Professional Documents

Culture Documents

Mnl-Wtp-00-Sdl-00001-Rev02 General Specification

Mnl-Wtp-00-Sdl-00001-Rev02 General Specification

Uploaded by

jan jhonnel punzalanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mnl-Wtp-00-Sdl-00001-Rev02 General Specification

Mnl-Wtp-00-Sdl-00001-Rev02 General Specification

Uploaded by

jan jhonnel punzalanCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12

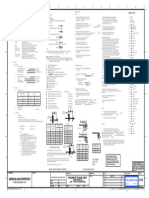

PLOT PLAN

GENERAL NOTES C8. BEFORE PLACING CONCRETE, CARE SHALL BE TAKEN THAT EMBEDDED ITEMS (ANCHOR BOLTS, PLATES, PIPES

SEISMIC LOAD SLEEVES, ETC.) ARE IN POSITION AND SECURELY FASTENED IN PLACE

GENERAL

C9. BEFORE GROUTING, THE CONCRETE SURFACE SHALL BE PROPERLY SCABBLED & CLEARED OF ALL DEFECTIVE

THE FINAL DBE RESPONSE SPECTRUM SHALL BE TAKEN AS THE MINIMUM ENVELOPE BETWEEN THE RESULTING

G1. THIS NOTES SHALL BE READ IN CONJUNCTION WITH THE NOTES OF EACH DRAWING. IN CONCRETE, TAITENCE, OIL, GREASE, OTHER CHEMICALS & DIRT. THE CONCRETE SURFACE SHALL BE ALSO BE WELL

RESPONSE SPECTRUM OF THE SIMULATED GROUND MOTIONS AND 80% OF THE NSCP 2015 SECTION 208

CASE OF DISCREPANCY BETWEEN DESIGN DRAWINGS, TECHNICAL SPECIFICATIONS AND SOAKED IN CLEAN WATER.

CODE-PRESCRIBED SPECTRUM.

A STANDARD GENERAL NOTES, THE PRIORITY SHALL BE AS FOLLOWS:

C10. GROUT SHALL CONFORM TO THE REQUIREMENTS ASTM C476 FOR COARSE GROUT, GROUT SHALL ATTAIN A

FIRST: DESIGN DRAWINGS AND NOTES OF EACH ONE

SEISMIC ZONE 4 MINIMUM COMPRESSIVE STRENGTH OF 2000 PSI AT 28 DAYS. AGGREGATES FOR COARSE GROUT SHALL CONFORM

SECOND: STANDARD GENERAL NOTES AND TECHNICAL SPECIFICATIONS.

SEISMIC SOURCE TYPE A: FAULTS THAT ARE CAPABLE OF PRODUCING LARGE MAGNITUDE EVENTS THAT HAVE A TO ASTM C404.

G2. NOT SCALE FROM DRAWINGS HIGH RATE OF SEISMIC ACTIVITY

C11. PRIOR TO PLACING CONCRETE, REINFORCING BARS, EMBEDDED PLATE, ANCHOR BOLTS AND OTHER CONCRETE

G3. ALL DRAWIGNS SALL BE CONSIDERED TOGETHER WITH THE DESIGN SPECIFICATIONS AND SEISMIC ZONE FACTOR Z=0.40. EMBEDMENTS SHALL BE WELL SECURED IN POSITION.

APPLICABLE CODES

G4. GENERAL ABBREVIATIONS SPECTRAL ACCELERATION Sa (g) SPECTRAL ACCELERATION Sa (g)

T (s) T (s) REINFORCING STEEL

TOC - TOP OF CONCRETE LEVEL 5% Damping 0.5% Damping 5% Damping 0.5% Damping

BOC - BOTTOM OF CONCRETE LEVEL R1. BAR REINFORCING STEEL SHALL BE DEFORMED STEEL BARS GRADE 40 OR ITS EQUIVALENT UNDER PNS‐49 FOR

TOS - TOP OF STEEL LEVEL 0 0.352 0.352 1.274 0.446 0.789

BAR SIZES 10MM AND LOWER, AND GRADE 60 OR ITS EQUIVALENT UNDER PNS‐49 FOR BAR SIZES 12MM AND HIGHER

TOG - TOP OF GRATING / TOP OF GROUT LEVEL 0.029 0.484 0.624 1.356 0.422 0.744

EL- ELEVATION PNS-49

0.058 0.616 0.936 1.443 0.409 0.720 REINFORCED BARS

0.087 0.748 1.251 1.535 0.387 0.678 DIA(MM) AREA(CM2) WEIGHT(KG/M)

CODES AND STANDARS

6 0.28 0.22

0.116 0.880 1.576 1.634 0.350 0.610

B C1. THE DESIGN SHALL BE IN ACCORDANCE WITH THE FOLLOWING INTERNATIONAL 10 0.79 0.616

DOCUMENTS AND STANDARDS WHERE APPLICABLE: 0.582 0.880 1.652 1.738 0.301 0.523 12 1.13 0.88

- NATIONAL BUILDING CODE OF THE PHILIPPINES 16 2.01 1.58

0.750 0.683 1.238 2.0 0.256 0.439

- NATIONAL STRUCTURAL CODE OF THE PHILIPPINES VOL 1&2. 2015

- ASCE 7-16 MINIMUM DESIGN LOADS FOR BUILDINGS AND OTHER STRUCTURES 20 3.14 2.47

0.825 0.644 1.163 2.5 0.205 0.345

- ACI 318-19 BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETE 25 4.91 3.85

