Professional Documents

Culture Documents

Bishop 2007

Bishop 2007

Uploaded by

Barry BishopOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bishop 2007

Bishop 2007

Uploaded by

Barry BishopCopyright:

Available Formats

Lithics 27

THE KENTISH PECULIAR? LATER BRONZE AGE POLISHED FLINTS FROM MAIDSTONE, KENT

Barry Bishop6 ___________________________________________________________________________ ABSTRACT The title of this paper, as many readers may remember, borrows from that of a paper published in the 1990 volume of Lithics. That was by Hazel Martingell and it described her research into a little-considered type of flake, the squat flake, which she had increasingly become aware of amongst the lithic collections of Essex. This report describes a further type of flake; one that exhibits many similarities to those described by Hazel Martingell. These share very similar technological and morphological characteristics but there are also very noticeable and important differences. The first, perhaps of little significance but reflected in the title, is that they were found in Kent, another, of much greater significance, was that many had been highly polished. So far as is known by this author, no other examples of these types of flakes have hitherto been recorded from Britain. Full reference: Bishop, B. 2006. The Kentish Peculiar? Later Bronze Age polished flints from Maidstone, Kent. Lithics: The Journal of the Lithic Studies Society 27: 3343. Keywords: Polished flint flake, polishing stone, Late Bronze Age, deposition, function, decorative, ceremonial, Maidstone, Kent INTRODUCTION This report describes and discusses a cache of flint flakes discovered during an archaeological excavation at West Borough School in Maidstone, Kent (NGR: TQ 7390 5515; Figure 1). The excavations were conducted by Pre-Construct Archaeology during September and October 2004 in advance of the schools redevelopment. A full report detailing all aspects of the excavations will be published shortly (Holden forthcoming). The site is located on a large eastward facing spur of land formed by a loop of the River Medway. It occupies high ground, situated just below the 70m contour and its underlying geology comprises the Hythe Beds of the Lower Greensand Formation. There are extensive views southwards and eastwards over the Medway valley and the confluence of two of its tributaries, the rivers Loose and Len, an area that subsequently formed the focus for the growth of the city of Maidstone. THE EXCAVATION The excavation revealed indications of activity at the site from the Middle Bronze Age through to the Roman period. Principal features identified included a large ditch measuring 3m to 4m in width and 1.7m deep, traversing the site in a northwestsoutheast direction (Figure 2). This produced pottery dating from the Middle to the Late Bronze Age and further features of this date were found scattered across the site, including a pit located close to the

Pre-Construct Archaeology, Unit 54, Brockley Cross Business Centre, 96 Endwell Road, Brockley, SE4 2PD. Contact email: bvfj@tinyworld.co.uk

6

33

Lithics 27

ditch that contained a complete Deverel-Rimbury Bucket Urn. After the ditch had fully infilled, an Early Iron Age ditch, part of a rectilinear enclosure, was cut along its southern edge. Other Early Iron Age features were also dug into the top of the infilled ditch, demonstrating that it had completely infilled by this time.

Barming Station

rail

A2

GREATER LONDON

rail line

B224

line

Hermitage Farm hospital MAIDSTONE CANTERBURY

BARMING HEATH OAKWOOD PARK

The Site

The Site

Rd A26 Tonbridge

FANT

TOVIL

BRIGHTON

EAST BARMING 0 50km 0 1km

lk Wa ley Val ay ay dw dw Me Me ver Ri

ABBEY GATE PLACE

573960

155150

Area of Excavation

Area of Excavation

Area of Excavation

50m

TONBRID

GE ROA

Figure 1: The site location. Scales 1:200,000; 1:50,000; & 1:1,000 respectively.

34

573960

DON COU HAMBLE RT

Community Centre

155050

Lithics 27

THE LITHIC MATERIAL During the excavations, 78 struck flints were recovered. Twenty-eight of these were found scattered across the site, mostly singly or in small quantities. These typically exhibit later Bronze Age or Iron Age characteristics and include thick, short flakes, opportunistically reduced cores and irregularly retouched flakes (e.g. Herne 1991; Young & Humphrey 1999; Ballin 2002; Humphrey 2003). These are likely to have been associated with the later prehistoric activity identified at the site and they are discussed in more detail in the forthcoming publication of the excavations (Holden forthcoming).

155130

Early Iron Age Ditch

Fig 3 Profile with flint location

Bronze Age Ditch

pitting

Early Iron Age Enclosure

Early Iron Age Ditch

155100

20m

Figure 2: The principal archaeological features identified at the site. Scale 1:400.

