Professional Documents

Culture Documents

Metric DIN 6796 Spec

Metric DIN 6796 Spec

Uploaded by

Devansh ChawlaCopyright:

Available Formats

You might also like

- Visual Inspection - Sample Report For Spherical VesselDocument8 pagesVisual Inspection - Sample Report For Spherical Vesselkamal90% (10)

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekNo ratings yet

- Din 929 PDFDocument1 pageDin 929 PDFprathmesh238No ratings yet

- Metric Clearance Hole Chart PDFDocument2 pagesMetric Clearance Hole Chart PDFAkshay PremkumarNo ratings yet

- Ebook s104 Book1 E2i1 n9781848731622 l3Document168 pagesEbook s104 Book1 E2i1 n9781848731622 l3Julie Firth100% (1)

- Metric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityShrikant DeshmukhNo ratings yet

- Metric DIN 7980 SpecDocument4 pagesMetric DIN 7980 SpecGowtham VenkatNo ratings yet

- Dimensions of Metric Hex NutsDocument2 pagesDimensions of Metric Hex Nutsdidik sNo ratings yet

- DIN 433 SpecDocument4 pagesDIN 433 SpecChris StefanouNo ratings yet

- Metric DIN 125 Spec PDFDocument4 pagesMetric DIN 125 Spec PDFSandro CNo ratings yet

- Cap Screw-C Sunk DimensionsDocument1 pageCap Screw-C Sunk DimensionsTan Hui ChewNo ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- GMAW - Complete GuideDocument1 pageGMAW - Complete GuideVijay OfficialNo ratings yet

- Screws Nuts Washer SizesDocument5 pagesScrews Nuts Washer SizesNanang RisdiantoNo ratings yet

- Thread Tolerances For Screws and NutsDocument2 pagesThread Tolerances For Screws and NutsBill WhiteNo ratings yet

- Pages From Astm-A194-2011pdf - CompressDocument1 pagePages From Astm-A194-2011pdf - CompressMuthazhagan SaravananNo ratings yet

- Metric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless SteelDocument2 pagesMetric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless Steelrobert_candra_tarunaNo ratings yet

- DIN 934 Hex NutDocument1 pageDIN 934 Hex NutfastenersworldNo ratings yet

- Metric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionsDocument1 pageMetric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionssnorklingmonkeyNo ratings yet

- Metric Bolt Sizes and DimensionsDocument13 pagesMetric Bolt Sizes and DimensionsTHEARY THUNNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Metric DIN 985 Low Profile Nylon Insert Hexagon Stop Lock NutsDocument4 pagesMetric DIN 985 Low Profile Nylon Insert Hexagon Stop Lock Nutsvikram jainNo ratings yet

- DIN 7980 Spring Lock Washer - Fasteners ChinaDocument2 pagesDIN 7980 Spring Lock Washer - Fasteners ChinaHala Ibrahim El-BassyouniNo ratings yet

- Thread Size Sheet V2Document3 pagesThread Size Sheet V2mehrdadNo ratings yet

- Metric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.PDocument2 pagesMetric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.Pdinesh panchalNo ratings yet

- Metric DIN 127 SpecDocument5 pagesMetric DIN 127 SpecmahfuzNo ratings yet

- Hex Jam Nut Metric (ISO 4035)Document1 pageHex Jam Nut Metric (ISO 4035)Abu IrfanNo ratings yet

- Iso 965 2 1998Document8 pagesIso 965 2 1998Gerald CelisNo ratings yet

- Metric DIN 916 SpecDocument5 pagesMetric DIN 916 SpecJUAN CARDONANo ratings yet

- Din125 WasherDocument2 pagesDin125 WasherHieu TranvanNo ratings yet

- Metric Clearance Hole Chart PDFDocument2 pagesMetric Clearance Hole Chart PDFMeleti Meleti MeletiouNo ratings yet

- Metric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDocument5 pagesMetric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDHEERAJ413No ratings yet

- Metric DIN 6926 SpecDocument4 pagesMetric DIN 6926 Spec叶开No ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- Metric Hex PDFDocument2 pagesMetric Hex PDFCarlos Eduardo Cardenas SochaNo ratings yet

