Professional Documents

Culture Documents

CPC+MCM+ACM Error Codes List

CPC+MCM+ACM Error Codes List

Uploaded by

Miguel Ángel Ortega CotrinaCopyright:

Available Formats

You might also like

- CPC 4 ManualDocument457 pagesCPC 4 Manualmario pastranaNo ratings yet

- Volvo Mid 136 Fault CodesDocument72 pagesVolvo Mid 136 Fault Codesnzimageoffrey96100% (3)

- Traxon Fault Tree: Foton Fault Tree Based On 32Xxxxfn5Vv46 - 03.V46A0000.Hex Version: 27-11-2015Document170 pagesTraxon Fault Tree: Foton Fault Tree Based On 32Xxxxfn5Vv46 - 03.V46A0000.Hex Version: 27-11-2015ivan oliveros100% (4)

- Iveco Truck OBD Error Codes TableDocument435 pagesIveco Truck OBD Error Codes Tablem0tte100% (4)

- Mid 222 2Document36 pagesMid 222 2danecuprija100% (1)

- PACCAR MX-13 EPA2013 Diagnostic Manual - P062A To P1223 - WK 11 2015Document440 pagesPACCAR MX-13 EPA2013 Diagnostic Manual - P062A To P1223 - WK 11 2015Ariel SanchezNo ratings yet

- DAF - Fault Codes For Engine Control Units, DMCI - 1 PDFDocument23 pagesDAF - Fault Codes For Engine Control Units, DMCI - 1 PDFДмитрий Андрущенко100% (8)

- DAF CF Electrical System (To Chassis 0E621376) Service ManualDocument792 pagesDAF CF Electrical System (To Chassis 0E621376) Service ManualAlex100% (5)

- GT2200120 D7E Fuel Syst TB EngDocument24 pagesGT2200120 D7E Fuel Syst TB Engsanikkp0% (1)

- EBS2Document5 pagesEBS2Mahmoud Farag50% (2)

- Volvo 440 Fuel SystemDocument3 pagesVolvo 440 Fuel Systemkamal0% (1)

- Denoxtronic 2.2 PDFDocument2 pagesDenoxtronic 2.2 PDFAlexandre Dantas Henrique50% (6)

- Volvo b12b Electric Diagrams PDFDocument78 pagesVolvo b12b Electric Diagrams PDFМихайло Пуравець50% (2)

- Wiring Diagram Link J1939 For Volvo D13ADocument17 pagesWiring Diagram Link J1939 For Volvo D13AThan MinZaw100% (3)

- Problem Solving forMID 128 Fault Code Guide - Electronic Engine Control UnitDocument20 pagesProblem Solving forMID 128 Fault Code Guide - Electronic Engine Control UnitThan MinZaw100% (1)

- DAF XF105 DMCI Service ManualDocument144 pagesDAF XF105 DMCI Service ManualRodion Pyasetskiy100% (2)

- MID 128, PPID 8 Piston Cooling Pressure (D12-800) : MID 128: Engine Control Unit. Fault CodeDocument1 pageMID 128, PPID 8 Piston Cooling Pressure (D12-800) : MID 128: Engine Control Unit. Fault Codeuser1No ratings yet

- Manual Esquema Electr Daf XFDocument605 pagesManual Esquema Electr Daf XFjuanagus_20100% (6)

- S Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssDocument50 pagesS Se Errvviicce Eb Bu Ulllle Ettiin N T Trru UcckkssAndy Chalifoux100% (2)

- P016F - Closed Loop Fuel Pressure Control at Limit - Pressure Too LowDocument3 pagesP016F - Closed Loop Fuel Pressure Control at Limit - Pressure Too Lowirfan0% (1)

- MERCEDES Actros & Atego Fault Codes DTCDocument20 pagesMERCEDES Actros & Atego Fault Codes DTCSoloniaina100% (1)

- MID 130 PID 161 Input Shaft, Rotation SpeedDocument1 pageMID 130 PID 161 Input Shaft, Rotation SpeedhadiNo ratings yet

- Adblue FEDocument31 pagesAdblue FESherzad Chem100% (6)

- 2013 Temsa TS30 Electrical Systems Manual Part 1 PDFDocument289 pages2013 Temsa TS30 Electrical Systems Manual Part 1 PDFIrwan Adhitya100% (3)

- BU1 Technical ManualDocument16 pagesBU1 Technical ManualkevinjonescomNo ratings yet

- Mid 185 - Ppid 294 - Fmi 8Document4 pagesMid 185 - Ppid 294 - Fmi 8AkbarNo ratings yet

- WABCO Blink Codes C VerDocument4 pagesWABCO Blink Codes C VeraleksandrNo ratings yet

- Fault Codes: STO U AndriivDocument19 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- ADM PLD: Mercdes Benz AND Schematic For Om501La All Large Adt'SDocument1 pageADM PLD: Mercdes Benz AND Schematic For Om501La All Large Adt'SBassie100% (5)

- Gear Selector Control Module (GSCM) MID 223, Diagnostic Trouble Code (DTC), GuideDocument9 pagesGear Selector Control Module (GSCM) MID 223, Diagnostic Trouble Code (DTC), GuideJohnsito Leal67% (3)

- Mid 130Document50 pagesMid 130Julio Jara AguileraNo ratings yet

- Exhaust Gas Aftertreatment, Euro 6: en-GBDocument16 pagesExhaust Gas Aftertreatment, Euro 6: en-GBRuan100% (2)

- 1939 1708 Data Link Fault TracingDocument16 pages1939 1708 Data Link Fault TracingAyoub Ayoub100% (1)

- TraXon Training - MBB - NM - 03-2021 - PrintDocument50 pagesTraXon Training - MBB - NM - 03-2021 - PrintLuis Leyva100% (4)

- MID 128, PID 110 Coolant Temperature: MID 128: Engine Control Unit Fault CodeDocument1 pageMID 128, PID 110 Coolant Temperature: MID 128: Engine Control Unit Fault Codeuser1100% (1)

- VECU Manual de Produccion 70312913 PDFDocument33 pagesVECU Manual de Produccion 70312913 PDFAbdelhak EzzahriouiNo ratings yet

- P EAS-2 (D342) : Ower Supply and Earth of UnitDocument62 pagesP EAS-2 (D342) : Ower Supply and Earth of UnitBranko Andric100% (3)

- MID 144 Vehicle Electronic Control Unit (VECU), Signal DescriptionDocument4 pagesMID 144 Vehicle Electronic Control Unit (VECU), Signal DescriptionИгорь БасмановNo ratings yet

- Cummins: Fault Code: 489 PID: P191 SPN: 191 FMI: 0Document6 pagesCummins: Fault Code: 489 PID: P191 SPN: 191 FMI: 0Enrrique LaraNo ratings yet

- ADM2 Fault Codes Diagnosis, Version 203: DTC Description Remedial ActionDocument5 pagesADM2 Fault Codes Diagnosis, Version 203: DTC Description Remedial ActionJulioRamirezNo ratings yet

- Fault Codes (PLD-MR) Via SAE J1939 - 1.2Document17 pagesFault Codes (PLD-MR) Via SAE J1939 - 1.2Patrick ByronNo ratings yet

- Wiring Diagram B12B B12M B9B B7B PDFDocument90 pagesWiring Diagram B12B B12M B9B B7B PDFAbdelhak Ezzahrioui100% (2)

- Ecas - Optiride PDFDocument71 pagesEcas - Optiride PDFDinu Gabriel100% (2)

- DAF Trainee Doc MX-13 Engine Service ManualDocument126 pagesDAF Trainee Doc MX-13 Engine Service ManualVallentuna Verkstad0% (1)

- Traxon Standard LKW: StromlaufplanDocument2 pagesTraxon Standard LKW: Stromlaufplanivan oliverosNo ratings yet

- ADM3 Manual Rev703jDocument181 pagesADM3 Manual Rev703jПавел100% (1)

- MID 144 Fault Codes DTCDocument10 pagesMID 144 Fault Codes DTCesam PhilipeNo ratings yet

- Mid 234Document38 pagesMid 234danecuprijaNo ratings yet

- Central On-Board Computer 2 (ZBR2) A302Document55 pagesCentral On-Board Computer 2 (ZBR2) A302esam Philipe100% (1)

- Problem Solving MID 140 - Dashboard Fault Codes VolvoDocument4 pagesProblem Solving MID 140 - Dashboard Fault Codes VolvoThan MinZaw100% (1)

- MID 163 - Transponder Reading TestDocument2 pagesMID 163 - Transponder Reading TestTun Tun Win KseNo ratings yet

- Emitec (Groundfos) System IntroductionDocument30 pagesEmitec (Groundfos) System IntroductionЕвгений100% (2)

- Knorr Bremse Tebs G2Document86 pagesKnorr Bremse Tebs G2Adrian Rusu100% (3)

- 38 Fault Codes Tachograph MID 220Document34 pages38 Fault Codes Tachograph MID 220Lazuardhitya oktananda100% (1)

- TSP23698-Wiring Diagram FL6, FS7 LHD PDFDocument106 pagesTSP23698-Wiring Diagram FL6, FS7 LHD PDFOliver lealNo ratings yet

- MID163-FL-FE-Edicion 1Document20 pagesMID163-FL-FE-Edicion 1Elifio Cortes MazaNo ratings yet