The struck flint cache The remaining 50 struck flints, alongside a small honestone, were recovered from within the above-mentioned large linear ditch. Due to the unusual nature of this group, it is worth examining its contextual associations in further detail. The ditch had witnessed at least three episodes of natural silting before being levelled with a mass of Greensandstone rubble. It would appear that the ditch had been open for some time, slowly accumulating silt, before being deliberately backfilled with the rubble. This may have originated from a stone bank or

35

573910

573910

Lithics 27

revetment that had been toppled into the ditch, apparently representing an intentional act of decommissioning or erasing the ditch. The flints and honestone were found during section cleaning as a small cluster close to the interface of the Greensandstone rubble layer and the underlying natural silting deposits, 0.73m below the machined surface of the ditch (Figure 3). They were all confined to within an area measuring approximately 0.30m across and the excavator suggested that they had the appearance of having been in a container such as a bag or box, no traces of which had survived. Despite further examination, no indications were found that the flints came from a later intrusion cut into the ditch and the excavator was satisfied that they had genuinely been deposited into the ditch just prior to it having been backfilled with the Greensandstone rubble. The ditch produced pottery of Deverel-Rimbury traditions dating to approximately 1500BC to 1000BC from throughout its fills (Rayner 2005). Stratigraphically, the ditchs infilling must have occurred prior to the Early Iron Age (600BC to 400BC) when a number of features of that date were cut into its backfill.

S N

69.50m OD

69.50m OD

Early Iron Age Ditch

greensand rubble backfill location of flints

primary silting

2m

Figure 3: Profile through the Bronze Age ditch. Scale 1:40.

The cache comprises 50 struck flakes and a single mud- or siltstone honestone (Figures 4 & 5). The flakes are all made from good quality black flint with a thick, slightly weathered chalky cortex and occasional heavily recorticated thermal scars, suggesting that the raw materials were obtained from derived deposits located close to the parent chalk (Gibbard 1986). The flints colour, texture and cortex are notably homogeneous and it would appear that only a few nodules from the same source had been used. All of the flakes are in a good, sharp condition with no suggestion of wear and with only very limited post-depositional damage evident. The flakes are technologically homogeneous, they had all been retouched and many had been polished. With the exception of their polish, their technological attributes can be closely matched with flakes from industries dating to the later parts of the Bronze Age and into the Iron Age (Fasham & Ross 1978; Saville 1981; Smith 1987; Brown 1991; Herne 1991; Bradley & Brown 1992; Young & Humphrey 1999; Greatorex 2001; Ballin 2002; Humphrey 2003). They are mostly broad, short and thick and have wide and obtuse striking platforms, comparable to Martingells (1990) squat flakes (see Tables 1 & 2 & Figure 6). Striking

36

Lithics 27

Figure 4: Unpolished flints. Scale 1:2.

platforms mostly consist of earlier flake scars although ten utilize cortex or ancient thermal scars, and visible points of percussion and developed Hertzian cones are commonly present. It is likely that the flakes were all detached with hard hammers. All but three of the flakes have pronounced bulbs of percussion and all possess either hinged or retouched distal terminations. It is possible that formation of the hinged distal terminations was at least partially intentional as all of the polished flints have blunt, rounded distal ends and, as evidenced on both unpolished and polished flakes, their distal ends were often retouched to further bevel them. Dorsal faces occasionally retain cortex although most consist of single flake scars. These are often markedly concave due to the previously removed flakes pronounced bulbs of percussion and this frequently required the trimming of the core face/striking platform edges in order to remove the worst excesses of the resultant overhangs. Generally, the dorsal scars are aligned in the same direction as the flake and it appears that the flakes were mostly removed by burrowing into the core, each flake being removed from directly behind the previous one. In order to allow for a succession of suitably shaped flakes to be detached, the core would have required trimming and reshaping, and this would have generated quantities

37

Lithics 27

of dbitage, none of which accompanied the flakes.

Figure 5: Polished flints. Scale 1:2.

All of the flakes had been shaped by heavy scalar retouch into sub-rectangular or, more commonly, trapezoidal-shaped tablets. Figure 6 indicates that although the flakes are broadly of similar dimension, the polished flakes tend to be slightly narrower than the unpolished

38

Lithics 27

examples. This may suggest that some of the unpolished flakes had not been as fully or extensively retouched as the polished ones and these may represent partially finished examples. The retouch is generally quite coarse but it has been undertaken very precisely, resulting in the flakes having very straight edges. The location of retouch is varied and occurs on between one and three of the flakes sides, occasionally including the bulbar end. The retouch appears to have been undertaken principally in order to provide a trapezoidal-shaped flake. In at least one case a lateral edge had been snapped off; again, apparently in order to achieve the desired shape. It is evident that the final shape of the flake was considered more important than the location or extent of the retouch, or the precise methods employed in producing this shape. Twenty of the flakes, or 40% of the cache, have been polished to varying degrees (Figure 5). The polishing was undertaken on both faces, concentrating along the distal termination and extending inwards between 3mm and 41mm from the flakes distal edge, although the extent of the polish is usually uneven on each face. Several have remnant patches of cortex near the distal end and these had also been polished. The polishing was undertaken whether or not there was cortex present.

