Professional Documents

Culture Documents

Improvement in Mechanical Efficiency in

Improvement in Mechanical Efficiency in

Uploaded by

angelog.ambiental3792Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Improvement in Mechanical Efficiency in

Improvement in Mechanical Efficiency in

Uploaded by

angelog.ambiental3792Copyright:

Available Formats

IJSRD - International Journal for Scientific Research & Development| Vol.

3, Issue 09, 2015 | ISSN (online): 2321-0613

Improvement in Mechanical Efficiency in Tesla Turbine by the

Employment of Carbon Fiber Disc

Akshaykumar Kakadiya1 Akhil Chhaniyara2

1

B.E Student 2Mechanical Maintenance Engineer

1,2

Department of Mechanical Engineering

1

G.K. Bharad Institute Of Engineering, (G.T.U) – Ahmedabad 2Essar Oil Limited - Jamnagar

Abstract— This paper enlightens about the use of Carbon

Fibers as a improvement material in the Tesla Turbine II. DISC TYPE TESLA TURBINE

instead of conventionally used blade materials. The main It is intended that compressed air be used as the medium for

convolution behind this paper reveals about the Mechanical this example, and suitable connections and an inlet nozzle

efficiency to be improved. In the case of the conventional are incorporated into the stator. Lubrication is from a

turbines the mechanical efficiency was low upto the great reservoir by a drip feed on an absolute loss system, as the

extent because of poor aerodynamic design for the blades as machine is not intended as a continuously running unit, but

well as low quality blade material. The improvement can be as a development item for a larger scale evaluation of the

laid upon by enhancing the blades which can sustain upto operating principles. The compressed air is at 80 p.s.i., and

higher temperatures. The main purpose behind the use of the performance is expected to be in excess of 100 h.p.

Carbon Fibre dics is to improve the strength of disc since the Provision is made in the design to operate the machine using

material has good advantages over the conventional blade gas generated by a combustion system, but it is only

material. The material has high stiffness, high tensile intended to be run for very short periods when operating

strength and other radiant properties. Here the experimental with this medium. Air for the combustion system is

investigation is laid upon and the analysis is employed to provided by an external air source, either an independent air

compare the properties with the conventional blade material. compressor, or from a works air network. The air should be

Key words: Carbon Fiber Disc, Tesla Turbine, Mechanical free from excess condensate, and from oil contamination.

Efficiency, High Tensile Strength, Prony Brake The air connection is shown on the drawing, and should

Dynamometer, Experimental Procurement incorporate a shut-off valve, preferably of the ball type. Fuel

is supplied through the union on the adaptor in the stator as

I. INTRODUCTION shown on the drawing, and delivers the fuel through the

Number of turbine have been developed which work needle valve shown. It then mixes with the air from the

efficiently with steam like: compressor in the combustor tube, where it is ignited, using

1) De Laval turbine: Impulse turbine which is less expensive the igniter, which is either an electric glow plug or similar

and not pressure proof. device. After the initial combustion, the process becomes

2) Pressure compound turbine: Auguste Rateau developed a self-sustaining. The heated gas follows the same path as that

pressure compounded impulse turbine using the de Laval previously described, namely a spiral circuit round the disc

principle as early as 1900. Today highly efficient and face, and exhausts through the ports as illustrated. The air

various size of steam hydraulic turbine available. But there pressure should be at 50 to 60 p.s.i. (3.4 to 4.0 bar), and the

are different design different capacity and different types of fuel supply, which should be either kerosene or propane, at

blades for hydraulic, wind, steam turbine. In 1910 Nikola 100 to 150 p.s.i. (7.0 to 10.0 bar).Here different type of

tesla has invented a ROTARY DISC TURBINE which can medium used like compressed air, gas and steam, this also

use to develop power from air, water, steam, or mixture of effect performance and space between discs. The machine

it. The Croatian born inventor and engineer Nikola Tesla described above aimed to develop power 100hp but it was

is probably best known for his invention of the coil and claimed that it develop 3 times power than aimed i.e. 330

the induction motor. However, in 1910, a dual patent was hp.