- Nuts DimDocument2 pagesNuts DimrezaNo ratings yet

- Metric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PDocument2 pagesMetric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PjoseocsilvaNo ratings yet

- Metric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PDocument2 pagesMetric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PnothingNo ratings yet

- Metric DIN 432 SpecDocument4 pagesMetric DIN 432 SpecivanNo ratings yet

- Metric DIN 6319 SpecDocument6 pagesMetric DIN 6319 SpecPavanNo ratings yet

- BN 8699Document2 pagesBN 8699Foocheong LoiNo ratings yet

- Metric DIN 7349 SpecDocument6 pagesMetric DIN 7349 SpecANIRBANNo ratings yet

- Metric, Hex Thin Nuts, DIN 936, Plain: Page 1 of 1 REV-03 Date: October 9, 2015 M.936.PDocument1 pageMetric, Hex Thin Nuts, DIN 936, Plain: Page 1 of 1 REV-03 Date: October 9, 2015 M.936.PSatnam Rachna FastenersNo ratings yet

- Metric Schnorr Lock Washer SpecDocument3 pagesMetric Schnorr Lock Washer SpecGatito FelinoNo ratings yet

- Metric DIN 7984 Low Profile Head Hexagon Socket Cap Screws: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 7984 Low Profile Head Hexagon Socket Cap Screws: Visit Our For Product AvailabilityTugay ArıçNo ratings yet

- Metric DIN 963 SpecDocument5 pagesMetric DIN 963 SpecKI FastenersNo ratings yet

- Tables of Mechanical FastenersDocument3 pagesTables of Mechanical Fastenersmiwep18125No ratings yet

- RATV - Socket Head Fasteners - MetricDocument1 pageRATV - Socket Head Fasteners - MetricGustavo CarvalhoNo ratings yet

- Din 985 - ParlockDocument1 pageDin 985 - Parlockmaicon sulivanNo ratings yet

- Hexalobular (6 Lobe) Socket Pan Head Thread Forming Screws Type C, Metric ThreadDocument3 pagesHexalobular (6 Lobe) Socket Pan Head Thread Forming Screws Type C, Metric ThreadRodrigo AugustoNo ratings yet

- Hex Key Chart: EnglishDocument1 pageHex Key Chart: EnglishRoss EdwardNo ratings yet

- Mechanical Thread TablesDocument38 pagesMechanical Thread TablesbarcristianNo ratings yet

- Tourqe Value 8.8Document1 pageTourqe Value 8.8MAKNo ratings yet

- Bolt & Screw DetailsDocument6 pagesBolt & Screw Detailsjee01No ratings yet

- Metric DIN 137 SpecDocument5 pagesMetric DIN 137 Specpradipbhosale81No ratings yet

- Din 9021 Specifications: Bucket Elevator PartsDocument2 pagesDin 9021 Specifications: Bucket Elevator PartsstefanbrindusaNo ratings yet

- Hex Key ChartDocument1 pageHex Key ChartMassimoNo ratings yet

- Grosime PereteDocument1 pageGrosime Peretebogd32000No ratings yet

- Hex Key ChartDocument1 pageHex Key Charter lop100% (1)

- Metric MSThreadDocument2 pagesMetric MSThreadarvindspakNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- The Art of Sculpture Welding: From Concept to CreationFrom EverandThe Art of Sculpture Welding: From Concept to CreationNo ratings yet

- Easy Genset Control: OperationDocument51 pagesEasy Genset Control: OperationdonothearNo ratings yet

- Read Jujutsu Kaisen Chapter 243 Manga Online - Read Jujutsu Kaisen Manga OnlineDocument19 pagesRead Jujutsu Kaisen Chapter 243 Manga Online - Read Jujutsu Kaisen Manga OnlinemarileyserNo ratings yet

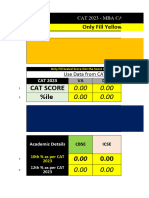

- CAT 2023 Composite Score and Calls Predictor - AmiyaDocument69 pagesCAT 2023 Composite Score and Calls Predictor - AmiyaHarsimran SinghNo ratings yet

