Professional Documents

Culture Documents

Chart Cooler

Chart Cooler

Uploaded by

hamadaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chart Cooler

Chart Cooler

Uploaded by

hamadaCopyright:

Available Formats

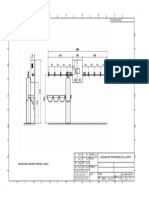

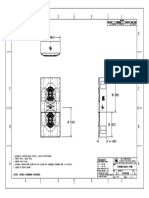

4 3 2 1

B B

A A

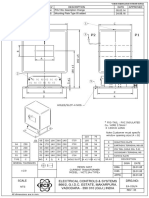

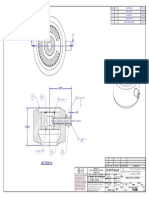

ISO VIEW MODELED BY:

UNLESS OTHERWISE SPECIFIED CHART COOLER SERVICE CO, INC.

ADM 3515 DAWSON RD.

1. REMOVE ALL BURRS 7. FABRICATION TULSA, OK 74115

DETAILED BY: AND SHARP CORNERS. .X = ± 0.25 (918)621-5200

ADM 2. COR. RAD .03 .XX = ± 0.125

TITLE:

3. DO NOT SCALE .XXX = ± 0.06 JOB: 35514 LI-MODEL GA COVER SHEET

CHECKED BY: DRAWING. FRACTION = ± 1/8

CLIENT:

