Professional Documents

Culture Documents

Tech Spect

Tech Spect

Uploaded by

Liezl Fanoe0 ratings0% found this document useful (0 votes)

9 views1 pageThis document provides technical specifications and mechanical properties for different types of fibreboard, including high density fibreboard (HDF) and medium density fibreboard (MDF). It lists physical properties such as thickness, density, bending strength, swelling, internal bond, screw holding, and surface absorption. The fibreboards are tested based on various British standards and specifications are provided for a range of thickness from 2mm to 30mm. Tolerances for dimensions, squareness, and edge straightness are also outlined.

Original Description:

Original Title

TECH SPECT-converted

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides technical specifications and mechanical properties for different types of fibreboard, including high density fibreboard (HDF) and medium density fibreboard (MDF). It lists physical properties such as thickness, density, bending strength, swelling, internal bond, screw holding, and surface absorption. The fibreboards are tested based on various British standards and specifications are provided for a range of thickness from 2mm to 30mm. Tolerances for dimensions, squareness, and edge straightness are also outlined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views1 pageTech Spect

Tech Spect

Uploaded by

Liezl FanoeThis document provides technical specifications and mechanical properties for different types of fibreboard, including high density fibreboard (HDF) and medium density fibreboard (MDF). It lists physical properties such as thickness, density, bending strength, swelling, internal bond, screw holding, and surface absorption. The fibreboards are tested based on various British standards and specifications are provided for a range of thickness from 2mm to 30mm. Tolerances for dimensions, squareness, and edge straightness are also outlined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

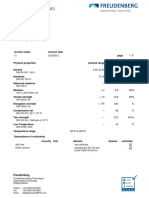

Dongwha Specification Revison No 12

Technical Specifications & Mechanical Properties Revison Date 15-02-2020

Physical & Mechanical Properties of Fibreboard

Range of thickness (mm)

Product Type Mechanical Properties Test Method Unit

≥ 2.0 - 2.7 > 2.7 - 3.6 > 3.6 - 4.5 > 4.5 - 6.0 > 6.0 - 9.0 > 9.0 - 12.0 >12.0 - 15.0 >15.0 - 19.0 > 19.0 - 30.0

Standard Thickness BS EN 324-1 mm ±0.2

HDF Tolerances in

Nominal Dimensions mm a) within 5mm (length) & within 2mm (width) for free trim panel

Length and Width BS EN 324-1

b) +2 mm (width) and + 5mm (length) for nett size panel

Squareness Tolerances (Diagonal) BS EN 324-2 mm/m ≤ 5.0

Edge Straightness Tolerances BS EN 324-2 mm/m ≤1.5

Moisture Content BS EN 322 % 5-8

Density BS EN 323 kg/m3 Average 880 ±20 880 ±20 870 ±20 860 ±20 840 ±20 820 ±20 800 ±20 760 ±20 740 ±20

Bending Strength BS EN 310 N/mm² Min Ave ≥ 35 ≥ 35 ≥ 35 ≥ 30 ≥ 30 ≥ 30 ≥ 28 ≥ 28 ≥ 25

Swelling in Thickness (24 hour) BS EN 317 % Max Ave ≤ 30 ≤ 25 ≤ 25 ≤ 20 ≤ 15 ≤ 15 ≤ 10 ≤ 10 ≤8

Internal Bond BS EN 319 N/mm² Min Ave ≥ 1.20 ≥ 1.20 ≥ 1.20 ≥ 1.20 ≥ 1.20 ≥ 1.00 ≥ 1.00 ≥ 0.90 ≥ 0.90

Internal Bond BS EN 319 N/mm² Min Specimen ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80

Face BS EN 320 N NA NA NA NA NA NA 1050 1050 1050

Screw Holding Ave

Edge BS EN 320 N NA NA NA NA NA NA 850 850 850

Surface Absorption (Toluene) BS EN 382-1 in-house mm Min Premium ≥ 150 Premium ≥ 200

