Professional Documents

Culture Documents

Units With Tandem Compressors SU Sheet

Units With Tandem Compressors SU Sheet

Uploaded by

Last Juan StandingOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Units With Tandem Compressors SU Sheet

Units With Tandem Compressors SU Sheet

Uploaded by

Last Juan StandingCopyright:

Available Formats

FIELD START-UP SHEET

230 W. BlueRidge Ave. Orange, CA 92865

Phone: (714) 921-6000 Fax: (714) 921-6010

www.dataaire.com

UNITS WITH TANDEM COMPRESSORS

gForce, Modular Data Temp and Data Aire Series Units

Instructions:

This test sheet must be completely filled out during start-up and returned to Data Aire, Inc. Failure to return the test

sheet may limit or cause delays in warranty coverage. Some of the terms listed require specific information to be

entered and others only need a check mark that verifies a test of inspection has been conducted. Items not

applicable should be marked “N/A”.

UNIT IDENTIFICATION Job Number:

Model Number: _____________________ Serial Number: __________________________

TEST VOLTAGE

Voltage: A-B ____________ A-C ____________ B-C ____________

TEST CONDITIONS

Supply Air Temperature: ___________°F Condenser/Ambient Air Temperature: ____________°F

Return Air Temperature: ___________°F Return Air Humidity: _______%

BLOWER/ FAN MOTOR NO. 1

Motor HP: ______ F.L.A.: ______ Voltage: ______ Operating Amps: L1____ L2_____ L3____

Motor, Drive and Pulleys Aligned: Yes or No Drive and Pulley Set Screws Tight: Yes or No

BLOWER/ FAN MOTOR NO. 2

Motor HP: ______ F.L.A.: ______ Voltage: ______ Operating Amps: L1____ L2_____ L3____

Motor, Drive and Pulleys Aligned: Yes or No Drive and Pulley Set Screws Tight: Yes or No

BLOWER/ FAN MOTOR NO. 3

Motor HP: ______ F.L.A.: ______ Voltage: ______ Operating Amps: L1____ L2_____ L3____

Motor, Drive and Pulleys Aligned: Yes or No Drive and Pulley Set Screws Tight: Yes or No

COMPRESSOR NO. 1 – Only Compressor No. 1 Running

Refrigerant Type __________ # of Pounds/Oz ____________

Operating Amps: L1 _____ L2 _____ L3 _____ Discharge Pressure: ______ PSIG

Liquid Line Temperature _________ Sub-cooling _________°F

Suction Pressure: _______ PSIG Suction Temperature: _____°F Superheat: _____°F

Liquid Line Temperature _______ Sub-cooling _________°F

Crankcase Temperature:_____°F Oil Level Sight Glass:_____% High Pressure Cutout:_____PSIG

Moisture Indicator: Green or Yellow Discharge Pressure Unloaded: __________PSIG

Suction Temperature Unloaded: ________°F AMPS Unloaded: L1______ L2______ L3______

Hot Gas Bypass: Yes or No Liquid Line Solenoid: Yes or No

07-05-1F-009 Rev. H 03/17/2016 1

COMPRESSOR NO. 3 – Only Compressor No. 3 Running

Refrigerant Type __________ # of Pounds/Oz ____________

Operating Amps: L1 _____ L2 _____ L3 _____ Discharge Pressure: ______ PSIG

Liquid Line Temperature _________ Sub-cooling _________°F

Suction Pressure: _______ PSIG Suction Temperature: _____°F Superheat: _____°F

Liquid Line Temperature _______ Sub-cooling _________°F

Crankcase Temperature:_____°F Oil Level Sight Glass:_____% High Pressure Cutout:_____PSIG

Moisture Indicator: Green or Yellow Discharge Pressure Unloaded: __________PSIG

Suction Temperature Unloaded: ________°F AMPS Unloaded: L1______ L2______ L3______

