Professional Documents

Culture Documents

11 1964 CH-Clutch

11 1964 CH-Clutch

Uploaded by

Jose LaproviteraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11 1964 CH-Clutch

11 1964 CH-Clutch

Uploaded by

Jose LaproviteraCopyright:

Available Formats

SECTION 11

CLUTCH

INDEX

Page

Page

Service Operations 11-2

General Description 11-1

11-2 Clutch and Brake Pedal 11-2

Maintenance and Adjustments 11-3

Clutch Linkage Adjustment 11-2 Clutch Assembly Replacement

Troubles-Remedies 11-4

GENERAL DESCRIPTION

Fig. 1 -Bent Finger Clutch Cross-Section

1. Flywheel 3. Pilot Bushing 5. Pressure Plate 7. Cover 9. Fork

2. Dowel-hole 4. Driven Disc 6. Diaphragm Spring 8. Throwout Bearing 10. Retracting Spring

The clutch linkage used in 1964 has no over-center

spring or clutch pedal sleeve assembly, and pedal

adjustment is made at the lower end of the pedal push

rod in the engine compartment. The clutch assembly is

enclosed in a 3600 bell housing which must be removed

to gain access to the clutch.

The 327 and 409 engines use a bent-finger diaphragm

type clutch assembly, fig. 1. All its integral release

fingers are bent to gain a centrifugal boost and insure

quick re-engagement at high engine speeds.

This type of clutch has the advantage of increasing

pressure plate load as the driven plate wears, and low

pedal efforts with high plate loads without requiring

over center booster springs on the clutch linkage. The

pressure plate is a high tensile strength iron designed

for maximum speed conditions.

Due to the clutch property of load increase with

wear, a new clutch should be properly worn or seated

in before being used for maximum performance. This

can be accomplished by making 20 to 50 normal starts

or by placing a .010" shim between the clutch cover

and the flywheel at each bolt location.

The clutch release bearing used with the bent finger

diaphragm clutch fig. 2 has an overall length of

approximately 11/4". A longer bearing will cause inabil

ity to obtain free pedal travel, especially as the clutch

wears, resulting in slippage and rapid wear. Fig. 2-Clutch Release Bearing Comparison

CHEVROLET SHOP MANUAL SUPPLEMENT

MAINTENANCE AND ADJUSTMENTS

CLUTCH LINKAGE ADJUSTMENT

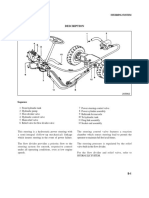

Refer to Figure 3

Clutch adjustment, for all normal wear, is made at

swivel on lower end of pedal push rod as follows:

1. Remove clutch pedal return spring.

2. Loosen nut "B" and back off from swivel approxi

mately ½ inch.

3. Hold clutch pedal push rod 1 so pedal is against

bumper stop and cross-shaft lever 2 in the

opposite direction so the throw-out bearing is

against clutch fingers. Adjust nut "B" to obtain

approximately 1/4" clearance between nut "B" and

upper edge of swivel.

4. Release push rod and cross-shaft lever and tighten

nut "A" to lock swivel against nut "B".

NOTE: Free pedal play should be ¼" to 1 ¼".

5. Install pedal return spring. Fig. 3-Clutch Linkage

SERVICE OPERATIONS

CLUTCH AND BRAKE PEDAL 3. Inspect nylon bushings for wear or damage. Re

Refer to Figure 4 place if necessary.

4. Inspect the mating surfaces of the bushings and

Removal replace necessary parts.

1. Remove retainers and disconnect push rods from

pedals. Installation

2. Remove clutch pivot shaft retainer from end of 1. Install one nylon bushing on clutch pedal pivot

shaft. shaft and one in right side of panel brace.

3. Remove clutch pedal by moving it out far enough 2. Position brake pedal, making sure two bushings

to clear bumper bracket, then rotate pedal upward are in brake pedal hub. Index the spring tip in

to clear push rod and remove pedal completely. notch of support brace and brake pedal push rod

in master cylinder.

NOTE: Brake pedal will also fall free and push

3. Reverse removal steps to complete installation.

rod will hang from boot on master cylinder.

4. Check clutch pedal free play and adjust if

Inspection necessary.

1. Clean all metal parts with a good solvent. 5. Check brake pedal adjustment and adjust push

2. Wipe nylon bushings clean with a clean cloth. rod if necessary.

NOTE: Check stop light switch adjustment for

CAUTION: Nylon bushings should not be treat

electrical contact when brake pedal is de

ed with cleansing agents of any kind.

pressed approximately %.

