Professional Documents

Culture Documents

Uop952 97

Uop952 97

Uploaded by

AverusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uop952 97

Uop952 97

Uploaded by

AverusCopyright:

Available Formats

TRACE LEAD IN GASOLINES AND

NAPHTHAS BY GF-AAS

UOP 952-97

SCOPE

This method is for determining trace concentrations (10 to 400 mass/vol-ppb) of lead in gasolines and

petroleum naphthas. The method has not been validated on higher boiling range materials. The method is

specifically applicable to alkyl lead compounds such as tetraethyllead (TEL) and tetramethyllead (TML),

other lead compounds have not been investigated.

OUTLINE OF METHOD

Tetraalkyllead compounds in gasoline and naphthas are converted into water-soluble lead species that are

subsequently extracted into dilute nitric acid. Lead concentrations in the nitric acid extracts are determined

using Graphite Furnace-Atomic Absorption Spectrometry (GF-AAS).

APPARATUS

References to catalog numbers and suppliers are included as a convenience to the method user. Other

suppliers may be used.

Atomic absorption spectrometer, with autosampler and graphite furnace capabilities, Perkin-Elmer,

Model 4100ZL

Balance, top loading, readability 0.01-g

Cylinders, graduated, 25- and 100-mL, Fisher Scientific, Cat. Nos. 08-552C and -552E, respectively

Flasks, volumetric, Class A, borosilicate glass, 50-, 100-, 200- and 1000-mL, Fisher Scientific, Cat. Nos.

10-210-5B, -5C, -5D and -5G, respectively

Lamp, lead, EDL, Perkin-Elmer, Cat. No. N305-0657

Pipets, volumetric transfer, Class A, 1-, 3-, 5-, 10- and 50-mL, Fisher Scientific, Cat. Nos. 13-651-1A, -

1C, -1E, -1K and P, respectively

IT IS THE USER'S RESPONSIBILITY TO ESTABLISH APPROPRIATE PRECAUTIONARY PRACTICES AND TO

DETERMINE THE APPLICABILITY OF REGULATORY LIMITATIONS PRIOR TO USE. EFFECTIVE HEALTH AND

SAFETY PRACTICES ARE TO BE FOLLOWED WHEN UTILIZING THIS PROCEDURE. FAILURE TO UTILIZE THIS

PROCEDURE IN THE MANNER PRESCRIBED HEREIN CAN BE HAZARDOUS. MATERIAL SAFETY DATA SHEETS

(MSDS) OR EXPERIMENTAL MATERIAL SAFETY DATA SHEETS (EMSDS) FOR ALL OF THE MATERIALS USED IN

THIS PROCEDURE SHOULD BE REVIEWED FOR SELECTION OF THE APPROPRIATE PERSONAL PROTECTION

EQUIPMENT (PPE).

© COPYRIGHT 1997 UOP LLC

ALL RIGHTS RESERVED

UOP Methods are available through ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken PA 19428-2959,

United States. The Methods may be obtained through the ASTM website, www.astm.org, or by contacting Customer Service at

service@astm.org, 610.832.9555 FAX, or 610.832.9585 PHONE.

Copyright by ASTM Int'l (all rights reserved);

Reproduction authorized per License Agreement with UOP; Thu Apr 29 07:23:50 EDT 2004

2 of 5

REAGENTS AND MATERIALS

All reagents shall conform to the specifications established by the Committee on Analytical Reagents of

the American Chemical Society, when such specifications exist, unless otherwise specified. References to

water mean distilled or deionized water.

References to catalog numbers and suppliers are included as a convenience to the method user. Other

suppliers may be used.

Ammonium dihydrogen phosphate, Puratronic, 99.998%, Alfa, Cat. No. 10633

Ammonium dihydrogen phosphate, 10% solution. Weigh 10.0 ± 0.01 g of ammonium dihydrogen

phosphate into a 100-mL volumetric flask, add 1 mL of concentrated nitric acid and dilute to volume

with water. Cap and shake well until dissolution is complete.

Bottle, Nalgene, 125-mL, Fisher Scientific, Cat. No. 03-313-2C

Cups, autosampler, polystyrene, Perkin-Elmer, Cat. No. B011-9079

Eye dropper, Nalgene, Fisher Scientific, Cat. No. 13-711-10

Iodine, Puratronic, 99.999%, Alfa, Cat. No. 10619

Iodine solution, 3%. Add 3.0 ± 0.01 g of iodine to a 100-mL volumetric flask and dilute with toluene to

the mark. Cap and shake until dissolved.