filed, under British Patent 24001, for a Rotary Disk type

air compressor and turbine engine. III. DESIGN AND MANUFACTURING OF PARTS

These machines were similar in principle, and Take rod of Aluminum having diameter 13 mm. As shown

comprise a series of thin discs, set close together but in figure turns all cross section by turning on lathe.

separated by spacing washers, mounted on a shaft to form Threading done by special threading tool. Transparent

a rotor. This rotor is mounted in a housing, or stator, in acrylic material selected as stator cover and support. 0.511

the form of a tube, and provided with end plates, which inch dia. hole drilled on each plate to provide support to

contain the bearings. The compressor differs from the bearing.

engine in that the stator takes the form of a spiral As shown in figure we design rectangular cross

volute, whereas that of the engine is circular in profile. section nozzle to cover all discs. 10mm diameter hole drilled

The direction of flow of the media, air or gas also differs. in nozzle and internally threaded on both side for pipe

The patent also identified other applications of the connection. By using milling machine extra material on

principal, with a motor unit and as a pump for liquids. lower portion removed and converging cross section created

Working fluid Steam as shown above. Thick x-ray sheet used as a spacer between

Horse power 100 HP two discs. Internal hole cut by using punch and external

Rotor diameter 18 “ diameter created

Table 1: Conventional Results

All rights reserved by www.ijsrd.com 1031

Improvement in Mechanical Efficiency in Tesla Turbine by the Employment of Carbon Fiber Disc

(IJSRD/Vol. 3/Issue 09/2015/253)

Fig. 1: Fiber Disc Fig. 6: Plastic Stator.

Fig. 2: Aluminium Shaft

Fig. 7: Assembly of all the parts

Fig. 3: Aluminium Nozzle Fig. 8: Prony Brake Dynamometer

Part Material Size

Stator Plastic 3.8”dia;2”width

Stator cover Acrylic 5.2”*6.4”;0.0478”width

Nozzle Aluminum 1.5”length bar

Washer X-ray paper 0.872”OD 0.405 ID

Disc Fiber 3.5” dia;0.036”width

Shaft Al 0.5”dia;5”length rod

Table 2

Fig. 4: Washer

IV. METHOD FOR ASSEMBLY

Take shaft as shown above. Insert spacer and disc one by

one and tight it by nut. Cover assembly by stator. Mount

bearing on shaft. Connect stator cover with stator by using

bolt and fix bearing in stator cover. Mount nozzle at top of

stator cover. Connect whole assembly with base.

Fig. 5: Acrylic Stator Cover

All rights reserved by www.ijsrd.com 1032

Improvement in Mechanical Efficiency in Tesla Turbine by the Employment of Carbon Fiber Disc

(IJSRD/Vol. 3/Issue 09/2015/253)

V. EXPERIMENTAL TESTING OF TURBINE B. On Load Condition:

A. Experimental Setups At No Load Condition:

1) Connect setup with compressor outlet. 1) Connect setup with outlet.

2) Set pressure 4 kg/cm2. 2) Set pressure 4 kg/cm2.

3) Decrease pressure continuously at 3, 2.5, 2, 1.5,1 3) Connect Prony Break Dynamometer with shaft.

kg/cm2. 4) Decrease pressure continuously at 3, 2.5, 2, 1.5,1

4) Measure RPM by using Tachometer at Each kg/cm2.

pressure. 5) Measure RPM in Tachometer and load by using

Dynamometer and weight scale.

6) Table1, 2, 3 shows reading for on load condition.

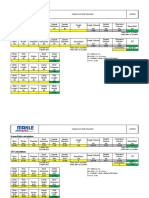

VI. RESULT TABLES-1, 2, 3

Weight Distance Torque Torque Power

pressure (bar) rpm

(gm) (cm) (gm cm) (Nm) (W)

0.98 0 25 10 250 0.024525 0

1.47 0 35 10 350 0.034335 0

1.96 400 35 10 350 0.034335 1.44207

2.45 2500 45 10 450 0.044145 11.5880625

2.94 4500 46 10 460 0.045126 21.322035

Table 3

Weight Distance Torque Torque Power

pressure (bar) Rpm

(gm) (cm) (gm cm) (Nm) (W)