TMD 4. ALL DIMENSIONS ARE ANGLES ± 3° GE OIL & GAS

IN INCHES. 8. MACHINE

5. ALT DIMENSIONS .X = ±0.030 SERVICE: ... | TAG NO.: N/A

0 APPROVAL DRAWING 9/8/2014 ADM APPROVED BY:

ARE IN MM .XX = ±0.015 PO#: 4510478424 | PROJECT: CT-11348 & CT-11349 ITALFLUID

1 FINAL CERTIFIED 9/30/2014 ADM BJY 6. MACHINE FIN. .XXX = ±0.005

FINAL CERTIFIED REV DESCRIPTION DATE APPROVED ANGLES ±1/2° DATE: 9/8/2014 JOB No.:35514 MODEL: LI96-14

RELEASED FOR FABRICATION FRACTION = ± 1/64 REV. 1 | DRAW NO.: 35514-O-1 | UNITS: 2

REVISION HISTORY

4 3 2 1

4 3 2 1

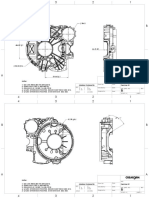

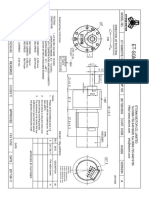

PRESSURES (psig) [barg] TEMPERATURES (°F) [°C] TOP OF

COIL # SERVICE CODE AIR DESIGN AIR DESIGN

GENERAL NOTES: DESIGN OPERATING TEST DESIGN INLET OUTLET INLET OUTLET

COIL

1. COOLER IS OF BOLTED CONSTRUCTION. 1795 8 1 EJW N/A 150 20 195 300 165 150 120 142 GUARD

2. BEARING GREASE POINTS TO TERMINATE NO HIGHER THAN 4 FEET ABOVE GRADE AT PERIMETER OF COOLER. 2 IC-1

ASME CODE SEC. VIII DIV. 1,

600 155 780 350 293 150 120 142 LOUVER

2013 ED., APP 13

3. MANWAY: 22" W X 35" L W/ LIFT OFF HINGES. ASME CODE SEC. VIII DIV. 1,

3 IC-2 900 404 1170 350 291 150 120 142 LOUVER

1 1 2013 ED., APP 13

4. SIDE PIPE HANGER - SHEET METAL: 4 " THK W/ 8- 2 " LAND ASME CODE SEC. VIII DIV. 1,

4 AC 1287 958 1674 350 286 130 120 142 LOUVER

2013 ED., APP 13

5. LOAD UNIFORMLY APPLIED TO SKID PER L-MODEL SKID DETAIL.

6. LIFTING POINTS. TYP BOTH SIDES.

7. CORE GUARD

8. SERIES 700 COMMON LOUVER W/ DURASTROKE 120 ACTUATOR & KIMRAY T12 DRIVE

OVER GAS SECTIONS FAN SHEAVE -

9. 3" X 3" INTERNAL ANGLE BRACING-SECTIONS TO BE WELDED TOGETHER MOTOR SHEAVE -

1

10. 1- 4 " HEAVY HEX NUTS FOR LEVELING SCREWS - 6 PLCS BELTS -

11. HEADER FINISH: PRIMER PER SPEC CENTER DIST -

12. STRUCTURE FINISH: PAINT PER SPEC

13. SKID BEAM: W12 X 26# MOTOR

14. MURPHY VS2-EX VIBRATION SWITCH 1321 2 HP -

B 15. 8" BHOLE BY OTHERS B

RPM -

FRAME -

COIL ORDER(TOP TO BOTTOM) W/ COIL VOLUMES.

ENCLOSURE -

EJW (COIL 1) = 42 GAL

IC-1 (COIL 2) = 12 GAL VOLTS -

IC-2 (COIL 3) = 13 GAL FREQUENCY -

AC (COIL 4) = 8 GAL PHASES -

NOTE 14 FAN

MAKE MOORE

DIA. (ft) 8

REF.:DIM "A"

20 MODEL 10000-36 SC

BLADE QTY 6

TOP VIEW PITCH 21.83

239 16

ACFM/FAN 109186.

REF.:DIM "D"

0

RPM 427

3

0 9 4 HP 28.75

NOTE 6

NOTE: 4

BEARING

1221 8 N1-1 FAN 2.1875 TAF

IDLER 1.9735 CC FAN&BLOWER

NOTE 7

(101 2) 5 5

0 10 8 16 8 781 2 1403 8 1463 8 157

ND ROT

C1 (511 16) HA

N2-1

AT

T

NOTE 9 N2-1

RIGH

ION

66-15/16 REF.:DIM "C" 0

N2-2 1 1

4

NOTE 8 50-1 2 MAX

37-1 2 MIN

271 2 NOTE 2

C1 (F.S.) N1-3

27 NOTE 3 N2-3

N1-4

NOTE 10 (N.S. & F.S.)

0 0 N2-4

NOTE 15 NOTE 10 (N.S. & F.S.) NOTE 10 (N.S. & F.S.)

SIDE VIEW

1081 2 100 12 1 0 24

REF.:DIM "B"

105 8

781 2

1463 8

0

157

4

BACK VIEW

A A

100 L-MODEL SKID DETAIL

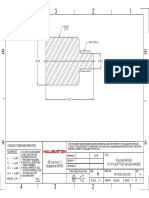

MODELED BY:

UNLESS OTHERWISE SPECIFIED CHART COOLER SERVICE CO, INC.

ADM 3515 DAWSON RD.

SCHEDULE OF OPENINGS/REFERENCE DIMENSION TABLE

1. REMOVE ALL BURRS 7. FABRICATION TULSA, OK 74115

TAG SERVICE DIM A DIM B DIM C DIM D DESCRIPTION DETAILED BY: (918)621-5200

AND SHARP CORNERS. .X = ± 0.25

N1-1 COIL 1 INLET 1 72-3/4 in 6-7/8 in 110-1/2 in 170-3/4 in 3"-150# RF-WN 0.3" WT(Sch. 80)(Wgt. X-Stg.) SA-105 ADM 2. COR. RAD .03 .XX = ± 0.125

TITLE:

N2-1 COIL 1 OUTLET 1 83-1/4 in 6-7/8 in 65-1/2 in 170-3/4 in 3"-150# RF-WN 0.3" WT(Sch. 80)(Wgt. X-Stg.) SA-105 3. DO NOT SCALE .XXX = ± 0.06 JOB: 35514 LI-MODEL GA

