Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

3 views2 - 3 Propeller Shaft Repair

2 - 3 Propeller Shaft Repair

Uploaded by

CAT MINING SHOVELA corroded flange connection on a propeller shaft in Dubai was repaired using Wencon products. The flange was corroded due to seawater penetration from a leaking o-ring. The surface was prepared using Wencon Perago discs and Cleaner. Wencon Rapid was applied in two layers to rebuild the flange, with the layers left to cure overnight. After shaping the rebuilt flange with emery paper, the final result successfully repaired the corroded connection.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Lasco Shower Pan InstallationDocument4 pagesLasco Shower Pan InstallationKen O'ConnellNo ratings yet

- Wencon RepairDocument5 pagesWencon RepairSaikat PurkaitNo ratings yet

- 2 29 Bearing Seat Fixation1Document4 pages2 29 Bearing Seat Fixation1Essam Abdelsalam El-AbdNo ratings yet

- 1 - Heating Coils85 - Heating Coils Cargo Tank1Document3 pages1 - Heating Coils85 - Heating Coils Cargo Tank1CHI-MING WENNo ratings yet

- Wencon Repair Manual EnglishDocument163 pagesWencon Repair Manual EnglishEduardNo ratings yet

- Heating Coil Repair MethodeDocument2 pagesHeating Coil Repair MethodeHary adiNo ratings yet

- 2013 E Easy Plaster BrochureDocument4 pages2013 E Easy Plaster BrochureVicente Beyrouthy ArribasNo ratings yet

- Anglo Eastern Singapore: Petredec Fleet - Deck MaintenanceDocument20 pagesAnglo Eastern Singapore: Petredec Fleet - Deck MaintenanceSushant PahujaNo ratings yet

- IWD2311 BrochureDocument2 pagesIWD2311 BrochureИгорь ПавловNo ratings yet

- Aquapanel Exterior BasecoatDocument2 pagesAquapanel Exterior BasecoatDaniel MaftNo ratings yet

- User Manual 2021 Digital 2Document216 pagesUser Manual 2021 Digital 2Necati Yunus OrbayNo ratings yet

- Sandvik Exchange ProgramsDocument4 pagesSandvik Exchange ProgramsBenjamin MurphyNo ratings yet

- Wencon Pipe TapeDocument2 pagesWencon Pipe TapePartagon PowNo ratings yet

- E126Document16 pagesE126José Antonio TenaNo ratings yet

- Wencon Uw CoatingDocument2 pagesWencon Uw CoatingsahilimuNo ratings yet

- Knauf Moisture Resistant Gypsum BoardsDocument2 pagesKnauf Moisture Resistant Gypsum Boardssr2011glassNo ratings yet

- Upload Main Entity DB AssetMedia FilenameDocument2 pagesUpload Main Entity DB AssetMedia Filenamesr2011glassNo ratings yet

- Chapter 4 UkDocument4 pagesChapter 4 Ukbjarne9800No ratings yet

- 04 - TDS - Concresive 2200Document3 pages04 - TDS - Concresive 2200aahtagoNo ratings yet

- Water 7Document4 pagesWater 7Malith De SilvaNo ratings yet

- Weberend OCRDocument2 pagesWeberend OCRaNo ratings yet

- Korodur Copetti Floor PDFDocument1 pageKorodur Copetti Floor PDFIbrahim SahinNo ratings yet

- Uzin Ke 2000 S: Product Data SheetDocument4 pagesUzin Ke 2000 S: Product Data SheetFloorkitNo ratings yet

- Arbejdstilsynet Da enDocument5 pagesArbejdstilsynet Da enpaulo.torres.rfdkNo ratings yet

- PSOW2 - MS For Waterproofing Dated 04.11.2023Document5 pagesPSOW2 - MS For Waterproofing Dated 04.11.2023projectsNo ratings yet

- Knauf Fill & Finish 60 Premium: Data SheetDocument2 pagesKnauf Fill & Finish 60 Premium: Data SheetMalak HindiNo ratings yet

- Weber - Therm SV EN Rev 006Document2 pagesWeber - Therm SV EN Rev 006maga2292No ratings yet

