Professional Documents

Culture Documents

02 - Ro PTS

02 - Ro PTS

Uploaded by

abdulhalimbinamrinCopyright:

Available Formats

You might also like

- Orange Crush 20l Guitar Amp SchematicDocument1 pageOrange Crush 20l Guitar Amp SchematicThiago Darós Fernandes80% (5)

- 11Document74 pages11Carolina Duque0% (1)

- Orange Crush 20l Guitar Amp SCH PDFDocument1 pageOrange Crush 20l Guitar Amp SCH PDFToto WaltherNo ratings yet

- Spec - Ohe - Cat (Cu MG) 0120 (11 - 12Document21 pagesSpec - Ohe - Cat (Cu MG) 0120 (11 - 12hardeep08No ratings yet

- ANSI H35-2 - ERRATA Pages - Dec 19 2017 - 0 PDFDocument3 pagesANSI H35-2 - ERRATA Pages - Dec 19 2017 - 0 PDFAhmad SyafiqNo ratings yet

- FS PLM 111 0008Document14 pagesFS PLM 111 0008Jako MishyNo ratings yet

- 6-2 Plan Situatie VLAICU BERD-43 PDFDocument1 page6-2 Plan Situatie VLAICU BERD-43 PDFwww.criticarad.roNo ratings yet

- DW044 P03 PRB SL 1059Document1 pageDW044 P03 PRB SL 1059mohammad shabazNo ratings yet

- Gon SNR B12Document1 pageGon SNR B12BNG GondomarNo ratings yet

- Aicc CNCH 3 PK000 FFP DRW 01 00103 - 00aDocument1 pageAicc CNCH 3 PK000 FFP DRW 01 00103 - 00aFrancisco QuiñonezNo ratings yet

- Planimetria General - Okok-Tramo 01 y 02 OkDocument1 pagePlanimetria General - Okok-Tramo 01 y 02 OkJHOAN APOLINARIONo ratings yet

- SHD Cscec 18 F01 ST SC 01 Ex 05 0007 0000 01 PDFDocument1 pageSHD Cscec 18 F01 ST SC 01 Ex 05 0007 0000 01 PDFMohamed SherifNo ratings yet

- Houston Bikeway NetworkDocument2 pagesHouston Bikeway NetworkCarl JonardNo ratings yet

- Guitar Collection: E B G D A EDocument3 pagesGuitar Collection: E B G D A EОлександр РешетухаNo ratings yet

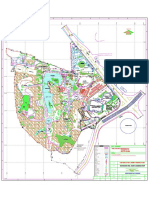

- Shilparamam Hyderabad Revised1 Model 1 PDFDocument1 pageShilparamam Hyderabad Revised1 Model 1 PDFPratima MaheshNo ratings yet

- 1473a-Ir-A0-0003 - Site Dev - Dripper Irrigation LayoutDocument1 page1473a-Ir-A0-0003 - Site Dev - Dripper Irrigation LayoutMohsin ShaikhNo ratings yet

- 1473a-Ir-A0-0005 - Site Dev - Popup Irrigation LayoutDocument1 page1473a-Ir-A0-0005 - Site Dev - Popup Irrigation LayoutMohsin ShaikhNo ratings yet

- Plano Belen 1 PDFDocument1 pagePlano Belen 1 PDFJunior BarbozaNo ratings yet

- Uno Emn Mil QuinientosDocument1 pageUno Emn Mil QuinientosPercy HNNo ratings yet

- Isométrico - Sprinklers Legenda: Detalhe Do Dreno Do SPKDocument1 pageIsométrico - Sprinklers Legenda: Detalhe Do Dreno Do SPKSamuel BatistaNo ratings yet

- Fadil 2013 Fix-A3 (Plot)Document1 pageFadil 2013 Fix-A3 (Plot)Dimas WiryaNo ratings yet

- Sector Huancapata 03Document1 pageSector Huancapata 03Carlos BustamanteNo ratings yet

- Plano en Planta: UbicaciónDocument1 pagePlano en Planta: UbicaciónCARLOS ALBERTONo ratings yet

- KEC RWSS GAN KHA SLU GA 014 Layout1Document1 pageKEC RWSS GAN KHA SLU GA 014 Layout1IkramNo ratings yet

- 191 Pampero J.morelDocument4 pages191 Pampero J.morelgiiuseppe.11No ratings yet

- Cobotta eDocument6 pagesCobotta eThắng HoàngNo ratings yet

- SANTA - PARCELLARY PLAN REVISED 6.0 Sheet 5Document1 pageSANTA - PARCELLARY PLAN REVISED 6.0 Sheet 5Gwapo AkoNo ratings yet

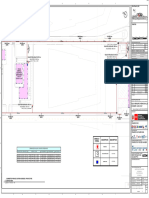

- Multi Purpose Hall GF LayoutDocument1 pageMulti Purpose Hall GF LayoutShivraj KmNo ratings yet

- Plano de Planimetria: Compañia Minera AntapaccayDocument1 pagePlano de Planimetria: Compañia Minera AntapaccayJoshep jimenez pereyraNo ratings yet

- X0231 PDW Eut DG 20007 AaDocument1 pageX0231 PDW Eut DG 20007 AajianranrenNo ratings yet

- Andante: "Broken Strings" Old Russian Waltz Music By: P.Gapon Arr. For Guitar O.KrohaDocument3 pagesAndante: "Broken Strings" Old Russian Waltz Music By: P.Gapon Arr. For Guitar O.Krohahuong trinhNo ratings yet

- Hotel SDP For DrawingDocument1 pageHotel SDP For DrawingJohn Zedrick MacaisaNo ratings yet

- FL3B-474-P-2635 As BuiltDocument1 pageFL3B-474-P-2635 As BuiltAlbet MulyonoNo ratings yet