Hot Gas Bypass: Yes or No Liquid Line Solenoid: Yes or No

COMPRESSOR NO. 1 – Compressors No. 1 and 2 Running at the Same Time

Refrigerant Type __________ # of Pounds/Oz ____________

Operating Amps: L1 _____ L2 _____ L3 _____ Discharge Pressure: ______ PSIG

Liquid Line Temperature _________ Sub-cooling _________°F

Suction Pressure: _______ PSIG Suction Temperature: _____°F Superheat: _____°F

Crankcase Temperature:_____°F Oil Level Sight Glass:_____% High Pressure Cutout:_____PSIG

Moisture Indicator: Green or Yellow Discharge Pressure Unloaded: __________PSIG

Suction Temperature Unloaded: ________°F AMPS Unloaded: L1______ L2______ L3______

Hot Gas Bypass: Yes or No Liquid Line Solenoid: Yes or No

COMPRESSOR NO. 3 – Compressors No. 3 and 4 Running at the Same Time

Refrigerant Type __________ # of Pounds/Oz ____________

Operating Amps: L1 _____ L2 _____ L3 _____ Discharge Pressure: ______ PSIG

Liquid Line Temperature _________ Sub-cooling _________°F

Suction Pressure: _______ PSIG Suction Temperature: _____°F Superheat: _____°F

Crankcase Temperature:_____°F Oil Level Sight Glass:_____% High Pressure Cutout:_____PSIG

Moisture Indicator: Green or Yellow Discharge Pressure Unloaded: __________PSIG

Suction Temperature Unloaded: ________°F AMPS Unloaded: L1______ L2______ L3______

Hot Gas Bypass: Yes or No Liquid Line Solenoid: Yes or No

COMPRESSOR NO. 1 – All Compressors Running at the Same Time

Refrigerant Type __________ # of Pounds/Oz ____________

Operating Amps: L1 _____ L2 _____ L3 _____ Discharge Pressure: ______ PSIG

Liquid Line Temperature _________ Sub-cooling _________°F

Suction Pressure: _______ PSIG Suction Temperature: _____°F Superheat: _____°F

Crankcase Temperature:_____°F Oil Level Sight Glass:_____% High Pressure Cutout:_____PSIG

Moisture Indicator: Green or Yellow Discharge Pressure Unloaded: __________PSIG

Suction Temperature Unloaded: ________°F AMPS Unloaded: L1______ L2______ L3______

Hot Gas Bypass: Yes or No Liquid Line Solenoid: Yes or No

07-05-1F-009 Rev. H 03/17/2016 2

COMPRESSOR NO. 3 – All Compressors Running at the Same Time

Refrigerant Type __________ # of Pounds/Oz ____________

Operating Amps: L1 _____ L2 _____ L3 _____ Discharge Pressure: ______ PSIG

Liquid Line Temperature _________ Sub-cooling _________°F

Suction Pressure: _______ PSIG Suction Temperature: _____°F Superheat: _____°F

Crankcase Temperature:_____°F Oil Level Sight Glass:_____% High Pressure Cutout:_____PSIG

Moisture Indicator: Green or Yellow Discharge Pressure Unloaded: __________PSIG

Suction Temperature Unloaded: ________°F AMPS Unloaded: L1______ L2______ L3______

Hot Gas Bypass: Yes or No Liquid Line Solenoid: Yes or No

ENERGY SAVING COOLING LOGIC

DC Volts Setting: _____________

Valve Operation: Modulates open: Yes or No Modulates open: Yes or No

REHEAT

Type: Electric______ Hot Water______ Hot Gas______ Steam______

(For Electric Reheat) Operating Amps: L1______ L2______ L3______

High Temperature Safety Operation: Yes or No

(For Non-Electric Reheat) Valve Operating: Yes or No

HUMIDIFIER

Steam Generator: Yes or No Immersion________ Infrared________ Dry Steam________

Operating Amps: L1______ L2______ L3______

Water Level: __________% Capacity Setting: __________%

Water Pressure Switch: Yes or No Dry Steam Solenoid: Yes or No

WATER VALVE/ AUX CHILLED WATER VALVE

DC Volt Setting: _______ Modulate Open: ________ Modulate Close: ________

Modulating Valve Operation: ___________

Unit Clearance: Front _____” Back _____” Right Side _____” Left Side _____”

Field Piping Size: Discharge Line ________” O.D. Liquid Line: _________”O.D.