High Thickness BS EN 324-1 mm ±0.2

Tolerances in

Moisture Nominal Dimensions mm a) within 5mm (length) & within 2mm (width) for free trim panel

Length and Width BS EN 324-1

Resistance b) +2 mm (width) and + 5mm (length) for nett size panel

Squareness Tolerances (Diagonal) BS EN 324-2 mm/m ≤ 5.0

[HMR]

Edge Straightness Tolerances BS EN 324-2 mm/m ≤1.5

Moisture Content BS EN 322 % 5-8

Density BS EN 323 kg/m3 Average 880 ±20 880 ±20 870 ±20 860 ±20 840 ±20 820 ±20 760 ±20 750 ±20 740 ±20

Bending Strength BS EN 310 N/mm² Ave ≥ 35 ≥ 35 ≥ 35 ≥ 30 ≥ 30 ≥ 30 ≥ 28 ≥ 28 ≥ 25

Swelling in Thickness (24 hour) BS EN 317 % Max Ave ≤ 30 ≤ 20 ≤ 18 ≤ 15 ≤ 12 ≤ 10 ≤8 ≤8 ≤7

Internal Bond BS EN 319 N/mm² Ave ≥ 1.20 ≥ 1.20 ≥ 1.20 ≥ 1.20 ≥ 1.20 ≥ 1.00 ≥ 1.00 ≥ 0.90 ≥ 0.90

Internal Bond BS EN 319 N/mm² Min Specimen ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80

Face BS EN 320 N NA NA NA NA NA NA 1050 1050 1050

Screw Holding Ave

Edge BS EN 320 N NA NA NA NA NA NA 850 850 850

Surface Absorption (Toluene) BS EN 382-1 in-house mm Min Premium ≥ 150 Premium ≥ 200

Standard Thickness BS EN 324-1 mm ±0.2

MDF Tolerances in

Nominal Dimensions a) within 5mm (length) & within 2mm (width) for free trim panel

Length and Width BS EN 324-1 mm

b) +2 mm (width) and + 5mm (length) for nett size panel

Squareness Tolerances (Diagonal) BS EN 324-2 mm ≤ 5.0

Edge Straightness Tolerances BS EN 324-2 mm/m ≤1.5

Moisture Content BS EN 322 % 5-8

Density BS EN 323 kg/m3 Average 810±20 810±20 790±20 780±20 750±20 740±20 720±20 700±20 670±20

Bending Strength BS EN 310 N/mm² Min Ave ≥ 30 ≥ 30 ≥ 30 ≥ 30 ≥ 30 ≥ 30 ≥ 25 ≥ 25 ≥ 25

Swelling in Thickness (24 hour) BS EN 317 % Max Ave ≤ 35 ≤ 35 ≤ 35 ≤ 30 ≤ 17 ≤ 17 ≤ 15 ≤ 12 ≤ 10

Internal Bond BS EN 319 N/mm² Min Ave ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.80 ≥ 0.65 ≥ 0.65 ≥ 0.60 ≥ 0.60 ≥ 0.50

Internal Bond BS EN 319 N/mm² Min Specimen ≥ 0.70 ≥ 0.70 ≥ 0.70 ≥ 0.70 ≥ 0.55 ≥ 0.55 ≥ 0.50 ≥ 0.50 ≥ 0.45

Face BS EN 320 N NA NA NA NA NA NA 1050 1050 1000

Screw Holding Ave

Edge BS EN 320 N NA NA NA NA NA NA 850 850 700

Surface Absorption (Toluene) BS EN 382-1 in-house mm Min Premium ≥ 100 Premium ≥ 150

Moisture Thickness BS EN 324-1 mm ±0.2

Tolerances in

Resistance Nominal Dimensions mm a) within 5mm (length) & within 2mm (width) for free trim panel