- Conbextra Ep300Document4 pagesConbextra Ep300Venkata RaoNo ratings yet

- Tankguard SF 2008 - tcm29 1613Document4 pagesTankguard SF 2008 - tcm29 1613Rescue_aditya111No ratings yet

- Amiblu Stream Magazine November19Document18 pagesAmiblu Stream Magazine November19Cristian OtekNo ratings yet

- Concrete Prestressed Panel & Rocket WallingDocument32 pagesConcrete Prestressed Panel & Rocket WallingWayne StevensonNo ratings yet

- Aquapanel Cement Board FloorDocument8 pagesAquapanel Cement Board FloormatsiasNo ratings yet

- Concresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarDocument4 pagesConcresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarFrancois-No ratings yet

- Instalación Sistemas MicrofiltradoDocument14 pagesInstalación Sistemas MicrofiltradoMario Alfonso Gallardo IrribarrraNo ratings yet

- Aquapanel Indoor ENG PDFDocument12 pagesAquapanel Indoor ENG PDFANTODO76No ratings yet

- EnvirAnode Datasheet 01Document6 pagesEnvirAnode Datasheet 01soltani aliNo ratings yet

- Wester Schelde TunnelDocument2 pagesWester Schelde TunnelAyman SobhyNo ratings yet

- Wienerberger Penter BrochureDocument60 pagesWienerberger Penter BrochureBintang KedjoraNo ratings yet

- Brief Reference ListDocument2 pagesBrief Reference ListSamson ObinnaNo ratings yet

- Repairing Methodology of Honeycombs in Concrete SurfaceDocument4 pagesRepairing Methodology of Honeycombs in Concrete Surfacejohn paul100% (1)

- Assignment Technical Specifications Division 7Document3 pagesAssignment Technical Specifications Division 7Patrisha SantosNo ratings yet

- Crea - Lign Freestyle Manual: Natural AestheticsDocument16 pagesCrea - Lign Freestyle Manual: Natural AestheticsAurelia CrismariNo ratings yet

- Brochure K-Bond 2021 en CompressedDocument4 pagesBrochure K-Bond 2021 en CompressedembenNo ratings yet

- (PDS) Conbextra EP300Document4 pages(PDS) Conbextra EP300Faizal HaziziNo ratings yet

- EC105Document31 pagesEC105api-3853441No ratings yet

- Polymer Thin Film Deposition by Spin Coating and Dip CoatingDocument2 pagesPolymer Thin Film Deposition by Spin Coating and Dip CoatingDhananjay PaweNo ratings yet

- En 7410Document6 pagesEn 7410kimberly solis100% (1)

- Oil-Less Decal Transfer: Copyfun WhiteDocument1 pageOil-Less Decal Transfer: Copyfun WhiteIgor Cece GigoNo ratings yet

- Epoxy Filler Sealer 51213-IDocument2 pagesEpoxy Filler Sealer 51213-IBudi_Salim_42590% (1)

- Dunlop Builder's Bond 0114Document2 pagesDunlop Builder's Bond 0114marklaforestNo ratings yet

- Praesentation Finow 2022 09 EnglDocument29 pagesPraesentation Finow 2022 09 EnglviktoriiabiskupNo ratings yet

- Press Release: ITMA Barcelona 2019Document7 pagesPress Release: ITMA Barcelona 2019孙兴峰No ratings yet

- Weber - Tec MC1Document2 pagesWeber - Tec MC1rangarajan1989No ratings yet

- Case Study Five Star Hotel, London For Web PDFDocument2 pagesCase Study Five Star Hotel, London For Web PDFBima AndriansyahNo ratings yet

- Case Study Five Star Hotel, London For Web PDFDocument2 pagesCase Study Five Star Hotel, London For Web PDFBima AndriansyahNo ratings yet

- Case Study Five Star Hotel, London For Web PDFDocument2 pagesCase Study Five Star Hotel, London For Web PDFBima AndriansyahNo ratings yet

- WEBER Kol SRK Ing Sari BantDocument2 pagesWEBER Kol SRK Ing Sari BantGökhan PanpaNo ratings yet