0.98 0 27 10 270 0.026487 0

1.47 2500 23 10 230 0.022563 5.9227875

1.96 4200 28 10 280 0.027468 12.113388

2.45 4800 30 10 300 0.02943 14.83272

2.94 5600 33 10 330 0.032373 19.035324

Table 4

Weight Distance Torque Torque Power

Pressure (bar) Rpm

(gm) (cm) (gm cm) (Nm) (W)

0.98 0 18 10 180 0.017658 0

1.47 2100 13 10 130 0.012753 2.8120365

1.96 4000 16 10 160 0.015696 6.59232

2.45 5000 24 10 240 0.023544 12.3606

2.94 5400 24 10 240 0.023544 13.349448

Table 5

A. Result Table: Free Rotation Of Turbine (Without Load):

Weight Distance Torque Torque Power

pressure (bar) rpm

(gm) (cm) (gm cm) (Nm) (W)

0.98 5000 0 10 0 0 0

All rights reserved by www.ijsrd.com 1033

Improvement in Mechanical Efficiency in Tesla Turbine by the Employment of Carbon Fiber Disc

(IJSRD/Vol. 3/Issue 09/2015/253)

1.47 6200 0 10 0 0 0

1.96 6800 0 10 0 0 0

2.45 7000 0 10 0 0 0

2.94 8500 0 10 0 0 0

Table 6

B. Graphical Representation: [6] www.instructtables.com

[7] www.opensourceecology.org

1) Torque-RPM:

Fig. 11: Torque-RPM

Fig. 12: Power-RPM

VII. CONCLUSION

The concept of Tesla turbine was verified by physically

constructing it within available resources. From engineering

point of view it was attempted to understand the phenomena

and characteristics. It is felt that the turbine made here can

be refined further with optimized parameters and can be

placed for study in turbo lab. Experimental reading shows

that in tesla turbine with increase in inlet pressure rotation of

shaft, torque and output power increase. At lower pressure

because of low velocity of fluid, rotation of turbine is zero

but torque increase due to zero velocity of shaft. High

rotational speed can be obtained by using this machine at

lower pressure compare to reciprocating machine. In case of

our turbine we got 8500 RPM at only 3 kg/cm2 pressure,

but because of higher rotational speed of disc it may cause

damage the disc at its center because of yielding and

elasticity of material this problem can solved by using

higher tensile strength material like steel. Graph of power-

speed shows that power varies linearly with speed.

REFERENCES

[1] Vincent R. Gingery- Building the Tesla turbine.

[2] W.M.J. Cairns- The Tesla Disc Turbine.

[3] G.F. Round- Incompressible Flow Turbo machines.

[4] www.bookoz.org

[5] www.wikipedia.net

All rights reserved by www.ijsrd.com 1034

You might also like

- CX-5 Technical Guide Workshop ManualDocument1,910 pagesCX-5 Technical Guide Workshop ManualRafael Olave67% (6)

- A13 HATCHBACK Engine Management System System Manual For M7.8Document47 pagesA13 HATCHBACK Engine Management System System Manual For M7.8Daly Poblete HenriquezNo ratings yet

- 3.2 L 177 KW Motronic, Engine Code BFHDocument19 pages3.2 L 177 KW Motronic, Engine Code BFHJohn StauntonNo ratings yet

- 5 Pierburg SingleDocument8 pages5 Pierburg Singlevanapeer100% (4)

- Manual de Mantenimiento TB504 MotorDocument169 pagesManual de Mantenimiento TB504 MotorCarlos RamirezNo ratings yet

- Mahindra Parts CatalogDocument91 pagesMahindra Parts CatalogTara ChandNo ratings yet

- Instalacion 3rz-FeDocument5 pagesInstalacion 3rz-FeAngel Lira100% (3)

- ManualDocument7 pagesManualjohnjohn72No ratings yet

- Nasa Technical Note NASA TN D-4630Document18 pagesNasa Technical Note NASA TN D-4630이주성No ratings yet