Suction Line: ________”O.D. (condensing units) Total Field Piping Length: ______ feet

Discharge Line Check Valve Installed: Yes or No

The following items must be checked and adjusted as required:

Electrical Connections: Yes or No Copper Conductors Used: Yes or No

Disconnect: Yes or No Remote Shutdown Jumper: Yes or No

Filters Clean: Yes or No System Leak Checked: Yes or No

System Evacuated: Yes or No Water Detection Probe Alarm: Yes or No

Smoke Detector Magnet Test: Yes or No

07-05-1F-009 Rev. H 03/17/2016 3

DATA ALARM PROCESSOR 4 – See Dap4 Checklist Attached

Comments: __________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

Company Name: _____________________________________ Telephone: (______)______________

Address: ___________________________________________________________________________

Start-Up Conducted by: _____________________________________ Date: ____________________

07-05-1F-009 Rev. H 03/17/2016 4

You might also like

- Códigos de Falha PSADocument94 pagesCódigos de Falha PSALeonardo Vieira100% (3)

- Pub A History of Everyday Life in Scotland 1800 1900Document345 pagesPub A History of Everyday Life in Scotland 1800 1900MioaraNo ratings yet

- Ariel Start-Up Check List (Er-10.4.0)Document6 pagesAriel Start-Up Check List (Er-10.4.0)Jose RattiaNo ratings yet

- JAPL-F-TE-003-Generator Daily Inspection ChecklistDocument1 pageJAPL-F-TE-003-Generator Daily Inspection ChecklistAli Hassan100% (1)

- Fire Pump System Test ReportDocument12 pagesFire Pump System Test Reportcoolsummer1112143100% (2)

- Trailer PMDocument2 pagesTrailer PMArnulfo LavaresNo ratings yet

- Stack Economizer CalculatorDocument4 pagesStack Economizer CalculatorAmit SarkarNo ratings yet

- BS 05883 1996 (En)Document10 pagesBS 05883 1996 (En)Emanuele Mastrangelo100% (1)

- Units With Compressors SU SheetDocument2 pagesUnits With Compressors SU SheetLast Juan StandingNo ratings yet

- Field Start-Up Test Sheet: Units With CompressorsDocument2 pagesField Start-Up Test Sheet: Units With Compressorsingeniero1968No ratings yet

- Xylem Flygt Products Start-Up Report:: N/A N/ADocument3 pagesXylem Flygt Products Start-Up Report:: N/A N/AErick Noel Manzanares HernandezNo ratings yet

- 03TA Service ManualDocument108 pages03TA Service ManualPTY Entertainment100% (1)

- Diesel Inspection Testing FormDocument6 pagesDiesel Inspection Testing Form5463RNo ratings yet

- 05TA Service ManualDocument111 pages05TA Service ManualPTY EntertainmentNo ratings yet

- Start-Up Sheet For CompressorsDocument1 pageStart-Up Sheet For CompressorsGreg LundyNo ratings yet

- 777 D Test ChartsDocument41 pages777 D Test ChartsAlejandro Alberto Robalino Mendez100% (1)

- Hyd Pressure Activity 2015Document2 pagesHyd Pressure Activity 2015jose muñozNo ratings yet

- Flow Application Information FormDocument2 pagesFlow Application Information FormRadhakrishnan PaulNo ratings yet