- WenconDocument8 pagesWenconCAT MINING SHOVELNo ratings yet

- Liebherr Measuring Instruments WGT 280 1200Document8 pagesLiebherr Measuring Instruments WGT 280 1200CAT MINING SHOVELNo ratings yet

- En Gjs 400 15 SG IronDocument3 pagesEn Gjs 400 15 SG IronCAT MINING SHOVELNo ratings yet

- Flyer MetalformingDocument19 pagesFlyer MetalformingCAT MINING SHOVELNo ratings yet

- Assembly Instructions DINDocument2 pagesAssembly Instructions DINCAT MINING SHOVELNo ratings yet

- Assembly Instructions 2018Document1 pageAssembly Instructions 2018CAT MINING SHOVELNo ratings yet

- Gear Milling 2021 (Inch) 290821 - BDocument20 pagesGear Milling 2021 (Inch) 290821 - BCAT MINING SHOVELNo ratings yet

- PT5 CatalogueDocument52 pagesPT5 CatalogueCAT MINING SHOVELNo ratings yet

- 80-500-009 - ZF - Multiple Disc Brake (Vehicle or Emergency) Data SheetDocument2 pages80-500-009 - ZF - Multiple Disc Brake (Vehicle or Emergency) Data SheetCAT MINING SHOVELNo ratings yet

- Flyer KISSsoft Manufacturing Website en v00 JL PublicDocument4 pagesFlyer KISSsoft Manufacturing Website en v00 JL PublicCAT MINING SHOVELNo ratings yet

- Pit Viper 271 XC Blasthole Drills: Single-Pass Rotary and Down-The-Hole (DTH) DrillingDocument7 pagesPit Viper 271 XC Blasthole Drills: Single-Pass Rotary and Down-The-Hole (DTH) DrillingCAT MINING SHOVELNo ratings yet

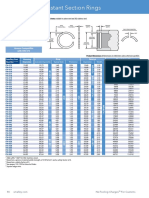

- Smalley RetainingRings FSDocument2 pagesSmalley RetainingRings FSCAT MINING SHOVELNo ratings yet

- Corning Gorilla GlassDocument2 pagesCorning Gorilla GlassCAT MINING SHOVELNo ratings yet

- 14 Spline NutDocument24 pages14 Spline NutCAT MINING SHOVELNo ratings yet

- RBC RPP Brochure 112117 WEBDocument4 pagesRBC RPP Brochure 112117 WEBCAT MINING SHOVELNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- About Radyne For WebDocument7 pagesAbout Radyne For WebCAT MINING SHOVELNo ratings yet

- Solutions For: E-MobilityDocument38 pagesSolutions For: E-MobilityCAT MINING SHOVELNo ratings yet

- SNFeb 2014Document5 pagesSNFeb 2014CAT MINING SHOVELNo ratings yet

- Q - Hyd Adapters PLDocument28 pagesQ - Hyd Adapters PLCAT MINING SHOVELNo ratings yet

- Infor - ERP - VISUAL - Detailed Functionality - Version9Document78 pagesInfor - ERP - VISUAL - Detailed Functionality - Version9CAT MINING SHOVELNo ratings yet

- L011393 - Rotex Standard 28 SeriesDocument4 pagesL011393 - Rotex Standard 28 SeriesCAT MINING SHOVELNo ratings yet

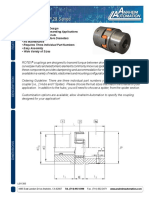

- DP, 20 PA Shank ShaperDocument2 pagesDP, 20 PA Shank ShaperCAT MINING SHOVELNo ratings yet

- Smalley RetainingRings FHDocument2 pagesSmalley RetainingRings FHCAT MINING SHOVELNo ratings yet

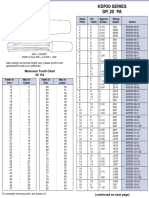

- K45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedDocument2 pagesK45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedCAT MINING SHOVELNo ratings yet

- VISUAL 9 Features and Benefit Through Release3Document93 pagesVISUAL 9 Features and Benefit Through Release3CAT MINING SHOVELNo ratings yet