- ACI 350-06 CODE REQUIREMENTS FOR ENVIRONMENTAL ENGINEERING CONCRETE 0.878 0.642 1.156 3.0 0.171 0.283 32 8.04 6.31

STRUCTURES 0.934 0.632 1.132 4.0 0.128 0.203 40 12.57 9.86

- ACI 350.3-06 SEISMIC DESIGN OF LIQUID CONTAINING CONCRETE STRUCTURES

- ACI 360 DESIGN OF SLABS-ON-GROUND 0.994 0.625 1.117 5.0 0.102 0.156 R2. STEEL REINFORCEMENT SHALL BE FREE FROM LOOSE MILL AND RUST SCALE AND FROM COATINGS THAT MAY

- AISC 341 SEISMIC PROVISIONS FOR STRUCTURAL STEEL BUILDINGS DESTROY OR REDUCE THE BOND

- AISC 360-16 SPECIFICATIONS FOR STRUCTURAL STEEL BUILDINGS

1.057 0.608 1.084 7.5 0.068 0.098 SYMBOLOGY

1.197 0.483 0.974 10.0 0.051 0.065 R3. STEEL MATS OR FABRIC SHALL COMPLY WITH ASTM A185, ASTM A497 OR ASTM A704M

- AISC DESIGN GUIDE 3 SERVICEABILITY DESIGN CONSIDERATIONS FOR STEEL

BUILDINGS R4. STEEL REINFORCEMENT SHALL BEAR MILL IDENTIFICATION SYMBOLS AND SHALL BE TAGGED WITH THE SIZE

- ASTM C55-85 CONCRETE BUILDING BRICK ORDINATES OF THE RECOMMENDED VERTICAL RESPONSE SPECTRAL: AND MARK NUMBER SO THAT DIFFERENT TYPES MAY BE INDETIFIED. IT SHALL BE STORED OFF THE GROUND

LOADS R5. EVERY BATCH OF STEEL REINFORCEMENT DELIVERED TO SITE SHALL BE TESTED TO VERIFY MASS AND

SPECTRAL ACCELERATION Sa (g) SPECTRAL ACCELERATION Sa (g)

C DEAD LOADS (D) T (s) T (s) TENSILE PROPERTIES TO EVERY SHIPMENT OF 5000 KG OR A FRACTION THEREOF C

5% Damping 0.5% Damping 5% Damping 0.5% Damping

R6. THE TEST SHALL CONSIST OF 5 SPECIMENS. ABBREVIATED TESTING MAY BE CONSIDERED ON A PARTICULAR

INCLUDE THE WEIGHT THAT COMES FROM THE DENSITY OF THE MATERIALS IN THE

0 0.409 0.409 1.50 0.228 0.401 BATCH AT THE DISCRETION OF THE ENGINEER THROUGH A WRITTEN REPORT INDICATING THE NUMER OF

STRUCTURE

SPECIMENTS TO BE TESTED

MATERIAL DENSITY (Kg/m3) DENSITY (KN/m2) 0.075 0.891 1.819 2.0 0.171 0.292

UNREINFORCEMENT CONCRETE 2,400 0.10 0.972 2.088 3.0 0.114 0.179 R7. BAR BENDING SCHEDULE IS NOT INCLUDED IN THE DRAWINGS AND SHALL BE MADE ACCORDING TO NSCP C101-15

REINFORCEMENT CONCRETE 2,500 0.15 4.0

0.732 1.637 0.085 0.133 R8. MINIMUM BAR CLEAR SPACING SHALL NOT BE LESS THAN THE BAR DIAMETER OR 5mm + AGGREGATE SIZE WHICHEVER

STRUCTURAL STEEL 7,850 IS GREATER

0.59 0.587 1.097 5.0 0.068 0.098

SALTWATER 1,025

FRESH WATER 1,000 0.75 0.455 0.822 7.5 0.046 0.061 R9. AL THE REQUIRED ELEMENTS FOR THE REINFORCEMENT SPACING ARE NOT SHOW IN THE DRAWING AND SHALL BE

TECHNICAL FLOORING FINISH 1.0 1.0 0.341 0.622 10.0 0.034 0.043 USE TO MANTAIN THE REINFORCEMENT IN ITS POSITION DURING CONCRETE POURING

R10. CONCRETE COVER

LIVE LOADS (Lr) FOR FURTHER INFORMATION SEE DOCUMENT MNL- WTP-00-SRD-00001 CIVIL, STRUCTURAL AND

ARCHITECTURAL DESIGN CRITERIA FOR SUBMERGED STRUCTURES, IN CONTACT WITH WATER OR LIQUID RETENTION:

DESCRIPTION UNIFORM (KN/m2)

ROOFS 1.0 - A MINIMUM OF 75 mm CONCRETE COVER SHALL BE PROVIDED ON ALL INTERIOR FACES OF ALL CONCRETE

D FORMWORK COMPONENTS D

OFFICES 2.4

- A MINIMUM OF 75 mm CONCRETE COVER SHALL BE PROVIDED ON THE BOTTOM REINFORCEMENT OF ALL

CONTROL ROOM 7.2 F1. ALL FORMWORK SHALL BE OF ADEQUATE STRENGTH, SECURELY FIXED AND SEALED TO PREVENT LEAKAGE

CONCRETE FACES BELOW GRADE, IRRESPECTIVE IF CONCRETE IS UTILIZED OR NOT.