All Flakes Average Maximum Minimum Standard Deviation Length (mm) 39.7 54.0 19.0 7.3 Breadth (mm) 39.4 63.0 18.0 10.5 Width (mm) 9.0 15.0 5.0 2.2 Weight (g) 16.3 49.0 4.0 9.0

Table 1: Metrical Dimensions of all flakes from the ditch

100 90 80 70 Length 60 50 40 30 20 10 0 0 10 20 30 40 50 Width 60 70 80 90 100 Polished Unpolished

Figure 6: Length (mm): Width (mm) of Polished and Unpolished Flakes

39

Lithics 27

As suggested by the retouching, it would appear that a trapezoidal shape for the finished polished flake was most desired, although square, tapered and expanding polished flakes were also present. What may have been of even more concern was the oblique angle made between the polished edge and the flakes axis. The obliqueness is consistently present and averages around 70, suggesting that, whatever its purpose, it was a required feature of the finished implement (Table 2).

Polished Flakes Average Maximum Minimum Standard Deviation Length Breadth (mm) (mm) 40.1 32.4 53.0 44.0 19.0 18.0 8.7 8.9 Width (mm) 8.3 11.0 5.0 1.3 Weight (g) 11.1 23.0 4.0 5.6 Flake axis as measured from polished edge 68.0 80.0 50.0 7.1

Table 2: Metrical Dimensions of the polished flakes from the ditch

The polish appears to be in various stages of completion and varies from a rather coarse grinding, leaving a dull finish with prominent striations, to a shiny and highly reflective finish where striations are not visible, even under low-power magnification. With a few flakes only one side had been polished, and then only coarsely. On others, both sides had been coarsely polished but fine polish was either absent or sporadic, and others had fine polish limited to only one side. These, alongside the unpolished flakes, may represent progressive stages in the manufacturing process and this allows the process of manufacture to be reconstructed. It would appear that suitably shaped flake blanks with blunt, hinged distal terminations were selected from what presumably must have been a mass of knapping debris, and were then retouched along one or more sides into the desired shape. They were then initially polished using a coarse, flat, grinding stone, possibly the honestone recovered alongside the flakes, leaving a flattish matt face with visible striations. They were then progressively polished with finer graded materials until a bright, mirror-like finish was obtained; this was concentrated and most fully developed around the distal end. The final polishing continued into depressions and concavities on the flake face, and had presumably been accomplished using a soft cloth and abrasive powder, such as leather and ochre. The honestone consists of a rod of yellow-brown gritty, fine sand/siltstone, worn from use and having a roughly triangular shaped cross-section. It measures 38mm x 11mm x 10mm and weighs 6.3g. Its gritty inclusions are too coarse to have provided the final polishing of the flakes but it may have been used for the initial grinding. DISCUSSION This assemblage appears to contain pieces from all stages leading to the production of the distally polished flakes. At present, they appear to be unique, with no known parallels in the published literature. They were shown to members of the Lithic Studies Society committee in October 2005 who, despite the breadth and depth of their knowledge of lithics, could suggest no parallels. The polishing of flint tools is one of the defining characteristics of the Neolithic. This technique is largely confined to prestigious implements, such as axes, chisels and knives and, very occasionally, other implements, such as scrapers and arrowheads (Green 1980; Manby 1974). However, this technique has not been documented as continuing beyond the Early