CHEVROLET SHOP MANUAL SUPPLEMENT

CLUTCH 11-3

6. Loosen the 6 clutch attaching bolts evenly, a little

CLUTCH ASSEMBLY at a time, until clutch diaphragm spring tension is

released; then remove bolts, clutch assembly and

The clutch assembly is enclosed in a 360° aluminum

pilot tool.

housing which must be removed to gain access to the

clutch assembly. 7. Slide clutch fork from ball stud and remove fork

1. Remove transmission as outlined in Transmission from dust boot.

Section 13.

NOTE: Ball stud is threaded into clutch housing

2. Disconnect clutch linkage spring from clutch fork and is easily replaced, if necessary.

and let push rod hang free of fork.

3. Remove throwout bearing from fork. 8. Inspect clutch fork for wear at ball socket and

4. Remove clutch housing cover plate screws and release bearing surfaces. Check ball spring tension.

clutch housing bolts, then remove housing on V-8 This spring may be bent toward fork if necessary

engines, the screw at oil filter may be removed last to tighten tension.

while supporting the housing during removal. 9. Clean the fork and lubricate ball socket and re

NOTE: The cover plate will now hang from lease bearing surfaces with graphite grease then

starter gear housing. reinstall in clutch housing.

5. Install Tool J-5824 to support the clutch assembly 10. Reverse removal procedure to install clutch then

during removal. adjust linkage.

BRAKE PEDAL CLUTCH PEDAL

LINKAGE LINKAGE

Fig. 4-Clutch and Brake Pedal

CHEVROLET SHOP MANUAL SUPPLEMENT

CLUTCH 11-4

TROUBLES AND REMEDIES

Symptoms and Probable Cause Probable Remedy

Fails to Release Pedal pressed to floor-shift lever does

not move freely in and out of reverse gear

a. Improper linkage adjustment excessive lash. a. Adjust linkage.

b. Improper pedal travel. b. Trim bumper stop and adjust linkage.

c. Loose or broken cross shaft lever. c. Tighten or replace ball studs or replace cross

shaft.

d. Worn bearing area on clutch gear retainer sleeve. d. Replace retainer.

e. Faulty driven disc. e. Replace disc.

f. Fork off ball stud. f. Install properly and lubricate fingers at throwout

bearing.

g. Clutch disc hub binding on clutch gear spline. g. Repair or replace clutch gear.

Slipping

a. Improper adjustment no lash. a. Adjust linkage.

b. Oil soaked driven disc. b. Install new disc and correct oil leak at its source.

c. Facing torn from disc or worn into rivets. c. Replace disc.

d. Warped pressure plate or- flywheel. d. Replace same.

e. Driven plate not seated in. e. Make 20-50 normal starts.

f. Driven plate overheated. f. Allow to cool-Check lash.

Grabbing

a. Oil on facing or burned or glazed facings. a. Install new disc.

b. Burned or smeared resin on flywheel or pressure b. Replace or repair as needed.

plate.

c. Linkage worn, broken or improperly installed. c. Tighten or replace mountings.

d. Loose engine mountings. d. Replace pressure plate or flywheel.

e. Warped pressure plate or flywheel. e. Sand off if superficial, replace burned or heat

checked parts.

Rattling-Transmission Click

a. Oil in driven plate damper. a. Replace driven disc.

b. Throwout fork loose on ball stud or in bearing b. Check ball stud and retaining spring and replace

groove. if necessary.

c. Driven plate damper spring failure. c. Replace driven disc.

Throwout Bearing Noise with Clutch Fully Engaged

a. Improper adjustment. a. Adjust linkage.

b. Throwout bearing binding on transmission. b. Clean, relubricate, check for burrs, nicks, etc.

c. Insufficient tension between clutch fork spring c. Replace fork.

and ball stud.

d. Fork improperly installed. d. Install properly.

e. Weak linkage return spring. e. Replace spring.

Noisy

a. Worn throwout bearing. a. Replace bearing.

b. Fork off ball stud Heavy clicking b. Install properly and lubricate fork fingers at

bearing.

High Pedal Effort

a. Bind in linkage a. Lubricate and free up linkage.

b. Linkage out of adjustment. b. Adjust.

c. Clutch gear bearing retainer gauled. c. Replace use cast iron retainer.