Length and Width BS EN 324-1

[MMR] b) +2 mm (width) and + 5mm (length) for nett size panel

Squareness Tolerances (Diagonal) BS EN 324-2 mm ≤5

Edge Straightness Tolerances BS EN 324-2 mm/m ≤1.5

Moisture Content BS EN 322 % 5-8

Density BS EN 323 kg/m3 Average 830±30 810±20 790±20 780±20 760±20 740±20 720±20 700±20 670±20

Bending Strength BS EN 310 N/mm² Min Ave ≥ 35 ≥ 35 ≥ 35 ≥ 30 ≥ 30 ≥ 30 ≥ 28 ≥ 28 ≥ 25

Swelling in Thickness (24 hour) BS EN 317 % Max Ave ≤ 30 ≤ 20 ≤ 18 ≤ 15 ≤ 12 ≤ 10 ≤8 ≤8 ≤7

Internal Bond BS EN 319 N/mm² Ave ≥ 1.00 ≥ 1.00 ≥ 1.00 ≥ 0.70 ≥ 0.70 ≥ 0.70 ≥ 0.70 ≥ 0.70 ≥ 0.70

Internal Bond BS EN 319 N/mm² Min Specimen ≥ 0.70 ≥ 0.70 ≥ 0.70 ≥ 0.60 ≥ 0.60 ≥ 0.60 ≥ 0.60 ≥ 0.60 ≥ 0.60

Face BS EN 320 N NA NA NA NA NA NA 1050 1050 1000

Screw Holding Ave

Edge BS EN 320 N NA NA NA NA NA NA 850 850 700

Surface Absorption (Toluene) BS EN 382-1 in-house mm Min Premium ≥ 100 Premium ≥ 150

Fire Thickness BS EN 324-1 mm ±0.2

Tolerances in

Retardant Nominal Dimensions mm a) within 5mm (length) & within 2mm (width) for free trim panel

Length and Width BS EN 324-1

[MFR] b) +2 mm (width) and + 5mm (length) for nett size panel

Squareness Tolerances (Diagonal) BS EN 324-2 mm ≤5

Edge Straightness Tolerances BS EN 324-2 mm/m ≤1.5

Moisture Content BS EN 322 % 5-8

Density BS EN 323 kg/m3 Average ≥ 700 ≥ 700 ≥ 700

Bending Strength BS EN 310 N/mm² Min Ave ≥ 30 ≥ 28 ≥ 25

Swelling in Thickness (24 hour) BS EN 317 % Max Ave ≤ 17 ≤ 15 ≤ 12

Internal Bond BS EN 319 N/mm² Ave ≥ 0.70 ≥ 0.70 ≥ 0.65

Internal Bond BS EN 319 N/mm² Min Specimen ≥ 0.60 ≥ 0.60 ≥ 0.60

Face BS EN 320 N NA 1050 1050

Screw Holding Ave

Edge BS EN 320 N NA 850 850

Surface Absorption (Toluene) BS EN 382-1 in-house mm Min Premium ≥150

Fire Retardancy BS 476: Part 7 - - Class 1

Standard Thickness BS EN 324-1 mm ±0.2

LDF Tolerances in

Nominal Dimensions a) within 5mm (length) & within 2mm (width) for free trim panel

Length and Width BS EN 324-1 mm

b) +2 mm (width) and + 5mm (length) for nett size panel

Squareness Tolerances (Diagonal) BS EN 324-2 mm ≤ 5.0

Edge Straightness Tolerances BS EN 324-2 mm/m ≤1.5

Moisture Content BS EN 322 % 5-8

3

Density BS EN 323 kg/m 680±20 680±20 670±20 670±20 650±20

Bending Strength BS EN 310 N/mm² Min Ave ≥ 22 ≥ 22 ≥ 20 ≥ 20 ≥ 18

Swelling in Thickness (24 hour) BS EN 317 % Max Ave ≤ 20 ≤ 18 ≤ 14 ≤ 14 ≤ 12

Internal Bond BS EN 319 N/mm² Min Ave ≥ 0.60 ≥ 0.55 ≥ 0.50 ≥ 0.50 ≥ 0.45

Internal Bond BS EN 319 N/mm² Min Specimen ≥ 0.55 ≥ 0.50 ≥ 0.45 ≥ 0.45 ≥ 0.40

Surface Absorption (Toluene) BS EN 382-1 in-house mm Min Premium ≥ 100 Premium ≥150