- The Design and Analysis of Gas Turbine Blade: Research PaperDocument3 pagesThe Design and Analysis of Gas Turbine Blade: Research PaperSai SushmaNo ratings yet

- Topic No. 6 TURBINE ASSEMBLY WADocument8 pagesTopic No. 6 TURBINE ASSEMBLY WASamarth SNo ratings yet

- Articl2 PDFDocument18 pagesArticl2 PDFAnonymous 80p9OVNo ratings yet

- Prototyping of Radial and Thrust Air Bearing For Micro Gas TurbineDocument6 pagesPrototyping of Radial and Thrust Air Bearing For Micro Gas TurbineAlex CooperNo ratings yet

- Study OF Operation OF Tesla Turbine: International Journal of Advance Research in Engineering, Science & TechnologyDocument5 pagesStudy OF Operation OF Tesla Turbine: International Journal of Advance Research in Engineering, Science & Technologyreventhk465No ratings yet

- Heat Loss Comparision Between Leading Edge Groove and Conventional Pad Bearing.Document7 pagesHeat Loss Comparision Between Leading Edge Groove and Conventional Pad Bearing.Dharmendra JainNo ratings yet

- Lit 14 ASEE - 2009-TB3 - 1Document9 pagesLit 14 ASEE - 2009-TB3 - 1kumarpskNo ratings yet

- 5Document15 pages5Ya gamiNo ratings yet

- A Research Paper On Design and Analysis of Shaftless Steam TurbineDocument5 pagesA Research Paper On Design and Analysis of Shaftless Steam TurbineEditor IJTSRDNo ratings yet

- Model Analysis of Gas Turbine Blades by Varying Fillet Radius With MaterialsDocument5 pagesModel Analysis of Gas Turbine Blades by Varying Fillet Radius With Materialsseventhsensegroup100% (1)

- United States Patent: Daywalt (45) Date of Patent: May 17, 2011Document4 pagesUnited States Patent: Daywalt (45) Date of Patent: May 17, 2011Orkhon GanchimegNo ratings yet

- Wemco CeldasDocument18 pagesWemco Celdasfornelas75% (4)

- 9 Wind DY1023Document11 pages9 Wind DY1023Nanda AnandaNo ratings yet

- FrommDocument13 pagesFrommSherjanNo ratings yet

- Static and Thermal Analysis of Gas Turbine Rotor BladeDocument15 pagesStatic and Thermal Analysis of Gas Turbine Rotor BladeJUKANTI VISHWASNo ratings yet

- Experimental Method: 1. The Wind TunnelDocument7 pagesExperimental Method: 1. The Wind TunnelWalid MohammedNo ratings yet

- Vertical Axis Wind Turbine Project ReportDocument18 pagesVertical Axis Wind Turbine Project ReportJace Thompson100% (2)

- Study On Design of Casing of Steam TurbineDocument3 pagesStudy On Design of Casing of Steam Turbinesevero97No ratings yet

- Shih 2008Document9 pagesShih 2008Abdellah BenaribaNo ratings yet

- Sagar - Report On Internship - 12115041Document18 pagesSagar - Report On Internship - 12115041Anonymous KzLOVgUcB0No ratings yet

- (IJET-V2I3 - 1P3) Authors: G.Siva Prasad K.Dinesh Achari E.Dileep Kumar Goud M.Nagaraju K.SrikanthDocument7 pages(IJET-V2I3 - 1P3) Authors: G.Siva Prasad K.Dinesh Achari E.Dileep Kumar Goud M.Nagaraju K.SrikanthInternational Journal of Engineering and TechniquesNo ratings yet

- Chapter 6-Equipment Design (Production of Lactic Acid From Sugarcane Bagasse)Document78 pagesChapter 6-Equipment Design (Production of Lactic Acid From Sugarcane Bagasse)kennethmsorianoNo ratings yet

- Wind Rotor Blade Construction - ITDG PDFDocument27 pagesWind Rotor Blade Construction - ITDG PDFDavid Merayo FernándezNo ratings yet

- automatedShockTube Fuller19Document9 pagesautomatedShockTube Fuller19ennioNo ratings yet