CHEVROLET SHOP MANUAL SUPPLEMENT

You might also like

- Service Manual For Ford Tractor Series 2000, 3000, 4000, 5000, 7000, 3400, 3500, 3550, 4400, 4500, 5500, 5550 Vol. 2Document352 pagesService Manual For Ford Tractor Series 2000, 3000, 4000, 5000, 7000, 3400, 3500, 3550, 4400, 4500, 5500, 5550 Vol. 2Taj Deluria100% (4)

- Sincronizacion de Motores Ssangyong d20dt d27dtDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dtMynor Witt100% (5)

- WiringDocument327 pagesWiringPIKO MOB50% (2)

- Bobcat S160 Parts ManualDocument653 pagesBobcat S160 Parts ManualTroy Morgan60% (5)

- Technical Bulletin 3Document17 pagesTechnical Bulletin 3RANAIVOARIMANANA100% (1)

- Catalogo de Parte COP 2550 UX +Document112 pagesCatalogo de Parte COP 2550 UX +Alvaro Varas100% (2)

- Rx8 SteeringDocument56 pagesRx8 SteeringwillyhuaNo ratings yet

- Lipe Clutch Installation Service ManualDocument35 pagesLipe Clutch Installation Service ManualCostel Antonie100% (3)

- Sturmey Archer Hub TechnicalDocument8 pagesSturmey Archer Hub TechnicalbobnunleyNo ratings yet

- 205 Rotary RigDocument4 pages205 Rotary RigBungleBugarlisNo ratings yet

- 2017 Skidoo G4 PDFDocument523 pages2017 Skidoo G4 PDFLasse BackNo ratings yet

- 11 1963 CH-ClutchDocument3 pages11 1963 CH-ClutchJose LaproviteraNo ratings yet

- 93FWD 6Document10 pages93FWD 6Luis Oswaldo Roa PerezNo ratings yet

- Tranmission - Clutch - 6090 PRODocument19 pagesTranmission - Clutch - 6090 PROGerman100% (1)

- 15 1977 11-SteeringDocument66 pages15 1977 11-SteeringDaniel DeBelloNo ratings yet

- Kalmar DRF 450 BrakeDocument42 pagesKalmar DRF 450 Braketuấn anh nguyễnNo ratings yet

- Reverse Modulated Wet Disc Brake System: SectionDocument7 pagesReverse Modulated Wet Disc Brake System: SectionAlexander MugabeNo ratings yet

- Brake SystemDocument12 pagesBrake Systemluis tocoraNo ratings yet

- Haima S5 1.5T Service Manual-2Document120 pagesHaima S5 1.5T Service Manual-2roydezNo ratings yet

- 1986-1988 SuzukiSamurai Clutch ManualDocument10 pages1986-1988 SuzukiSamurai Clutch ManualHatnean CristianNo ratings yet

- Brake System - GDP25MXDocument25 pagesBrake System - GDP25MXvicmart3030No ratings yet

- Harley-Davidson Custom Hand Lever KitDocument3 pagesHarley-Davidson Custom Hand Lever KitelvisandmickNo ratings yet

- PL Clutch 6 - 1Document12 pagesPL Clutch 6 - 1Pelis CloneNo ratings yet

- Models FA and FB Transmission Control 8-1Document12 pagesModels FA and FB Transmission Control 8-1Komatsu Perkins HitachiNo ratings yet

- 1600258-Steering AxleDocument7 pages1600258-Steering AxleFrancisco DiazNo ratings yet

- (MG) Manual de Taller MG TF 2011 (392-497)Document106 pages(MG) Manual de Taller MG TF 2011 (392-497)Santa Rosa HuarocondoNo ratings yet

- 05 1964 CH-Rear AxleDocument3 pages05 1964 CH-Rear AxleJose LaproviteraNo ratings yet

- Ma 2604000 WMDocument55 pagesMa 2604000 WMCarlos ReyesNo ratings yet

- Service BulletinDocument12 pagesService BulletinEdward Adrian Moreno FernandezNo ratings yet

- 13 - Adjustment and OperationDocument12 pages13 - Adjustment and Operationlawternay stevaneli de britoNo ratings yet

- Dokumen - Tips - Engine Mechanical DaihatsuDocument33 pagesDokumen - Tips - Engine Mechanical DaihatsuJovie GrohlNo ratings yet

- RTS TG M78Document9 pagesRTS TG M78woosah1234No ratings yet

- Brake SystemDocument24 pagesBrake Systemamin nullahNo ratings yet

- Yale 15 - 20 Ak - Reparos Na TransmissaoDocument30 pagesYale 15 - 20 Ak - Reparos Na TransmissaoMarcelo RossiNo ratings yet

- Manual Terex # 55 (Iguana) - 2Document26 pagesManual Terex # 55 (Iguana) - 2Victor Manuel riveraNo ratings yet

- Land Rover V8: and ToolDocument56 pagesLand Rover V8: and ToolAntonio OliveiraNo ratings yet