Standard Thickness BS EN 324-1 mm ±0.2

IDF Tolerances in

Nominal Dimensions mm a) within 5mm (length) & within 2mm (width) for free trim panel

Length and Width BS EN 324-1

b) +2 mm (width) and + 5mm (length) for nett size panel

Squareness Tolerances (Diagonal) BS EN 324-2 mm ≤ 5.0

Edge Straightness Tolerances BS EN 324-2 mm/m ≤1.5

Moisture Content BS EN 322 % 5-8

Density BS EN 323 kg/m3 650±20 640±20 630±20 630±20 620±20

Bending Strength BS EN 310 N/mm² Min Ave ≥ 20 ≥ 18 ≥ 18 ≥ 18 ≥ 16

Swelling in Thickness (24 hour) BS EN 317 % Max Ave ≤ 25 ≤ 20 ≤ 20 ≤ 18 ≤ 16

Internal Bond BS EN 319 N/mm² Min Ave ≥ 0.50 ≥ 0.45 ≥ 0.45 ≥ 0.45 ≥ 0.40

Internal Bond BS EN 319 N/mm² Min Specimen ≥ 0.45 ≥ 0.40 ≥ 0.40 ≥ 0.40 ≥ 0.35

Surface Absorption (Toluene) BS EN 382-1 in-house mm Min Premium ≥ 100 Premium ≥150

Formaldehyde Emission of Fibreboard MDF

MFB

Properties Test method Unit Classification Standard Latex Free Lamination Grade Moisture Resistance

E1 ≤9.0 E1 ≤8.0 √ √ √ √

Perforator Method BS EN 120 mg/100g E2 > 9.0 ≤30 E2 > 8.0 ≤30 √ √ √ √

E3 >30 E3 >30 √ √ √ √

F****(SE0) :Ave ≤ 0.3 Max ≤0.4 - - - - -

F***(E0) :Ave ≤ 0.5 Max ≤0.7 √ √ √ √ √

Desiccators Method JIS A 1460 mg/L

F**(E1): Ave ≤1.5. Max ≤2.1 √ √ √ √ √

F*(E2) < 5 √ √ √ √ √

CARB Phase 2 MDF Thin Board ≤ 8mm ≤ 0.13 √ √ √ √ √

ASTM D6007-14 ppm

(Small Chamber method) Phase 2 MDF Thick Board ≥ 8.1mm ≤ 0.11 √ √ √ √ √

Note: The perforator values in this table apply to panels with moisture contents of 6.5%

You might also like

- 2.5 - FAT - C1574 - FAT Procedure PDFDocument7 pages2.5 - FAT - C1574 - FAT Procedure PDFGeorge Jhonson100% (2)

- ZCS300 ManualDocument24 pagesZCS300 ManualFabricio BorgattaNo ratings yet

- Promiment Sobriquets (World) : S.No. Place SobriquetDocument6 pagesPromiment Sobriquets (World) : S.No. Place Sobriquetkausik nath100% (1)

- Standard Welded Wire Mesh For Concrete ReinforcementDocument3 pagesStandard Welded Wire Mesh For Concrete Reinforcementmarksantana100% (2)

- 07a. MR MDF TECHNICAL DATADocument2 pages07a. MR MDF TECHNICAL DATAsacdawoodNo ratings yet

- FT LG DecotileDocument1 pageFT LG DecotileELIBER DIONISIO RODR�GUEZ GONZALESNo ratings yet

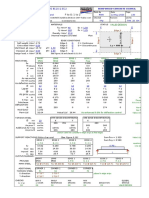

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.1.0 License # 1FQDT7JK6TR3GARDocument1 pageETABS 2016 Concrete Frame Design: ETABS 2016 16.1.0 License # 1FQDT7JK6TR3GARChandra SNo ratings yet