MEETING ROOM 4.8 FOR THE REST OF THE ESTRUCTURES THAT ARE NOT IN CONTACT WITH WATER, THE CONCRETE COVER IS

ARCHIVE ROOM 6.0 CONCRETE ACCORDING TO NSCP-2015 TABLE 420.6.1.3.1 NOTES

DATA PROCESING ROOM 4.0 C1. CONCRETE REQUIREMENTS ACCORDING TO: SPECIFIED COVER

ROOM OF LOAD DISTRIBUTION CENTER 7.2 CONCRETE EXPOSURE MEMBER REINFORCEMENT (mm)

• HIGH STRENGHT STRUCTURAL TYPE I, MINIMUM COMPRESSION STRENGHT TYPE I @28MPa FOR

ELECTRICAL ROOM 12.0 CAST AGAINST AND PERMANENTLY IN ALL ALL 75

GENERAL STRUCTURES, TYPE II 35 MPa FOR RETAINING STRUCTURES.

LABORATORIES 2.9 • CEMENT SHALL CONFORM TO THE REQUIREMENTS OF ASTM TYPE I FOR GENERAL STRUCTURES AND CONTACT WITH GROUND

STAIRS AND CORRIDORS 4.8 TYPE II MH WITH TYPE "F" FLY ASH FOR WATER-RETAINING STRUCTURES IN ACCORDANCE WITH ASTM EXPOSED TO WEATHER OR IN CONTACT ALL 20 mm through 50

PLATFORMS, FLOORS RACKS 5.0 C150 REQUIREMENTS OR APPROVED EQUIVALENT. PROPERTIES OF CEMENT SHOWN IN TABLE 4 OF WITH GROUND 58mm bars

ASTM C150 SHALL ALSO BE CONSIDERED.

16 mm and 40

• GRADE OF CONCRETE smaller

WIND LOAD NSCP 2015 SECTION 207

MINIMUM COMPRESSION NOT EXPOSED TO WEATHER OR IN CONTACT SLABS, JOIST 40 mm and 40

THE BASE PRESSURE EVALUATED AT HEIGHT Z CONCRETE USAGE TYPE OF CONCRETE WITH GROUND AND WALLS 58mm bars

E STRENGHT @28 DAYS (MPa) E

qz= 0.613 Kz Kzt Kd V2 (N/m2) 36 mm and 20

WATER RETAINING CONCRETE II 35

smaller

HIGHT STRENGTH STRUCTURAL I 28

WHERE: I

BEAMS, Primary 40

MASS CONCRETE 17

V= BASIC WIND SPEED. COLUMNS, reinforcement,

PEDESTALS stirrups, ties,

• WATER SHALL BE DESCRIBED IN SES02 "MATERIALS" SECTION 2.91 AND MUST BE KEPT TO A MINIMUM TO

BASIC WIND spirals and

STRUCTURE OCCUPANCY CATEGORY OBTAIN A DENSE AND WATERLIGHT CONCRETE. IN GENERAL, THE QUANTITY OF CEMENT TO BE USED

SPEED (Km/h) hoops

WILL BE THE MINIMUM NECESARY TO PRODUCE THE REQUIRED DESIGN STRENGTHS. BUT SHALL NO BE

CATEGORY I - ESSENTIAL INSTALLATIONS LESS THAN 310 KG PER CUBIC METER FOR A CLASS A CONCRETE

CRITICAL 280 Km/h R11. DEVELOPMENT LENGTH

STRUCTURE

DEVELOPMENT LENGTH OF STANDARD HOOK IN TENSION

NON-CRITICAL CATEGORY III - ESSENTIAL INSTALLATIONS 260 Km/h NOMINAL MAXIMUM COARSE AGGREGATE MINIMUM CEMENTITIOUS MATERIALS

STRUCTURE

AGGREGATE SIZE, mm (ASTM C33) SIZE NO. (kg/cu.m.) DETAILS AND DIMENSIONS HOOKS (mm) DEVELOPMENT REFERENCE DRAWINGS

37.5 467 305 HOOKS BAR

Kd= WIND DIRECTIONALITY FACTOR.

A A A

25 57 317 ldh ldh

IN TENSION ldh (mm.)

19 67 332

ldh ldh

12.5 7 345

d

F STRUCTURE Kd

D

J

D D

F

9.5 8 356

D D

ENGINEER-OF-RECORD: ENG. MANUEL M. SANTOS JR.

PRC. Licence No. 0012137

0.85

J

BUILDINGS *For nominal maximum coarse aggregate size not indicated, interpolate the minimum cementitious

N

material content between nominal sizes shown (SIGNATURE & SEAL)

SQUARE TANKS 0.90

C2. ALL CONCRETE SURFACES SHALL BE ADEQUATELY CURED TO AVOID CRACKS

HEXAGONAL AND ROUND TANKS 0.95

C3. NO BACKFILLING IS PERMITED UNTIL THE CONCRETE REACHED ITS DESIGN STRENGTH

C4. CONCRETE JOINTS FOR ELEMENTS CASTED IN MORE THAN ONE STEP AS MARKED ON THE DRAWINGS. THE

Kz= VELOCITY PRESSURE EXPOSURE COEFFICIENT. FACES OF THE CONCRETE IN THES JOINTS SHALL BE ADEQUATELY ROUGHED

HEIGHT ABOVE C5. ALL CONCRETE EDGES SHALL BE CHAMFERED 20X20mm UNLESS NOTED OTHERWISE

EXPOSURE

GROUND LEVEL, z

(C) C6. WATER CEMENT RATIO - IN ANY STRUCTURAL MEMBER, THE MAXIMUM WATER/CEMENT RATIO SALL BE 0.5.