- Kingspan Kooltherm K7Document1 pageKingspan Kooltherm K7Diaconu FlorinNo ratings yet

- Executive Fellow Program in Management: Information BrochureDocument3 pagesExecutive Fellow Program in Management: Information Brochureaniruddh nainNo ratings yet

- Glimpses of Consumer Behaviour Towards 2020Document196 pagesGlimpses of Consumer Behaviour Towards 2020Najeemudeen K.P100% (1)

- DokasetDocument52 pagesDokasetAnupam GhoshNo ratings yet

- Premier Collection: Whirlpool Spa Owner's ManualDocument24 pagesPremier Collection: Whirlpool Spa Owner's ManualJomari PecsonNo ratings yet

- Crodasinic LS LeafletDocument2 pagesCrodasinic LS LeafleticraoNo ratings yet

- Otc 31506 MsDocument10 pagesOtc 31506 MsAdriana UstarizNo ratings yet

- Concrete & Shuttering Working-R1Document20 pagesConcrete & Shuttering Working-R1vivekNo ratings yet

- Ethernet Gersis GMBH DsDocument93 pagesEthernet Gersis GMBH DsMuhammad AdeelNo ratings yet

- Principles of Human Resource Management 16 e Bohlander - SnellDocument36 pagesPrinciples of Human Resource Management 16 e Bohlander - SnellAmirul AswadNo ratings yet

- LEM Active P SeriesDocument8 pagesLEM Active P Seriesjuan manuel sierra solisNo ratings yet

- Shiny PDFDocument2 pagesShiny PDFBhaktiNo ratings yet

- Optical Character Recognition Research: IndexDocument6 pagesOptical Character Recognition Research: IndexPhi Thiện HồNo ratings yet

- Ameyo Product BrochureDocument8 pagesAmeyo Product BrochureSudhanshu Gupta100% (1)

- Triton Wireline ValvesDocument2 pagesTriton Wireline ValvesrezaNo ratings yet

- 06xa SDocument2 pages06xa SOscarNo ratings yet

- Varistores-D V680K14 0 V680K14 VARISTOR DOCUMENTACIÓNDocument12 pagesVaristores-D V680K14 0 V680K14 VARISTOR DOCUMENTACIÓNAlberto Morillo ParelladaNo ratings yet

- Company Profile: A B o U T U SDocument3 pagesCompany Profile: A B o U T U SRaghavendar Reddy BobbalaNo ratings yet

- Strategic Entrepreneurship: Hitt - Chapter 13Document32 pagesStrategic Entrepreneurship: Hitt - Chapter 13E Kay MutemiNo ratings yet

- Progress ReportDocument12 pagesProgress ReportNOKHAIZ HAMMAD 2021-BS-MLS-007No ratings yet

- 04 JP - WeldingDocument8 pages04 JP - WeldingShubhamShuklaNo ratings yet

- Types of Video Cameras Vid 1Document8 pagesTypes of Video Cameras Vid 1Adelite sabiriNo ratings yet

- Bpme 6093 Modenas Combine LastDocument12 pagesBpme 6093 Modenas Combine LastjibamcomotNo ratings yet

- Individual Work Plan - TeachersDocument9 pagesIndividual Work Plan - TeachersMarinelle OpeñaNo ratings yet

- Heavy Duty BrochureDocument16 pagesHeavy Duty BrochureАлексей ГордиенкоNo ratings yet

Metric DIN 6796 Spec

Metric DIN 6796 Spec

Uploaded by

Devansh ChawlaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metric DIN 6796 Spec

Metric DIN 6796 Spec

Uploaded by

Devansh ChawlaCopyright:

Available Formats

All your fastener needs from a single source

Product Dimensions and Weights DIN 6796 Technical Specifications

Metric DIN 6796 Conical Spring Washers

Visit our online store for product availability

Dimensions of Metric DIN 6796 Conical Spring Washers

d1 d2 h For

Weight

Nominal size s thread

kg/1000pcs

H14 h14 max. min. size

2 2.2 5 0.4 0.6 0.5 0.05 M2

2.5 2.7 6 0.5 0.72 0.61 0.09 M2.5

3 3.2 7 0.6 0.85 0.72 0.14 M3

3.5 3.7 8 0.8 1.06 0.92 0.25 M3.5

4 4.3 9 1 1.3 1.12 0.38 M4

5 5.3 11 1.2 1.55 1.35 0.69 M5

6 6.4 14 1.5 2 1.7 1.43 M6

7 7.4 17 1.75 2.3 2 2.53 M7

8 8.4 18 2 2.6 2.4 3.13 M8

10 10.5 23 2.5 3.2 2.8 6.45 M10

12 13 29 3 3.95 3.43 12.4 M12

14 15 35 3.5 4.65 4.04 21.6 M14

16 17 39 4 5.25 4.58 30.4 M16

Aspen Fasteners 4807 Rockside Road, Suite 400, Independence, OH 44131 USA

www.aspenfasteners.com | aspensales@aspenfasteners.com | 1-800-479-0056

Headquarters: Independence OH USA; Montreal QC Canada;

Distribution Centers: Boston MA; Chicago IL; Cincinnati KY; Dallas TX; Denver CO; Houston TX; Jersey City NJ; Los Angeles CA; Miami FL;

San Francisco CA; Seattle WA; Washington VA; Toronto ON; Calgary AB; Vancouver BC; Jiutepec (Temixco); Mexico City; Monterrey

All your fastener needs from a single source

d1 d2 h For

Weight

Nominal size s thread

kg/1000pcs

H14 h14 max. min. size

18 19 42 4.5 5.6 5.08 38.9 M18

20 21 45 5 6.4 5.6 48.8 M20

22 23 49 5.5 7.05 6.15 63.5 M22

24 25 56 6 7.75 6.77 92.9 M24

27 28 60 6.5 8.35 7.3 113 M27

30 31 70 7 9.2 8 170 M30

Metric DIN 6796 Conical Spring Washers for bolted connections are conical shaped washers that act as heavy duty spring

discs when loaded in the axial direction. They are designed to be used in bolted connections where they help prevent

loosening or unfastening of the connection due to thermal expansion/contraction and/or vibrational forces. Aspen Fasteners

offers the following sizes for immediate delivery from stock: Diameters ranging from M3 to M24 available in A2 and marine

grade A4 stainless steel. View available parts by clicking on the following link: DIN 6796 Conical Spring Washers

DIN (Deutsches Institut für Normung - German Institute for Standardization) standards are issued for a variety of

components including industrial fasteners as metric DIN 6796 Conical Spring Washers. The DIN standards remain

common in Germany, Europe and globally even though the transition to ISO standards is taking place. DIN standards

continue to be used for parts which do not have ISO equivalents or for which there is no need for standardization.

1) Mechanical properties of stainless steel for metric DIN 6796 Conical Spring Washers

Stainless steels can be divided into three groups of steel - austenitic, ferritic and martensitic. Austenitic steel is by

far the most common type (>90% of commercial fasteners). The steel groups and strength classes are designated by a four-

digit sequence of letters and numbers (eg A2-70) as shown in the following table. DIN EN ISO 3506 governs screws and nuts

made from stainless steel.

Screws, Nuts and Bolts

Tensile Tensile

Strength strength strength Dia range Nut Load

Steel group Steel grade N/mm2 PSI

class N/mm2

50 500 70,000 <=M39 500

Austenitic A2 and A4 70 700 100,000 <=M20 700

80 800 118,000 <=M20 800

The tensile stress is calculated with reference to the tensile stress area (see DIN EN ISO 3506-1979). Nuts to be paired

with same grade of stainless steel screws

Aspen Fasteners 4807 Rockside Road, Suite 400, Independence, OH 44131 USA

www.aspenfasteners.com | aspensales@aspenfasteners.com | 1-800-479-0056

Headquarters: Independence OH USA; Montreal QC Canada;

Distribution Centers: Boston MA; Chicago IL; Cincinnati KY; Dallas TX; Denver CO; Houston TX; Jersey City NJ; Los Angeles CA; Miami FL;