N1-2 COIL 2 INLET 1 72-3/4 in 164 in 58-7/16 in 171-1/16 in 4"-300# RF-WN 0.438" WT(Sch. 120) SA-105 CHECKED BY: DRAWING. FRACTION = ± 1/8

N2-2 COIL 2 OUTLET 1 81-3/4 in 164 in 49-11/16 in 171-1/16 in 4"-300# RF-WN 0.438" WT(Sch. 120) SA-105 FINAL CERTIFIED TMD 4. ALL DIMENSIONS ARE ANGLES ± 3° CLIENT:

GE OIL & GAS

RELEASED FOR FABRICATION IN INCHES. 8. MACHINE

N1-3 COIL 3 INLET 1 72-1/2 in 163-7/8 in 42-1/4 in 170-3/4 in 3"-600# RF-WN 0.438" WT(Sch. 160) SA-105 SERVICE: ... | TAG NO.: N/A

5. ALT DIMENSIONS .X = ±0.030

N2-3 COIL 3 OUTLET 1 81-1/2 in 163-7/8 in 34-5/8 in 170-3/4 in 3"-600# RF-WN 0.438" WT(Sch. 160) SA-105 0 APPROVAL DRAWING 9/8/2014 ADM APPROVED BY:

ARE IN MM .XX = ±0.015 PO#: 4510478424 | PROJECT: CT-11348 & CT-11349 ITALFLUID

N1-4 COIL 4 INLET 1 75-7/8 in 163-7/8 in 27-3/8 in 170-3/4 in 2"-600# RF-WN 0.344" WT(Sch. 160) SA-105 1 FINAL CERTIFIED 9/30/2014 ADM BJY 6. MACHINE FIN. .XXX = ±0.005

N2-4 COIL 4 OUTLET 1 78-7/8 in 163-7/8 in 14-7/8 in 170-3/4 in 2"-600# RF-WN 0.344" WT(Sch. 160) SA-105 REV DESCRIPTION DATE APPROVED ANGLES ±1/2° DATE: 9/8/2014 JOB No.:35514 MODEL: LI96-14

C1 TEMP -- -- -- -- HALF CPLG: 1"-3000# THD SA-105 W/ HEX PLUG REVISION HISTORY FRACTION = ± 1/64 REV. 1 | DRAW NO.: 35514-O-2 | UNITS: 2

4 3 2 1

You might also like

- Service Manual: 19990220-99800 Hamamatsu, JapanDocument51 pagesService Manual: 19990220-99800 Hamamatsu, JapanSantiago JacoboNo ratings yet

- Roscas Api Planos 31-69 PDFDocument46 pagesRoscas Api Planos 31-69 PDFJesus CacharucoNo ratings yet

- Manufacturing Rework Procedure: Form-510)Document2 pagesManufacturing Rework Procedure: Form-510)Prince Moni50% (2)

- Automatic Manfiold Layout AmcareMedDocument1 pageAutomatic Manfiold Layout AmcareMedJhay TorresNo ratings yet

- Item 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACDocument6 pagesItem 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACanghelo marquezNo ratings yet

- 3842600C00 PDFDocument1 page3842600C00 PDFzizouhicheNo ratings yet

- Hdmi Aoc P/N Overall Length, L (M) 1064134401 1 1064134403 3 1064134405 5 1064134410 10 1064134420 20 1064134430 30Document2 pagesHdmi Aoc P/N Overall Length, L (M) 1064134401 1 1064134403 3 1064134405 5 1064134410 10 1064134420 20 1064134430 30Petr BruzaNo ratings yet

- 9C24 9092 A T BOLT Cast 2Document1 page9C24 9092 A T BOLT Cast 2Mayur RankNo ratings yet

- PROPERTY OF J.M. Die Company: 3IN D DefaultDocument1 pagePROPERTY OF J.M. Die Company: 3IN D DefaultMuti Ur RehmanNo ratings yet

- Post Crimp Assembly : Dynalloy, IncDocument1 pagePost Crimp Assembly : Dynalloy, IncaxatpgmeNo ratings yet