- KRONOSPANDocument1 pageKRONOSPANRely TokNo ratings yet

- Beam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Document4 pagesBeam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Dũng QuangNo ratings yet

- Ficha Tecnica ChicagoDocument1 pageFicha Tecnica ChicagomanuNo ratings yet

- Glass Filament Fabrics For Plastics Reinforcement: Product SpecificationDocument2 pagesGlass Filament Fabrics For Plastics Reinforcement: Product Specificationquyet ngoNo ratings yet

- TD EGGER Edging ABS enDocument3 pagesTD EGGER Edging ABS enArki ValaNo ratings yet

- BBS FormateDocument1 pageBBS FormateahamedthousifNo ratings yet

- ETABS Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS Concrete Frame Design: ACI 318-14 Beam Section Designdimas cahyoNo ratings yet

- SSAB Domex 420MC: General Product DescriptionDocument2 pagesSSAB Domex 420MC: General Product DescriptionpeterNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3No ratings yet

- Beam Design For FlexureDocument8 pagesBeam Design For FlexureKhajaNo ratings yet

- Stiffeners: (MM) (MM) (MM)Document4 pagesStiffeners: (MM) (MM) (MM)Md Ahsanul KabirNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BADocument2 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BAjuanda sinagaNo ratings yet

- Specification - GL Wires - MESPL May 2021Document2 pagesSpecification - GL Wires - MESPL May 2021M. I. BhadiNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.1.0 License # 1FQDT7JK6TR3GARDocument1 pageETABS 2016 Concrete Frame Design: ETABS 2016 16.1.0 License # 1FQDT7JK6TR3GARChandra SNo ratings yet

- Hasil Tulangan Diperoleh Dari Luas Tulangan Atas (As Top) Terbesar Dan Luas Tulangan Bawah (As Min) Terbesar Melalui Program ETABSDocument11 pagesHasil Tulangan Diperoleh Dari Luas Tulangan Atas (As Top) Terbesar Dan Luas Tulangan Bawah (As Min) Terbesar Melalui Program ETABSDendy NurrochimNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)christi SNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- MDF Data SheetDocument2 pagesMDF Data Sheetrmbardollo07No ratings yet

- ANCLAJEDocument7 pagesANCLAJEJesus Jaimes ManceraNo ratings yet

- Specification For Galvanized Steel: Raw Material SpecificationsDocument2 pagesSpecification For Galvanized Steel: Raw Material SpecificationsAnonymous aBZfewNo ratings yet

- DPIS Condura - Prime AMB-Si3N4Document4 pagesDPIS Condura - Prime AMB-Si3N4masonNo ratings yet

- ETABS Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS Concrete Frame Design: ACI 318-14 Beam Section Designdimas cahyoNo ratings yet

- Two-Way Slab DesignDocument4 pagesTwo-Way Slab DesignRaghNo ratings yet

- Gaskets - Graphite PDFDocument4 pagesGaskets - Graphite PDFSH1961No ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BADocument2 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BAjuanda sinagaNo ratings yet

- Beam To BeamDocument6 pagesBeam To BeamShaikh ImranNo ratings yet

- Fisa Tehnica Panouri Din Lemn Pentru Placari Exterioare-Parklex Facade FDocument1 pageFisa Tehnica Panouri Din Lemn Pentru Placari Exterioare-Parklex Facade FPopa MarianNo ratings yet

- ETABS Concrete Frame Design: ETABS 20.1.0 License # 1PWEY5GKVXGJ5BPDocument1 pageETABS Concrete Frame Design: ETABS 20.1.0 License # 1PWEY5GKVXGJ5BPTamilselvi MNo ratings yet

- TDS - ColorFabb StoneFillDocument2 pagesTDS - ColorFabb StoneFillPIETRO DAVID DE LUCANo ratings yet