(m)

CONCRETE IN MEMBERS OR STRUCTURES THAT ARE TO RETAIN AQUEOUS LIQUID SHALL HAVE A MAXIMUM DEVELOPMENT LENGTH 02 ISSUED FOR APPROVAL 13/01/2022 EPR MCG BRI

DEVELOPMENT LENGTH

G 0 - 4.5 0.85 FREE WATER/CEMENT RATIO OF 0.4 01 SECOND REVIEW 16/11/2021 EPR MCG BRI G

TENSION Ld (mm.) COMPRESION Ldc (mm)

00 INITIAL REVIEW 25/10/2021 EPR MCG BRI

6.0 0.90 C7. EXPOSURE CLASSIFICATION IS AS FOLLOWS REV. DESCRIPTION DATE DRAWN CHECKED APPROVED

0.94

REVISIONS

7.5 CATEGORY CLASS CONDITION

9.0 0.98 SULFATE (S) S2 1500≤SO 42≤10000 (SULFATE DISOLVED IN WATER PPM)

12.0 1.04 IN CONTACT WITH WATER IN CONTACT WITH WATER WHERE LOW PERMEABILITY

W1

(W) IS REQUIRED

DRY CONCRETE OR PROTECTED AGAINST

Kzt= TOPOGRAPHIC FACTOR KZT IS IMPORTANT TO DETERMINATE THE WIND C0 PROJECT :

CORROSION PROTECTION OF MOISTURE

SPEED-UP EFFECT. REINFORCEMENT (C)

EASTBAY WATER TREATMENT PLANT.

CONCRETE EXPOSED TO MOISTURE BUT NOT AN EXTERNAL

C1 SOURCE OF CHLORIDES .

50 MLD (PHASE 1).

Kzt= ( 1+ K1 + K2 + K3)2 Scale : TITLE DRAWING :

H

STRUCTURES AND BUILDINGS H

WHERE K1, K2 AND K3 ARE GIVEN IN FIGURE 207A.8-1. IF SITE CONDITIONS AND LOCATIONS OF

REFERENCE :

STRUCTURE DO NOT MEET ALL THE CONDITIONS SPECIFIED IN SECTION 207A.8.1 THEN Kzt=1

.

MNL GENERAL NOTES

THE GUST-EFFECT FACTOR (G) FOR A RIGID BUILDING OR OTHER STRUCTURE IS PERMITTED SIZE

TO BE TAKEN AS 0.85. FOR DETAILED APPROACH FOR FLEXIBLE BUILDING, SEE INTO THE NSCP ORIGINAL DRAWING No JV. MNL-WTP-00-SDL-00001 SHEET 1

2015 7th EDITION IN SECTION 207A.9

A1 DRAWING No MWC. 2020-0389-0000-S022 OF 2

0 100 200 300 mm © TEDAGUA Técnicas de Desalinización de Aguas, S.A.

THIS DOCUMENT IS PROPERTY OF TEDAGUA AND CAN NOT BE DUPLICATED, PROCESSED OR DISCLOSED TO THIRD PARTIES FOR ANY USE OTHER THAN THIS PROJECT AND THE PURPOSE FOR WHICH IT

IS ISSUED FOR WITHOUT THE WRITTEN CONSENT OF TEDAGUA

DIN A1 ( 841 x 594 )

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

PLOT PLAN

R12. LAP LENGTH

WELDING

TENSION BAR OVERLAP

W1. ALL WELDED STRUCTURAL CONNECTIONS SHALL USE WELD FILLER MATERIAL CONFORMING TO

LENGTH (mm) AWS D1.1 AND AWS D1.4

A COMPRESION W2. WELDING ELECTRODES MATERIALS AND FILLER METAL SHALL HAVE HIGHER STRENGTH THAN THE

BAR OVERLAP BASE

LENGTH (mm)

ANCHORAGE STEEL

A1. ANCHOR BAR SHALL BE ACCORDING ASTM F1554 Gr 36 AND Gr 55 UNLESS ON DRAWINGS

DETAILS INDICATES ANOTHER MATERIAL.

A2. HEAVY HEX NUTS ASTM A563.

WASHERS ASTM F436.

THREADED BOLTS AND RODS ASTM 307 Gr B

A3. ANCHOR ASSEMBLY ARE MADE FROM AN ANCHOR WITH INFERIOR WELDED HEX NUT. SUPERIOR

SIDE ONE HEX NUT AND WASHER.

A4. ANCHORS SHALL TO BE INSTALLED ACCORDING WITH FOLLOW TOLERANCES:

- ANCHOR PROJECTION: +6 mm/0 mm

.

- CENTER OF ANCHOR GROUP: +- 6 mm

- CENTER TO CENTER ANCHOR: +- 3 mm

B - CENTER TO CENTER ANCHOR GROUP: +- 6 mm

.

- VERTICALITY: 4 mm on 1 mm

A5. THREAD ANCHOR NEED TO BE COVER WITH TAPE OR OTHER MATERIAL, TO HOLD CLEAN AND

R13. FOR OPENING ON SLABS OR WALLS NEED TO BE ADD REINFORCEMENT BARS ACCORDING PREVENT ANY DAMAGE DURING WORKS.

WITH THE FOLLOW DETAILS: A6. TEMPLATES FOR SETTING ANCHOR SHALL BE FURNISHED EVEN THOUGH THEY ARE NOT SHOWN

ON DRAWINGS DIMENSIONS AND MATERIAL NEED TO BE DEFINED BY STEEL SUPPLIER..