Lead standard solution, 1,000-µg/mL, SPEX CertiPrep, Cat. No. PLPB2-2Y

Lead standard solution, 10-µg/mL. Pipet 10 mL of the 1,000-µg/mL lead standard into a 1000-mL

volumetric flask, dilute to the mark with 10% nitric acid, cap and shake well. Lifetime of this standard

is one month.

Lead standard solution, 1-µg/mL. Pipet 10 mL of the 10-µg/mL lead standard into a 100-mL volumetric

flask, dilute to the mark with 10% nitric acid, cap and shake well. Lifetime of this standard is one

week.

Magnesium standard solution, 10,000-mg/L (1% Mg in 2% HNO3), SPEX Certiprep, Cat. No. PLMG2-

3Y

Nitric acid, concentrated, Ultrex II ultrapure reagent, J.T. Baker, Cat. No. 6901-05

Nitric acid, 10%. Mix one part concentrated nitric acid with nine parts water.

Toluene, Optima grade, Fisher Scientific, Cat. No. T291-4

PROCEDURE

The GF-AAS instrument is calibrated using an acid blank, and 15- and 30-µg/L lead standards. Samples

are then analyzed and the 30-µg/L standard is reanalyzed as a sample at the end of the run. A matrix

modifier composed of ammonium dihydrogen phosphate and magnesium nitrate is used to increase the

vaporization temperature of the lead.

952-97

Copyright by ASTM Int'l (all rights reserved);

Reproduction authorized per License Agreement with UOP; Thu Apr 29 07:23:50 EDT 2004

3 of 5

The method as written yields a close approximation of the lead concentration in the sample, and is

considered adequate for its intended use. In the procedure below, some accuracy has been compromised for

speed. To generate data on a more accurate mass/mass basis, the standards would need to be prepared on a

mass/mass basis and the sample and nitric acid extract aliquots would also need to be weighed.

1. Pipet 10 mL of sample into a 120-mL Nalgene bottle, add 1 mL of 3% iodine solution and cap. Mix

the contents by shaking for 30 seconds. Set aside and allow the reaction to proceed for 10 minutes.

• If the sample is known to contain more than 150 mass/vol-ppb of lead, use a smaller sample size, or dilute

the resulting nitric acid extract. Although excess iodine is added to ensure complete reaction, this method

is not recommended for lead levels above 400 mass/vol-ppb. Use 1 mL of iodine solution regardless of the

sample size used.

2. Pipet 50 mL of 10% nitric acid solution into the bottle, cap and shake continuously for another 10

minutes. Allow a few minutes for the two layers to separate.

3. Take an aliquot of the lower aqueous layer using a Nalgene eye dropper and transfer to an

autosampler cup on the GF-AAS instrument.

4. Prepare fresh 15- and 30-µg/L calibration standards daily by pipeting separate 3 mL aliquots of the 1-

µg/mL lead standard solution into 200- and 100-mL volumetric flasks. Dilute to the mark with 10%

nitric acid, cap and shake well.

5. Prepare the matrix modifier solution by pipeting 10 mL of 10% ammonium dihydrogen phosphate

solution and 1 mL of 10,000-mg/L Mg standard solution into a 100-mL volumetric flask. Add 1 mL

of concentrated nitric acid, bring to the mark with water, cap and shake well.

6. Transfer aliquots of the matrix modifier, two calibration standards and an acid blank (10% nitric acid)

to separate autosampler cups on the GF-AAS instrument.

7. Set up the GF-AAS instrument according to the manufacturer’s instructions, using the conditions in

the Table.

• If an instrument other than the Perkin-Elmer Model 4100ZL is used, contact the instrument manufacturer

for help in determining appropriate settings for the instrument and furnace.

8. Enter the locations of the matrix modifier, acid blank, standards and sample(s) into the instrument

computer. Program the autosampler to take 5 µL of the matrix modifier and 20 µL of either the acid

blank, calibration standards or sample(s) with each injection.

9. Run the calibration (acid blank and two calibration standards), followed by the samples; and then run

the 30-µg/L standard as a sample to verify the calibration.

• The instrument autosampler will pick up 5 µL of the matrix modifier and 20 µL of acid blank, calibration

standard or sample, and inject both solutions together into the furnace. This provides 5 µg of phosphate

and 3 µg of magnesium nitrate to increase the vaporization temperature of the lead species.