- Manual Transmission/Transaxle - Transmission: RemovalDocument30 pagesManual Transmission/Transaxle - Transmission: RemovalJim LiebNo ratings yet

- Somas A23 DADocument12 pagesSomas A23 DAfarm numNo ratings yet

- Service BrakesDocument5 pagesService BrakesamineNo ratings yet

- Enfield Bullet Workshop Manual 2000 2 PDFDocument53 pagesEnfield Bullet Workshop Manual 2000 2 PDFsivakumar natarajanNo ratings yet

- Brake JMC CamionetaDocument63 pagesBrake JMC CamionetaRusonegroNo ratings yet

- Interbrake AEBDocument6 pagesInterbrake AEBKarim BaddagNo ratings yet

- Section05 DrawworksDocument10 pagesSection05 Drawworkssertecs polNo ratings yet

- HAIMA 7 Service Manual (MT) - H Clutch PDFDocument7 pagesHAIMA 7 Service Manual (MT) - H Clutch PDFjhon greigNo ratings yet

- Mazda Fe y f2Document27 pagesMazda Fe y f2Nicolás CastroNo ratings yet

- Atkinson Tractor Service Shop Manual Unit 2 - TransmissionDocument18 pagesAtkinson Tractor Service Shop Manual Unit 2 - TransmissionDavid Kelly100% (1)

- 700R4 Manual Reverse Valve Body: Installation InstructionsDocument4 pages700R4 Manual Reverse Valve Body: Installation InstructionsAbbode HoraniNo ratings yet

- Fujitec BrakesDocument10 pagesFujitec Brakesjeferson_camiloNo ratings yet

- Brake System LG953Document25 pagesBrake System LG953Imam MuhhudaNo ratings yet

- Sincronizacion de Motores Ssangyong d20dt d27dt PDFDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dt PDFMynor WittNo ratings yet

- Ati Manual Reverse Valve BodyDocument4 pagesAti Manual Reverse Valve BodyPaul OfsthunNo ratings yet

- 07 1955 CAD-SteeringDocument9 pages07 1955 CAD-SteeringLuis Fernando ZampieriNo ratings yet

- Track Chain Removal and AssemblyDocument12 pagesTrack Chain Removal and AssemblyAaron MulengaNo ratings yet

- 12 Series-32Document1 page12 Series-32RE musicNo ratings yet

- EI-4195 SERIES: Instruction ManualDocument16 pagesEI-4195 SERIES: Instruction ManualKhalid AbdelRahimNo ratings yet

- Steering System: DescriptionDocument18 pagesSteering System: DescriptionNoe CuandonNo ratings yet

- Z8 (CF800) Service Manual 2013 (057-211) (151-155)Document5 pagesZ8 (CF800) Service Manual 2013 (057-211) (151-155)francisco jose ramirez perezNo ratings yet

- SB1208 - ZF As Tronic - Clutch Component LubricationDocument12 pagesSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNo ratings yet

- Clutch ManualDocument16 pagesClutch ManualCO BDNo ratings yet

- Acs Lab ManualDocument59 pagesAcs Lab ManualAanshu SinghNo ratings yet

- ClutchDocument37 pagesClutchMohan PreethNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- A1700 Torques y OtrosDocument6 pagesA1700 Torques y OtrosJose LaproviteraNo ratings yet

- 14 1963 CH-BodyDocument97 pages14 1963 CH-BodyJose LaproviteraNo ratings yet

- 02 1964 CH-LubricationDocument2 pages02 1964 CH-LubricationJose LaproviteraNo ratings yet

- Mosa Welder 2 Stroke Gas ManualDocument54 pagesMosa Welder 2 Stroke Gas ManualJose LaproviteraNo ratings yet

- 16 1963 CH-SpecificationsDocument8 pages16 1963 CH-SpecificationsJose LaproviteraNo ratings yet

- 10 1963 CH-Fuel & ExhaustDocument28 pages10 1963 CH-Fuel & ExhaustJose LaproviteraNo ratings yet

- 02 1963 CH-LubricationDocument2 pages02 1963 CH-LubricationJose LaproviteraNo ratings yet

- 12 1964 CH-Man TransDocument18 pages12 1964 CH-Man TransJose LaproviteraNo ratings yet

- 13 1964 CH-Auto TransDocument32 pages13 1964 CH-Auto TransJose LaproviteraNo ratings yet

- 10 1964 CH-Fuel & ExhaustDocument51 pages10 1964 CH-Fuel & ExhaustJose LaproviteraNo ratings yet