- Checklist AS-Tronic / AS - MidDocument5 pagesChecklist AS-Tronic / AS - MidBroCactusNo ratings yet

- Errores Motor MRTDocument55 pagesErrores Motor MRTcomercialcoalciNo ratings yet

- Chelsea Pto Parts ManualDocument18 pagesChelsea Pto Parts ManualVic3501No ratings yet

- BF600-2 P, BF800 P - Error Code List: Actuator / Input Device / Sensor Device BSPNDocument228 pagesBF600-2 P, BF800 P - Error Code List: Actuator / Input Device / Sensor Device BSPNJuan PerezNo ratings yet

- PSI HAR-1013LS1HarnessInstructionsDocument14 pagesPSI HAR-1013LS1HarnessInstructionsسالم العطويNo ratings yet

- IPS-230X-IR 1.1 Starlight enDocument1 pageIPS-230X-IR 1.1 Starlight enahmed hashemNo ratings yet

- Flood Precast - Super Wideslab Load Span TablesDocument1 pageFlood Precast - Super Wideslab Load Span TablesRaymond KinnairdNo ratings yet

- R Reference Manual Volume 1Document736 pagesR Reference Manual Volume 1PH1628No ratings yet

- Power Quality Enhancement Using Custom Power DevicesDocument1 pagePower Quality Enhancement Using Custom Power DevicesankitNo ratings yet

- Month + Teaching Days Unit Total Teaching Periods: Vibgyor High Grade - 2 English Literature Year Plan (AY 2020 - 2021)Document65 pagesMonth + Teaching Days Unit Total Teaching Periods: Vibgyor High Grade - 2 English Literature Year Plan (AY 2020 - 2021)TAPASsenguptaNo ratings yet

- RFQ-97 For Supply of Biscuit & Soap-2Document1 pageRFQ-97 For Supply of Biscuit & Soap-2Prodip Debnath NayanNo ratings yet

- Vacant Seats: 5-Year Integrated M.Sc. (Hons.) ProgrammesDocument2 pagesVacant Seats: 5-Year Integrated M.Sc. (Hons.) Programmesmana khantNo ratings yet

- Noun (Subject) + Verb + The + Superlative Adjective + Noun (Object)Document6 pagesNoun (Subject) + Verb + The + Superlative Adjective + Noun (Object)anaNo ratings yet

- Office of The President: Bicol UniversityDocument1 pageOffice of The President: Bicol UniversityElmer BelgaNo ratings yet

- Solution To Microwave Engineering Pozar Chapter 14 Exercise 17 With MATLABDocument3 pagesSolution To Microwave Engineering Pozar Chapter 14 Exercise 17 With MATLABJohn Bofarull GuixNo ratings yet

- CE441 Class Lecture 01Document9 pagesCE441 Class Lecture 01ASHJAEE MANSIB CHOWDHURYNo ratings yet

- CCE Catalogue DetailedDocument28 pagesCCE Catalogue DetailedIshaan SinghNo ratings yet

- 2SUPMaT2019 - Bacani - Number TheoryDocument109 pages2SUPMaT2019 - Bacani - Number TheoryRomelaBalasotoParamiNo ratings yet

- 13-GB 50018-2002-EnDocument109 pages13-GB 50018-2002-Enyyyy071220100% (1)

- 3d Internet PDFDocument3 pages3d Internet PDFSam CrazeNo ratings yet

- Data Structures (Sample) Course ReportDocument128 pagesData Structures (Sample) Course Reportsiddardtha666666No ratings yet

- AHU Vibration Data - PostingDocument2 pagesAHU Vibration Data - PostingNeal JohnsonNo ratings yet

- Lean StartupDocument10 pagesLean StartupAlfredo Romero GNo ratings yet

- Frampton AntithesispedagogyDocument2 pagesFrampton AntithesispedagogyJohann WieseNo ratings yet

- Sharp Edge OrificeDocument2 pagesSharp Edge Orificeleo.caguimbal6433No ratings yet

- Solve The Problems: (1 Marks)Document7 pagesSolve The Problems: (1 Marks)Govin RocketzNo ratings yet

- ThevoidsummaryDocument6 pagesThevoidsummaryVaibhav Mishra80% (5)

- 03 Molar Volume of A Gas Long ReportDocument5 pages03 Molar Volume of A Gas Long ReportHoomehr TayariyanNo ratings yet

- 21st Century Skills PaperDocument8 pages21st Century Skills PaperemilyraleyNo ratings yet

- Development of Sensory TestingDocument35 pagesDevelopment of Sensory TestingEmmae ThaleenNo ratings yet

- Reasons For Diminishing Returns To A FactorDocument2 pagesReasons For Diminishing Returns To A FactorRobert AyalaNo ratings yet

- Spatial Modulation - Optimal Detection and Performance AnalysisDocument3 pagesSpatial Modulation - Optimal Detection and Performance AnalysisAliakbar AlastiNo ratings yet

- AMRITA EXAM DatesheetDocument9 pagesAMRITA EXAM DatesheetSARRALLE EQUIPMENT INDIA PVT LTDNo ratings yet

- Iso 7966 1993Document11 pagesIso 7966 1993Sci KelayNo ratings yet

CPC+MCM+ACM Error Codes List

CPC+MCM+ACM Error Codes List

Uploaded by

Miguel Ángel Ortega CotrinaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CPC+MCM+ACM Error Codes List

CPC+MCM+ACM Error Codes List

Uploaded by

Miguel Ángel Ortega CotrinaCopyright:

Available Formats

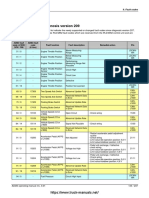

Fault Codes

CPC Based on: FaultCodes_R34_v2.0.xlsx

Color Description

relevant for vehicles with Daimler Transmission

(Tier4 Powerpack) only

SPN FMI DTC Fault description Recommended Action CEL SEL MIL Fault location

Check J1939 link connection to Park Brake Switch

Check Parameter 13/28 (Park Brake Switch Config) for correct

source

70 2 460002 Park Brake Status Not Plausible (Vehicle Moving) OFF OFF OFF

Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Check J1939 link connection to Park Brake Switch

Check Parameter 13/28 (Park Brake Switch Config) for correct

J1939 Park Brake Switch Signal from Source source

70 13 46000D CCVS1, CCVS2 or CCVS3 is missing or not ON OFF OFF

available = SNA (signal not available) Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Check J1939 link connection to Park Brake Switch

Check Parameter 13/28 (Park Brake Switch Config) for correct

J1939 Park Brake Switch Signal from Source source

70 19 460013 CCVS1, CCVS2 or CCVS3 is erractic = undefined ON OFF OFF

value but not SNA Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

This is an information-only fault. It indicates the vehicle is above

Vehicle Speed above programmable Threshold #1.

84 0 540000 a programmable threshold. Check Parameter 08/23 (vss ON OFF OFF

This is not a system failure/fault.

driving diagnostrtic limit).

Unexpected Loss of hard-wired Vehicle Speed signal. Check

84 2 540002 Vehicle Speed Signal lost OFF OFF OFF Pin 3/13

wiring of associated pin and cables.

84 3 540003 Vehicle Speed Sensor Circuit shorted to Ubat Check wiring of associated pin ON OFF OFF Pin 3/13

84 4 540004 Vehicle Speed Sensor Circuit shorted to GND Check wiring of associated pin ON OFF OFF Pin 3/13

Pin 3/13

Vehicle Speed Sensor open Circuit (broken wire, (Supply)

84 5 540005 Check wiring of associated pins ON OFF OFF

terminal floating) Pin 3/02

(GND)

Vehicle Speed Sensor Anti-Tamper Detection via Check wiring of ABS Module and VSS(Pin 3/13) .

84 6 540006 ABS Vehicle Speed Comparison (ABS speed and ON OFF OFF Pin 3/13

Vehicle Speed Sensor are not consistent) Check max. Parameter 40/01(ABS Diff Thresh Veh Speed).

Hall effect Vehicle Speed Sensor wiring mismatch,

84 7 540007 Check wiring of hall effect Vehicle Speed Sensor ON OFF OFF

rationality fault

This is an information-only fault. It indicates the vehicle is above

Vehicle Speed above programmable Threshold #2.

84 11 54000B a programmable threshold. Check Parameter 08/15 (vss ON OFF OFF

This is not a system failure/fault.

absolute diagnostic limit).