• If the 30-µg/L calibration standard, when run as a sample, returns less than 28 µg/L lead or more than 32

µg/L lead, rerun the calibration and samples until a value between 28 and 32 µg/L lead is obtained.

• If the sample reading exceeds the calibration range of the standards, the acid extract may be diluted once

with 10% nitric acid.

952-97

Copyright by ASTM Int'l (all rights reserved);

Reproduction authorized per License Agreement with UOP; Thu Apr 29 07:23:50 EDT 2004

4 of 5

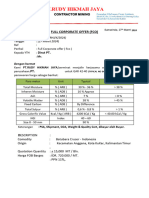

Table

Instrument Parameters for the

Perkin-Elmer Model 4100 ZL

Wavelength 283.3 nm

Slit 0.7 nm

Background correction on

Sample size 20 µL

Dry temperature Step 1 140ºC 30 sec gas flow 250 mL/min

2 150ºC 20 sec “

3 200ºC 10 sec “

Ash temperature 4 850ºC 20 sec “

Atomize and read 5 1500ºC 5 sec “

Clean-out 6 2400ºC 2 sec “

Matrix modifier 5 µL of 10% NH4H2PO4 and 0.06% Mg(NO3)2

CALCULATIONS

Calculate the lead concentration using the equation and report results to two significant figures.

Lead, mass/vol-ppb = 5C

where:

C = concentration of lead in the solution read by GF-AAS, µg/L

5 = 50/10

where:

10 = volume of sample taken, mL

50 = volume of 10% HNO3 extract, mL

If a dilution of the extract was required to bring the sample reading within range of the standards,

multiply the dilution factor times the result from the equation to obtain the final result. If less than 10 mL of

sample was used (or available), substitute the actual volume used in place of 10 in the equation.

PRECISION

Repeatability

Based on eight tests performed by one analyst on one day in one laboratory, the within-laboratory

estimated standard deviations (esd) were calculated for lead in gasoline at the 133 and 28 µg/L levels. The

estimated standard deviations were 3.3 and 2.2 µg/L, respectively. Two tests performed in one laboratory by

the same analyst on different days should not differ by more than 11 or 7 µg/L, at the 133 and 28 µg/L

levels, respectively (the allowable differences at the 95% probability level).

952-97

Copyright by ASTM Int'l (all rights reserved);

Reproduction authorized per License Agreement with UOP; Thu Apr 29 07:23:50 EDT 2004

5 of 5

The data quoted above is a “best case” estimate of the repeatability, and is equivalent to ASTM

repeatability statements. When the test is run routinely in the field, a control standard and chart should be

used to develop a better estimate of the long term repeatability.

Reproducibility

There is insufficient data to calculate the reproducibility of the test at this time.

TIME FOR ANALYSIS

The setup time may vary but once prepared a single sample can be run in 1.5 hours (elapsed time). The

labor requirement is 1.2 hours. Multiple samples run together will decrease the average elapsed time and

labor time requirements on a per sample basis.

REFERENCE

“Determination of Lead and Lead Isotope Ratios in Gasoline by Inductively Coupled Plasma-Mass Spec-

trometry”, Phillips Petroleum Company, Journal of Analytical Atomic Spectroscopy, May 1994, Vol. 9

SUGGESTED SUPPLIERS

Alfa, Johnson Matthey, P.O. Box 8247, Ward Hill, MA 01835-0747 (508-521-6300)

J.T. Baker Inc., 222 Red School Lane, Phillipsburg, NJ 08865 (908-859-2151)

Fisher Scientific, 711 Forbes Ave., Pittsburgh, PA 15219-4785 (412-562-8300)

Perkin-Elmer Corp., 761 Main Ave., Norwalk, CT 06859-0012 (203-762-1000)

SPEX CertiPrep, Inc., 203 Norcross Ave., Metuchen, NJ 08840-1253 (908-549-7144)

952-97

Copyright by ASTM Int'l (all rights reserved);

Reproduction authorized per License Agreement with UOP; Thu Apr 29 07:23:50 EDT 2004

You might also like

- UOP 163-10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitratDocument7 pagesUOP 163-10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitratBalas43100% (2)

- Titrimetric Determination of CO2 in EthanolaminesDocument3 pagesTitrimetric Determination of CO2 in EthanolaminesDavinNo ratings yet

- UOP 981-14 Trace Nitrogen in Liquid Hydrocarbons by Oxidative Combustion With ChemiluminescenceDocument9 pagesUOP 981-14 Trace Nitrogen in Liquid Hydrocarbons by Oxidative Combustion With ChemiluminescenceRamakrishnan HariNo ratings yet