San Francisco CA; Seattle WA; Washington VA; Toronto ON; Calgary AB; Vancouver BC; Jiutepec (Temixco); Mexico City; Monterrey

All your fastener needs from a single source

Steel Property Made From Characteristics

group Strength

class

50 A1, A2 Soft; cold worked, turned and soft pressed fasteners

Austenitic 70 A2, A4 Cold worked, normal70,000

strength formed fasteners

fasteners

<=M39

80 A2, A4 Extreme cold worked, high strength, special applications

70,000

500

fasteners fasteners

<=M39

70,000

500

<=M39

500

2) Chemical composition of stainless steel metric DIN 6796 Conical Spring Washers

Grade USA Grade Material Material C Si Mn Cr Mo Ni

designation no. % ≤% ≤% % % %

17.5 8.0

≤

X 5Cr Ni 1810 1.4301 1.0 2.0 to - to

0.07

19.5 10.5

18.0 10

≤

A2 304 X 2 Cr Ni 1811 1.4306 1.0 2.0 to - to

0.03

20.0 12.0

17.0 11.0

≤

X 8 Cr Ni 19/10 1.4303 1.0 2.0 to - to

0.07

19.0 13.0

16.5 2.0 10.0

≤

X 5 Cr Ni Mo 1712 1.4401 1.0 2.0 to to to

0.07

18.5 2.5 13.0

A4 316

16.5 2.0 10

≤

X 2 Cr Ni Mo 1712 1.4404 1.0 2.0 to to to

0.03

18.5 2.5 13

Aspen Fasteners 4807 Rockside Road, Suite 400, Independence, OH 44131 USA

www.aspenfasteners.com | aspensales@aspenfasteners.com | 1-800-479-0056

Headquarters: Independence OH USA; Montreal QC Canada;

Distribution Centers: Boston MA; Chicago IL; Cincinnati KY; Dallas TX; Denver CO; Houston TX; Jersey City NJ; Los Angeles CA; Miami FL;

San Francisco CA; Seattle WA; Washington VA; Toronto ON; Calgary AB; Vancouver BC; Jiutepec (Temixco); Mexico City; Monterrey

All your fastener needs from a single source

3) Chemical composition of steel metric DIN 6796 Conical Spring Washers

CHEMICAL COMPOSITION LIMITS %

TEMPERING

PROPERTY

MATERIAL AND TREATMENT C P S TEMP ºC MIN.

CLASS

min. max. max. max.

4.6, 4.8, 5.8, 6.8 Low or medium carbon steel - 0.55 0.05 0.06 -

8.8 Medium carbon steel quenched, tempered 0.25 0.55 0.04 0.05 425

9.8 Medium carbon steel quenched, tempered 0.25 0.55 0.04 0.05 425

Medium carbon steel additives e.g. boron, Mn, Cr or

10.9 0.20 0.55 0.04 0.05 425

Alloy steel - quenched, tempered

12.9 Alloy steel - quenched, tempered 0.20 0.50 0.035 0.035 380

4) Mechanical properties of steel for metric DIN 6796 Conical Spring Washers

PROPERTY CLASS

8.8

MECHANICAL PROPERTY

4.8 5.6 5.8 6.8 Up to M Over M 9.8 10.9 12.9

16 16

Tensile Strength nom. 400 500 600 800 900 1000 1200

(Rm, N/mm²) min. 420 500 520 600 800 830 900 1040 1220

min. 130 155 160 190 250 255 290 320 385

Vickers Hardness

max 250 320 336 360 380 435

min. 124 147 152 181 319 242 266 295 353

Brinell Hardness

max. 238 385 319 342 363 412

min. HR 71 79 82 89 -

HRC - - - - 20 23 28 32 39

Rockwell Hardness

HR 95 99 -

max. HRC - - - - 32 34 37 39 44

Yield Stress ReL. nom. 320 300 400 480 -

N/mm² min. 340 300 420 480 -

Stress at permanent nom. - 640 720 900 1080

set limit N/mm² min. - 640 660 720 940 1100

Disclaimer

Dimensional data and technical information for metric DIN 6796 Conical Spring Washers was obtained from publicly available

sources and not acquired through standards agencies. It has been completed and compiled for reference purposes only;

where discrepancies are found they are subject to change without notice. Aspen Fasteners makes no warranties or

representations regarding the accuracy and validity of the compiled information and data. Contact the relevant standards

authorities for accurate and detailed information.