Check J1939 link connection to Wheel-Based Vehicle Speed

Sensor

Check Parameter 08/13 (Vehicle Speed Sensor) for correct

J1939 Wheel-Based Vehicle Speed Signal from

source

84 13 54000D Source CCVS1, CCVS2 or CCVS3 is missing or not OFF OFF OFF

available = SNA (signal not available) Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Hall effect Vehicle Speed Sensor supply voltage out

84 14 54000E Check wiring of hall effect Vehicle Speed Sensor ON OFF OFF

of range

Check J1939 link connection to Wheel-Based Vehicle Speed

Sensor

Check Parameter 08/13 (Vehicle Speed Sensor) for correct

J1939 Wheel-Based Vehicle Speed Signal from

source

84 19 540013 Source CCVS1, CCVS2 or CCVS3 is erractic = OFF OFF OFF

undefined value but not SNA Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Vehicle Speed Sensor Drifted High Error (VSS

84 20 540014 Check wiring of associated pin ON OFF OFF Pin 3/13

signal not plausible)

84 21 540015 Vehicle Speed failure (VSS Signal Not Plausible) Check wiring of associated pin ON OFF OFF Pin 3/13

Pin 1/07

(Supply)

91 0 5B0000 Accelerator Pedal Circuit shorted to Ubat Check wiring of associated pins ON OFF OFF

Pin 1/04

(GND)

Check wiring and calibration; Restart learning routine (chapter

91 2 5B0002 Accelerator Pedal out of adjustment (Learn error) ON OFF OFF Pin 1/07

6.4, routines 1 to 3)

Pin 1/07

(Supply)

91 4 5B0004 Accelerator Pedal Circuit shorted to GND Check wiring of associated pins ON OFF OFF

Pin 1/04

(GND)

Pin 1/03

2-Channel Accelerator Pedal Idle Not Recognized Pin 1/04

91 7 5B0007 Check wiring of associated pins. Check Idle Position ON OFF OFF

(idle area not evaluated)

Pin 1/06

Pin 1/07

91 8 5B0008 2-Channel Accelerator Pedal Signal 1 missing Check wiring of associated pins ON OFF OFF Pin 1/03

Rationality check routine for throttle pedal position:

91 10 5B000A Throttle pedal rationality check failed OFF OFF OFF

18.02.2015 Seite 1 CPC+MCM+ACM Error Codes List.xlsx

SPN FMI DTC Fault description Recommended Action CEL SEL MIL Fault location

If current throttle pedal value is above a certain calibratable

value (i.e. 10%) while service brake is actuated in conjunction

91 10 5B000A Throttle pedal rationality check failed with a real strong vehicle deceleration, throttle pedal position is OFF OFF OFF

recognized as erroneous and a fault will be logged. The

position furthermore is ramped down to 0%. As soon as original

pedal position is back again to 0% the fault is deactivated.

91 13 5B000D J1939 EEC2 message is missing or not available Check J1939 link connection and devices: Turbocharger ON OFF OFF

Start learning routine (chapter 6.4, routines 1 to 3): Pin 1/03

– Accelerator Pedal Learning: Start Pin 1/04

91 14 5B000E 2-Channel Accelerator Pedal Not Learned ON OFF OFF

– Accelerator Pedal Learning: Stop Pin 1/06

– Accelerator Pedal Learning: Request Results Status Pin 1/07

Check wiring and calibration; Restart learning routine (chapter

Pin 1/03

6.4, routines 1 to 3):

2-Channel Accelerator Pedal Learned Range to – Accelerator Pedal Learning: Start Pin 1/04

91 31 5B001F ON OFF OFF

Large – Accelerator Pedal Learning: Stop Pin 1/06

– Accelerator Pedal Learning: Request Results Status Pin 1/07

Check CPC4 PT-CAN link connection.

96 13 60000D Fuel Level Sensor Missing or Not Available Check MCM functionality / PT-CAN link connection. Check OFF OFF OFF

J1939 CAN message PGN 65276 (Dash Display) and

according ECU (e. g. Dashboard)

Check CPC4 PT-CAN link connection.

96 19 600013 Fuel Level Sensor Received Network Data in Error Check MCM functionality / PT-CAN link connection. Check OFF OFF OFF

J1939 CAN message PGN 65276 (Dash Display) and

according ECU (e. g. Dashboard)

Check air cleaner for restriction. Perform pressure check/visual

inspection of plugged inlet air filters, charge air cooler leaks or

restriction, leaking or plugged intake manifold, exhaust

107 0 6B0000 Air Filter Restriction High OFF OFF OFF

leaks/plugging.

Replace Air filter and delete fault code memory via service tool

or instrument cluster if supported.

Check wiring of associated pin

Check parameter 13/11 (3 01 AI Selection) for correct

configuration of input pin 3/01

Check air cleaner for restriction. Perform pressure check/visual

107 2 6B0002 Air Filter Sensor plausibility error inspection of plugged inlet air filters, charge air cooler leaks or ON OFF OFF Pin 3/01

restriction, leaking or plugged intake manifold, exhaust

leaks/plugging.

Replace Air filter and delete fault code memory via service tool

or instrument cluster if supported.

Check wiring of associated pin

Check parameter 13/11 (3 01 AI Selection) for correct

configuration of input pin 3/01

Air Filter diff.-pressure Sensor or switch shorted to Check air cleaner for restriction. Perform pressure check/visual

107 3 6B0003 inspection of plugged inlet air filters, charge air cooler leaks or ON OFF OFF Pin 3/01

Ubat

restriction, leaking or plugged intake manifold, exhaust

leaks/plugging.

Replace Air filter and delete fault code memory via service tool

or instrument cluster if supported.

Check wiring of associated pin

Check parameter 13/11 (3 01 AI Selection) for correct

configuration of input pin 3/01

Air Filter diff.-pressure Sensor or switch shorted to Check air cleaner for restriction. Perform pressure check/visual

107 4 6B0004 inspection of plugged inlet air filters, charge air cooler leaks or ON OFF OFF Pin 3/01

GND

restriction, leaking or plugged intake manifold, exhaust

leaks/plugging.

Replace Air filter and delete fault code memory via service tool

or instrument cluster if supported.

Check coolant level in reservoir. If coolant level is not within

limit, refill coolant to proper level. If it is within proper level,

Coolant Level below safe operating level – (SEL change collant level sensor. Check coolant leak at cylinder

111 1 6F0001 ON ON OFF

Condition) head gasket, coolant leak at air compressor head gasket,

external coolant leak at hose connections, coolant in oil, loose

or faulty radiator cap, heating system for leaks.

Pin 3/02

(GND)

111 3 6F0003 Coolant Level Circuit shorted to Ubat Check wiring of associated pins ON OFF OFF

Pin 3/11

(Supply)

Pin 3/02

(GND)

111 4 6F0004 Coolant Level Sensor Circuit Failed Low Check wiring of associated pins ON OFF OFF

Pin 3/11

(Supply)

Pin 3/02

(GND)

111 6 6F0006 Coolant Level Sensor Circuit shorted to GND Check wiring of associated pins ON OFF OFF

Pin 3/11

(Supply)

Check coolant level in reservoir. If coolant level is not within

limit, refill coolant to proper level. If it is within proper level,

Coolant Level below operating level (pre-warning change coolant level sensor. Check coolant leak at cylinder

111 18 6F0012 ON OFF OFF

condition) head gasket, coolant leak at air compressor head gasket,

external coolant leak at hose connections, coolant in oil, loose

or faulty radiator cap, heating system for leaks.

J1939 Retarder Fluid Message is missing or not

120 13 78000D available (J1939 Cabin Message is missing or not Check J1939 link connection to transmission retarder OFF OFF OFF

available?)

KL15 ignition switch status of CPC and MCM do not

158 2 9E0002 Check KL15 wiring at Pin 2/03 ON OFF OFF Pin 2/03

match.

Check Voltage KL15 and KL30 (Fault Condition Battery

Pin 2/01

168 0 A80000 Battery Voltage High Voltage > 35V) ON OFF OFF

Check wiring of associated pins Pin 2/03

Check Voltage KL15 and Kl30 (Fault Condition Battery Voltage

Pin 2/01

< 9.8V)

168 1 A80001 Battery Voltage Very Low ON OFF OFF

18.02.2015 Seite 2 CPC+MCM+ACM Error Codes List.xlsx

SPN FMI DTC Fault description Recommended Action CEL SEL MIL Fault location

168 1 A80001 Battery Voltage Very Low Check wiring of associated pins ON OFF OFF Pin 2/03

If vehicle Is equipped with a battery disconnect switch, it must

be inspected

Opt Idle Detected Charging System or Battery Pin 2/01

168 7 A80007 Check battery main switch and battery wiring (KL30) ON OFF OFF

Failure Pin 2/03

Pin 2/01

168 9 A80009 Main battery connection lost Check battery main switch and battery wiring (KL30) ON OFF OFF

Pin 2/03

Check wiring of associated pins Pin 2/01

ECU powerdown not completed (Main Battery

168 14 A8000E If vehicle Is equipped with a battery disconnect switch, it must OFF OFF OFF

Terminal Possibly Floating) Pin 2/03

be inspected

Check Voltage KL15 and KL30 (Fault Condition Battery

Pin 2/01

168 18 A80012 Battery Voltage Low Voltage < 19.2V) ON OFF OFF

Check wiring of associated pins Pin 2/03

Check ambient temperature sensor (wiring and associated pin)

171 2 AB0002 Ambient Temperature Sensor Data Erratic ON OFF OFF Pin 3/15

Check parameter 31/01 (Ambient Air Temp Sensor Enable) for

correct configuration of Ambient Temperature Sensor

Check ambient temperature sensor (wiring and associated pin)

171 3 AB0003 Ambient Temperature Sensor shorted to Ubat ON OFF OFF Pin 3/15

Check parameter 31/01 (Ambient Air Temp Sensor Enable) for

correct configuration of Ambient Temperature Sensor

Check ambient temperature sensor (wiring and associated pin)

171 4 AB0004 Ambient Temperature Sensor shorted to GND ON OFF OFF Pin 3/15

Check parameter 31/01 (Ambient Air Temp Sensor Enable) for

correct configuration of Ambient Temperature Sensor

Check J1939 link connection to ambient Air Temp Sensor and

J1587 Ambient Air Temp Sensor Data Message

171 9 AB0009 wiring. Check Parameter 31/01 (Ambient Air Temp Sensor ON OFF OFF Pin 3/15

Stopped Arriving

Enable) for proper configuration.