- Bodine-Electric Standard Products CatalogDocument44 pagesBodine-Electric Standard Products CatalogAlexanderNaranjoOsorioNo ratings yet

- Mirror Glass - 11033475Document1 pageMirror Glass - 11033475Cesar GuerraNo ratings yet

- 10J01762 Ict DS 000 012 D0Document14 pages10J01762 Ict DS 000 012 D0Sardar PerdawoodNo ratings yet

- Base Magnetica 6306-1020Document1 pageBase Magnetica 6306-1020Martin Andre AlburquequeNo ratings yet

- NG - CD - HD16 9 1939SX P080 - A - PDF - hd16 9 1939sx p080 - 605159Document2 pagesNG - CD - HD16 9 1939SX P080 - A - PDF - hd16 9 1939sx p080 - 605159O mecanicoNo ratings yet

- DN 25 X 25 X 300# - GUIDE BUSH MACHINING - R1Document1 pageDN 25 X 25 X 300# - GUIDE BUSH MACHINING - R1Arman MominNo ratings yet

- Q063.22.03 - VOLVO Davao Service Center SERVICE BAY-21.01.08Document12 pagesQ063.22.03 - VOLVO Davao Service Center SERVICE BAY-21.01.08Thinh LuongNo ratings yet

- DF4168 062Document1 pageDF4168 062Erick RiosNo ratings yet

- OL-388.8-Hitachi 20211203184635.614 XDocument1 pageOL-388.8-Hitachi 20211203184635.614 XWilson AlvesNo ratings yet

- F/2.313 Soft Set Gauge Hanger 88 Tuas Ave 11 A Singapore 639100 Pulling Prong 8P10002-A (CUST)Document1 pageF/2.313 Soft Set Gauge Hanger 88 Tuas Ave 11 A Singapore 639100 Pulling Prong 8P10002-A (CUST)song LiNo ratings yet

- HEAD MANUFACTURING-Boiler Building-REV00-05.01.2022Document10 pagesHEAD MANUFACTURING-Boiler Building-REV00-05.01.2022Thinh LuongNo ratings yet

- Universal Boss Head PDFDocument1 pageUniversal Boss Head PDFthe vaultNo ratings yet

- D10367150a PDFDocument1 pageD10367150a PDFGaurav VashishtNo ratings yet

- Final Certified: Chart Cooler Service Co, IncDocument3 pagesFinal Certified: Chart Cooler Service Co, IncArslanNo ratings yet

- Bend 2Document1 pageBend 2karpagavalli NNo ratings yet

- Impeller - Skin Cut HubDocument1 pageImpeller - Skin Cut HubAditya PrajasNo ratings yet

- Q063.22.03 - VOLVO Davao Service Center GUARD HOUSE-21.01.08Document12 pagesQ063.22.03 - VOLVO Davao Service Center GUARD HOUSE-21.01.08Thinh LuongNo ratings yet

- Tutorial 1 DrawingDocument2 pagesTutorial 1 DrawingAlexNo ratings yet

- Standing Valve Ball TypeDocument2 pagesStanding Valve Ball TypeNattakorn sangmarkNo ratings yet

- Rev 1 E4-036-4 - 05Document1 pageRev 1 E4-036-4 - 05Naveen NagisettiNo ratings yet

- Notes:: ThermxDocument1 pageNotes:: ThermxTruong CaoNo ratings yet

- Sun GearDocument1 pageSun Gearapi-439460086No ratings yet

- Approval Drawn Date Ecn No Description Index Rev NoDocument1 pageApproval Drawn Date Ecn No Description Index Rev NosathishNo ratings yet

- Do Not Scale: SR - No. Qty. 1 1 2 1 3 1 4 1Document1 pageDo Not Scale: SR - No. Qty. 1 1 2 1 3 1 4 1vinothNo ratings yet

- Q063.22.03 - VOLVO Davao Service Center WAREHOUSE-21.01.08Document13 pagesQ063.22.03 - VOLVO Davao Service Center WAREHOUSE-21.01.08Thinh LuongNo ratings yet