40

Lithics 27

Bronze Age, furthermore the polishing of flakes in the manner described here is not attested during any period. The flakes were recovered from a securely dated, later Bronze Age, context. That they were found as an integral group makes it highly implausible that they might be of earlier date but residually deposited. Other explanations, such as that they had been curated over a considerable period before being placed in the ditch or, conversely, that they are more recent and had been somehow intrusively inserted into the ditch, would seem very unlikely but cannot, of course, be entirely dismissed. However, they are technologically most comparable with flakes from similarly dated later Bronze Age industries (e.g. Fasham & Ross 1978; Saville 1981; Smith 1987; Brown 1991; Herne 1991; Bradley & Brown 1992; Young & Humphrey 1999; Greatorex 2001; Ballin 2002; Humphrey 2003), with the single, but significant, exception of their polish. There are no other known parallels for the polishing of struck flints from the later Bronze Age. Possibly the closest recorded parallels were flint flakes described by Clark as sub-rectangular forms, three sides of which are blunted, the fourth retaining the primary flake-edge unretouched and recovered from a Bronze Age site at Mildenhall Fen in Suffolk (Clark 1936: 46, Fig. 10.3 & 10.4.). Although of similar form, these exhibited no traces of polish. The assemblage therefore represents an intriguing and so far unique set of artefacts. Their production involved considerable expenditure of time and effort and, where present, the final polishing is accomplished to a very high degree, resulting in an almost mirror-like quality. It is much finer than that usually seen on earlier polished stone implements and than would have been required for providing a working edge; the edges, in any case, are very rounded and blunt. They could have been used for burnishing pottery or other items, although none show any traces that they had been used as such and they were polished to a far higher degree than would have been necessary. In addition, their very rarity, perhaps even uniqueness, would also argue against them being used for any commonly conducted tasks. It is perhaps more likely that they were produced for ornamental, aesthetic or ceremonial reasons. Their trapezoidal shape would have enabled them to have been mounted close together with the polished sides forming a continuous edge, as has been suggested for composite sickles. Alternatively, their shape would have allowed them to be sewn onto cloth or a belt as separate or contiguous plates. It is, of course, entirely possible that they were produced as a curiosity, perhaps purely as a display of workmanship. As no parallels to these unique artefacts have yet been found, any interpretation remains speculative. Whatever their intended use, they appear to have been deposited into the ditch just prior to it being levelled and, in this respect, it is tempting to suggest that they represent a special or closing deposit, placed into the ditch to commemorate its demise. Although unique in that these examples are polished, there are indications elsewhere that during the later Bronze Age unusual deposits of worked flint were occasionally inserted into or placed upon earlier structures (e.g. Bradley 1972; Fasham & Ross 1978; Saville 1981; Smith 1987; Herne 1991; Pollard 1998 & 2002; Seager Thomas 1999; Greatorex 2001; Ballin 2002; Bishop & Mortimer in prep.). The frequently noted association of such assemblages with earlier monuments is often explained as the expedient use of raw materials fortuitously exposed by earlier construction. In many respects these flintworking assemblages do appear utilitarian; they are often crudely and simply produced and rarely contain obviously prestigious items. Nevertheless, there are dangers of over-emphasising the distinction between rational activity and ritual intent (e.g. Hill 1993; Brck 1999; Bradley 2003), and closer considerations of the nature of those assemblages and circumstances surrounding their deposition may suggest that assuming a purely functional explanation is too simplistic. In many of the cases cited here it is possible that the assemblages were deliberately created for the specific purposes of deposition

41

Lithics 27

(cf. Needham 1993) and they may have been used in ritual or ceremonial activity, often appearing in circumstances where they may have acted as part of a process of symbolically closing or decommissioning old or redundant monuments and structures. The flakes reported here are exceptionally intriguing but so far very perplexing. To conclude, therefore, I would like to echo the final sentence of Hazel Martingells 1990 paper, that to continue with this study, I would be very interested to hear about any similar polished flakes that are known of or become available through future excavations from any part of Britain. ACKNOWLEDGEMENTS

The author would like to thank Stuart Holden, the excavator of the site, for providing the information concerning the excavations that was necessary to complete this paper, Frank Meddens, who managed the post-excavation aspects of the project and Vicki Ridgeway who prepared the paper for publication and offered many useful amendments. The author is also indebted to the anonymous reviewers for providing useful comments and suggesting improvements on the text. Adrian Nash produced the figure plans and Cate Davies the lithic illustrations. I would also like to thank the committee and other members of the Lithic Studies Society who graciously examined and commented on the worked flints described here.