- Nfpa8 D PDFDocument2 pagesNfpa8 D PDFPOLPMENo ratings yet

- Fan Heater Inverter Laser Clean LC-52 EN GR INSTRUCTIONS MANUALDocument32 pagesFan Heater Inverter Laser Clean LC-52 EN GR INSTRUCTIONS MANUALmanosmatNo ratings yet

- Códigos de Fallas de Problemas Específicos de PEUGEOTDocument8 pagesCódigos de Fallas de Problemas Específicos de PEUGEOTJesus GarciaNo ratings yet

- Er-10 4 0Document6 pagesEr-10 4 0Dibyendu ChakrabortyNo ratings yet

- Diesel Generator Inspection ChecklistDocument1 pageDiesel Generator Inspection ChecklistPeter BoiyNo ratings yet

- F-030-Diesel Generator Inspection ChecklistDocument1 pageF-030-Diesel Generator Inspection ChecklistAbdus SamadNo ratings yet

- F-030-Diesel Generator Inspection ChecklistDocument1 pageF-030-Diesel Generator Inspection ChecklistAri PrastyantoNo ratings yet

- F-030-Diesel Generator Inspection ChecklistDocument1 pageF-030-Diesel Generator Inspection ChecklistDedy Rifky SetyawanNo ratings yet

- Ops Plan TempDocument21 pagesOps Plan TempTiago HenriquesNo ratings yet

- APE Power Unit Check ListDocument1 pageAPE Power Unit Check Listankesh_ghoghariNo ratings yet

- ProFloSe UF UseDocument2 pagesProFloSe UF UseintermountainwaterNo ratings yet

- Service ReportDocument1 pageService ReportMohammed R. Al Khaz'alyNo ratings yet

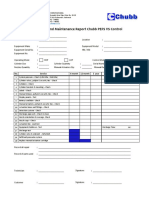

- Annual Sprinkler Inspection FormDocument4 pagesAnnual Sprinkler Inspection FormBryan NavarroNo ratings yet

- JOBO CPP-3 Manual GB V1.1 26.03.13Document11 pagesJOBO CPP-3 Manual GB V1.1 26.03.13Marian TudorNo ratings yet

- Compressor Start-Up and Warranty ValidationDocument3 pagesCompressor Start-Up and Warranty ValidationAhmed SofaNo ratings yet

- Usa Dishwasher Tech. TrainingDocument68 pagesUsa Dishwasher Tech. TrainingJostin Castillo Hurtado50% (2)

- CCU206GDocument3 pagesCCU206Gvitor marianoNo ratings yet

- Vog0038 PDFDocument99 pagesVog0038 PDFjorge castillo100% (1)

- LAWA Basic Commissioning Forms - CompleteDocument53 pagesLAWA Basic Commissioning Forms - Completemohammed_hatem0% (1)

- Start-Up Checklist Rev 6 061212Document1 pageStart-Up Checklist Rev 6 061212Sirdavis SilvaNo ratings yet

- Bombardier Dash 8 Q Normal ChecklistDocument2 pagesBombardier Dash 8 Q Normal ChecklistThe Dutch Flightsim PilotNo ratings yet

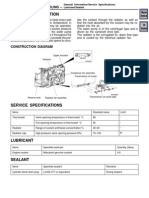

- General Information: Engine CoolingDocument13 pagesGeneral Information: Engine Coolinganonymous2abcNo ratings yet

- Carel EVD +030220205Document10 pagesCarel EVD +030220205elshan_asgarovNo ratings yet

- SymgenicsTQ Automation Gas Start Up - SI UnitsDocument28 pagesSymgenicsTQ Automation Gas Start Up - SI UnitscahyaNo ratings yet

- Fokker f28 Normal ChecklistDocument1 pageFokker f28 Normal ChecklistThe Dutch Flightsim PilotNo ratings yet

- NIBE SMO 10 Stary TypDocument68 pagesNIBE SMO 10 Stary TyppiotriewaNo ratings yet