- Bonfiglioli Offshore Innovative Solutions: 700 Series With Integrated InverterDocument12 pagesBonfiglioli Offshore Innovative Solutions: 700 Series With Integrated InverterCAT MINING SHOVELNo ratings yet

- TR Cat Ramob STD Eng R04 1 4Document44 pagesTR Cat Ramob STD Eng R04 1 4CAT MINING SHOVELNo ratings yet

- 500 Series: Hybrid Mixer Drum DriveDocument8 pages500 Series: Hybrid Mixer Drum DriveCAT MINING SHOVELNo ratings yet

- Product Range: Wind SolutionsDocument28 pagesProduct Range: Wind SolutionsCAT MINING SHOVELNo ratings yet

2 - 3 Propeller Shaft Repair

2 - 3 Propeller Shaft Repair

Uploaded by

CAT MINING SHOVEL0 ratings0% found this document useful (0 votes)

3 views4 pagesA corroded flange connection on a propeller shaft in Dubai was repaired using Wencon products. The flange was corroded due to seawater penetration from a leaking o-ring. The surface was prepared using Wencon Perago discs and Cleaner. Wencon Rapid was applied in two layers to rebuild the flange, with the layers left to cure overnight. After shaping the rebuilt flange with emery paper, the final result successfully repaired the corroded connection.

Original Description:

Original Title

2_3-propeller-shaft-repair

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA corroded flange connection on a propeller shaft in Dubai was repaired using Wencon products. The flange was corroded due to seawater penetration from a leaking o-ring. The surface was prepared using Wencon Perago discs and Cleaner. Wencon Rapid was applied in two layers to rebuild the flange, with the layers left to cure overnight. After shaping the rebuilt flange with emery paper, the final result successfully repaired the corroded connection.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views4 pages2 - 3 Propeller Shaft Repair

2 - 3 Propeller Shaft Repair

Uploaded by

CAT MINING SHOVELA corroded flange connection on a propeller shaft in Dubai was repaired using Wencon products. The flange was corroded due to seawater penetration from a leaking o-ring. The surface was prepared using Wencon Perago discs and Cleaner. Wencon Rapid was applied in two layers to rebuild the flange, with the layers left to cure overnight. After shaping the rebuilt flange with emery paper, the final result successfully repaired the corroded connection.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

APPLICATION REPORT

Propeller Shaft repair

Application: Rebuilding of corroded flange connection

Place: Dubai, UAE

Date: July 2009

Job and report done by: Local Dubai workshop and Wencon

technician

Wencon products used: Rapid, Cleaner, appl. tools

WENCON ApS • Jyllandsvej 15 • DK-5400 Bogense •

Phone +45 6481 1010 • wencon@wencon.com • www.wencon.com No. 2.3

1. & 2.

1

Due to a leaking o-ring, the seawater has

been penetrating and caused corrosion at the

flange

3. The Wencon Perago disc is used to make the 3

surface as rough as possible.

4. Area is cleaned twice with Wencon Cleaner.

4

WENCON ApS • Jyllandsvej 15 • DK-5400 Bogense •

Phone +45 6481 1010 • wencon@wencon.com • www.wencon.com No. 2.3

5.

5. A spatula was made to create the original

6.

shape of the surface. Wencon Rapid is used

for this job, due to the fast curing time.

After applying the first layer of Wencon

Rapid it is left to semi cure in approx. 45

minutes, afterwards second layer is applied

and left to cure overnight.

We choosed to apply Wencon Rapid in two

7.

layers, in order to be sure that the final layer

is oversized.

6. Flange after first layer.

7. Flange after second layer.

WENCON ApS • Jyllandsvej 15 • DK-5400 Bogense •

Phone +45 6481 1010 • wencon@wencon.com • www.wencon.com No. 2.3

8. & 9.

8.

The flange is formed, by hand, to original

size and shape with emery paper.

An alternative solution to emery paper will

be machining in the lathe. All Wencon Coat-

ings/Rapid/Cream are fully machineable.

9.

10. & 11.

10.

Final result

11.