BIBLIOGRAPHY

Ballin, T.B. 2002. Later Bronze Age Flint Technology: a presentation and discussion of post-barrow dbitage from monuments in the Raunds Area, Northamptonshire. Lithics: The Newsletter of the Lithic Studies Society 23: 328. Bishop, B.J. & Mortimer, R. In preparation. Middle Bronze Age Enclosures and Depositional Activity at Sawston, South Cambridgeshire. Bradley, R. 2003. A Life Less Ordinary: the ritualization of the domestic sphere in later prehistoric Europe. Cambridge Archaeological Journal 13(1): 523. Brown, A. 1991. Structured Deposition and Technological Change among the Flaked Stone Artefacts from Cranbourne Chase. In J. Barrett, R. Bradley & M. Hall (eds.) Papers on the Prehistoric Archaeology of Cranbourne Chase: 101133. Oxbow Monograph No. 11. Oxbow, Oxford. Bradley, R. 1972. The Flint Industry. In E.W. Holden: A Bronze Age Cemetery-barrow on Itford Hill, Beddingham, Sussex: 93102. Sussex Archaeological Collections 110: 70117. Bradley, R. & Brown, A. 1992. Flint Artefacts. In J. Moore & D. Jennings: Reading Business Park: A Bronze Age Landscape: 8993. Thames Valley Landscapes: The Kennet Valley 1. Oxford University Committee for Archaeology for the Oxford Archaeological Unit, Oxford. Brck, J. 1999. Ritual and Rationality: some problems of interpretation in European Archaeology. European Journal of Archaeology 2(3): 313344. Clark, J.G.D. 1936. Report on a Late Bronze Age Site in Mildenhall Fen, West Suffolk. The Antiquaries Journal 16: 2950. Fasham, P.J. & Ross, J.M. 1978. A Bronze Age Flint Industry from a Barrow in Micheldever Wood, Hampshire. Proceedings of the Prehistoric Society 44: 4767. Gibbard, P.L. 1986. Flint Gravels in the Quaternary of Southeast England. In G. de G. Sieveking & M.B. Hart (eds.) The Scientific Study of Flint and Chert: 141149. Cambridge University Press, Cambridge. Greatorex, C. 2001. Evidence of Sussex Prehistoric Ritual Traditions. The Archaeological Investigation of a Bronze Age Funerary Monument Situated on Bailys Hill, near Crowlink, Eastbourne. Sussex Archaeological Collections 139: 2773. Green, H.S. 1980. The Flint Arrowheads of the British Isles. British Archaeological Reports (British Series) 75. BAR, Oxford. Herne, A. 1991. The Flint Assemblage. In I. Longworth, A. Herne, G. Varndell & S. Needham (eds.) Excavations at Grimes Graves Norfolk 19721976. Fascicule 3. Shaft X: Bronze Age flint, chalk and metal working: 2193. British Museum Press, Dorchester. Hill, J.D. 1993. Can We Recognize a Different European Past? A Contrastive Archaeology of Later Prehistoric Settlement in Southern England. Journal of European Archaeology 1: 5775. Holden, S. Forthcoming. Later Prehistoric and Romano-British Activity at West Borough School, Maidstone. Archaeologia Cantiana. Humphrey, J. 2003. The Utilization and Technology of Flint in the British Iron Age. In J. Humphrey (ed.) Re-

42

Lithics 27

searching the Iron Age: selected papers from the proceedings of the Iron Age research student seminars, 1999 and 2000: 1723. Leicester Archaeology Monograph No. 11. University of Leicester, School of Archaeology and Ancient History, Leicester. Manby, T.G. 1974. Grooved Ware Sites in the North of England. British Archaeological Reports (British Series) 9. BAR, Oxford. Martingell, H. 1990. The East Anglian Peculiar? The Squat Flake. Lithics: The Newsletter of the Lithic Studies Society 11: 4043. Needham, S. 1993. The Structure of Settlement and Ritual in the Late Bronze Age of South-East Britain. In C. Mordant & A. Richard (eds.) Lhabitat et loccupation du Sol LAge du Bronze en Europe: 4969. Editions du Comit des Travaux Historiques et Scientifiques, Paris. Pollard, J. 1998. Prehistoric Settlement and Non-Settlement in Two Southern Cambridgeshire River Valleys: the lithic dimension and interpretative dilemmas. Lithics: The Newsletter of the Lithic Studies Society 19: 61 71. Pollard, J. 2002. The Ring-Ditch and the Hollow: excavation of a Bronze Age shrine and associated features at Pampisford, Cambridgeshire. Proceedings of the Cambridge Antiquarian Society 91: 521 Rayner, L. 2005. Assessment of the prehistoric and Roman pottery. In S. Holden: Assessment of an Archaeological Excavation of Land at West Borough School, Maidstone, Kent. Unpublished PreConstruct Archaeology manuscript. Saville, A. 1981. Grimes Graves, Norfolk. Excavations 19712, Volume II: The Flint Assemblage. Department of Environment Archaeological Reports No. 11. DoE, London. Seager Thomas, M. 1999. Stone Finds in Context: a contribution to the study of later prehistoric artefact assemblages. Sussex Archaeological Collections 137: 3948. Smith, G.H. 1987. A Beaker (?) Burial Monument and a Late Bronze Age Assemblage from East Northdown, Margate. Archaeologia Cantiana 104: 237289. Young, R. & Humphrey, J. 1999. Flint Use in England after the Bronze Age: time for a re-evaluation? Proceedings of the Prehistoric Society 65: 231242.

43

You might also like

- Diamonds & Diamond Grading: Book 4Document152 pagesDiamonds & Diamond Grading: Book 4MykhailoNo ratings yet

- Understanding Stone Tools and Archaeological Sites (PDFDrive)Document549 pagesUnderstanding Stone Tools and Archaeological Sites (PDFDrive)Allan D GrtNo ratings yet

- Caskey 1968 Lerna BronzeDocument5 pagesCaskey 1968 Lerna Bronzesmitrovic482No ratings yet

- Jane SlivaDocument108 pagesJane SlivaAlberto Duran IniestraNo ratings yet

- 2 Area Ii: The Pictish Assemblage: Thepictish HorizonDocument35 pages2 Area Ii: The Pictish Assemblage: Thepictish Horizonsonnyoneand2No ratings yet