- Seamless Cold Drawn Precision Tubes According To EN-10305-1 (DIN 2391) E235+C/+N (St. 35 BK/NBK) E355+C/+N (ST 52 BK / NBK)Document32 pagesSeamless Cold Drawn Precision Tubes According To EN-10305-1 (DIN 2391) E235+C/+N (St. 35 BK/NBK) E355+C/+N (ST 52 BK / NBK)jean bouNo ratings yet

- Calculation For Moment Connection - Type ADocument15 pagesCalculation For Moment Connection - Type ANitesh Singh100% (1)

- Spreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130Document1 pageSpreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130buddikalrNo ratings yet

- ETABS 19.1.0-Design Details3Document2 pagesETABS 19.1.0-Design Details3Alejandro Tovar MolinaNo ratings yet

- Trelleborg Dielectric MattingDocument2 pagesTrelleborg Dielectric MattingStephenNo ratings yet

- BS 970 070 M46Document2 pagesBS 970 070 M46Dinesh GaikwadNo ratings yet

- C1 CalcDocument1 pageC1 CalcJayar Valloyas MendietaNo ratings yet

- Moment Connection DesignDocument2 pagesMoment Connection DesignmaheshbandhamNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)adelalwailyNo ratings yet

- 1%ni For Improved Toughness: Data SheetDocument4 pages1%ni For Improved Toughness: Data Sheetmohamed AdelNo ratings yet

- App B RISA ReportDocument110 pagesApp B RISA ReportgertkroonNo ratings yet

- Opcija 2, 2x250, 2x150Document8 pagesOpcija 2, 2x250, 2x150stomakosNo ratings yet

- T Beam To BS 8110Document11 pagesT Beam To BS 8110Samitha SoysaNo ratings yet

- Technical Datasheet: Tests Standard Property or Attribute Measurement Unit ResultDocument1 pageTechnical Datasheet: Tests Standard Property or Attribute Measurement Unit ResultRaul AntonieNo ratings yet

- Materialdatasheet 75 FKM 595 2Document3 pagesMaterialdatasheet 75 FKM 595 2Pillar ManufacturingNo ratings yet

- CBH-22-172 Din 603 CB M8 X 60 WTZP 4.8Document1 pageCBH-22-172 Din 603 CB M8 X 60 WTZP 4.8qualityNo ratings yet

- La Copia Stampata Non E' Soggetta A Controllo: Electrostatic Painting With Epoxy-Polyester Powder PaintsDocument3 pagesLa Copia Stampata Non E' Soggetta A Controllo: Electrostatic Painting With Epoxy-Polyester Powder PaintsdmejiaNo ratings yet

- Specification - GI Wires - MESPL May 2021Document2 pagesSpecification - GI Wires - MESPL May 2021M. I. BhadiNo ratings yet

- Catalogo Perfil Estrutural Info Tecnicas InglesDocument7 pagesCatalogo Perfil Estrutural Info Tecnicas InglesWagner SilvaNo ratings yet

- Vdocuments - MX Moment Connection Beam Column Is Bs Section For Is800xlsDocument27 pagesVdocuments - MX Moment Connection Beam Column Is Bs Section For Is800xlsDhimant ParmarNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document7 pagesRCC92 Ribbed Slabs (Tables)Cioabla BogdanNo ratings yet

- Barra Sanmac 2205Document8 pagesBarra Sanmac 2205Lei WuNo ratings yet

- Design of Reinforcement For RC Capping Beam: ProjectDocument1 pageDesign of Reinforcement For RC Capping Beam: ProjectNikit MaskeNo ratings yet

- Product Specification BS-4449Document2 pagesProduct Specification BS-4449Cyprian Cypu100% (2)

- 75 FKM 585Document3 pages75 FKM 585Victor CadilloNo ratings yet

- Thunder Cake StoryDocument5 pagesThunder Cake Storyapi-21226401No ratings yet

- All About Steamers - The Boilers and EnginesDocument7 pagesAll About Steamers - The Boilers and EnginesClyde SteamersNo ratings yet