WENCON ApS • Jyllandsvej 15 • DK-5400 Bogense •

Phone +45 6481 1010 • wencon@wencon.com • www.wencon.com No. 2.3

You might also like

- Lasco Shower Pan InstallationDocument4 pagesLasco Shower Pan InstallationKen O'ConnellNo ratings yet

- Wencon RepairDocument5 pagesWencon RepairSaikat PurkaitNo ratings yet

- 2 29 Bearing Seat Fixation1Document4 pages2 29 Bearing Seat Fixation1Essam Abdelsalam El-AbdNo ratings yet

- 1 - Heating Coils85 - Heating Coils Cargo Tank1Document3 pages1 - Heating Coils85 - Heating Coils Cargo Tank1CHI-MING WENNo ratings yet

- Wencon Repair Manual EnglishDocument163 pagesWencon Repair Manual EnglishEduardNo ratings yet

- Heating Coil Repair MethodeDocument2 pagesHeating Coil Repair MethodeHary adiNo ratings yet

- 2013 E Easy Plaster BrochureDocument4 pages2013 E Easy Plaster BrochureVicente Beyrouthy ArribasNo ratings yet

- Anglo Eastern Singapore: Petredec Fleet - Deck MaintenanceDocument20 pagesAnglo Eastern Singapore: Petredec Fleet - Deck MaintenanceSushant PahujaNo ratings yet

- IWD2311 BrochureDocument2 pagesIWD2311 BrochureИгорь ПавловNo ratings yet

- Aquapanel Exterior BasecoatDocument2 pagesAquapanel Exterior BasecoatDaniel MaftNo ratings yet

- User Manual 2021 Digital 2Document216 pagesUser Manual 2021 Digital 2Necati Yunus OrbayNo ratings yet

- Sandvik Exchange ProgramsDocument4 pagesSandvik Exchange ProgramsBenjamin MurphyNo ratings yet

- Wencon Pipe TapeDocument2 pagesWencon Pipe TapePartagon PowNo ratings yet

- E126Document16 pagesE126José Antonio TenaNo ratings yet

- Wencon Uw CoatingDocument2 pagesWencon Uw CoatingsahilimuNo ratings yet

- Knauf Moisture Resistant Gypsum BoardsDocument2 pagesKnauf Moisture Resistant Gypsum Boardssr2011glassNo ratings yet

- Upload Main Entity DB AssetMedia FilenameDocument2 pagesUpload Main Entity DB AssetMedia Filenamesr2011glassNo ratings yet

- Chapter 4 UkDocument4 pagesChapter 4 Ukbjarne9800No ratings yet

- 04 - TDS - Concresive 2200Document3 pages04 - TDS - Concresive 2200aahtagoNo ratings yet

- Water 7Document4 pagesWater 7Malith De SilvaNo ratings yet

- Weberend OCRDocument2 pagesWeberend OCRaNo ratings yet

- Korodur Copetti Floor PDFDocument1 pageKorodur Copetti Floor PDFIbrahim SahinNo ratings yet

- Uzin Ke 2000 S: Product Data SheetDocument4 pagesUzin Ke 2000 S: Product Data SheetFloorkitNo ratings yet

- Arbejdstilsynet Da enDocument5 pagesArbejdstilsynet Da enpaulo.torres.rfdkNo ratings yet

- PSOW2 - MS For Waterproofing Dated 04.11.2023Document5 pagesPSOW2 - MS For Waterproofing Dated 04.11.2023projectsNo ratings yet

- Knauf Fill & Finish 60 Premium: Data SheetDocument2 pagesKnauf Fill & Finish 60 Premium: Data SheetMalak HindiNo ratings yet

- Weber - Therm SV EN Rev 006Document2 pagesWeber - Therm SV EN Rev 006maga2292No ratings yet

- Conbextra Ep300Document4 pagesConbextra Ep300Venkata RaoNo ratings yet

- Tankguard SF 2008 - tcm29 1613Document4 pagesTankguard SF 2008 - tcm29 1613Rescue_aditya111No ratings yet

- Amiblu Stream Magazine November19Document18 pagesAmiblu Stream Magazine November19Cristian OtekNo ratings yet