Check J1939 link connection to ambient Air Temp Sensor and

J1587 Ambient Air Temp Sensor Data Not Received

171 14 AB000E wiring. Check Parameter 31/01 (Ambient Air Temp Sensor ON OFF OFF Pin 3/15

This Ign Cycle

Enable) for proper configuration.

187 3 BB0003 Idle Volume Sensor circuit shorted to Ubat FUSO Idle Volume Switch circuit shorted to Ubat ON OFF OFF

187 4 BB0004 Idle Volume Sensor circuit shorted to GND FUSO Idle Volume Switch circuit shorted to GND ON OFF OFF

Check J1939 link connection to Transmission Controller /

191 9 BF0009 J1939 ETC1 Message is missing or not available ON OFF OFF

Check if Electronic Transmission Controller is CAN capable

J1939 Transmission Output Shaft Speed Signal is Check J1939 link connection to Transmission Controller /

191 13 BF000D OFF OFF OFF

missing or not available = SNA (signal not available) Check if electronic Transmission Controller is CAN capable

J1939 Transmission Output Shaft Speed Signal

191 19 BF0013 Check J1939 link connection to Transmission Controller OFF OFF OFF

erractic = undefined value but not SNA

247 0 F70000 MCM Engine Hours Data higher than expected Check MCM. OFF OFF OFF

CPC or MCM. The internal clocks of the CPC or MCM do not

247 1 F70001 MCM Engine Hours Data lower than expected OFF OFF OFF

match. Check MCM.

MCM Engine Hours Data not received or stopped

247 9 F70009 Check MCM. OFF OFF OFF

arriving

MCM Engine Hours Data increasing at an CPC or MCM. The internal clocks of the CPC or MCM do not

247 10 F7000A OFF OFF OFF

implausible rate match. Check MCM.

J1939 Transmission Current Gear Signal is missing

523 13 0B020D Check J1939 link connection to Transmission ON OFF OFF

or not available

J1939 Transmission Current Gear Signal is erractic

523 19 0B0213 Check J1939 link connection to Transmission OFF OFF OFF

= undefined value but not SNA

Check J1939 link connection to Transmission Controller /

524 9 0C0209 J1939 ETC2 message is missing or not available ON OFF OFF

Check if Electronic Transmission Controller is CAN capable

Check J1939 link connection to Transmission Controller /

Transmission gear selection switch reports internal Check if Electronic Transmission Controller is CAN capable.

525 7 0D0207 ON OFF OFF

error.

Check LIN wiring / stalk switch.

J1939 Powertrain Message (transfer case / PTO) is

525 9 0D0209 Check wiring of OEM ICU and related J1939 link connection ON OFF OFF

missing

Check J1939 link connection to Transmission Controller /

Transmission gear selection switch reports Check if Electronic Transmission Controller is CAN capable.

525 19 0D0213 ON OFF OFF

unplausible engine brake stage requests.

Check LIN wiring / stalk switch.

Check J1939 link connection to Cruise Control

Check Parameter 13/22 (CC ON OFF Switch Config) for

correct source

527 9 0F0209 J1939 CCVS is missing or not available OFF OFF OFF

Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Check J1939 link connection to Transmission Retarder.

J1939 RC Message from Transmission Retarder is

556 9 2C0209 Check if Transmission Retarder is enabled and correct ON OFF OFF

missing

configured, Parameter 55/01. (Trans Ret Number of Stages)

Pin 1/03

558 2 2E0202 Idle Validation Switch Inputs Reversed. Check Idle Validation switch wiring ON OFF OFF

Pin 1/06

Check wiring of associated pin

Check parameters 35/01 (Selection), 35/20 (Fault Detection)

and 35/38 (Configuration) for correct configuration of output pin

Idle Validation Switch 1 Circuit shorted to Ubat. The

558 3 2E0203 1/04 ON OFF OFF Pin 1/04

two idle switches are not synchron (check AP)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 13

Check wiring of associated pin

Check parameters 35/01 (Selection), 35/20 (Fault Detection)

and 35/38 (Configuration) for correct configuration of output pin

Idle Validation Switch 1 Circuit shorted to GND. The

558 4 2E0204 1/04 ON OFF OFF Pin 1/04

two idle switches are not synchron (check AP)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 13

Check wiring of associated pin

Check parameters 35/01 (Selection), 35/20 (Fault Detection)

and 35/38 (Configuration) for correct configuration of output pin

Idle Validation Switch 2 Circuit shorted to GND. The

558 5 2E0205 1/04 ON OFF OFF Pin 1/04

two idle switches are not synchron (check AP)

18.02.2015 Seite 3 CPC+MCM+ACM Error Codes List.xlsx

SPN DTC Idle Validation Switch

Fault2 description

Circuit shorted to GND. The Recommended Action

558 FMI

5 2E0205 CEL

ON SEL

OFF MIL

OFF Fault

Pinlocation

1/04

two idle switches are not synchron (check AP)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 13

Check wiring of associated pin

Check parameters 35/01 (Selection), 35/20 (Fault Detection)

and 35/38 (Configuration) for correct configuration of output pin

Idle Validation Switch 2 Circuit shorted to Ubat. The

558 6 2E0206 1/04 ON OFF OFF Pin 1/04

two idle switches are not synchron (check AP)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 13

569 9 390209 J1939 EAC1 Message is missing or not available Check J1939 link connection to Electronic Axle Control ON OFF OFF

Check wiring of associated pin

Engine Brake Disable push-button shorted to

571 4 3B0204 Check parameters 13/19 (Selection), 13/62 (Fault Detect Ena) ON OFF OFF Pin 4/18

Ground or pressed too long

for correct configuration of input pin 4/18

Check J1939 link connection to Cruise Control

Check Parameter 13/22 (CC ON OFF Switch Config) for

J1939 Cruise Control Enable Switch Signal from correct source

596 13 54020D Source CCVS1, CCVS2 or CCVS3 missing or not OFF OFF OFF

available = SNA (signal not available) Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Check J1939 link connection to Cruise Control

Check Parameter 13/22 (CC ON OFF Switch Config) for

J1939 Cruise Control Enable Switch Signal from correct source

596 19 540213 Source CCVS1, CCVS2 or CCVS3 erractic = OFF OFF OFF

undefined value but not SNA Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

597 2 550202 Service Brake Status Not Plausible FUSO Only. ON OFF OFF

Check J1939 link connection to Cruise Control

Check Parameter 13/29 (Service Brake Switch Config) for

J1939 Service Brake Switch Signal from Source correct source

597 13 55020D CCVS1, CCVS2 or CCVS3 missing or not available OFF OFF OFF

= SNA (signal not available) Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Check J1939 link connection to Cruise Control

Check Parameter 13/29 (Service Brake Switch Config) for

J1939 Service Brake Switch Signal from Source correct source

597 19 550213 CCVS1, CCVS2 or CCVS3 erractic = undefined OFF OFF OFF

value but not SNA Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

598 2 560202 Clutch switch status not plausible Check wiring of Clutch Switch and Driveline Open Status ON OFF OFF

Cruise Control SET and RESUME Circuits shorted Pin 1/12

599 4 570204 to GND (SET and RESUME applied at the same Check wiring of associated pins ON OFF OFF

time) Pin 1/16

Check J1939 link connection to Cruise Control

Check Parameter 13/24 (CC Set Cst Res Accel Sw Config) for

J1939 Cruise Control Coast Switch Signal from correct source

600 13 58020D Source CCVS1, CCVS2 or CCVS3 missing or not OFF OFF OFF

available = SNA (signal not available) Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Check J1939 link connection to Cruise Control

Check Parameter 13/24 (CC Set Cst Res Accel Sw Config) for

J1939 Cruise Control Coast Switch Signal from correct source

600 19 580213 Source CCVS1, CCVS2 or CCVS3 erractic = OFF OFF OFF

undefined value but not SNA Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Check J1939 link connection to Cruise Control

Check Parameter 13/24 (CC Set Cst Res Accel Sw Config) for

J1939 Cruise Control Accelerator Switch Signal correct source

602 13 5A020D from Source CCVS1, CCVS2 or CCVS3 = SNA OFF OFF OFF

(signal not available) Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Check J1939 link connection to Cruise Control

Check Parameter 13/24 (CC Set Cst Res Accel Sw Config) for

J1939 Cruise Control Accelerator Switch from correct source

602 19 5A0213 Source CCVS1, CCVS2 or CCVS3 erractic = OFF OFF OFF

undefined value but not SNA Check Parameter 01/04 (CC1 Source Adress SAE J1939),

01/05 (CC2 Source Adress SAE J1939) and 01/06 (CC3

Source Adress SAE J1939) for correct Source Adress

Fault is active IF j1708_g_TransFaultValFlag_u1 AND

608 14 60020E J1708 Data Link Failure ON OFF OFF

j1708_g_TransFaultFlag_u1 are TRUE

Try reprogramming the CPC with the new software release.

609 12 61020C CPC electronics are defect (EEPROM, CPU…) OFF OFF OFF

Replace CPC4 and reprogram with the latest software.

Source address setting conflict.