A7. THREAD AND ANCHOR LENGTH ARE INDICATED ON CONCRETE DRAWINGS

SYMBOLOGY

FIRE RESISTANT

Id

Id

F1. REQUIREMENTS FOR DETERMINING FIRE RESISTANCE ACCORDING WITH ACI 216.1 M-07

F2. BUILDINGS ELEMENTS NEED TO CONSIDERED MINIMUM COVER AS FOLLOW TABLE:

COVER FOR CORRESPONDING FIRE RESISTANCE, mm

C C

TIME

ELEMENT 1 HOUR 2 HOUR

ROOFS 20 25

AND

SLABS

Id Id BEAMS 20 20

F3. MINIMUM CONCRETE COLUMN SIZE:

1 HOUR: 200 mm

2 HOURS: 250 mm

MASONRY

R14. ALL REINFORCED STEEL SHALL BE SECURELY HELD IN PLACE WHILE PLACING CONCRETE. IF

REQUIRED, ADDITIONAL BARS OR STIRRUPS SHALL BE PROVIDED BY THE CONTRACTOR TO IN INTERIOR WALLS, MASONRY WILL BE USE STANDARD CONCRETE BRICK

FURNISH SUPPORT FOR ALL REINFORCING. 200x200x400mm FOR NON STRUCTURAL WALLS

D D

R15. ALL REINFORCING STEEL SHALL BE MARKED SO THEIR IDENTIFICATION CAN BE MADE WHEN

FINAL INSPECTION IN CONDUCTED.

NOTES

UNDERGROUND

U1.FOR UNDERGROUND DETAILED INFORMATION SEE DRAWINGS:

MNL- WTP - 00 - CDP - 00001 UNDERGROUND NETWORKS. GENERAL PLAN

MNL- WTP - 00 - CDP - 00002 UNDERGROUND NETWORKS. CROSS SECTIONS

MNL- WTP - 00 - CDP - 00003 UNDERGROUND NETWORKS. DETAILS

EXCAVATION AND PREPARATION OF FOUNDATION BASE

E1. ALL EARTH SURFACES AGAINST WHICH CONCRETE IS TO BE POURED SHALL BE CLEAN

AND FREE OF ANY DETRIMENTAL IMPURITIES, ORGANIC MATTER OR UNSUITABLE MATERIAL.

E E2. EXCAVATION, BACKFILL AND COMPACTION SHALL BE DONE IN STRICT ACCORDANCE WITH E

THE FOLLOWING DOCUMENTS:

MNL-WTP-00-BEF-00001 GEOTECHNICAL STUDY REPORT

MNL-WTP-00-BDA-00002 GROUND TREATMENTS GENERAL LAYOUT

MNL-WTP-00-BDL-00002 GROUND TREATMENTS CROSS SECTIONS

STRUCTURAL STEEL

S1. ALL STRUCTURAL STEEL SHAPES CONFORM TO AISC MANUAL OF STEEL CONSTRUCTION 15th EDITION

S2. STRUCTURAL SHAPES REFERENCE DRAWINGS

YIELD STRENGTH / ULTIMATE

TYPE STRUCTURAL STEEL PROFILES TENSILE STRENGTH

STEEL ASTM A36 ALL STEEL PROFILES (EXCEPT CIRCULAR, HSS Fy = 250 MPa ; Fu = 400 MPa

AND COLD ROLLED CF)

F F

STEEL ASTM A53 GR. B CIRCULAR TUBULAR PROFILES Fy = 240 MPa ; Fu = 415 MPa

ENGINEER-OF-RECORD: ENG. MANUEL M. SANTOS JR.

STEEL ASTM A500 GR. B HSS PROFILES Fy = 315 MPa ; Fu = 400 MPa PRC. Licence No. 0012137

STEEL ASTM A1008 GR. 50 COLD ROLLED CF Fy = 345 Mpa ; Fu = 415 MPa

STEEL ASTM F1554 ANCHORS Fy = 250 MPa ; Fu = 400 MPa GR 36 (SIGNATURE & SEAL)

STEEL ASTM F1554 ANCHORS Fy = 380 Mpa ; Fu = 520 MPa GR 55

S3. ALL THE BOLTS FOR THE STRUCTURAL STEEL CONNECTIONS SHALL BE HIGH STRENGTH

BOLTS CONFORMING TO ASTM A 325 AND HOT DIP GALVANIZED ACCORDING TO ASTM A 123

S4. ALL THE HEAVY HEX NUTS SHALL BE CONFORMING TO ASTM A 563 AND HOT DIP GALVANIZED

ACCORDING TO ASTM A 123

S5. ALL THE STEEL WASHERS SHALL BE HOT DIP GALVANIZED ACCORDING TO ASTM A 123

S6. ALL THE GRATING SHALL BE CONFORMING TO ANSI NAAMM MBG 531-17, AND HOT DIP GALVANIZED

ACORDING TO ASTM A 123

S7. ALL THE STEP SHALL BE HOT DIP GALVANIZED ACCORDING TO ASTM A 123 02 ISSUED FOR APPROVAL 13/01/2022 EPR MCG BRI

G S8. HOLES DIAMETER IN BASE PLATE SHALL BE 1/8 '' OVERSIZED RELATED TO ANCHOR BOLT DIAMETER

01 SECOND REVIEW 16/11/2021 EPR MCG BRI G

00 INITIAL REVIEW 25/10/2021 EPR MCG BRI

UNLESS STATED OTHERWISE.

REV. DESCRIPTION DATE DRAWN CHECKED APPROVED

S9. PROTECTIVE PAINT SYSTEM FOR ALL STRUCTURAL STEEL SHALL CONFORM TO ISO 12944-5 FOR A

CORROSIVITY CATEGORY C4 WITH A AT LEAST A MEDIUM (M) DURABILITY CLASSIFICATION REVISIONS

S10. CHECKERED PLATE COVER SHALL BE MADE OF ASTM A36 AND HOT CHIP GALVANIZED ACCORDING

TO ASTM A123

S11. METAL ROOFING PANEL SHALL BE RIB-TYPE WITH A TOTAL COATED THICKNESS OF NOT LESS

THAN 0.6 mm UTILIZING A DOUBLE BAKED-ON EPOXY PRIMER AND HIGH-GRADE POLYESTER FINISH.