- R134A Digital Manifold: Includes Automotive Refrigerant and Oil Capacity ReadingsDocument4 pagesR134A Digital Manifold: Includes Automotive Refrigerant and Oil Capacity ReadingsJoe NoboNo ratings yet

- Er 10 4 01Document8 pagesEr 10 4 01Mohammad Shafaet JamilNo ratings yet

- JOBO CPP-3 Manual GB V1.1 26.03.13 PDFDocument11 pagesJOBO CPP-3 Manual GB V1.1 26.03.13 PDFMarian TudorNo ratings yet

- Installation and Maintenance Manual-CTC V22 - V40-16210521Document60 pagesInstallation and Maintenance Manual-CTC V22 - V40-16210521Mihai OvidiuNo ratings yet

- 2015.06 Why You Cant Rely On Temperature MeasurementsDocument4 pages2015.06 Why You Cant Rely On Temperature MeasurementsLasse HansenNo ratings yet

- Job Sheet: Name: Date: Use of A VoltmeterDocument5 pagesJob Sheet: Name: Date: Use of A VoltmeterJonephine Gonzales PortonNo ratings yet

- 05.fuel SystemDocument634 pages05.fuel SystemTony D'AngeloNo ratings yet

- PMCL VS Control PDFDocument1 pagePMCL VS Control PDFHandrean Yudya PratamaNo ratings yet

- 4045 L16 Low Pressure Fuel System TestingDocument16 pages4045 L16 Low Pressure Fuel System TestingjonNo ratings yet

- Repair Guide: Vehicle Details Fault Summary / SignsDocument2 pagesRepair Guide: Vehicle Details Fault Summary / SignsFortune IsaacNo ratings yet

- Cla250 1Document2 pagesCla250 1Fortune IsaacNo ratings yet

- Reefer Unit Inspection Form ChecklistDocument1 pageReefer Unit Inspection Form ChecklistImtiaz Nazir-KhaleelNo ratings yet

- Compressor Start-Up Check ListDocument6 pagesCompressor Start-Up Check ListCokro YudhaNo ratings yet

- Flowmeter Preventive Maintenance FormDocument1 pageFlowmeter Preventive Maintenance FormWaseem TariqNo ratings yet

- Case 2Document6 pagesCase 2Nadiel Aceto 46No ratings yet

- Quotation Request Form For BALL VALVESDocument2 pagesQuotation Request Form For BALL VALVESSreekumar Nair100% (1)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Johnson 016Document2 pagesJohnson 016Last Juan StandingNo ratings yet

- Mini Data Alarm Processor IIDocument28 pagesMini Data Alarm Processor IILast Juan StandingNo ratings yet

- Gforce R410ADocument66 pagesGforce R410ALast Juan StandingNo ratings yet

- LT32599 02Document20 pagesLT32599 02Last Juan StandingNo ratings yet

- Cyberair 3pro cw2Document72 pagesCyberair 3pro cw2Last Juan StandingNo ratings yet

- LT32599 05Document128 pagesLT32599 05Last Juan StandingNo ratings yet

- Ritar 12260Document1 pageRitar 12260Last Juan StandingNo ratings yet

- Generac Home Generators Powerpact 7.5kw - Spec Sheet 2017Document5 pagesGenerac Home Generators Powerpact 7.5kw - Spec Sheet 2017Last Juan StandingNo ratings yet

- 02 IVD-R Deep-Dive Deck NewDocument215 pages02 IVD-R Deep-Dive Deck Newrajiveacharya100% (1)

- Psychological TheoriesDocument19 pagesPsychological TheoriesYapieeNo ratings yet

- Caso #3Document2 pagesCaso #3Viviana Liz AlverioNo ratings yet

- Journal of Adolescence: Nele Laporte, Bart Soenens, Katrijn Brenning, Maarten VansteenkisteDocument17 pagesJournal of Adolescence: Nele Laporte, Bart Soenens, Katrijn Brenning, Maarten Vansteenkisterisa agustinaNo ratings yet