Aspen Fasteners 4807 Rockside Road, Suite 400, Independence, OH 44131 USA

www.aspenfasteners.com | aspensales@aspenfasteners.com | 1-800-479-0056

Headquarters: Independence OH USA; Montreal QC Canada;

Distribution Centers: Boston MA; Chicago IL; Cincinnati KY; Dallas TX; Denver CO; Houston TX; Jersey City NJ; Los Angeles CA; Miami FL;

San Francisco CA; Seattle WA; Washington VA; Toronto ON; Calgary AB; Vancouver BC; Jiutepec (Temixco); Mexico City; Monterrey

You might also like

- Visual Inspection - Sample Report For Spherical VesselDocument8 pagesVisual Inspection - Sample Report For Spherical Vesselkamal90% (10)

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekNo ratings yet

- Din 929 PDFDocument1 pageDin 929 PDFprathmesh238No ratings yet

- Metric Clearance Hole Chart PDFDocument2 pagesMetric Clearance Hole Chart PDFAkshay PremkumarNo ratings yet

- Ebook s104 Book1 E2i1 n9781848731622 l3Document168 pagesEbook s104 Book1 E2i1 n9781848731622 l3Julie Firth100% (1)

- Metric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityShrikant DeshmukhNo ratings yet

- Metric DIN 7980 SpecDocument4 pagesMetric DIN 7980 SpecGowtham VenkatNo ratings yet

- Dimensions of Metric Hex NutsDocument2 pagesDimensions of Metric Hex Nutsdidik sNo ratings yet

- DIN 433 SpecDocument4 pagesDIN 433 SpecChris StefanouNo ratings yet

- Metric DIN 125 Spec PDFDocument4 pagesMetric DIN 125 Spec PDFSandro CNo ratings yet

- Cap Screw-C Sunk DimensionsDocument1 pageCap Screw-C Sunk DimensionsTan Hui ChewNo ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- GMAW - Complete GuideDocument1 pageGMAW - Complete GuideVijay OfficialNo ratings yet

- Screws Nuts Washer SizesDocument5 pagesScrews Nuts Washer SizesNanang RisdiantoNo ratings yet

- Thread Tolerances For Screws and NutsDocument2 pagesThread Tolerances For Screws and NutsBill WhiteNo ratings yet

- Pages From Astm-A194-2011pdf - CompressDocument1 pagePages From Astm-A194-2011pdf - CompressMuthazhagan SaravananNo ratings yet

- Metric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless SteelDocument2 pagesMetric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless Steelrobert_candra_tarunaNo ratings yet

- DIN 934 Hex NutDocument1 pageDIN 934 Hex NutfastenersworldNo ratings yet

- Metric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionsDocument1 pageMetric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionssnorklingmonkeyNo ratings yet

- Metric Bolt Sizes and DimensionsDocument13 pagesMetric Bolt Sizes and DimensionsTHEARY THUNNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Metric DIN 985 Low Profile Nylon Insert Hexagon Stop Lock NutsDocument4 pagesMetric DIN 985 Low Profile Nylon Insert Hexagon Stop Lock Nutsvikram jainNo ratings yet

- DIN 7980 Spring Lock Washer - Fasteners ChinaDocument2 pagesDIN 7980 Spring Lock Washer - Fasteners ChinaHala Ibrahim El-BassyouniNo ratings yet

- Thread Size Sheet V2Document3 pagesThread Size Sheet V2mehrdadNo ratings yet

- Metric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.PDocument2 pagesMetric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.Pdinesh panchalNo ratings yet

- Metric DIN 127 SpecDocument5 pagesMetric DIN 127 SpecmahfuzNo ratings yet

- Hex Jam Nut Metric (ISO 4035)Document1 pageHex Jam Nut Metric (ISO 4035)Abu IrfanNo ratings yet