- Making Candles at Home PDFDocument17 pagesMaking Candles at Home PDFHam FG67% (3)

- D5153 PDFDocument3 pagesD5153 PDFJGD123No ratings yet

- UOP 304-08 Bromine Number and Bromine Index of Hydrocarbons by Potentiometric TitrationDocument13 pagesUOP 304-08 Bromine Number and Bromine Index of Hydrocarbons by Potentiometric TitrationMorteza SepehranNo ratings yet

- D1696Document4 pagesD1696Ненад КнежевићNo ratings yet

- BSW Laboratory and Field TestDocument4 pagesBSW Laboratory and Field TestRonald Figo Torres Eche100% (1)

- Astm D 3605-00 AasDocument4 pagesAstm D 3605-00 AasAntony HoNo ratings yet

- Nitrogen Bases in Hydrocarbons by Titration: UOP Method 269-10 ScopeDocument10 pagesNitrogen Bases in Hydrocarbons by Titration: UOP Method 269-10 ScopeEdwin CastilloNo ratings yet

- UOP971Document8 pagesUOP971Do Duc ThanhNo ratings yet

- Cadmio en CacaoDocument7 pagesCadmio en CacaoFelipe Arcila ZambranoNo ratings yet

- Uop303 97Document7 pagesUop303 97Anix DiazNo ratings yet

- AAS - As EPA-Method-7060ADocument6 pagesAAS - As EPA-Method-7060AAhmed GwealyNo ratings yet

- 5990 4547en PDFDocument16 pages5990 4547en PDFMario_126No ratings yet

- EPA Method - 206 - 2 - Arsenic AA - Furnace TechniqueDocument2 pagesEPA Method - 206 - 2 - Arsenic AA - Furnace TechniqueNilton Flavio Benites QuispeNo ratings yet

- Uop 987Document11 pagesUop 987pramod23septNo ratings yet

- IMPCA MethanolDocument13 pagesIMPCA MethanolHito Jimenez SalinasNo ratings yet

- Furanic Compounds v2 PDFDocument6 pagesFuranic Compounds v2 PDFlevymiguel3012726No ratings yet

- Furanic Compounds PDFDocument6 pagesFuranic Compounds PDFAKGH2024No ratings yet

- Furanic Compounds v2 PDFDocument6 pagesFuranic Compounds v2 PDFusamafalakNo ratings yet

- Furanic Compounds v2 PDFDocument6 pagesFuranic Compounds v2 PDFAnjar TriyokoNo ratings yet

- Furanic Compounds v2Document6 pagesFuranic Compounds v2Anjar TriyokoNo ratings yet

- Furanic Compounds v2 PDFDocument6 pagesFuranic Compounds v2 PDFAKGH2024No ratings yet

- Uop 163Document8 pagesUop 163Julio RiveroNo ratings yet

- D6470 SaliniteDocument6 pagesD6470 SaliniteleofrazaoNo ratings yet

- D 3231 Phosphorus in GasolineDocument5 pagesD 3231 Phosphorus in GasolineEssam Eldin Metwally AhmedNo ratings yet

- Copper, ULR, Porphyrin Method 8143, 02-2009, 9th EdDocument5 pagesCopper, ULR, Porphyrin Method 8143, 02-2009, 9th EdMarcTimNo ratings yet

- Astm D 1977 - 03Document3 pagesAstm D 1977 - 03phaindikaNo ratings yet

- UOP 555-10 Trace Impurities in Benzene by GCDocument11 pagesUOP 555-10 Trace Impurities in Benzene by GCMorteza SepehranNo ratings yet

- Method For Determining The Concentration of FLUORIDE in Water SampleDocument4 pagesMethod For Determining The Concentration of FLUORIDE in Water SampleValter NevesNo ratings yet

- Lead in Gasoline by Atomic Absorption Spectroscopy: Standard Test Method ForDocument4 pagesLead in Gasoline by Atomic Absorption Spectroscopy: Standard Test Method ForKu BonNo ratings yet

- Phosphorus in Gasoline: Standard Test Method ForDocument6 pagesPhosphorus in Gasoline: Standard Test Method ForJoao FernándezNo ratings yet

- AN5391 Determination of TKN in Water by Using KT8000 SeriesDocument7 pagesAN5391 Determination of TKN in Water by Using KT8000 SeriesJaysonAbenirCabahugNo ratings yet