- 1970 84 Military Buttons Manufacturers From The London Directories 1800-1899Document13 pages1970 84 Military Buttons Manufacturers From The London Directories 1800-1899leongorissenNo ratings yet

- East Chisenbury - Ritual and Rubbish atDocument9 pagesEast Chisenbury - Ritual and Rubbish atNones NoneachNo ratings yet

- APL40 - 20 - Gardiner Between Foraging and FarmingDocument14 pagesAPL40 - 20 - Gardiner Between Foraging and Farming1heUndertakerNo ratings yet

- 1995 114 Researches and Discoveries in KentDocument23 pages1995 114 Researches and Discoveries in KentleongorissenNo ratings yet

- A. Flint Blanks B. Knives C. Spearheads D. Arrowpoints E. Drills F. Harpoons and Hooks G. Hoes H. Scrapers I. Celts J. Disks K. Hammer-StonesDocument28 pagesA. Flint Blanks B. Knives C. Spearheads D. Arrowpoints E. Drills F. Harpoons and Hooks G. Hoes H. Scrapers I. Celts J. Disks K. Hammer-StonesFvg Fvg FvgNo ratings yet

- A Ceramic Definition of Late Helladic I From TsoungizalDocument19 pagesA Ceramic Definition of Late Helladic I From Tsoungizalsuneerav17No ratings yet

- Excavations at Stansted Airport: Prehistoric PotteryDocument48 pagesExcavations at Stansted Airport: Prehistoric PotteryFramework ArchaeologyNo ratings yet

- 1972 Mary Rose Reporte Interino 2Document4 pages1972 Mary Rose Reporte Interino 2Alejandro LealNo ratings yet

- SealsDocument122 pagesSealsninzuNo ratings yet

- Mucking Excavation JonesDocument3 pagesMucking Excavation Jonesjoehague1No ratings yet

- SCCHC 2012 Pluckemin RPT 2 Surface CollectionDocument44 pagesSCCHC 2012 Pluckemin RPT 2 Surface Collectionjvanderveerhouse100% (1)

- Collapsing Commodities or Lavish OfferinDocument31 pagesCollapsing Commodities or Lavish Offerinjorge ricardo camaraNo ratings yet

- An Archaeologists Guide To Chert and FlintDocument161 pagesAn Archaeologists Guide To Chert and Flintmountain fairyNo ratings yet

- Bagwell Et Al. 2001 Beddington SyAC88Document19 pagesBagwell Et Al. 2001 Beddington SyAC88Barry BishopNo ratings yet

- The Food of The Prehistoric CeltsDocument16 pagesThe Food of The Prehistoric CeltsHeather SmithNo ratings yet

- The Newstead 'Lorica Segmentata'Document20 pagesThe Newstead 'Lorica Segmentata'M.C. BishopNo ratings yet

- Feeding The Fort Romano-British Settleme - OdtDocument5 pagesFeeding The Fort Romano-British Settleme - OdtEm RNo ratings yet

- Festschrift Niemeier DriessenFarnouxLangohr LibreDocument12 pagesFestschrift Niemeier DriessenFarnouxLangohr LibreMuammer İreçNo ratings yet

- AJ81 Selsey LBA and EIA WellsDocument42 pagesAJ81 Selsey LBA and EIA Wellsseager thomasNo ratings yet

- Gardiner The Tomb TravellerDocument16 pagesGardiner The Tomb TravellerInpwNo ratings yet

- Sealing Without Seals, VipDocument15 pagesSealing Without Seals, VipnaglaaNo ratings yet

- D. H. French - Late Chalcolithic Pottery.....Document44 pagesD. H. French - Late Chalcolithic Pottery.....ivansuvNo ratings yet

- Tools Available For Cultivation in Prehistoric Britain Davam 1Document4 pagesTools Available For Cultivation in Prehistoric Britain Davam 1alo62No ratings yet

- Lamb Ay MacalisterDocument13 pagesLamb Ay MacalisterCiara HoweNo ratings yet

- Tell Farakh PDFDocument41 pagesTell Farakh PDFsrdjanNo ratings yet

- Notes News: Overton Down Experimental EarthworkDocument4 pagesNotes News: Overton Down Experimental EarthworkunocienNo ratings yet

- The Roman Lead Tank From Perry OaksDocument3 pagesThe Roman Lead Tank From Perry OaksFramework Archaeology100% (1)

- Mythe To Mitcheldean Mains Reinforcement, Gloucestershire - PotteryDocument24 pagesMythe To Mitcheldean Mains Reinforcement, Gloucestershire - PotteryWessex ArchaeologyNo ratings yet

- Excavations at Kew Bridge House, BrentfordDocument32 pagesExcavations at Kew Bridge House, BrentfordWessex ArchaeologyNo ratings yet

