Document1 pageSection at A-A, 1:50: 40 Cable Elevation 120 40saubhagya majhiNo ratings yet

- Chapter 3Document7 pagesChapter 3saubhagya majhiNo ratings yet

- Chapter 1Document1 pageChapter 1saubhagya majhiNo ratings yet

- 44 2nconDocument1 page44 2nconsaubhagya majhiNo ratings yet

- TABLE: Joint Reactions Story Joint Label Unique Name Load Case/Combo FX FY FZDocument2 pagesTABLE: Joint Reactions Story Joint Label Unique Name Load Case/Combo FX FY FZsaubhagya majhiNo ratings yet

- A3 Comb-10 A4 Comb-10 B1 Comb-10 C1 Comb-10 C3 Comb-10 C4 Comb-10 D1 Comb-10 D3 Comb-10 D4 Comb-10 A2 Comb-10Document10 pagesA3 Comb-10 A4 Comb-10 B1 Comb-10 C1 Comb-10 C3 Comb-10 C4 Comb-10 D1 Comb-10 D3 Comb-10 D4 Comb-10 A2 Comb-10saubhagya majhiNo ratings yet

- Precision t7810 Workstation - Owners Manual - en UsDocument58 pagesPrecision t7810 Workstation - Owners Manual - en Usfotograf nuntaNo ratings yet

- Introductory Botulinum PresentationDocument113 pagesIntroductory Botulinum Presentationprontaprintpottersbar100% (5)

- Hex 6.3 User Manual: Dave Ritchie Team Orpailleur INRIA Nancy Grand Est, LORIA 54506 Vavdoeuvre-les-Nancy, FranceDocument69 pagesHex 6.3 User Manual: Dave Ritchie Team Orpailleur INRIA Nancy Grand Est, LORIA 54506 Vavdoeuvre-les-Nancy, FranceParisha SinghNo ratings yet

- Din en Iso 1302Document51 pagesDin en Iso 1302Akshay Patil100% (1)

- Plum Concrete WallsDocument4 pagesPlum Concrete WallsnileshNo ratings yet

- Use Code INDIA5 For Extra Discount (Till 17 Aug) : (A) Mitotic Cell Division OnlyDocument6 pagesUse Code INDIA5 For Extra Discount (Till 17 Aug) : (A) Mitotic Cell Division OnlyrajatNo ratings yet

- 4 - Liber XIII - Graduum Montis AbiegniDocument10 pages4 - Liber XIII - Graduum Montis AbiegniMts JlnNo ratings yet

- Reading 1 IwakDocument37 pagesReading 1 IwakJaredsol E. DebsioNo ratings yet

- Ideal Installation: I & M Mark 68G SeriesDocument4 pagesIdeal Installation: I & M Mark 68G SeriesByron PanchiNo ratings yet

- Muet 1Document15 pagesMuet 1Sity Noor QiyahNo ratings yet

- FRIGOMILK G9 From 2.000 LT To 30.000 LTDocument2 pagesFRIGOMILK G9 From 2.000 LT To 30.000 LTJorge PontonNo ratings yet

- High Entropy Oxides and SinteringDocument6 pagesHigh Entropy Oxides and SinteringVenkateswararao BuridiNo ratings yet

- Test Bank For Biology of Plants 7th Edition Peter H RavenDocument9 pagesTest Bank For Biology of Plants 7th Edition Peter H RavenElaine Scully100% (38)

- Lesson Notes For Atoms and MoleculesDocument3 pagesLesson Notes For Atoms and MoleculesQurrat Ul AinNo ratings yet

- GALLO-SCYTHIANS - Celtic Ukraine (By Mac Congail)Document22 pagesGALLO-SCYTHIANS - Celtic Ukraine (By Mac Congail)Toma100% (1)

- RedoDocument1 pageRedogmpzgamerNo ratings yet

- D31P-18A Komatsu 6D95LDocument3 pagesD31P-18A Komatsu 6D95Lsrabesh basnetNo ratings yet

- Revised Holiday HomeDocument4 pagesRevised Holiday HomerashmichemistryNo ratings yet

- Evs Project & SeminarDocument21 pagesEvs Project & Seminarpratibhaawari01No ratings yet

- Aereal PhotogrammetryDocument13 pagesAereal PhotogrammetryJuan GarzonNo ratings yet

- FMT DFX WorkbookDocument25 pagesFMT DFX WorkbookSaurav SinghNo ratings yet

- Unit4 PDFDocument36 pagesUnit4 PDFDane SinclairNo ratings yet

- Non Routine ProblemsDocument3 pagesNon Routine ProblemsRichelleNo ratings yet

- MATHEMATICS Compulsory Part 2011/12 Mock Exam Paper 2Document24 pagesMATHEMATICS Compulsory Part 2011/12 Mock Exam Paper 2mkan_3No ratings yet

- GeneralMathematics11 q1 Mod5b LogarithmicfunctionDocument28 pagesGeneralMathematics11 q1 Mod5b LogarithmicfunctionBrendan Millard Cruda100% (1)

- Gonda - NOTES ON THE INDO-EUROPEAN Kwi - AND kwo-PRONOUNSDocument45 pagesGonda - NOTES ON THE INDO-EUROPEAN Kwi - AND kwo-PRONOUNSAnonymous Jj8TqcVDTyNo ratings yet

- TexturingDocument25 pagesTexturingRtr Hasan MahmudNo ratings yet

- Mysterypowderse 2Document5 pagesMysterypowderse 2api-2125257840% (2)

- Form 0NE PDFDocument3 pagesForm 0NE PDFAlphonsius WongNo ratings yet