- Design Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeDocument6 pagesDesign Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeNeeraj SamadhiyaNo ratings yet

- Micro-Scale Radial-Flow Compressor Impeller Made of Silicon Nitride - Manufacturing and PerformanceDocument10 pagesMicro-Scale Radial-Flow Compressor Impeller Made of Silicon Nitride - Manufacturing and PerformanceKerrie SpenceNo ratings yet

- .....Document14 pages.....55MESuman sahaNo ratings yet

- Unique Online Leak Repair TechniquesDocument8 pagesUnique Online Leak Repair TechniquesMario Alfredo MunafóNo ratings yet

- Wind Turbine Building For Saving Home Electricity: Mohammed Jasim Mohammed, Salam MohammedDocument8 pagesWind Turbine Building For Saving Home Electricity: Mohammed Jasim Mohammed, Salam MohammedyunanNo ratings yet

- Putra Adnan 2018 J. Phys. Conf. Ser. 1005 012026Document13 pagesPutra Adnan 2018 J. Phys. Conf. Ser. 1005 012026uma shankarNo ratings yet

- Make A Pulse Jet Engine, (Scanned From 1958 Plans) - 17 Steps - InstructablesDocument20 pagesMake A Pulse Jet Engine, (Scanned From 1958 Plans) - 17 Steps - Instructablesjames gNo ratings yet

- Power Calculations For Tesla TurbineDocument10 pagesPower Calculations For Tesla TurbineNajam Ul QadirNo ratings yet

- Unit 15 Aircraft Propulsion AssignmentDocument18 pagesUnit 15 Aircraft Propulsion AssignmentTerrence Owens50% (2)

- Manual3 PDFDocument8 pagesManual3 PDFemir_delic2810No ratings yet

- Ecway Technologies: Design and Fabrication of Cyclone Seperator Using Vane PumpDocument9 pagesEcway Technologies: Design and Fabrication of Cyclone Seperator Using Vane Pumpieee4mybusinessonly100% (1)

- Konference KDP 2007 Bloudicek PetrDocument6 pagesKonference KDP 2007 Bloudicek PetrMitmaNo ratings yet

- Special Problems Aerospace ManufacturingDocument10 pagesSpecial Problems Aerospace ManufacturingJoaquim Villén BensenyNo ratings yet

- Pressurized Water ReactorsDocument23 pagesPressurized Water ReactorsMario AndreiNo ratings yet

- 0001Document15 pages0001Jhohan Franklin Meza LimaymantaNo ratings yet

- Vertical Axis Wind Turbine For Highway Application: Saurabh Arun Kulkarni & Prof. M.R. BirajdarDocument4 pagesVertical Axis Wind Turbine For Highway Application: Saurabh Arun Kulkarni & Prof. M.R. BirajdarViner VamsiNo ratings yet

- IJRET ManuscriptTemplateDocument9 pagesIJRET ManuscriptTemplateGopal krishnaNo ratings yet

- The Design of A Test Rig and Study of The Performance and Efficiency of A Tesla Disc TurbineDocument15 pagesThe Design of A Test Rig and Study of The Performance and Efficiency of A Tesla Disc Turbinearturo ortegaNo ratings yet

- Main Components of Steam TurbineDocument31 pagesMain Components of Steam TurbineYaser AkarNo ratings yet

- Aerodynamic Optimization and Open Field Testing of A 1 KW Vertical-Axis Wind TurbineDocument12 pagesAerodynamic Optimization and Open Field Testing of A 1 KW Vertical-Axis Wind TurbineaenergieNo ratings yet

- UC-3000 3inch ManualDocument16 pagesUC-3000 3inch ManualwortserNo ratings yet

- My - Project EzejiDocument13 pagesMy - Project EzejiJoseph IsraelNo ratings yet

- Jet Engine Fan Blade Containment Using An Alternate GeometryDocument9 pagesJet Engine Fan Blade Containment Using An Alternate GeometryMikecz JuliannaNo ratings yet