- The Origins of House and HomeDocument13 pagesThe Origins of House and HomeOrsi GyurkaNo ratings yet

- 2012-45 Boughton Malherbe Hoard Excavation ReportDocument13 pages2012-45 Boughton Malherbe Hoard Excavation ReportCroxford100% (1)

- Joyce 1932Document19 pagesJoyce 1932Josh DobleNo ratings yet

- CBM From Alfoldean ReportDocument21 pagesCBM From Alfoldean ReportRichard SymondsNo ratings yet

- Haines - 2011 Bedrock VaseDocument5 pagesHaines - 2011 Bedrock VasecfblaineNo ratings yet

- Archaeology Under The House: Three Occupations Literally Under One RoofDocument91 pagesArchaeology Under The House: Three Occupations Literally Under One RoofCraig ChartierNo ratings yet

- G. Davidson-A Medieval Glass Factory in CorinthDocument30 pagesG. Davidson-A Medieval Glass Factory in CorinthedermendgievNo ratings yet

- Pp. 21-50Document34 pagesPp. 21-50EssamradwanNo ratings yet

- Caradoc SiteDocument18 pagesCaradoc SiteJulio AvalosNo ratings yet

- Westerton: A Roman Watchtower On The Gask Frontier: W S Hanson & J G P FriellfDocument21 pagesWesterton: A Roman Watchtower On The Gask Frontier: W S Hanson & J G P FriellfVladan StojiljkovicNo ratings yet

- Cambourne - MetalworkDocument21 pagesCambourne - MetalworkWessex ArchaeologyNo ratings yet

- 30096990Document27 pages30096990gmoladd6No ratings yet

- Hamadiya in The Central Jordan Valley A PDFDocument57 pagesHamadiya in The Central Jordan Valley A PDFKatarinaFelcNo ratings yet

- Limenaria, A Neolithic and Early Bronze Age Settlement at Thasos - Stratis Papadopoulos, Dimitra MalamidouDocument20 pagesLimenaria, A Neolithic and Early Bronze Age Settlement at Thasos - Stratis Papadopoulos, Dimitra MalamidouSonjce Marceva100% (1)

- 1987 103 Researches and Discoveries in Kent Archaeological Notes From Maidstone MuseumDocument12 pages1987 103 Researches and Discoveries in Kent Archaeological Notes From Maidstone MuseumleongorissenNo ratings yet

- SCCHC 2012 Pluckemin RPT 3 Officers TrashDocument16 pagesSCCHC 2012 Pluckemin RPT 3 Officers Trashjvanderveerhouse100% (3)

- The Neolithic Site of Ghosh 1995: ExcavationsDocument4 pagesThe Neolithic Site of Ghosh 1995: Excavationskacanx31No ratings yet

- Pottery From The Predynastic Settlement at Halfia Gibli (Diospolis Parva)Document13 pagesPottery From The Predynastic Settlement at Halfia Gibli (Diospolis Parva)ISAC ANDRADENo ratings yet

- Telling Time For Archaeologists PDFDocument24 pagesTelling Time For Archaeologists PDFVic RsNo ratings yet

- Alden Site Archaeological ReportDocument44 pagesAlden Site Archaeological ReportCraig ChartierNo ratings yet

- IlipinarDocument18 pagesIlipinarRichFishNo ratings yet

- Note On The Stone Axe From A Middle Bronze Age Waterhole at Perry OaksDocument4 pagesNote On The Stone Axe From A Middle Bronze Age Waterhole at Perry OaksFramework Archaeology100% (2)

- Archaic Rock InscriptionsDocument116 pagesArchaic Rock InscriptionsCelephaïs Press / Unspeakable Press (Leng)93% (15)

- Thrapston SpaldwickDocument55 pagesThrapston SpaldwickWessex ArchaeologyNo ratings yet

- Archaeological Watching Brief of Test Pits and Boreholes Along The Route of The Proposed Northern Bypass Addlethorpe, Lincolnshire (ANB98)Document21 pagesArchaeological Watching Brief of Test Pits and Boreholes Along The Route of The Proposed Northern Bypass Addlethorpe, Lincolnshire (ANB98)Syed Abdul HannanNo ratings yet

- 1972 - Mary Rose Reporte InterinoDocument4 pages1972 - Mary Rose Reporte InterinoAlejandro LealNo ratings yet

- Early Journal Content On JSTOR, Free To Anyone in The WorldDocument8 pagesEarly Journal Content On JSTOR, Free To Anyone in The WorldKıvanç TatlıtuğNo ratings yet

- Kettel HelmetDocument9 pagesKettel Helmetsstanislav2323No ratings yet

- Atlas Of Pennsylvanian (Carboniferous) Age Plant Fossils of the Central Appalachian Coalfields: Volume 2From EverandAtlas Of Pennsylvanian (Carboniferous) Age Plant Fossils of the Central Appalachian Coalfields: Volume 2No ratings yet