- Iso 965 2 1998Document8 pagesIso 965 2 1998Gerald CelisNo ratings yet

- Metric DIN 916 SpecDocument5 pagesMetric DIN 916 SpecJUAN CARDONANo ratings yet

- Din125 WasherDocument2 pagesDin125 WasherHieu TranvanNo ratings yet

- Metric Clearance Hole Chart PDFDocument2 pagesMetric Clearance Hole Chart PDFMeleti Meleti MeletiouNo ratings yet

- Metric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDocument5 pagesMetric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDHEERAJ413No ratings yet

- Metric DIN 6926 SpecDocument4 pagesMetric DIN 6926 Spec叶开No ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- Metric Hex PDFDocument2 pagesMetric Hex PDFCarlos Eduardo Cardenas SochaNo ratings yet

- Nuts DimDocument2 pagesNuts DimrezaNo ratings yet

- Metric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PDocument2 pagesMetric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PjoseocsilvaNo ratings yet

- Metric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PDocument2 pagesMetric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PnothingNo ratings yet

- Metric DIN 432 SpecDocument4 pagesMetric DIN 432 SpecivanNo ratings yet

- Metric DIN 6319 SpecDocument6 pagesMetric DIN 6319 SpecPavanNo ratings yet

- BN 8699Document2 pagesBN 8699Foocheong LoiNo ratings yet

- Metric DIN 7349 SpecDocument6 pagesMetric DIN 7349 SpecANIRBANNo ratings yet

- Metric, Hex Thin Nuts, DIN 936, Plain: Page 1 of 1 REV-03 Date: October 9, 2015 M.936.PDocument1 pageMetric, Hex Thin Nuts, DIN 936, Plain: Page 1 of 1 REV-03 Date: October 9, 2015 M.936.PSatnam Rachna FastenersNo ratings yet

- Metric Schnorr Lock Washer SpecDocument3 pagesMetric Schnorr Lock Washer SpecGatito FelinoNo ratings yet

- Metric DIN 7984 Low Profile Head Hexagon Socket Cap Screws: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 7984 Low Profile Head Hexagon Socket Cap Screws: Visit Our For Product AvailabilityTugay ArıçNo ratings yet

- Metric DIN 963 SpecDocument5 pagesMetric DIN 963 SpecKI FastenersNo ratings yet

- Tables of Mechanical FastenersDocument3 pagesTables of Mechanical Fastenersmiwep18125No ratings yet

- RATV - Socket Head Fasteners - MetricDocument1 pageRATV - Socket Head Fasteners - MetricGustavo CarvalhoNo ratings yet

- Din 985 - ParlockDocument1 pageDin 985 - Parlockmaicon sulivanNo ratings yet

- Hexalobular (6 Lobe) Socket Pan Head Thread Forming Screws Type C, Metric ThreadDocument3 pagesHexalobular (6 Lobe) Socket Pan Head Thread Forming Screws Type C, Metric ThreadRodrigo AugustoNo ratings yet

- Hex Key Chart: EnglishDocument1 pageHex Key Chart: EnglishRoss EdwardNo ratings yet

- Mechanical Thread TablesDocument38 pagesMechanical Thread TablesbarcristianNo ratings yet

- Tourqe Value 8.8Document1 pageTourqe Value 8.8MAKNo ratings yet

- Bolt & Screw DetailsDocument6 pagesBolt & Screw Detailsjee01No ratings yet

- Metric DIN 137 SpecDocument5 pagesMetric DIN 137 Specpradipbhosale81No ratings yet

- Din 9021 Specifications: Bucket Elevator PartsDocument2 pagesDin 9021 Specifications: Bucket Elevator PartsstefanbrindusaNo ratings yet

- Hex Key ChartDocument1 pageHex Key ChartMassimoNo ratings yet

- Grosime PereteDocument1 pageGrosime Peretebogd32000No ratings yet

- Hex Key ChartDocument1 pageHex Key Charter lop100% (1)