COLOR SHALL BE MWC BLUE (PANTONE DS 234-3c) OR CLOSEST FOR PREPAINTED METAL SHEET.

S12. RAILING SHALL BE NOT LESS THAN 1.0 M IN HEIGHT. FOR OPERATIONAL OR WALKWAYS, KICK

PLATES/TOE BOARD 75 mm IN HEIGHT SHALL BE PROVIDED. PROJECT :

FOR ADMINISTRATION BUILDING, PUMPING AND BOOSTER STATIONS:

EASTBAY WATER TREATMENT PLANT.

- TYPE 1. RAILINGS SHALL BE MADE OF 12 mm THICK CLEAR GLASS, TEMPERED, IN 50x50 mm/50x75 50 MLD (PHASE 1).

mm STAINLESS STEEL 304 TUBULAR FRAME, SATIN FINISH, WITH COMPLETE ACCESSORIES. Scale : TITLE DRAWING :

- TYPE 2. RAILINGS SHALL BE MADE OF 50x50 mm/50x75 mm STAINLESS STEEL 304 TUBULAR FRAME, STRUCTURES AND BUILDINGS

H SATIN FINISH, WITH COMPLETE ACCESORIES H

REFERENCE :

FOR OTHER FACILITIES:

- RAILING SHALL BE MADE OF GALVANIZED IRON TUBULAR FRAME PAINTED GRAY/SILVER.

MNL GENERAL NOTES

HANDRAILS SHALL BE DN 40 AND DN 25 BOTH SCHEDULE 40. SIZE

ORIGINAL DRAWING No JV. MNL-WTP-00-SDL-00001 SHEET 2

S13. HANDRAILS AND BALUSTERS. PROTECTIVE BARRIERS SHALL COMPLY WITH THE PROVISIONS OF

NATIONAL BUILDING CODE OF PHILIPPINES MINIMUM DESIGN-IMPOSED LOAD VALUE OF 36 kN/m RUN.

A1 DRAWING No MWC. 2020-0389-0000-S022 OF 2

0 100 200 300 mm © TEDAGUA Técnicas de Desalinización de Aguas, S.A.

THIS DOCUMENT IS PROPERTY OF TEDAGUA AND CAN NOT BE DUPLICATED, PROCESSED OR DISCLOSED TO THIRD PARTIES FOR ANY USE OTHER THAN THIS PROJECT AND THE PURPOSE FOR WHICH IT

IS ISSUED FOR WITHOUT THE WRITTEN CONSENT OF TEDAGUA

DIN A1 ( 841 x 594 )

1 2 3 4 5 6 7 8 9 10 11 12

You might also like

- Philosophy Paper in Apa FormatDocument5 pagesPhilosophy Paper in Apa Formatapi-317480948No ratings yet

- A Treatise of Military DisciplineDocument403 pagesA Treatise of Military Disciplineraiderscinema100% (2)

- Original U.S.A. Constitution - The Missing 13th AMENDMENT WRITTEN by Judge Dale, Ret'dDocument7 pagesOriginal U.S.A. Constitution - The Missing 13th AMENDMENT WRITTEN by Judge Dale, Ret'ddgrgxNo ratings yet

- Enterprise Rent A Car PlanningDocument4 pagesEnterprise Rent A Car PlanningTepenter CatcherNo ratings yet

- GA of ACCDocument5 pagesGA of ACCshashinaganurNo ratings yet

- Excavation and Lateral Support TeklaDocument9 pagesExcavation and Lateral Support TeklaTEE Yu Yang TEENo ratings yet

- Girls Hostle StructuralDocument9 pagesGirls Hostle StructuralNoor MuhammadNo ratings yet

- DR - 1.majid Albana Structural 13 Floor BUILDING 23Document1 pageDR - 1.majid Albana Structural 13 Floor BUILDING 23Mohamad RammelNo ratings yet

- General Notes: Index of DrawingDocument1 pageGeneral Notes: Index of DrawingJames Darwin SorianoNo ratings yet

- Schedule of Drawings:: Drawing Drawing Title NODocument4 pagesSchedule of Drawings:: Drawing Drawing Title NOma.shaheNo ratings yet

- SFSDFDocument1 pageSFSDFbillNo ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- Arch Plans v2 (Approved)Document12 pagesArch Plans v2 (Approved)rabbetmrNo ratings yet

- Plumbing DWGDocument3 pagesPlumbing DWGJamillette NovesterasNo ratings yet

- S020-General Notes (Sheet 1 of 3)Document1 pageS020-General Notes (Sheet 1 of 3)WNo ratings yet

- MosquejDocument12 pagesMosquejdr.afroza1875No ratings yet

- Tunis MallDocument16 pagesTunis Mallعبدالمجيد اشرف عادل مجيدNo ratings yet

- RA612003001P0A1Document1 pageRA612003001P0A1Muhammad AbrarNo ratings yet

- AASHTO Standard Details - Folded Steel Plate Girder System - 2014Document20 pagesAASHTO Standard Details - Folded Steel Plate Girder System - 2014houstonhimselfNo ratings yet

- Part I - Introduction To Well DesignDocument15 pagesPart I - Introduction To Well DesignSyazwan wan ibrahimNo ratings yet

- Rates of Spread An D Spray in Bituminous Surface-Dressing of RoadsDocument6 pagesRates of Spread An D Spray in Bituminous Surface-Dressing of RoadsEnermy-123No ratings yet