- Proportions Grading Scales Gia Natural Diamond Grading ReportDocument1 pageProportions Grading Scales Gia Natural Diamond Grading ReportNguyen Hoang DuyNo ratings yet

- Proportions Grading Scales Gia Natural Diamond Grading ReportDocument1 pageProportions Grading Scales Gia Natural Diamond Grading ReportPamms IntlNo ratings yet

- Acheulean - WikipediaDocument19 pagesAcheulean - WikipediaAbongile PhinyanaNo ratings yet

- List of Advisers Sy 2020-2021Document3 pagesList of Advisers Sy 2020-2021Jucel MarcoNo ratings yet

- Sillen 2011 Lithic Technology in Southern Mozambique PDFDocument69 pagesSillen 2011 Lithic Technology in Southern Mozambique PDFfelisbertoNo ratings yet

- Runnels 1994 - Tinderflints and Firemaking in The Historical PeriodDocument11 pagesRunnels 1994 - Tinderflints and Firemaking in The Historical Periodmarko7bandaNo ratings yet

- Lapidary Fundamentals - Cabochon Cutting - International Gem SociDocument17 pagesLapidary Fundamentals - Cabochon Cutting - International Gem SociNick M100% (1)

- 01 Pre-Historic ArchitectureDocument22 pages01 Pre-Historic Architecturelalen maraseganNo ratings yet

- Culet and Girdle AssessmentDocument8 pagesCulet and Girdle Assessmentpawnshop6666No ratings yet

- Introduction. en Leakey, M.. Olduvai Gorge Volume 3. Excavations in Beds I & 2, 1960-1963.Document8 pagesIntroduction. en Leakey, M.. Olduvai Gorge Volume 3. Excavations in Beds I & 2, 1960-1963.Pere No SiNo ratings yet

- Https WWW - Gemselect.com PDF-files Gemstone-Hardness-Chart GemselectDocument9 pagesHttps WWW - Gemselect.com PDF-files Gemstone-Hardness-Chart GemselectAlvaro GuarinNo ratings yet

- Shatkhandagam-Pustak-04 (VGM-184)Document396 pagesShatkhandagam-Pustak-04 (VGM-184)DJICRNo ratings yet

- SU21 - Ho PDFDocument3 pagesSU21 - Ho PDFraghuvansham boutique100% (1)

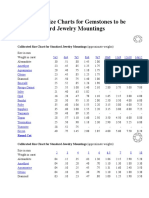

- Calibrated Size Charts For Gemstones To Be Set in Standard Jewelry MountingsDocument4 pagesCalibrated Size Charts For Gemstones To Be Set in Standard Jewelry Mountingsxem lo hangNo ratings yet

- The 'Chaîne Opératoire' Approach To Lithic Analysis by Roger GraceDocument21 pagesThe 'Chaîne Opératoire' Approach To Lithic Analysis by Roger GraceRubén N. Ocampo100% (1)

- Flint Paper DigitalDocument32 pagesFlint Paper DigitalsimonblackmoreNo ratings yet

- 1985 - 08 - Corvinus WordDocument18 pages1985 - 08 - Corvinus WordAmita Amita100% (1)

- Proportions Grading Scales Gia Natural Diamond Grading ReportDocument1 pageProportions Grading Scales Gia Natural Diamond Grading ReportNguyen Hoang DuyNo ratings yet

- Cultural Adaptations in Dakhleh OasisDocument11 pagesCultural Adaptations in Dakhleh OasisSebastian Muñoz DíazNo ratings yet

- Gr. 10 - Wisdom: Antonio J. Villegas Vocational High SchoolDocument35 pagesGr. 10 - Wisdom: Antonio J. Villegas Vocational High SchoolMaryjane judillaNo ratings yet

- Kolkata GemsDocument6 pagesKolkata GemsAnkit JainNo ratings yet

- Beginner Cutter Gems BookDocument64 pagesBeginner Cutter Gems BookZe Ze100% (2)

- GIA Certificate SampleDocument1 pageGIA Certificate SampleAung Ye KyawNo ratings yet

- Gems and Jewels PDFDocument319 pagesGems and Jewels PDFJuliana AmmarNo ratings yet

- Les Industries Des Sites Du Haut Rio Sao PDFDocument10 pagesLes Industries Des Sites Du Haut Rio Sao PDFisnardisNo ratings yet

- Site ExtentDocument36 pagesSite Extentபூவை ஜெ ரூபன்சார்லஸ்No ratings yet

- Chart - Colors of Gemstones, Shell and More - Fire Mountain Gems and BeadsDocument8 pagesChart - Colors of Gemstones, Shell and More - Fire Mountain Gems and Beadsmattandmarie8No ratings yet