- Metric MSThreadDocument2 pagesMetric MSThreadarvindspakNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- The Art of Sculpture Welding: From Concept to CreationFrom EverandThe Art of Sculpture Welding: From Concept to CreationNo ratings yet

- Easy Genset Control: OperationDocument51 pagesEasy Genset Control: OperationdonothearNo ratings yet

- Read Jujutsu Kaisen Chapter 243 Manga Online - Read Jujutsu Kaisen Manga OnlineDocument19 pagesRead Jujutsu Kaisen Chapter 243 Manga Online - Read Jujutsu Kaisen Manga OnlinemarileyserNo ratings yet

- CAT 2023 Composite Score and Calls Predictor - AmiyaDocument69 pagesCAT 2023 Composite Score and Calls Predictor - AmiyaHarsimran SinghNo ratings yet

- Kingspan Kooltherm K7Document1 pageKingspan Kooltherm K7Diaconu FlorinNo ratings yet

- Executive Fellow Program in Management: Information BrochureDocument3 pagesExecutive Fellow Program in Management: Information Brochureaniruddh nainNo ratings yet

- Glimpses of Consumer Behaviour Towards 2020Document196 pagesGlimpses of Consumer Behaviour Towards 2020Najeemudeen K.P100% (1)

- DokasetDocument52 pagesDokasetAnupam GhoshNo ratings yet

- Premier Collection: Whirlpool Spa Owner's ManualDocument24 pagesPremier Collection: Whirlpool Spa Owner's ManualJomari PecsonNo ratings yet

- Crodasinic LS LeafletDocument2 pagesCrodasinic LS LeafleticraoNo ratings yet

- Otc 31506 MsDocument10 pagesOtc 31506 MsAdriana UstarizNo ratings yet

- Concrete & Shuttering Working-R1Document20 pagesConcrete & Shuttering Working-R1vivekNo ratings yet

- Ethernet Gersis GMBH DsDocument93 pagesEthernet Gersis GMBH DsMuhammad AdeelNo ratings yet

- Principles of Human Resource Management 16 e Bohlander - SnellDocument36 pagesPrinciples of Human Resource Management 16 e Bohlander - SnellAmirul AswadNo ratings yet

- LEM Active P SeriesDocument8 pagesLEM Active P Seriesjuan manuel sierra solisNo ratings yet

- Shiny PDFDocument2 pagesShiny PDFBhaktiNo ratings yet

- Optical Character Recognition Research: IndexDocument6 pagesOptical Character Recognition Research: IndexPhi Thiện HồNo ratings yet

- Ameyo Product BrochureDocument8 pagesAmeyo Product BrochureSudhanshu Gupta100% (1)

- Triton Wireline ValvesDocument2 pagesTriton Wireline ValvesrezaNo ratings yet

- 06xa SDocument2 pages06xa SOscarNo ratings yet

- Varistores-D V680K14 0 V680K14 VARISTOR DOCUMENTACIÓNDocument12 pagesVaristores-D V680K14 0 V680K14 VARISTOR DOCUMENTACIÓNAlberto Morillo ParelladaNo ratings yet

- Company Profile: A B o U T U SDocument3 pagesCompany Profile: A B o U T U SRaghavendar Reddy BobbalaNo ratings yet

- Strategic Entrepreneurship: Hitt - Chapter 13Document32 pagesStrategic Entrepreneurship: Hitt - Chapter 13E Kay MutemiNo ratings yet

- Progress ReportDocument12 pagesProgress ReportNOKHAIZ HAMMAD 2021-BS-MLS-007No ratings yet

- 04 JP - WeldingDocument8 pages04 JP - WeldingShubhamShuklaNo ratings yet

- Types of Video Cameras Vid 1Document8 pagesTypes of Video Cameras Vid 1Adelite sabiriNo ratings yet

- Bpme 6093 Modenas Combine LastDocument12 pagesBpme 6093 Modenas Combine LastjibamcomotNo ratings yet

- Individual Work Plan - TeachersDocument9 pagesIndividual Work Plan - TeachersMarinelle OpeñaNo ratings yet

- Heavy Duty BrochureDocument16 pagesHeavy Duty BrochureАлексей ГордиенкоNo ratings yet