- Human Anatomy NotesDocument2 pagesHuman Anatomy NotesSamantha LiberatoNo ratings yet

- FB-1 - Beam Detector Specification PDFDocument1 pageFB-1 - Beam Detector Specification PDFRafiq MagdyNo ratings yet

- Marathi - Shri Siddhnath Shikhamani - Abhang GathaDocument88 pagesMarathi - Shri Siddhnath Shikhamani - Abhang GathaVeeresh BTNo ratings yet

- Legrand Compact RCBO 1P N 01Document2 pagesLegrand Compact RCBO 1P N 01Sonal RamjununNo ratings yet

- JB W9 DPP 22 24Document21 pagesJB W9 DPP 22 24Anonymous H8TylnrHNo ratings yet

- NVSM 116 PDFDocument7 pagesNVSM 116 PDF会沢 裕貴No ratings yet

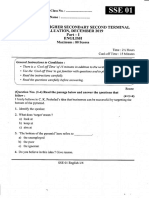

- Preparation of Salt (Worksheet)Document11 pagesPreparation of Salt (Worksheet)terencechen1225No ratings yet

- SSS 2 TD CAT 2nd TermDocument3 pagesSSS 2 TD CAT 2nd TermFagbohunka EricNo ratings yet

- Hsslive XII Term II Dec 2019 EnglishDocument4 pagesHsslive XII Term II Dec 2019 Englishvivek vNo ratings yet

- Gear Box Catalogue PDFDocument7 pagesGear Box Catalogue PDFPiyush Anand100% (2)

- 1986 GT CatalogDocument16 pages1986 GT CatalogtspinnerNo ratings yet

- Alcium LAT Late: 256-1800ah 0.613 - 5.248kWDocument4 pagesAlcium LAT Late: 256-1800ah 0.613 - 5.248kWJunior Ramirez ReyesNo ratings yet

- The Psychoanalyzer - FinalDocument25 pagesThe Psychoanalyzer - Finalalvinlarano11No ratings yet

- Asthma Action PlanDocument1 pageAsthma Action PlanAkosNo ratings yet

- Medibuddy-EnrolPolicyConditions 22Document23 pagesMedibuddy-EnrolPolicyConditions 22Vadivelan BaskarNo ratings yet

- MF-131 NANIWA Make Pump (Booklet Including Test Record)Document136 pagesMF-131 NANIWA Make Pump (Booklet Including Test Record)Thanh Nghị BùiNo ratings yet

- Lincoln, Bruce. How To Read A Religious Text - Reflections On Some Passages of The Chandogya UpanisadDocument14 pagesLincoln, Bruce. How To Read A Religious Text - Reflections On Some Passages of The Chandogya UpanisadvkasNo ratings yet

- MacNeal & Harder - Standard Problems FE AccuracyDocument18 pagesMacNeal & Harder - Standard Problems FE AccuracyRm1262No ratings yet

- 5 - Stability & Root LocusDocument10 pages5 - Stability & Root Locusahmed4665No ratings yet

- Daily ReportDocument3 pagesDaily ReportJoseph AbousafiNo ratings yet

- P1662/D8.0, March 2016 - IEEE Draft Recommended Practice For Design and Application of Power Electronics in Electrical Power SystemsDocument63 pagesP1662/D8.0, March 2016 - IEEE Draft Recommended Practice For Design and Application of Power Electronics in Electrical Power SystemsHgoglezNo ratings yet

- E Exe Ef Fluorescent: Standard S Specification FeaturesDocument4 pagesE Exe Ef Fluorescent: Standard S Specification FeaturesrelaxjackNo ratings yet

- Aqualisa Quartz Simply A Better ShowerDocument12 pagesAqualisa Quartz Simply A Better ShowerPranjal SinghNo ratings yet

- HCIDocument15 pagesHCIAbrivylle CeriseNo ratings yet