- Samal Residence-Rev00-05.01.2022Document9 pagesSamal Residence-Rev00-05.01.2022Thinh LuongNo ratings yet

- Ti - OLFs - Vol - XVII 17Document1 pageTi - OLFs - Vol - XVII 17Rangaswamy DoraiswamyNo ratings yet

- Ti - OLFs - Vol - XVII 20Document1 pageTi - OLFs - Vol - XVII 20Rangaswamy DoraiswamyNo ratings yet

- Sa 1002 R0C PDFDocument1 pageSa 1002 R0C PDFAditya JainNo ratings yet

- DN 25 X 25 X 300# CONTOUR SEAT RING MACHININGDocument1 pageDN 25 X 25 X 300# CONTOUR SEAT RING MACHININGArman MominNo ratings yet

- Bmm006-102.ext Model Z3PRTDocument1 pageBmm006-102.ext Model Z3PRTshashiranjan18021995No ratings yet

- Nhd-C0216Ciz-Fn-Fbw-3V: Cog (Chip-On-Glass) Liquid Crystal Display ModuleDocument14 pagesNhd-C0216Ciz-Fn-Fbw-3V: Cog (Chip-On-Glass) Liquid Crystal Display ModuleLakshmanan SethupathiNo ratings yet

- Cebu Warehouse-Rev00-20.02.2022-Op 1Document10 pagesCebu Warehouse-Rev00-20.02.2022-Op 1Thinh LuongNo ratings yet

- Conn MC 2127rev.b Web00Document1 pageConn MC 2127rev.b Web00changiz2220No ratings yet

- PDFDocument1 pagePDFNemekhbayar GanbatNo ratings yet

- Impeler PDFDocument1 pageImpeler PDFArief FibonacciNo ratings yet

- ET-SGM37FE-1222 (20170810003-H16035) ModelDocument1 pageET-SGM37FE-1222 (20170810003-H16035) Modelruta0405No ratings yet

- JBL C222HP Customer DrawingDocument1 pageJBL C222HP Customer DrawingTricolor GameplayNo ratings yet

- PROPERTY OF J.M. Die Company: 5x10x15 D DefaultDocument1 pagePROPERTY OF J.M. Die Company: 5x10x15 D DefaultMuti Ur RehmanNo ratings yet

- Bmm007-102.ext Model Z3PRTDocument1 pageBmm007-102.ext Model Z3PRTshashiranjan18021995No ratings yet

- DWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcessDocument1 pageDWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcesshadeNo ratings yet

- Jomastic 90 Hard Top XP: Bill of MaterialsDocument1 pageJomastic 90 Hard Top XP: Bill of MaterialsAndriNo ratings yet

- TUGAS 01 RBI Group 3 (Pipping OD 2 In)Document3 pagesTUGAS 01 RBI Group 3 (Pipping OD 2 In)citra puspita sariNo ratings yet

- PROPERTY OF J.M. Die Company: 2in Diameter D DefaultDocument1 pagePROPERTY OF J.M. Die Company: 2in Diameter D DefaultMuti Ur RehmanNo ratings yet

- This Drawing and The Information Contained Within It Are Confidential and May Not Be Copied or Disclosed Without The Written Permission of LittelfuseDocument3 pagesThis Drawing and The Information Contained Within It Are Confidential and May Not Be Copied or Disclosed Without The Written Permission of LittelfuseAbdo RsvNo ratings yet

- GE7410 - Digging BucketDocument1 pageGE7410 - Digging BucketAngel HernandezNo ratings yet

- Visual: Inspected By: Quality ManagerDocument3 pagesVisual: Inspected By: Quality Managermechtek 20No ratings yet

- Motiongoo Stepper Motor Drawing-17HT19S4168C1Document1 pageMotiongoo Stepper Motor Drawing-17HT19S4168C1Make RownNo ratings yet

- KGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingDocument1 pageKGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingGauravNo ratings yet