Messages with more than one source address (e.g. “CM1 Fan

609 13 61020D the CPC SW is corrupt (CPC Software Diagnostics) Source Addr1” and ”CM1 Fan Source Addr2”) have to be OFF OFF OFF

parameterized with different addresses. Check calibration for

these addresses (PGR 01 “Communication”)

Check CPC4 case and cooling measurements. Turn off

609 16 610210 Internal temperature of CPC4 too high. ON OFF OFF

vehicle.

MCM Sys ID not valid (MCM initialization not finished). Check

625 2 710202 PTCAN Incorrect MCM System ID received ON OFF ON

MCM.

ECAN Hardware Link Failure. Check Engine Controller, Check

625 4 710204 ECAN Link Circuit Failure ON OFF OFF

engine can circuitry

MCM PT-CAN DM1 Message Not Received or has Check CPC4 PT-CAN link connection.

625 8 710208 ON OFF ON

Stopped Arriving Check MCM functionality / PT-CAN link connection

ACM PT-CAN DM1 Message Not Received or has Check CPC4 PT-CAN link connection.

625 9 710209 ON OFF ON

Stopped Arriving Check ACM functionality / PT-CAN link connection

TCM System ID Not Received or Stopped Arriving Check CPC4 PT-CAN link connection.

625 13 71020D OFF OFF OFF

(TCM Outage -> Check Translamp) Check TCM functionality / PT-CAN link connection

18.02.2015 Seite 4 CPC+MCM+ACM Error Codes List.xlsx

SPN FMI DTC Fault description Recommended Action CEL SEL MIL Fault location

PTCAN: MCM Sytem ID Not Received or Stopped Check PT-CAN link connection.

625 14 71020E Arriving (ECAN ID_596/7 not received or it has ON OFF ON

stopped arriving) Check MCM functionality / PT-CAN link connection

Try reprogramming the CPC with the new software release.

Reset EEPROM values to default. Redownload CPC

628 2 740202 EEPROM Checksum Failure parameter set. ON OFF OFF

Replace CPC4 and reprogram with the latest software.

FUSO only. None. To be checked PEP. Replace modul if

628 12 74020C EEPROM Checksum Failure for the SCR Block ON OFF OFF

this failure occurs again.

XFLASH Static Fault Code Memory Page Read Replace CPC4 box due to XFLASH failure and reprogram with

628 14 74020E OFF OFF OFF

Write Failure (XFLASH Failure.) the latest software.

1000ms ECU OS Task Timed out Prior to Try reprogramming the CPC with the new software release.

628 17 740211 Completion. (Indication of a critical resource OFF OFF OFF

allocation issue. Task restructuring required.) Replace CPC4 and reprogram with the latest software.

Try reprogramming the CPC with the new software release.

CPC Hardware / Software Mismatch (Incorrect Reset EEPROM values to default. Redownload CPC

629 2 750202 parameter set. ON OFF OFF

Hardware Configuration - NAFTA Vs. EUROPE)

Replace CPC4 and reprogram with the latest software.

DDEC Data Xflash Write Error. Replace CPC. Try reprogramming the CPC with the new software release.

629 12 75020C OFF OFF OFF

(XFLASH Failure.)

Replace CPC4 and reprogram with the latest software.

FUSO only. Reset EEPROM values to default. Redownload

630 13 76020D SCR Number out Of Range ON OFF OFF

CPC.

J1939 PROP11 message no longer received within Use SPN default values. SA Parameter 01/17 (FUSO ISS

639 9 7F0209 OFF OFF OFF

it’s expected time. Source Addr SAE J1939)

Check J1939 link connection to the air conditioner transducer.

HDMS Fan is configured and the J1939 message

639 13 7F020D Check if CPC4 parameters correct for the vehicle OFF OFF OFF

was not received or has stopped arriving.

configuration.

Pin 2/16

J1939 Data Link Failure (CPC is no longer sending

639 14 7F020E Check J1939 data link connection ON OFF OFF Pin 2/17

or receiving data from the J1939 link.)

Pin 2/18

667 3 9B0203 Starter Pin 1/18 Circuit shorted to Ubat (KL50) Check KL50 wiring at Pin 1/18 ON OFF OFF Pin 1/18

Check wiring of associated pin

Check parameters 35/06 (Selection), 35/25 (Fault Detection)

and 35/42 (Configuration) for correct configuration of output pin

701 3 BD0203 Digital Output 3/07 Circuit shorted to Ubat 3/07 ON OFF OFF Pin 3/07

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 9

Check wiring of associated pin

Check parameters 35/06 (Selection), 35/25 (Fault Detection)

and 35/42 (Configuration) for correct configuration of output pin

701 4 BD0204 Digital Output 3/07 Circuit shorted to GND 3/07 ON OFF OFF Pin 3/07

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 9

Check wiring of associated pin

Check parameters 35/06 (Selection), 35/25 (Fault Detection)

and 35/42 (Configuration) for correct configuration of output pin

Digital Output 3/07 Open Circuit (broken wire,

701 5 BD0205 3/07 ON OFF OFF Pin 3/07

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 9

Check wiring of associated pin

Check parameters 35/07 (Selection), 35/26 (Fault Detection)

and 35/43 (Configuration) for correct configuration of output pin

702 3 BE0203 Digital Output 3/08 Circuit shorted to Ubat 3/08 ON OFF OFF Pin 3/08

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 10

Check wiring of associated pin

Check parameters 35/07 (Selection), 35/26 (Fault Detection)

and 35/43 (Configuration) for correct configuration of output pin

702 4 BE0204 Digital Output 3/08 Circuit shorted to GND 3/08 ON OFF OFF Pin 3/08

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 10

Check wiring of associated pin

Check parameters 35/07 (Selection), 35/26 (Fault Detection)

and 35/43 (Configuration) for correct configuration of output pin

Digital Output 3/08 Open Circuit (broken wire,

702 5 BE0205 3/08 ON OFF OFF Pin 3/08

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 10

Check wiring of associated pin

Check parameters 35/08 (Selection), 35/27 (Fault Detection)

and 35/44 (Configuration) for correct configuration of output pin

703 3 BF0203 Digital Output 3/09 Circuit shorted to Ubat 3/09 ON OFF OFF Pin 3/09

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 14

Check wiring of associated pin

Check parameters 35/08 (Selection), 35/27 (Fault Detection)

and 35/44 (Configuration) for correct configuration of output pin

703 4 BF0204 Digital Output 3/09 Circuit shorted to GND 3/09 ON OFF OFF Pin 3/09

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 14

Check wiring of associated pin

Check parameters 35/08 (Selection), 35/27 (Fault Detection)

and 35/44 (Configuration) for correct configuration of output pin

Digital Output 3/09 Open Circuit (broken wire,

703 5 BF0205 3/09 ON OFF OFF Pin 3/09

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 14

Check wiring of associated pin

704 3 C00203 Digital Output 4/07 Circuit shorted to Ubat ON OFF OFF Pin 4/07

18.02.2015 Seite 5 CPC+MCM+ACM Error Codes List.xlsx

SPN FMI DTC Fault description Recommended Action CEL SEL MIL Fault location

Check parameters 35/16 (Selection), 35/35 (Fault Detection)

and 35/52 (Configuration) for correct configuration of output pin

704 3 C00203 Digital Output 4/07 Circuit shorted to Ubat 4/07 ON OFF OFF Pin 4/07

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 15

Check wiring of associated pin

Check parameters 35/16 (Selection), 35/35 (Fault Detection)

and 35/52 (Configuration) for correct configuration of output pin

704 4 C00204 Digital Output 4/07 Circuit shorted to GND 4/07 ON OFF OFF Pin 4/07

Run Service Routine (chapter 6.4, routines 15 to 17):

– Dvigital Output Pin Under Software Control: Start

Response with Signal Parameter 15

Check wiring of associated pin

Check parameters 35/16 (Selection), 35/35 (Fault Detection)

and 35/52 (Configuration) for correct configuration of output pin

Digital Output 4/07 Open Circuit (broken wire,

704 5 C00205 4/07 ON OFF OFF Pin 4/07

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 15

Check wiring of associated pin

Check parameters 35/03 (Selection), 35/22 (Fault Detection)

and 35/40 (Configuration) for correct configuration of output pin

705 3 C10203 Digital Output 1/13 Circuit shorted to Ubat 1/13 ON OFF OFF Pin 1/13

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 1

Check wiring of associated pin

Check parameters 35/03 (Selection), 35/22 (Fault Detection)

and 35/40 (Configuration) for correct configuration of output pin

705 4 C10204 Digital Output 1/13 Circuit shorted to GND 1/13 ON OFF OFF Pin 1/13

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 1

Check wiring of associated pin

Check parameters 35/03 (Selection), 35/22 (Fault Detection)

and 35/40 (Configuration) for correct configuration of output pin

Digital Output 1/13 Open Circuit (broken wire,

705 5 C10205 1/13 ON OFF OFF Pin 1/13

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 1

Check wiring of associated pin

Check parameters 35/09 (Selection), 35/28 (Fault Detection)

and 35/45 (Configuration) for correct configuration of output pin

706 3 C20203 Digital Output 3/10 Circuit shorted to Ubat 3/10 ON OFF OFF Pin 3/10