- D1240Document6 pagesD1240Ненад Кнежевић50% (2)

- ASTM D4928-00 (2005) Standard Test Methods For Water in Crude Oils by Coulometric Karl Fischer TitrationDocument5 pagesASTM D4928-00 (2005) Standard Test Methods For Water in Crude Oils by Coulometric Karl Fischer TitrationGermán José CovelliNo ratings yet

- Application Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerDocument4 pagesApplication Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerPrianurraufikachmadNo ratings yet

- Phosphorus in Gasoline: Standard Test Method ForDocument5 pagesPhosphorus in Gasoline: Standard Test Method ForRaul Gonzalo BeretaNo ratings yet

- Phosphorus in Gasoline: Standard Test Method ForDocument5 pagesPhosphorus in Gasoline: Standard Test Method ForAbdallah ElkasbyNo ratings yet

- For Sulfate Ion in Brackish Water, Seawater, and Brines: This Is A 2 Page(s) Preview of Total 4Document2 pagesFor Sulfate Ion in Brackish Water, Seawater, and Brines: This Is A 2 Page(s) Preview of Total 4Enrique Alejandro OvandoNo ratings yet

- Nitrogen, Ammonia, 0 To 0.50, Salicylate Method 8155, 02-2009, 9th Ed PDFDocument5 pagesNitrogen, Ammonia, 0 To 0.50, Salicylate Method 8155, 02-2009, 9th Ed PDFmelanie_chaw896No ratings yet

- Uop 481 - 10Document13 pagesUop 481 - 10lovehackinggalsNo ratings yet

- Doc316 53 01053Document8 pagesDoc316 53 01053Veronica BoydNo ratings yet

- Astm Metodo Complexometrico para Determinar Zinc en ConcentradosDocument4 pagesAstm Metodo Complexometrico para Determinar Zinc en Concentradosquimicaunsa100% (1)

- Astm D4468Document5 pagesAstm D4468Anonymous xERghLP8V100% (2)

- Catalogue EnglishDocument59 pagesCatalogue Englishbigweb100% (2)

- 0018AN - Performance of Method 8270 Using Hydrogen Carrier GasDocument4 pages0018AN - Performance of Method 8270 Using Hydrogen Carrier GasAuxiliar SySNo ratings yet

- Osha Id219sgDocument6 pagesOsha Id219sgvictor japposanNo ratings yet

- Hardness: DR 900 Analytical ProcedureDocument4 pagesHardness: DR 900 Analytical Procedurewulalan wulan100% (1)

- Method 12 PDFDocument27 pagesMethod 12 PDFMichael StevenNo ratings yet

- P05 031A Determination of Sodium and Potassium in Biological FluidsDocument4 pagesP05 031A Determination of Sodium and Potassium in Biological FluidsSree Nivas ReddyNo ratings yet

- Sop For in Vitro Determination of Chlorophyll A in Freshwater 201303 11ppDocument11 pagesSop For in Vitro Determination of Chlorophyll A in Freshwater 201303 11ppTri AriyantoNo ratings yet

- E 1899 - 97 Rte4otktukveDocument7 pagesE 1899 - 97 Rte4otktukveGaraje ToysNo ratings yet

- TESTING PB, CD, As, HG FOR FRUITY FLV POWDERDocument9 pagesTESTING PB, CD, As, HG FOR FRUITY FLV POWDERNguyễn Ngọc MaiNo ratings yet

- Astm1884 Ressol Versa Ht3Document6 pagesAstm1884 Ressol Versa Ht3Matteo DMNo ratings yet

- D1093Document2 pagesD1093rimi7alNo ratings yet

- Standard methods for the examination of water and sewageFrom EverandStandard methods for the examination of water and sewageNo ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Manual of Analytical ChemistryFrom EverandPractical Manual of Analytical ChemistryRating: 4.5 out of 5 stars4.5/5 (3)

- Y9 P1 Progression 2024Document20 pagesY9 P1 Progression 2024yahia farouq100% (2)

- Installation, Operation, and Maintenance: Packaged Rooftop Air Conditioners Precedent™ - Electric/ElectricDocument72 pagesInstallation, Operation, and Maintenance: Packaged Rooftop Air Conditioners Precedent™ - Electric/ElectricHector AntonioNo ratings yet

- Catalog+OilGas+2020 +vfinal+-+ENGDocument17 pagesCatalog+OilGas+2020 +vfinal+-+ENGLucas Matias AriasNo ratings yet