- 46 EB9 CFFD 01Document11 pages46 EB9 CFFD 01agmateoNo ratings yet

- Experimental Thermal and Fluid Science: Kazumasa Ameku, Baku M. Nagai, Jitendro Nath RoyDocument8 pagesExperimental Thermal and Fluid Science: Kazumasa Ameku, Baku M. Nagai, Jitendro Nath RoyBhagyashree KadaleNo ratings yet

- Guha Smiley IMechE PartA 2010 Tesla TurbineDocument18 pagesGuha Smiley IMechE PartA 2010 Tesla Turbineemir__dNo ratings yet

- Investigation of Diesel Generator Shaft and BearinDocument22 pagesInvestigation of Diesel Generator Shaft and BearinMohd Shahrom IsmailNo ratings yet

- Notebook ScifairDocument40 pagesNotebook Scifairapi-331985309No ratings yet

- GT2006 90992Document15 pagesGT2006 90992lizfireupNo ratings yet

- Finite Element Analysis of Connecting Rod Using Composite MaterialDocument14 pagesFinite Element Analysis of Connecting Rod Using Composite MaterialIJRASETPublicationsNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- A&F Pump V10-H Model Number Creation ChartDocument3 pagesA&F Pump V10-H Model Number Creation ChartPromagEnviro.comNo ratings yet

- PsaDocument5 pagesPsaFrancisco Molina CardenasNo ratings yet

- SupraguideDocument9 pagesSupraguidevolrothNo ratings yet

- Worx125 Service Manual2Document165 pagesWorx125 Service Manual2doctee100% (1)

- Tecumseh Fast Moving Parts Guide PDFDocument50 pagesTecumseh Fast Moving Parts Guide PDFWilliam WebbNo ratings yet

- High-Efficiency Nox and PM Exhaust Emission Control For Heavy-Duty On-Highway Diesel Engines - Part TwoDocument14 pagesHigh-Efficiency Nox and PM Exhaust Emission Control For Heavy-Duty On-Highway Diesel Engines - Part TwoSantosh TrimbakeNo ratings yet

- Unit 5 - Design of IC Engine ComponentsDocument5 pagesUnit 5 - Design of IC Engine ComponentsVikas RathodNo ratings yet

- Use of Carburetor Heat Control PDFDocument2 pagesUse of Carburetor Heat Control PDFcalibranrNo ratings yet

- Johnson Outboard Power PacksDocument6 pagesJohnson Outboard Power PacksJSMarine Parts ChinaNo ratings yet

- Toyota Engine 7M-GE 7M-GTEDocument335 pagesToyota Engine 7M-GE 7M-GTEАндрей Евдокимов0% (1)

- OMC Cooling System PartsDocument13 pagesOMC Cooling System PartswguenonNo ratings yet

- Amsoil European Car Formula 5W-30 TDSDocument2 pagesAmsoil European Car Formula 5W-30 TDSwwwglroNo ratings yet

- ON I-Vtec Engine: A SeminarDocument19 pagesON I-Vtec Engine: A Seminarakshay gopalNo ratings yet

- Euro III BH117L Engine DL08 Operation Maintenance ManualDocument221 pagesEuro III BH117L Engine DL08 Operation Maintenance ManualLeticia Naranjo100% (5)

- Workshop Manual 2G e Motores HatzDocument161 pagesWorkshop Manual 2G e Motores HatzLuis Enrique Peña100% (3)

- AISAN Carb DiagramDocument2 pagesAISAN Carb DiagramSolomon XI100% (1)

- TYREDocument89 pagesTYREkaswade BrianNo ratings yet

- Chap4 - Air Standard CycleDocument38 pagesChap4 - Air Standard CycleHabiba AmrNo ratings yet

- B&S Teileliste - 12F800 - 12F809Document20 pagesB&S Teileliste - 12F800 - 12F809ThorbenWegenerweb.deNo ratings yet

- Rover 14CUX Hot Wire Mass Flow EFI - Service and TroubleshootingDocument20 pagesRover 14CUX Hot Wire Mass Flow EFI - Service and TroubleshootingClint CooperNo ratings yet

- c18 Parts Manual600kvaDocument156 pagesc18 Parts Manual600kvankr4726923No ratings yet

- CR CalcDocument7 pagesCR Calcprj57No ratings yet