- Concrete Prestressed Panel & Rocket WallingDocument32 pagesConcrete Prestressed Panel & Rocket WallingWayne StevensonNo ratings yet

- Aquapanel Cement Board FloorDocument8 pagesAquapanel Cement Board FloormatsiasNo ratings yet

- Concresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarDocument4 pagesConcresive 2200: High Strength, Thixotropic, Epoxy Bedding MortarFrancois-No ratings yet

- Instalación Sistemas MicrofiltradoDocument14 pagesInstalación Sistemas MicrofiltradoMario Alfonso Gallardo IrribarrraNo ratings yet

- Aquapanel Indoor ENG PDFDocument12 pagesAquapanel Indoor ENG PDFANTODO76No ratings yet

- EnvirAnode Datasheet 01Document6 pagesEnvirAnode Datasheet 01soltani aliNo ratings yet

- Wester Schelde TunnelDocument2 pagesWester Schelde TunnelAyman SobhyNo ratings yet

- Wienerberger Penter BrochureDocument60 pagesWienerberger Penter BrochureBintang KedjoraNo ratings yet

- Brief Reference ListDocument2 pagesBrief Reference ListSamson ObinnaNo ratings yet

- Repairing Methodology of Honeycombs in Concrete SurfaceDocument4 pagesRepairing Methodology of Honeycombs in Concrete Surfacejohn paul100% (1)

- Assignment Technical Specifications Division 7Document3 pagesAssignment Technical Specifications Division 7Patrisha SantosNo ratings yet

- Crea - Lign Freestyle Manual: Natural AestheticsDocument16 pagesCrea - Lign Freestyle Manual: Natural AestheticsAurelia CrismariNo ratings yet

- Brochure K-Bond 2021 en CompressedDocument4 pagesBrochure K-Bond 2021 en CompressedembenNo ratings yet

- (PDS) Conbextra EP300Document4 pages(PDS) Conbextra EP300Faizal HaziziNo ratings yet

- EC105Document31 pagesEC105api-3853441No ratings yet

- Polymer Thin Film Deposition by Spin Coating and Dip CoatingDocument2 pagesPolymer Thin Film Deposition by Spin Coating and Dip CoatingDhananjay PaweNo ratings yet

- En 7410Document6 pagesEn 7410kimberly solis100% (1)

- Oil-Less Decal Transfer: Copyfun WhiteDocument1 pageOil-Less Decal Transfer: Copyfun WhiteIgor Cece GigoNo ratings yet

- Epoxy Filler Sealer 51213-IDocument2 pagesEpoxy Filler Sealer 51213-IBudi_Salim_42590% (1)

- Dunlop Builder's Bond 0114Document2 pagesDunlop Builder's Bond 0114marklaforestNo ratings yet

- Praesentation Finow 2022 09 EnglDocument29 pagesPraesentation Finow 2022 09 EnglviktoriiabiskupNo ratings yet

- Press Release: ITMA Barcelona 2019Document7 pagesPress Release: ITMA Barcelona 2019孙兴峰No ratings yet

- Weber - Tec MC1Document2 pagesWeber - Tec MC1rangarajan1989No ratings yet

- Case Study Five Star Hotel, London For Web PDFDocument2 pagesCase Study Five Star Hotel, London For Web PDFBima AndriansyahNo ratings yet

- Case Study Five Star Hotel, London For Web PDFDocument2 pagesCase Study Five Star Hotel, London For Web PDFBima AndriansyahNo ratings yet

- Case Study Five Star Hotel, London For Web PDFDocument2 pagesCase Study Five Star Hotel, London For Web PDFBima AndriansyahNo ratings yet

- WEBER Kol SRK Ing Sari BantDocument2 pagesWEBER Kol SRK Ing Sari BantGökhan PanpaNo ratings yet

- WenconDocument8 pagesWenconCAT MINING SHOVELNo ratings yet

- Liebherr Measuring Instruments WGT 280 1200Document8 pagesLiebherr Measuring Instruments WGT 280 1200CAT MINING SHOVELNo ratings yet