- 15 1964 CH-Heater & AccDocument59 pages15 1964 CH-Heater & AccJose LaproviteraNo ratings yet

- 04 1964 CH-SteeringDocument24 pages04 1964 CH-SteeringJose LaproviteraNo ratings yet

- 09 1964 CH-Electrical SystemsDocument52 pages09 1964 CH-Electrical SystemsJose LaproviteraNo ratings yet

- 07 1964 CH-Engine Tune-UpDocument3 pages07 1964 CH-Engine Tune-UpJose LaproviteraNo ratings yet

- 03 1964 CH-Frame & SuspDocument4 pages03 1964 CH-Frame & SuspJose LaproviteraNo ratings yet

- Kubota D1105 V1505 Operators ManualDocument108 pagesKubota D1105 V1505 Operators ManualJose LaproviteraNo ratings yet

- Deutz Parts Catalogue - BAM Parts TurkeyDocument140 pagesDeutz Parts Catalogue - BAM Parts TurkeyJose LaproviteraNo ratings yet

- Ada Motor MWM ArosDocument1 pageAda Motor MWM ArosJose LaproviteraNo ratings yet

- Cummins C Series: Clevite Heavy Duty Engine Parts Offering ForDocument4 pagesCummins C Series: Clevite Heavy Duty Engine Parts Offering ForAlex BonillaNo ratings yet

- Manual de Partes Alimentador de Originales DF2000 (B813)Document23 pagesManual de Partes Alimentador de Originales DF2000 (B813)Juan Carlos Pino CamposNo ratings yet

- Duty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerDocument3 pagesDuty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerHawaz BeyeneNo ratings yet

- Brochure Mixer DBX 50Document2 pagesBrochure Mixer DBX 50Khoa NguyenNo ratings yet

- LRP-2102.03 2022MY Land Rover Defender - Product SummaryDocument25 pagesLRP-2102.03 2022MY Land Rover Defender - Product SummaryBi GouaNo ratings yet

- Manual Chipeadora 18XP (120-185)Document66 pagesManual Chipeadora 18XP (120-185)Mantenimiento BiocicloNo ratings yet

- High OutputDocument36 pagesHigh Outputxmen norNo ratings yet

- Balmerol MP Grease No.3 BLGXDocument2 pagesBalmerol MP Grease No.3 BLGXamit1003_kumarNo ratings yet

- Internal Reference Name CategoryDocument247 pagesInternal Reference Name CategoryM Ramiaji AnggoroNo ratings yet

- Electrical Power Management (EPM) OverviewDocument4 pagesElectrical Power Management (EPM) OverviewMemo VelascoNo ratings yet

- IBERNADocument17 pagesIBERNAKiritza CarageaNo ratings yet

- SHOW DIRECTORY BM 2024 - CompressedDocument4 pagesSHOW DIRECTORY BM 2024 - Compressedsales6No ratings yet

- Fuse Box Location E39Document2 pagesFuse Box Location E39T. HankitiwatNo ratings yet

- Bentley BrochureDocument8 pagesBentley BrochurealdoNo ratings yet

- 9852 2219 01 Driving B104 Simba157Document2 pages9852 2219 01 Driving B104 Simba157Евгений БармаNo ratings yet

- Cablemaster CM-7 - Gear Replacement GuideDocument1 pageCablemaster CM-7 - Gear Replacement GuideGlendinning Products, LLC.No ratings yet

- WerkplaatshandboekDocument379 pagesWerkplaatshandboekKevin KarnataNo ratings yet

- G2-5 - AslDocument46 pagesG2-5 - AslHitesh sharmaNo ratings yet

- HM06643 02 UG20K Grader Web ReadyDocument20 pagesHM06643 02 UG20K Grader Web ReadyCarlos Indigoyen LimaymantaNo ratings yet

- Technical Catalogue: Chiller and Heat Pumps Air/WaterDocument64 pagesTechnical Catalogue: Chiller and Heat Pumps Air/WaterArif HusainNo ratings yet

- Air Brake Connections Ltd. - Full-CatalogueDocument149 pagesAir Brake Connections Ltd. - Full-CataloguejcNo ratings yet

- CVVT Oil Control Valve (Ocv) : DescriptionDocument6 pagesCVVT Oil Control Valve (Ocv) : DescriptionERICK CHRISTOPHER ZURITA VINUEZANo ratings yet

- MAINTENANCE MANUAL LWS500A3-phaseDocument22 pagesMAINTENANCE MANUAL LWS500A3-phaseMonthep RodthaiNo ratings yet

- Ring and Pinion Contact PatternsDocument2 pagesRing and Pinion Contact Patterns92vmax4No ratings yet