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 2

Check wiring of associated pin

Check parameters 35/09 (Selection), 35/28 (Fault Detection)

and 35/45 (Configuration) for correct configuration of output pin

706 4 C20204 Digital Output 3/10 Circuit shorted to GND 3/10 ON OFF OFF Pin 3/10

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 2

Check wiring of associated pin

Check parameters 35/09 (Selection), 35/28 (Fault Detection)

and 35/45 (Configuration) for correct configuration of output pin

Digital Output 3/10 Open Circuit (broken wire,

706 5 C20205 3/10 ON OFF OFF Pin 3/10

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 2

Check wiring of associated pin

Check parameters 35/04 (Selection), 35/23 (Fault Detection)

and 35/41 (Configuration) for correct configuration of output pin

Digital Output 2/10 Circuit shorted to Ubat (CEL /

707 3 C30203 2/10 OFF OFF OFF Pin 2/10

AWL Lamp)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 3

Check wiring of associated pin

Check parameters 35/04 (Selection), 35/23 (Fault Detection)

and 35/41 (Configuration) for correct configuration of output pin

Digital Output 2/10 Circuit shorted to GND (CEL /

707 4 C30204 2/10 OFF OFF OFF Pin 2/10

AWL Lamp)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 3

Check wiring of associated pin

Check parameters 35/04 (Selection), 35/23 (Fault Detection)

and 35/41 (Configuration) for correct configuration of output pin

Digital Output 2/10 Open Circuit (broken wire,

707 5 C30205 2/10 OFF OFF OFF Pin 2/10

terminal floating / CEL / AWL Lamp)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 3

Check wiring of associated pin

Check parameters 35/10 (Selection), 35/29 (Fault Detection)

and 35/46 (Configuration) for correct configuration of output pin

708 3 C40203 Digital Output 3/12 Circuit shorted to Ubat 3/12 ON OFF OFF Pin 3/12

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 4

Check wiring of associated pin

Check parameters 35/10 (Selection), 35/29 (Fault Detection)

and 35/46 (Configuration) for correct configuration of output pin

708 4 C40204 Digital Output 3/12 Circuit shorted to GND 3/12 ON OFF OFF Pin 3/12

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 4

18.02.2015 Seite 6 CPC+MCM+ACM Error Codes List.xlsx

SPN FMI DTC Fault description Recommended Action CEL SEL MIL Fault location

Check wiring of associated pin

Check parameters 35/10 (Selection), 35/29 (Fault Detection)

and 35/46 (Configuration) for correct configuration of output pin

Digital Output 3/12 Open Circuit (broken wire,

708 5 C40205 3/12 ON OFF OFF Pin 3/12

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 4

Check wiring of associated pin

Check parameters 35/11 (Selection), 35/30 (Fault Detection)

and 35/47 (Configuration) for correct configuration of output pin

709 3 C50203 Digital Output 3/16 Circuit shorted to Ubat 3/16 ON OFF OFF Pin 3/16

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 5

Check wiring of associated pin

Check parameters 35/11 (Selection), 35/30 (Fault Detection)

and 35/47 (Configuration) for correct configuration of output pin

709 4 C50204 Digital Output 3/16 Circuit shorted to GND 3/16 ON OFF OFF Pin 3/16

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 5

Check wiring of associated pin

Check parameters 35/11 (Selection), 35/30 (Fault Detection)

and 35/47 (Configuration) for correct configuration of output pin

Digital Output 3/16 Open Circuit (broken wire,

709 5 C50205 3/16 ON OFF OFF Pin 3/16

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 5

Check wiring of associated pin

Check parameters 35/15 (Selection), 35/34 (Fault Detection)

and 35/51 (Configuration) for correct configuration of output pin

710 3 C60203 Digital Output 4/06 Circuit shorted to Ubat 4/06 ON OFF OFF Pin 4/06

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 6

Check wiring of associated pin

Check parameters 35/15 (Selection), 35/34 (Fault Detection)

and 35/51 (Configuration) for correct configuration of output pin

710 4 C60204 Digital Output 4/06 Circuit shorted to GND 4/06 ON OFF OFF Pin 4/06

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 6

Check wiring of associated pin

Check parameters 35/15 (Selection), 35/34 (Fault Detection)

and 35/51 (Configuration) for correct configuration of output pin

Digital Output 4/06 Open Circuit (broken wire,

710 5 C60205 4/06 ON OFF OFF Pin 4/06

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 6

Check wiring of associated pin

Check parameters 35/02 (Selection), 35/21 (Fault Detection)

and 35/39 (Configuration) for correct configuration of output pin

711 3 C70203 Digital Output 1/05 Circuit shorted to Ubat 1/05 ON OFF OFF Pin 1/05

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 12

Check wiring of associated pin

Check parameters 35/02 (Selection), 35/21 (Fault Detection)

and 35/39 (Configuration) for correct configuration of output pin

711 4 C70204 Digital Output 1/05 Circuit shorted to GND 1/05 ON OFF OFF Pin 1/05

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 12

Check wiring of associated pin

Check parameters 35/02 (Selection), 35/21 (Fault Detection)

and 35/39 (Configuration) for correct configuration of output pin

Digital Output 1/05 Open Circuit (broken wire,

711 5 C70205 1/05 ON OFF OFF Pin 1/05

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 12

Check wiring of associated pin

Check parameters 35/01 (Selection), 35/20 (Fault Detection)

and 35/38 (Configuration) for correct configuration of output pin

712 3 C80203 Digital Output 1/04 Circuit shorted to Ubat 1/04 ON OFF OFF Pin 1/04

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 13

Check wiring of associated pin

Check parameters 35/01 (Selection), 35/20 (Fault Detection)

and 35/38 (Configuration) for correct configuration of output pin

712 4 C80204 Digital Output 1/04 Circuit shorted to GND 1/04 ON OFF OFF Pin 1/04

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 13

Check wiring of associated pin

Check parameters 35/01 (Selection), 35/20 (Fault Detection)

and 35/38 (Configuration) for correct configuration of output pin

Digital Output 1/04 Open Circuit (broken wire,

712 5 C80205 1/04 ON OFF OFF Pin 1/04

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 13

Check wiring of associated pin

713 7 C90207 TOP2 Shift Failure Check parameters 35/06 (Selection), 35/25 (Fault Detection) OFF OFF OFF Pin 3/07

and 35/42 (Configuration) for correct configuration of output pin

3/07

Check wiring of associated pin

714 3 CA0203 Digital Output 4/10 Circuit shorted to Ubat ON OFF OFF Pin 4/10

18.02.2015 Seite 7 CPC+MCM+ACM Error Codes List.xlsx

SPN FMI DTC Fault description Recommended Action CEL SEL MIL Fault location

Check parameters 35/18 (Selection), 35/37 (Fault Detection)

and 35/54 (Configuration) for correct configuration of output pin

714 3 CA0203 Digital Output 4/10 Circuit shorted to Ubat 4/10 ON OFF OFF Pin 4/10

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 11

Check wiring of associated pin

Check parameters 35/18 (Selection), 35/37 (Fault Detection)

and 35/54 (Configuration) for correct configuration of output pin

714 4 CA0204 Digital Output 4/10 Circuit shorted to GND 4/10 ON OFF OFF Pin 4/10

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 11

Check wiring of associated pin

Check parameters 35/18 (Selection), 35/37 (Fault Detection)

and 35/54 (Configuration) for correct configuration of output pin

Digital Output 4/10 Open Circuit (broken wire,

714 5 CA0205 4/10 ON OFF OFF Pin 4/10

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 11

Check wiring of associated pin

715 3 CB0203 Frequency Output 4/12 Circuit shorted to Ubat Run Service Routine (chapter 6.4, routines 8 to 10): ON OFF OFF Pin 4/12

– Analog Output Pin Under Software: Start with Signal

Parameter 1, Frequency in Hz, Width in %

Check wiring of associated pin

715 4 CB0204 Frequency Output 4/12 Circuit shorted to GND Run Service Routine (chapter 6.4, routines 8 to 10): ON OFF OFF Pin 4/12

– Analog Output Pin Under Software: Start with Signal

Parameter 1, Frequency in Hz, Width in %

Check wiring of associated pin

Frequency Output 4/12 Open Circuit (broken wire, Run Service Routine (chapter 6.4, routines 8 to 10):

715 5 CB0205 OFF OFF OFF Pin 4/12

terminal floating)

– Analog Output Pin Under Software: Start with Signal

Parameter 1, Frequency in Hz, Width in %

Check wiring of associated pin

716 3 CC0203 Frequency Output 1/09 Circuit shorted to Ubat Run Service Routine (chapter 6.4, routines 8 to 10): ON OFF OFF Pin 1/09

– Analog Output Pin Under Software: Start with Signal

Parameter 2, Frequency in Hz, Width in %

Check wiring of associated pin

716 4 CC0204 Frequency Output 1/09 Circuit shorted to GND Run Service Routine (chapter 6.4, routines 8 to 10): ON OFF OFF Pin 1/09

– Analog Output Pin Under Software: Start with Signal

Parameter 2, Frequency in Hz, Width in %

Check wiring of associated pin

Frequency Output 1/09 Open Circuit (broken wire, Run Service Routine (chapter 6.4, routines 8 to 10):

716 5 CC0205 ON OFF OFF Pin 1/09

terminal floating)