- Flakiness and Elongation Test PoliDocument4 pagesFlakiness and Elongation Test PoliMuhd Fariz KarimNo ratings yet

- SAES-B-068 Editorial Revision (10-28-2021)Document17 pagesSAES-B-068 Editorial Revision (10-28-2021)Daniel MeanaNo ratings yet

- Chemistry PAG 11.1 Learner v2.0Document3 pagesChemistry PAG 11.1 Learner v2.0CostaCoNo ratings yet

- Sikaswell s-2Document4 pagesSikaswell s-2Eko PriambudiNo ratings yet

- Hawkes & Webb 1962 ReviewDocument2 pagesHawkes & Webb 1962 Reviewjose antonioNo ratings yet

- DRMCDocument8 pagesDRMCkabirNo ratings yet

- A Comparative Study of Crosslinked Sodium Alginate/Gelatin Hydrogels For Wound DressingDocument6 pagesA Comparative Study of Crosslinked Sodium Alginate/Gelatin Hydrogels For Wound DressingJake EjaNo ratings yet

- AFFF FOAM CHARGE FOR UNITOR EXTINGUISHERS EnglishDocument7 pagesAFFF FOAM CHARGE FOR UNITOR EXTINGUISHERS EnglishGerman KodzhebashNo ratings yet

- Libro - Fluid Filtration Gas Vol. 1Document436 pagesLibro - Fluid Filtration Gas Vol. 1Tamara Silvana CárcamoNo ratings yet

- Rapid Visco Analyser (RVA) As A Tool For Measuring Starch-Related Physiochemical Properties in Cereals - A ReviewDocument17 pagesRapid Visco Analyser (RVA) As A Tool For Measuring Starch-Related Physiochemical Properties in Cereals - A ReviewIvan SebastianNo ratings yet

- ASTM C1403 - pdqv6897Document3 pagesASTM C1403 - pdqv6897Nayth Andres GalazNo ratings yet

- Combined Steam and CO2 Reforming of CH4 Using Coke Oven Gas On Nickel-Based Catalyst - Effects of Organic Acids To Nickel Dispersion and ActivityDocument11 pagesCombined Steam and CO2 Reforming of CH4 Using Coke Oven Gas On Nickel-Based Catalyst - Effects of Organic Acids To Nickel Dispersion and ActivityWassachol SumarasinghaNo ratings yet

- Tech (2018) Craftstone Veneer Technical ManualDocument13 pagesTech (2018) Craftstone Veneer Technical Manualvikon.rabbitNo ratings yet

- Autopure 96 ManualDocument3 pagesAutopure 96 ManualjarguedasNo ratings yet

- Stereochemistry PDFDocument57 pagesStereochemistry PDFvijayNo ratings yet

- Manish STUDYONAQUEOUSEXTRACTOFCitrusDocument5 pagesManish STUDYONAQUEOUSEXTRACTOFCitrusZurielle LuboaNo ratings yet

- Water Treatment - Class NotesDocument84 pagesWater Treatment - Class NotesSankalp ShandilyaNo ratings yet

- Chemistry of Fireworks 930 ODocument4 pagesChemistry of Fireworks 930 OBrendaNo ratings yet

- Home Care ProductGreen Guide 2014 US Letter WEBDocument21 pagesHome Care ProductGreen Guide 2014 US Letter WEBShingi MameNo ratings yet

- SolutionDocument2 pagesSolutionZuber SheikhNo ratings yet

- Din Iso 4381Document1 pageDin Iso 4381Soroosh YaghoubiNo ratings yet

- Mechanical Catalysis: Methods of Enzymatic, Homo-Geneous, and Heterogeneous Catalysis. by Gerhard FDocument2 pagesMechanical Catalysis: Methods of Enzymatic, Homo-Geneous, and Heterogeneous Catalysis. by Gerhard FLuis Avila OctavianoNo ratings yet

- Fco PTMMC Gar 42-40Document5 pagesFco PTMMC Gar 42-40mahendrarakasiwi631No ratings yet

- Microbial Physiology LectureDocument88 pagesMicrobial Physiology LectureDaniNo ratings yet

- ADD4605 Sulfopolyeste EastmanDocument8 pagesADD4605 Sulfopolyeste EastmanSantos de Prados100% (1)

- Pyrolysis of Wood-Biomass For Bio-Oil A Critical Review-3Document9 pagesPyrolysis of Wood-Biomass For Bio-Oil A Critical Review-3Some ParawhoreNo ratings yet