- En Gjs 400 15 SG IronDocument3 pagesEn Gjs 400 15 SG IronCAT MINING SHOVELNo ratings yet

- Flyer MetalformingDocument19 pagesFlyer MetalformingCAT MINING SHOVELNo ratings yet

- Assembly Instructions DINDocument2 pagesAssembly Instructions DINCAT MINING SHOVELNo ratings yet

- Assembly Instructions 2018Document1 pageAssembly Instructions 2018CAT MINING SHOVELNo ratings yet

- Gear Milling 2021 (Inch) 290821 - BDocument20 pagesGear Milling 2021 (Inch) 290821 - BCAT MINING SHOVELNo ratings yet

- PT5 CatalogueDocument52 pagesPT5 CatalogueCAT MINING SHOVELNo ratings yet

- 80-500-009 - ZF - Multiple Disc Brake (Vehicle or Emergency) Data SheetDocument2 pages80-500-009 - ZF - Multiple Disc Brake (Vehicle or Emergency) Data SheetCAT MINING SHOVELNo ratings yet

- Flyer KISSsoft Manufacturing Website en v00 JL PublicDocument4 pagesFlyer KISSsoft Manufacturing Website en v00 JL PublicCAT MINING SHOVELNo ratings yet

- Pit Viper 271 XC Blasthole Drills: Single-Pass Rotary and Down-The-Hole (DTH) DrillingDocument7 pagesPit Viper 271 XC Blasthole Drills: Single-Pass Rotary and Down-The-Hole (DTH) DrillingCAT MINING SHOVELNo ratings yet

- Smalley RetainingRings FSDocument2 pagesSmalley RetainingRings FSCAT MINING SHOVELNo ratings yet

- Corning Gorilla GlassDocument2 pagesCorning Gorilla GlassCAT MINING SHOVELNo ratings yet

- 14 Spline NutDocument24 pages14 Spline NutCAT MINING SHOVELNo ratings yet

- RBC RPP Brochure 112117 WEBDocument4 pagesRBC RPP Brochure 112117 WEBCAT MINING SHOVELNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- About Radyne For WebDocument7 pagesAbout Radyne For WebCAT MINING SHOVELNo ratings yet

- Solutions For: E-MobilityDocument38 pagesSolutions For: E-MobilityCAT MINING SHOVELNo ratings yet

- SNFeb 2014Document5 pagesSNFeb 2014CAT MINING SHOVELNo ratings yet

- Q - Hyd Adapters PLDocument28 pagesQ - Hyd Adapters PLCAT MINING SHOVELNo ratings yet

- Infor - ERP - VISUAL - Detailed Functionality - Version9Document78 pagesInfor - ERP - VISUAL - Detailed Functionality - Version9CAT MINING SHOVELNo ratings yet

- L011393 - Rotex Standard 28 SeriesDocument4 pagesL011393 - Rotex Standard 28 SeriesCAT MINING SHOVELNo ratings yet

- DP, 20 PA Shank ShaperDocument2 pagesDP, 20 PA Shank ShaperCAT MINING SHOVELNo ratings yet

- Smalley RetainingRings FHDocument2 pagesSmalley RetainingRings FHCAT MINING SHOVELNo ratings yet

- K45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedDocument2 pagesK45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedCAT MINING SHOVELNo ratings yet

- VISUAL 9 Features and Benefit Through Release3Document93 pagesVISUAL 9 Features and Benefit Through Release3CAT MINING SHOVELNo ratings yet

- Bonfiglioli Offshore Innovative Solutions: 700 Series With Integrated InverterDocument12 pagesBonfiglioli Offshore Innovative Solutions: 700 Series With Integrated InverterCAT MINING SHOVELNo ratings yet

- TR Cat Ramob STD Eng R04 1 4Document44 pagesTR Cat Ramob STD Eng R04 1 4CAT MINING SHOVELNo ratings yet

- 500 Series: Hybrid Mixer Drum DriveDocument8 pages500 Series: Hybrid Mixer Drum DriveCAT MINING SHOVELNo ratings yet

- Product Range: Wind SolutionsDocument28 pagesProduct Range: Wind SolutionsCAT MINING SHOVELNo ratings yet