- EMX 11 G MB - EN EA 005-En - 111A ARR - CABLE TRAY & INSTRUMENTATION PDFDocument17 pagesEMX 11 G MB - EN EA 005-En - 111A ARR - CABLE TRAY & INSTRUMENTATION PDFcarlosNo ratings yet

- Surface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1Document1 pageSurface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1அம்ரு சாந்திவேலுNo ratings yet

- Structural Design Criteria Abbreviations:: S1.00 Raemulan Land IncorporatedDocument1 pageStructural Design Criteria Abbreviations:: S1.00 Raemulan Land Incorporateddaveglai24No ratings yet

- DR - Majid Albana Structural 13 Floor BUILDING 23Document20 pagesDR - Majid Albana Structural 13 Floor BUILDING 23arya winataNo ratings yet

- 135t9237 - Outline Turbine Compt Enclosure Vent FanDocument4 pages135t9237 - Outline Turbine Compt Enclosure Vent FanOscar Lopez TinocoNo ratings yet

- 6 Phase 1: Front ViewDocument1 page6 Phase 1: Front ViewMAXWELL ERIPONNo ratings yet

- Att-06 Drawing MarkupsDocument13 pagesAtt-06 Drawing MarkupsabdullahNo ratings yet

- S001 76-10526-Detail Design: Adac Midfield Terminal Fire Station Structural General Notes & Details Sheet 1Document1 pageS001 76-10526-Detail Design: Adac Midfield Terminal Fire Station Structural General Notes & Details Sheet 1Mazen Ismail0% (1)

- 1.Rc Details Industrial Building Details-Rev-1Document7 pages1.Rc Details Industrial Building Details-Rev-1Civil StructureNo ratings yet

- NWIT 16 38 Tender DrawingsDocument5 pagesNWIT 16 38 Tender Drawingsvernyhora.nataliiaNo ratings yet

- D92-1020-ABCD: TolerancesDocument4 pagesD92-1020-ABCD: Tolerancescarlosar1477No ratings yet

- Design Details Canopy Ground FloorDocument1 pageDesign Details Canopy Ground FloorAditya K100% (1)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- General Notes Concrete Works and Reinforcing Bars: Project TitleDocument5 pagesGeneral Notes Concrete Works and Reinforcing Bars: Project TitleCamille Ariel100% (1)

- S 001Document1 pageS 001Rashed SiddiqiNo ratings yet

- CDCBP P086 Cp02a Jec SD STR 1119 1Document1 pageCDCBP P086 Cp02a Jec SD STR 1119 1Md ArifNo ratings yet

- Structural ResidenceDocument4 pagesStructural Residence2226558No ratings yet

- Cable Route MarkerDocument2 pagesCable Route Markersundareee96No ratings yet

- Mcpherson Design GROUP P.CDocument26 pagesMcpherson Design GROUP P.CdeviationzNo ratings yet

- STRUCDocument5 pagesSTRUCEdward D. SarcoNo ratings yet

- General Slab On Ground Concrete Concrete Continued Chemical AnchorsDocument12 pagesGeneral Slab On Ground Concrete Concrete Continued Chemical AnchorsJelenaNo ratings yet

- PARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1Document1 pagePARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1irshad khanNo ratings yet

- ST-01 To ST-12Document12 pagesST-01 To ST-12Regina LagaticNo ratings yet

- NoteDocument1 pageNotePom tancoNo ratings yet

- E. Formworks: (Structural)Document1 pageE. Formworks: (Structural)Nonoy Justiniane-Giray JrNo ratings yet

- 1) General Notes: 9) Design Consideration: AS Civil Engg ServicesDocument4 pages1) General Notes: 9) Design Consideration: AS Civil Engg ServicesCivil Engineering projectNo ratings yet

- El - Boc - Roof Rathnapura-A2-DocketDocument1 pageEl - Boc - Roof Rathnapura-A2-DocketmodapalamaratNo ratings yet

- Cariño Structural (A3)Document7 pagesCariño Structural (A3)Alvin DeliroNo ratings yet

- Nail Head Construction: Surface Excavation & Rock Support General NotesDocument1 pageNail Head Construction: Surface Excavation & Rock Support General Notesஅம்ரு சாந்திவேலுNo ratings yet

- Irc 2018 With SC Modifications - Load Table: General Structural NotesDocument6 pagesIrc 2018 With SC Modifications - Load Table: General Structural Notespriya giriNo ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 1Document1 pageGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 1TOM YEENo ratings yet

- General Structural Notes Structural Steel Framing Notes:: Site Prep For CT ScannerDocument14 pagesGeneral Structural Notes Structural Steel Framing Notes:: Site Prep For CT ScannerMark JangadNo ratings yet

- Project Title: Project Location: Prepared By: Sheet Content: Sheet # Raymar R. Bartolome Carlo C. Cairel SB - 1 6 Submitted ToDocument1 pageProject Title: Project Location: Prepared By: Sheet Content: Sheet # Raymar R. Bartolome Carlo C. Cairel SB - 1 6 Submitted ToRaymar BartolomeNo ratings yet

- A. General Notes: B. Notes and Concrete Mixes and PlacingDocument1 pageA. General Notes: B. Notes and Concrete Mixes and Placingdomin domNo ratings yet

- KIL2189 - 208 - 0001 - REV03 - Structural Notes 1Document1 pageKIL2189 - 208 - 0001 - REV03 - Structural Notes 1NiemNo ratings yet