- SR - Rotating Equip. Engineer CV-2024Document3 pagesSR - Rotating Equip. Engineer CV-2024hamadaNo ratings yet

- Engcalc130 1.11 4 24Document1 pageEngcalc130 1.11 4 24hamadaNo ratings yet

- Watlow AF Style ThermocoulpeDocument3 pagesWatlow AF Style ThermocoulpehamadaNo ratings yet

- Devcon F - MsdsDocument10 pagesDevcon F - MsdshamadaNo ratings yet

- AOP BSS Ball ValveDocument2 pagesAOP BSS Ball ValvehamadaNo ratings yet

- KeywayDocument1 pageKeywayhamadaNo ratings yet

- 2G Avus1000aDocument3 pages2G Avus1000ahamadaNo ratings yet

- Karima Reports 1-2023Document26 pagesKarima Reports 1-2023hamadaNo ratings yet

- Altronic GSVDocument8 pagesAltronic GSVhamadaNo ratings yet

- Petrosannan Gas Analysis Report 18-1-23Document1 pagePetrosannan Gas Analysis Report 18-1-23hamadaNo ratings yet

- Eni Blasia 220Document2 pagesEni Blasia 220hamadaNo ratings yet

- Om Manual TemplateDocument46 pagesOm Manual TemplatehamadaNo ratings yet

- All ServicesDocument4 pagesAll ServiceshamadaNo ratings yet

- Plan1 PDFDocument3 pagesPlan1 PDFhamadaNo ratings yet

- Rotating Equip. Engineer CV - UpdateddocDocument4 pagesRotating Equip. Engineer CV - UpdateddochamadaNo ratings yet

- Rotating Equip. Engineer CV - UpdateddocDocument4 pagesRotating Equip. Engineer CV - UpdateddochamadaNo ratings yet

- P9394GSI: VHP Series FourDocument2 pagesP9394GSI: VHP Series FourhamadaNo ratings yet

- Daily Report For Emc Team 24-10-2020Document10 pagesDaily Report For Emc Team 24-10-2020hamadaNo ratings yet

- Rotating Equip. Engineer CV - UpdateddocDocument4 pagesRotating Equip. Engineer CV - UpdateddochamadaNo ratings yet

- Booster Pump Agiba PDFDocument518 pagesBooster Pump Agiba PDFhamadaNo ratings yet

- API 610 Centrifugal Pumps ModelsDocument1 pageAPI 610 Centrifugal Pumps ModelshamadaNo ratings yet

- Mir20 1 2015Document1 pageMir20 1 2015hamadaNo ratings yet

- LVA Pump PDFDocument2 pagesLVA Pump PDFhamadaNo ratings yet

- Couplings Type TSK - TSP - Tsa - TSC - TLKDocument4 pagesCouplings Type TSK - TSP - Tsa - TSC - TLKhamadaNo ratings yet

- Motor Inspection Report: Speed RPM Bearing Temp. ºc Frequency HZ Current Amp. Time MinDocument1 pageMotor Inspection Report: Speed RPM Bearing Temp. ºc Frequency HZ Current Amp. Time MinhamadaNo ratings yet

- Motor Inspection Report: Vibration Records Time Min Bearing Temp. 20 15 50 30 3000 at 500volt Time Phase ResistanceDocument2 pagesMotor Inspection Report: Vibration Records Time Min Bearing Temp. 20 15 50 30 3000 at 500volt Time Phase ResistancehamadaNo ratings yet

- Modern Programming Concepts in Engineering: Topic 2: ObjectsDocument32 pagesModern Programming Concepts in Engineering: Topic 2: ObjectsthaoNo ratings yet

- Submittal Review Comments FormDocument1 pageSubmittal Review Comments Formahmadgce04No ratings yet

- Audit Check List (ISO 9001)Document12 pagesAudit Check List (ISO 9001)morshed_mahamud7055No ratings yet

- Synology Diskstation User'S Guide: Based On Firmware DSM 2.3-1139Document163 pagesSynology Diskstation User'S Guide: Based On Firmware DSM 2.3-1139Robert CantwellNo ratings yet