– Analog Output Pin Under Software: Start with Signal

Parameter 2, Frequency in Hz, Width in %

J1939 EBC2 Message from ABS is missing or not Check J1939 link connection to the ABS and Devices Brake

904 9 880309 OFF OFF OFF

available = SNA (signal not available) System Controller

J1939 Front Axle Speed Signal is missing or not

904 13 88030D Check J1939 link connection to Front Axle Speed Sensor OFF OFF OFF

available = SNA (signal not available)

J1939 Front Axle Speed Signal is erratic =

904 19 880313 Check J1939 link connection to Front Axle Speed Sensor OFF OFF OFF

undefined value but not SNA

Check wiring of associated pin

Check parameters 35/17 (Selection), 35/36 (Fault Detection)

and 35/53 (Configuration) for correct configuration of output pin

924 3 9C0303 Digital Output 4/09 Circuit shorted to Ubat 4/09 ON OFF OFF Pin 4/09

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 7

Check wiring of associated pin

Check parameters 35/17 (Selection), 35/36 (Fault Detection)

and 35/53 (Configuration) for correct configuration of output pin

924 4 9C0304 Digital Output 4/09 Circuit shorted to GND 4/09 ON OFF OFF Pin 4/09

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 7

Check wiring of associated pin

Check parameters 35/17 (Selection), 35/36 (Fault Detection)

and 35/53 (Configuration) for correct configuration of output pin

Digital Output 4/09 Open Circuit (broken wire,

924 5 9C0305 4/09 ON OFF OFF Pin 4/09

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 7

Check wiring of associated pin

Check parameters 35/12 (Selection), 35/31 (Fault Detection)

and 35/48 (Configuration) for correct configuration of output pin

925 3 9D0303 Digital Output 3/17 Circuit shorted to Ubat 3/17 ON OFF OFF Pin 3/17

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 8

Check wiring of associated pin

Check parameters 35/12 (Selection), 35/31 (Fault Detection)

and 35/48 (Configuration) for correct configuration of output pin

925 4 9D0304 Digital Output 3/17 Circuit shorted to GND 3/17 ON OFF OFF Pin 3/17

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 8

Check wiring of associated pin

Check parameters 35/12 (Selection), 35/31 (Fault Detection)

and 35/48 (Configuration) for correct configuration of output pin

Digital Output 3/17 Open Circuit (broken wire,

925 5 9D0305 3/17 ON OFF OFF Pin 3/17

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 8

Check wiring of associated pin

Check parameters 35/13 (Selection), 35/32 (Fault Detection)

and 35/49 (Configuration) for correct configuration of output pin

926 3 9E0303 Digital Output 4/01 Circuit shorted to Ubat 4/01 ON OFF OFF Pin 4/01

18.02.2015 Seite 8 CPC+MCM+ACM Error Codes List.xlsx

SPN

926 FMI

3 DTC

9E0303 Fault

Digital Output 4/01 description

Circuit shorted to Ubat Recommended Action CEL

ON SEL

OFF MIL

OFF Fault

Pinlocation

4/01

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 16

Check wiring of associated pin

Check parameters 35/13 (Selection), 35/32 (Fault Detection)

and 35/49 (Configuration) for correct configuration of output pin

926 4 9E0304 Digital Output 4/01 Circuit shorted to GND 4/01 ON OFF OFF Pin 4/01

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 16

Check wiring of associated pin

Check parameters 35/13 (Selection), 35/32 (Fault Detection)

and 35/49 (Configuration) for correct configuration of output pin

Digital Output 4/01 Open Circuit (broken wire,

926 5 9E0305 4/01 ON OFF OFF Pin 4/01

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 16

Check wiring of associated pin.

970 3 CA0303 Engine Aux. Shutdown Input shorted to Ubat Check parameters 13/03 (Selection) and 13/35 (Fault ON OFF OFF Pin 1/10

Detection) for correct configuration of input pin 1/01.

Check wiring of associated pin.

970 4 CA0304 Engine Aux. Shutdown Input shorted to GND Check parameters 13/03 (Selection) and 13/35 (Fault ON OFF OFF Pin 1/10

Detection) for correct configuration of input pin 1/01.

Check wiring of associated pin.

Throttle inhibit switch signal not plausible due to

972 2 CC0302 Check parameters 13/05 (Selection) and 13/43 (Fault ON OFF OFF Pin 1/17

excess vehicle speed

Detection) for correct configuration of input pin 1/17.

Check wiring of associated pin.

973 2 CD0302 Evobus 5stage retarder level position not plausible Check parameters 13/08 (Selection) and 13/49 (Fault ON OFF OFF Pin 2/13

Detection) for correct configuration of input pin 2/13.

Check J1939 link connection and Devices Turbocharger.

973 9 CD0309 J1939 EBC1 Message is missing or not available ON OFF OFF

Check Parameter 01/10 (EBC1 Source Adress SAE J1939)

J1939 Engine Retarder Selection Signal Missing or

973 13 CD030D Check J1939 link connection to Engine Retarder ON OFF OFF

not available = SNA (signal not available)

J1939 Engine Retarder Selection Signal erractic =

973 19 CD0313 Check J1939 link connection to Engine Retarder ON OFF OFF

undefined value but not SNA

Remote Accelerator Pedal Supply Voltage Out of Pin 3/03

974 2 CE0302 Check wiring of associated pins ON OFF OFF

Range Pin 3/04

Pin 3/02

974 3 CE0303 Remote Accelerator Pedal Circuit shorted to Ubat Check wiring of associated pins ON OFF OFF Pin 3/03

Pin 3/04

Pin 3/02

974 4 CE0304 Remote Accelerator Pedal Circuit shorted to GND Check wiring of associated pins ON OFF OFF Pin 3/03

Pin 3/04

Check J1939 link connection.

J1939 PTO Message Not Received This Ignition

979 9 D30309 Check Parameter 01/52 (PTO Source Adress SAE J1939) for ON OFF OFF

Cycle

proper configuration.

Check J1939 link connection and Devices Cab Controller 1

J1939 CM1 DPF Message is missing or not and Climate Control.

986 9 DA0309 OFF OFF OFF

available Check Parameter 01/07 (CM1 DPF Source Adress SAE J1939)

for proper configuration.

Check J1939 link connection.

J1939 CM1 Fan SPN986 Signal from source

986 13 DA030D address #1 or #2 is missing or not available = SNA Check Parameter 01/08 (CM1 Fan Source Adress #1 SAE OFF OFF OFF

(signal not available) J1939) and Parameter 01/09 (CM1 Fan Source Adress #2 SAE

J1939) for proper configuration.

Check J1939 link connection.

J1939 CM1 Fan SPN986 Signal from source

986 19 DA0313 address #1 or #2 is erractic = undefined value but Check Parameter 01/08 (CM1 Fan Source Adress #1 SAE OFF OFF OFF

not SNA J1939) and Parameter 01/09 (CM1 Fan Source Adress #2 SAE

J1939) for proper configuration.

Check J1939 link connection

J1939 AIR1 Message (Air Supply Pressure) is

1089 9 410409 ON OFF OFF

missing from first source address Check Parameter 01/96 (AIR1 Source Address 1 SAE J1939)

Check J1939 link connection

J1939 AIR1 Message (Air Supply Pressure) is

1089 13 41040D ON OFF OFF

missing from second source address Check Parameter 01/102 (AIR1 Source Address 2 SAE J1939)

J1939 Powertrain Message (AMT – Detroit

1121 2 610402 Check wiring of J2CC and related J1939 link connection ON OFF OFF

transmission) is missing

J1939 Service Brake Switch Signal from EBC1 is Check J1939 link connection to Service Brake. Check

1121 13 61040D OFF OFF OFF

missing or not available = SNA (signal not available) Parameter 01/10 (EBC1 Source Adress SAE J1939)

J1939 Service Brake Switch Signal from EBC1 is Check J1939 link connection to Service Brake. Check

1121 19 610413 OFF OFF OFF

erractic = undefined value but not SNA Parameter 01/10 (EBC1 Source Adress SAE J1939)

Check wiring of associated pin.

Stop Engine Override Switch shorted to Ground (if

1237 4 D50404 Check parameters 13/04 (Selection) and 13/41 (Fault Detect ON OFF OFF Pin 1/15

applied more than 5 sec this error flags)

Enable) for correct configuration of input pin 1/15.

Check ABS for proper function. Combination of ABS and ASC

ABS fault restricts automatic gear selection

1243 14 DB040E error. ABS error = v > 1km/h and req-gear < current gear and OFF OFF OFF

functionality.

ABS in stat “not fully operable”

J1939 TC1 Message (Transmission Mode) is

1482 9 CA0509 Check J1939 link connection to Transmission Control ON OFF OFF

missing

1484 9 CC0509 J1939 Message was lost (Message Counter Error) Check J1939 link connection OFF OFF OFF

1484 13 CC050D J1939 Message was lost (CRC Error) Check J1939 link connection OFF OFF OFF

Check J1939 link connection. J1939 ACC Message not

1590 9 360609 Adaptive Cruise Control Message Not Received OFF OFF OFF

received.

Adaptive Cruise Control – General Error. Disables ACC

1590 19 360613 Adaptive Cruise Control – General Error OFF OFF OFF

feature.

Check J1939 link connection to ABS.