- BoQ For HVAC Requirement For ZPPLDocument2 pagesBoQ For HVAC Requirement For ZPPLBehram CiodiaNo ratings yet

- Criminal Law 2008 Zone B PaperDocument5 pagesCriminal Law 2008 Zone B Paperశ్రీ లత Sri Lata100% (1)

- Basics of PLA - Bioplastics MAGAZINEDocument3 pagesBasics of PLA - Bioplastics MAGAZINEIsadora HenriquesNo ratings yet

- EverFlo Broch PDFDocument6 pagesEverFlo Broch PDFAdnan HuskicNo ratings yet

- Q.1 Write Short Answers of The Following Questions: Ghazali Guess Chemistry 1 10thDocument9 pagesQ.1 Write Short Answers of The Following Questions: Ghazali Guess Chemistry 1 10thAwais AliNo ratings yet

- ESET AntivirusDocument7 pagesESET Antivirusblackmamba etti jeanNo ratings yet

- KRAUSE 2016 Standard Catalog O1901-2000 20th Century 43rd Ed 381Document1 pageKRAUSE 2016 Standard Catalog O1901-2000 20th Century 43rd Ed 381Millona usdNo ratings yet

- GG Pricelist Baltics Oct 2016-1Document78 pagesGG Pricelist Baltics Oct 2016-1ivanlawms6745No ratings yet

- Air Pollution 4. Noise & Light PollutionDocument3 pagesAir Pollution 4. Noise & Light Pollutionclara olsenNo ratings yet

- Rele Ups CyberDocument4 pagesRele Ups CyberFrancisco Javier Duran MejiasNo ratings yet

- Titan Aviation 30000l Semi Trailer Refueller PDFDocument4 pagesTitan Aviation 30000l Semi Trailer Refueller PDFcloudysunNo ratings yet

- Jaggery Making: How To Make Jaggery?Document5 pagesJaggery Making: How To Make Jaggery?Subham BhattacharyaNo ratings yet

- 13.revised Rate ListDocument51 pages13.revised Rate ListAsif Icbal100% (1)

- BASKS2Document7 pagesBASKS2NGUYEN EthanNo ratings yet

- DCP082 Motorized Screw JackDocument3 pagesDCP082 Motorized Screw JackANAND KRISHNANNo ratings yet

- PARTY ROCKER ONE ManualDocument80 pagesPARTY ROCKER ONE ManualJustino BalancaNo ratings yet

- SaludDocument16 pagesSaluddianamera84No ratings yet

- National Drug Policy/Generics Law: Romeo R. Andaya, MD, MSCPD, PHD, Fpafp Chair, DPMCH Uph-DjgtmuDocument14 pagesNational Drug Policy/Generics Law: Romeo R. Andaya, MD, MSCPD, PHD, Fpafp Chair, DPMCH Uph-DjgtmuKatNo ratings yet

- Fruit Serving Calculation PureesDocument2 pagesFruit Serving Calculation PureesRuben ViegasNo ratings yet

- EnerMech TrainingDocument4 pagesEnerMech TrainingZulhilmi ZalizanNo ratings yet

- Latihan Autocad KIMI-A2 - PlanDocument1 pageLatihan Autocad KIMI-A2 - PlanMuhd HakimieNo ratings yet

- Ultra Tech CementDocument14 pagesUltra Tech CementRaunak Doshi71% (14)

- Adolescent Reproductive Health Albay S.Y. 2022-2023: Region V-Bicol Division: School: District: Period/Date: Grade LevelDocument1 pageAdolescent Reproductive Health Albay S.Y. 2022-2023: Region V-Bicol Division: School: District: Period/Date: Grade LevelPamela Rose Baraquiel-BelardoNo ratings yet

- ELSci Q2 Lesson 6 - Organ Systems of Representative AnimalsDocument51 pagesELSci Q2 Lesson 6 - Organ Systems of Representative AnimalsItsClarence100% (2)