- CSIT409 ExaminationDocument9 pagesCSIT409 ExaminationSelormNo ratings yet

- Udl Literacy Lesson Plan 2Document5 pagesUdl Literacy Lesson Plan 2api-723119786No ratings yet

- DSS PDFDocument7 pagesDSS PDFRaktimNo ratings yet

- C Programming All-In-One Resource For C Programming, Comprehensive Tutorials, Expert TipsDocument236 pagesC Programming All-In-One Resource For C Programming, Comprehensive Tutorials, Expert Tipssklee0730No ratings yet

- Course Outline - Computer Application and MaintenanceDocument4 pagesCourse Outline - Computer Application and MaintenanceNanotech MidwiferyNo ratings yet

- A Learning Report On Short Circuit Studies From IEEE-399Document8 pagesA Learning Report On Short Circuit Studies From IEEE-399Walter MenesesNo ratings yet

- ZXVZXVDocument4 pagesZXVZXVboiroyNo ratings yet

- Chapter3 MasterdataanddocumenthandlingDocument8 pagesChapter3 MasterdataanddocumenthandlingJanna Hazel Villarino VillanuevaNo ratings yet

- Communications in Computer and Information Science 330: Editorial BoardDocument540 pagesCommunications in Computer and Information Science 330: Editorial BoardSimi MarNo ratings yet

- P8Z77-M ProDocument170 pagesP8Z77-M ProEnglish Training Studio -ETSNo ratings yet

- Transmission Control Protocol (TCP) : Mcgraw-Hill ©the Mcgraw-Hill Companies, Inc., 2000Document76 pagesTransmission Control Protocol (TCP) : Mcgraw-Hill ©the Mcgraw-Hill Companies, Inc., 2000Keyur MahantNo ratings yet

- Ecler MPA4-150R Data SheetDocument2 pagesEcler MPA4-150R Data SheetBerndNo ratings yet

- Training Activity Matrix in Grade 9: Aaron G. GimpaoDocument1 pageTraining Activity Matrix in Grade 9: Aaron G. GimpaoÇrïsśá G. AgîpëģNo ratings yet

- ETO - Interview SyllabusDocument3 pagesETO - Interview SyllabusKarthikeyan GNo ratings yet

- RTU-2001-AC Isi Series Interior System Interface: Installation, Operation, and Maintenance ManualDocument19 pagesRTU-2001-AC Isi Series Interior System Interface: Installation, Operation, and Maintenance ManualMo Salah100% (1)

- Site Supervisor - MFE Formwork Technology SDN BHDDocument1 pageSite Supervisor - MFE Formwork Technology SDN BHDBrandon AdnanNo ratings yet

- SsangYong-Korando 2012 EN US Manual de Taller Manual Estereo Parlante F1c281ad1cDocument14 pagesSsangYong-Korando 2012 EN US Manual de Taller Manual Estereo Parlante F1c281ad1cRAMON LANDERO PEREZNo ratings yet

- # Consensus and Agreement Algorithms: Distributed ComputingDocument9 pages# Consensus and Agreement Algorithms: Distributed ComputingTrending MediaNo ratings yet

- Webengenering Assignment No 3Document5 pagesWebengenering Assignment No 3zeeshan noorNo ratings yet

- Distributed Smart PV Solution Brochure - APAC (20190517)Document25 pagesDistributed Smart PV Solution Brochure - APAC (20190517)Rhey NaturalNo ratings yet

- LKG 601 User ManualDocument20 pagesLKG 601 User ManualBolawali KiNo ratings yet

- BigML Getting Started Resources 170209Document16 pagesBigML Getting Started Resources 170209CDR DownloadNo ratings yet

- XV-N33SL: DVD Video PlayerDocument35 pagesXV-N33SL: DVD Video PlayerAlejandro PinoNo ratings yet

- HNB Garhwal MSC CS SyllabusDocument31 pagesHNB Garhwal MSC CS Syllabuslibranhitesh7889No ratings yet