J1939 HRW Message from ABS is missing (HRW

1592 9 380609 Check correct configuration (parameter 02/09 (Transmission ON OFF OFF

not received in case newAMT Transmission used)

Type)) if newAMT Transmission is used

Check J1939 link connection to ABS.

J1939 HRW Wheel Speed Signal Missing (HRW

1592 13 38060D Check correct configuration (parameter 02/09 (Transmission OFF OFF OFF

received but at least one signal not available)

Type)) if newAMT Transmission is used

18.02.2015 Seite 9 CPC+MCM+ACM Error Codes List.xlsx

SPN FMI DTC Fault description Recommended Action CEL SEL MIL Fault location

Check J1939 link connection to ABS.

J1939 HRW Wheel Speed Signal Erroneous (HRW

1592 19 380613 Check correct configuration (parameter 02/09 (Transmission OFF OFF OFF

received but at least one signal erroneous)

Type)) if newAMT Transmission is used

J1939 Tachograph Output Shaft Speed Signal is

1623 9 570609 Check wiring of associated pin OFF OFF OFF

erratic = undefined value but not SNA

J1939 Tachograph Output Shaft Speed Signal is

1623 13 57060D Check wiring of associated pin OFF OFF OFF

missing or not available = SNA (signal not available)

Check J1939 link connection to Vehicle Speed Sensor. Check

1624 9 580609 J1939 TCO1 Message is missing or not available Parameter 08/13 (Vehicle Speed Sensor Configuration) for OFF OFF OFF

proper configuration

J1939 Tachograph Vehicle Speed Signal is missing Check J1939 link connection to Vehicle Speed Sensor. Check

1624 13 58060D or not available = SNA (signal not available) + Parameter 08/13 (Vehicle Speed Sensor Configuration) for OFF OFF OFF

J1939 TCO1 speed sensor selected proper configuration

J1939 Tachograph Vehicle Speed Signal is erractic Check J1939 link connection to Vehicle Speed Sensor. Check

1624 19 580613 = undefined value but not SNA + J1939 TCO1 Parameter 08/13 (Vehicle Speed Sensor Configuration) for OFF OFF OFF

speed sensor selected proper configuration

Check if Park brake is applied, Engine Hood is Closed and

Optimized idle prevented from resuming (Safety Transmission is in Neural Position.

1663 7 7F0607 ON OFF OFF

Loop Faulted)

Check the wiring of the involved switches and sensors.

1681 9 910609 J1939 BM Message (Battery Main Switch) is missing Check J1939 link connection ON OFF OFF

1716 9 B40609 J1939 ERC1 Message is missing or not available Check J1939 link connection to Retarder OFF OFF OFF

Check wiring of associated pin.

Evobus 5stage retarder level calibration not

1716 13 B4060D Check parameters 13/08 (Selection) and 13/49 (Fault Detect ON OFF OFF Pin 2/13

plausible

Enable) for correct configuration of input pin 2/13.

J1939 VDC1 Message was not received or has Check J1939 link connection. Check Parameter 01/57 (VDC1

1814 9 160709 OFF OFF OFF

stopped arriving. Source Adress SAE J1939)

1845 9 350709 J1939 TCFG2 Message is missing or not available Check J1939 link connection to Transmission Control OFF OFF OFF

J1939 Message is missing from source adress 3

2003 9 D30709 Check J1939 link connection to Cruise Control ECU ON OFF OFF

(3dec = Transmission #1 ECU missing)

J1939 Message is missing from source address 11

2011 9 DB0709 OFF OFF OFF

(dec).

J1939 Message is missing from source address 17

2017 9 E10709 Check J1939 link connection to Cruise Control ECU OFF OFF OFF

(17dec = Cruise Control ECU missing)

J1939 Message is missing from source 23 (23dec =

2023 9 E70709 Check J1939 link connection to Instrument Cluster ECU OFF OFF OFF

Instrument Cluster ECU missing)

J1939 Message is missing from source 25 (25dec = Check J1939 link connection to Passenger Operator Climate

2025 9 E90709 OFF OFF OFF

Passenger-Operator Climate Control ECU missing) Control ECU

J1939 Message is missing from source 33 (33dec =

2033 9 F10709 Check J1939 link connection to body Controller ECU ON OFF OFF

Body Controller ECU missing)

J1939 Message is missing from source 42 (42dec =

Headway Controller (forward-looking collision

2042 9 FA0709 Check J1939 link connection to Headway Controller ECU ON OFF OFF

warning, collision avoidance, speed Controller, or

speed matching) ECU is missing)

J1939 Message is missing from source 49 (49dec =

2049 9 10809 Check J1939 link connection to Gab Controller – Primary ECU ON OFF OFF

Gab Controller - Primary ECU missing)

J1939 CM1 Message (Maximum Vehicle Speed

2596 9 240A09 Check J1939 link connection ON OFF OFF

Limit) is Missing or Not Available

Check wiring of associated pins and calibration; Restart

2-Channel Accelerator Pedal “in-range” fault (AP learning routine. (chapter 6.4, routines 1 to 3):

2623 2 3F0A02 ON OFF OFF

Ch1 and Ch2 values differ to much) Check Accelerator Pedal for proper behavier regarding voltage

of the 2 channels.

2623 8 3F0A08 2-Channel Accelerator Pedal Signal 2 Missing Check wiring of associated pin ON OFF OFF Pin 1/06

Check wiring of associated pin

Check parameters 35/14 (Selection), 35/33 (Fault Detection)

and 35/50 (Configuration) for correct configuration of output pin

2646 3 560A03 Digital Output 4/02 Circuit shorted to Ubat 4/02 ON OFF OFF Pin 4/02

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 9

Check wiring of associated pin

Check parameters 35/14 (Selection), 35/33 (Fault Detection)

and 35/50 (Configuration) for correct configuration of output pin

2646 4 560A04 Digital Output 4/02 Circuit shorted to GND 4/02 ON OFF OFF Pin 4/02

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 9

Check wiring of associated pin

Check parameters 35/14 (Selection), 35/33 (Fault Detection)

and 35/50 (Configuration) for correct configuration of output pin

Digital Output 4/02 Open Circuit (broken wire,

2646 5 560A05 4/02 ON OFF OFF Pin 4/02

terminal floating)

Run Service Routine (chapter 6.4, routines 15 to 17):

– Digital Output Pin Under Software Control: Start

Response with Signal Parameter 9

Check the J1939 link connection

Off-Highway Engine Configuration Selection

Check parameter 01/72 for configuration of OHECS source

2882 13 420B0D message on J1939 was not received or has stopped ON OFF OFF

address

arriving.

Check parameter 05/06 for proper configuration

Check J1939 link connection to Transmission Controller /

2900 9 540B09 J1939 ETC7 Message is missing or not available ON OFF OFF

Check if Electronic Transmission Controller is CAN capable

3187 9 730C09 Transmission Shift Console Datalink (LIN) Check LIN wiring / stalk switch ON OFF OFF

Check wiring of Generator Terminal D+ or check Generator

3353 2 190D02 Generator (Charging System) D+ terminal failure OFF OFF OFF

functionality

Accelerator Pedal Supply Voltage Circuit shorted to Pin 1/08

3510 4 B60D04 Check wiring of associated pins ON OFF OFF

GND

Pin 3/03

Accelerator Pedal Supply Voltage Circuit shorted to Pin 1/08

3510 7 B60D07 Check wiring of associated pins ON OFF OFF

Ubat

Pin 3/03

Remote Accelerator Pedal Supply Voltage circuit Pin 3/03 (Supply)

3511 3 B70D03 Check wiring of associated pins ON OFF OFF

shorted to Ubat Pin 3/02 (GND)

18.02.2015 Seite 10 CPC+MCM+ACM Error Codes List.xlsx

SPN FMI DTC Fault description Recommended Action CEL SEL MIL Fault location

Remote Accelerator Pedal Supply Voltage circuit Pin 3/03 (Supply)

3511 4 B70D04 Check wiring of associated pins ON OFF OFF

shorted to GND Pin 3/02 (GND)

3606 9 160E09 J1939 PROP04 Message is missing or not available Check J1939 link connection to Diesel Particulate Filter ON OFF OFF

J1939 TCI Message (Transfer Case Information) is

3645 9 3D0E09 Check J1939 link connection ON OFF OFF

missing

Check wiring of associated pin.

3840 3 000F03 Frequency Output 4/15 Circuit shorted to Ubat Check Parameters 09/07 (Selection), 09/13 (Fault Detection) ON OFF OFF Pin 4/15

and 09/17 (Output Configuration) for correct configuration.

Check wiring of associated pin.

3840 4 000F04 Frequency Output 4/15 Circuit shorted to GND Check Parameters 09/07 (Selection), 09/13 (Fault Detection) ON OFF OFF Pin 4/15

and 09/17 (Output Configuration) for correct configuration.

Check wiring of associated pin.

Frequency Output 4/15 Open Circuit (broken wire,

3840 5 000F05 Check Parameters 09/07 (Selection), 09/13 (Fault Detection) ON OFF OFF Pin 4/15

terminal floating)

and 09/17 (Output Configuration) for correct configuration.

Check wiring of associated pin.

3841 3 010F03 Frequency Output 4/11 Circuit shorted to Ubat Check Parameters 09/07 (Selection), 09/13 (Fault Detection) ON OFF OFF Pin 4/11

and 09/17 (Output Configuration) for correct configuration.

Check wiring of associated pin.