- HR 7Document1 pageHR 7MAXWELL ERIPONNo ratings yet

- General Notes and Specification: 3-LegendDocument1 pageGeneral Notes and Specification: 3-LegendReadian FedelinNo ratings yet

- General Notes: Structural DetailsDocument1 pageGeneral Notes: Structural DetailsMohammad AlkahteebNo ratings yet

- NotesDocument1 pageNotesMohammad AlkahteebNo ratings yet

- Ekene Semi Detached StructuralDocument18 pagesEkene Semi Detached StructuralNwachukwu PrinceNo ratings yet

- Ab01-3389704-General Notes and Summary of Pay Quantities (Bridge)Document1 pageAb01-3389704-General Notes and Summary of Pay Quantities (Bridge)Roly DinampoNo ratings yet

- HR 10Document1 pageHR 10MAXWELL ERIPONNo ratings yet

- M'lang Plans and Drawings - Part IDocument10 pagesM'lang Plans and Drawings - Part Ijan jhonnel punzalanNo ratings yet

- M'lang Plans and Drawings - Part IIIDocument14 pagesM'lang Plans and Drawings - Part IIIjan jhonnel punzalanNo ratings yet

- As Built, 40 DB 11, 8sep22, Ebwtp1Document55 pagesAs Built, 40 DB 11, 8sep22, Ebwtp1jan jhonnel punzalanNo ratings yet

- Zamboanga Plans and Drawings - Part IIDocument13 pagesZamboanga Plans and Drawings - Part IIjan jhonnel punzalanNo ratings yet

- As Built, 60 MCC 03, 8sep22, Ebwtp1Document91 pagesAs Built, 60 MCC 03, 8sep22, Ebwtp1jan jhonnel punzalanNo ratings yet

- As-Built, LVSG, 8sep22, Ebwtp1Document81 pagesAs-Built, LVSG, 8sep22, Ebwtp1jan jhonnel punzalanNo ratings yet

- YAMAHA P121 SmartPianist - Specification - For202101Document2 pagesYAMAHA P121 SmartPianist - Specification - For202101Romélio LustozaNo ratings yet

- Veeam One 10 0 Alarms Guide PDFDocument207 pagesVeeam One 10 0 Alarms Guide PDFBack Office ScannerNo ratings yet

- PenicillinDocument4 pagesPenicillinEms SekaiNo ratings yet

- KD 3Document9 pagesKD 3abu kahfNo ratings yet

- Polar Basic and Graphing Review Packet 2Document16 pagesPolar Basic and Graphing Review Packet 2abyun84No ratings yet

- Ejecrcicios Ingles, R e S U e L T o 31-03Document11 pagesEjecrcicios Ingles, R e S U e L T o 31-03Andres TapiasNo ratings yet

- RiddlesDocument12 pagesRiddlesajaypadmanabhanNo ratings yet

- List Link VideokingDocument27 pagesList Link VideokingStanley GeeksNo ratings yet

- Power of Positive Self Talk and AffirmationsDocument2 pagesPower of Positive Self Talk and Affirmationsupendra.znrNo ratings yet

- Tom Steyer Letter To Sec Kerry With SignaturesDocument382 pagesTom Steyer Letter To Sec Kerry With SignaturesnextgenclimateNo ratings yet

- Gondwana Research: Susanne J.H. Buiter, Trond H. TorsvikDocument27 pagesGondwana Research: Susanne J.H. Buiter, Trond H. TorsvikJankoStankovicNo ratings yet

- Poulos Bill - The Truth About Fibonacci TradingDocument23 pagesPoulos Bill - The Truth About Fibonacci TradingPantera1010No ratings yet

- Toshiba TV RL938 3240 EnglishDocument90 pagesToshiba TV RL938 3240 EnglishJakub RybárNo ratings yet

- GulliverDocument6 pagesGulliverflorinNo ratings yet

- Topic 1: Before You Begin Determine Personal Support RequirementsDocument20 pagesTopic 1: Before You Begin Determine Personal Support Requirementsdefa reyNo ratings yet

- Java Vs PHPDocument3 pagesJava Vs PHPHeadless77No ratings yet

- Recognition of Construction Contract Revenue Based On PSAK 34 at PT Tunggal Jaya RayaDocument8 pagesRecognition of Construction Contract Revenue Based On PSAK 34 at PT Tunggal Jaya RayamegakadirNo ratings yet

- The Battle of Uhud NotesDocument9 pagesThe Battle of Uhud NotesSifat ullah shah pakhtoonNo ratings yet

- BUS 525 Questions PDFDocument2 pagesBUS 525 Questions PDFMD NAZIM UDDIN BABUNo ratings yet

- Design & Fabrication of Pedal Operated Multi-Purpose MachineDocument5 pagesDesign & Fabrication of Pedal Operated Multi-Purpose MachineDeepak ChaurasiaNo ratings yet

- Joint Venture Agreement (Sample) - JabaDocument4 pagesJoint Venture Agreement (Sample) - JabaBetson EsromNo ratings yet

- 80's Quiz NightDocument14 pages80's Quiz NightElaine BarnettNo ratings yet

- Qualitative Versus Quantitative ResearchDocument12 pagesQualitative Versus Quantitative ResearchRustian Akbar ChumallaNo ratings yet

- The Comaparative Data Between Various Brands of Tea Powders and Green TeaDocument6 pagesThe Comaparative Data Between Various Brands of Tea Powders and Green TeaAyush PorwalNo ratings yet

- I-Day 32Document4 pagesI-Day 32Ivan Rey Porras VerdeflorNo ratings yet

- Project Plan BirdfeederDocument2 pagesProject Plan BirdfeederJessie-Marie Mata MorcosoNo ratings yet