- Hassan Allam: Refer Comments Made On Isometric Drawing at 693186-V-5001-0345-01 and Update This Isometric AccordinglyDocument1 pageHassan Allam: Refer Comments Made On Isometric Drawing at 693186-V-5001-0345-01 and Update This Isometric AccordinglymohsinqcqaNo ratings yet

- 191 Pampero J.MorelDocument4 pages191 Pampero J.Morelhuong trinhNo ratings yet

- Ubicacion Sr. Roger CumapaDocument1 pageUbicacion Sr. Roger CumapaAnghy VicenteNo ratings yet

- Mudarra Alonso Fantasia N 10Document2 pagesMudarra Alonso Fantasia N 10saornil100% (1)

- Pyramids Sections-Sec A-ADocument1 pagePyramids Sections-Sec A-AMAHMOUD HISHAMNo ratings yet

- BP805 BP805 BP806 BP806: Bav70 (Sot-23) Bav70 (Sot-23)Document3 pagesBP805 BP805 BP806 BP806: Bav70 (Sot-23) Bav70 (Sot-23)Adilson ManoelNo ratings yet

- Ku Plumbing Progress Set-6162023Document19 pagesKu Plumbing Progress Set-6162023Chainlink EngineeringNo ratings yet

- Remi K30 ProDocument14 pagesRemi K30 ProMohamed RafiudeenNo ratings yet

- Colour Tv Schematic Diagram: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Document1 pageColour Tv Schematic Diagram: Pdf 文件使用 "Pdffactory Pro" 试用版本创建gansolNo ratings yet

- PDF Pembahasan Osk Fisika 2023Document5 pagesPDF Pembahasan Osk Fisika 2023syakurahyNo ratings yet

- Project Oxygas (15687558)Document2 pagesProject Oxygas (15687558)Mario Alberto Pineda CastilloNo ratings yet

- El CálizDocument1 pageEl CálizscribdcristinaNo ratings yet

- Catalog of Book Publish in Burma 1877-1882Document26 pagesCatalog of Book Publish in Burma 1877-1882kerrypwlNo ratings yet

- Sewer Pipe Installation PDFDocument1 pageSewer Pipe Installation PDFnavisNo ratings yet

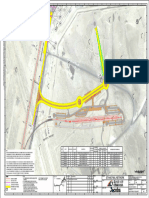

- Clearing and Grubbing 052622Document1 pageClearing and Grubbing 052622CCDC PTP MabalacatNo ratings yet

- SHD Cscec 18 F01 ST SC 01 Ex 05 0009 0000 00Document1 pageSHD Cscec 18 F01 ST SC 01 Ex 05 0009 0000 00Mohamed SherifNo ratings yet

- Choque PlanoDocument1 pageChoque Planojosue elias colqueNo ratings yet

- RMC Plant LayoutDocument1 pageRMC Plant LayoutSinamm Engineering LimitedNo ratings yet

- Baritone Sax JF - Baritone Sax Days of Whine and RoseDocument3 pagesBaritone Sax JF - Baritone Sax Days of Whine and RoseTadeo RodriguezNo ratings yet

- Ci PW 01 06 004Document1 pageCi PW 01 06 004harihfclNo ratings yet

- Project 257 DBPDocument10 pagesProject 257 DBPĐỨC LÊ QUANGNo ratings yet

- TOPOGRAFICODocument1 pageTOPOGRAFICOpaulorenita1997No ratings yet

- Redmi Note 8 (LLDM516) Schematic DiagramDocument29 pagesRedmi Note 8 (LLDM516) Schematic Diagramakash0% (1)

- Oslo M Schematics KB 180929 1438Document2 pagesOslo M Schematics KB 180929 1438Federico Héctor UsseglioNo ratings yet

- Road Crossing DuctsDocument1 pageRoad Crossing Ductsmohan890No ratings yet

- Orange Crush 20l Guitar Amp SCHDocument1 pageOrange Crush 20l Guitar Amp SCHHelson Jader RochaNo ratings yet

- Birsa Munda To Fauzi Chouk-0-230Document1 pageBirsa Munda To Fauzi Chouk-0-230shivshankar kushwahaNo ratings yet

- 3.0 LPG 2010 Schematic Rev C 2010-11-26Document1 page3.0 LPG 2010 Schematic Rev C 2010-11-26David CraigNo ratings yet

- 2.1 - Manual Ball ValveDocument4 pages2.1 - Manual Ball ValveabdulhalimbinamrinNo ratings yet

- Noreply@fiorentini Com - 20150306 - 102137 (LATEST!!!)Document13 pagesNoreply@fiorentini Com - 20150306 - 102137 (LATEST!!!)abdulhalimbinamrinNo ratings yet

- ContentsDocument8 pagesContentsabdulhalimbinamrinNo ratings yet

- Iso 5168 - 1998Document75 pagesIso 5168 - 1998abdulhalimbinamrinNo ratings yet

- Visio-PLAN LAYOUT SJL TIOMAN 2020 Rev.1 UpgradingDocument1 pageVisio-PLAN LAYOUT SJL TIOMAN 2020 Rev.1 UpgradingabdulhalimbinamrinNo ratings yet

- 11kV Primary SG DWG (Tioman) - Tender AttachmentDocument48 pages11kV Primary SG DWG (Tioman) - Tender AttachmentabdulhalimbinamrinNo ratings yet

- PR FormDocument2 pagesPR FormabdulhalimbinamrinNo ratings yet

- Manufacturing-Equipment Calibration CertificateDocument14 pagesManufacturing-Equipment Calibration CertificateabdulhalimbinamrinNo ratings yet

- Pet Ro 26Document1 pagePet Ro 26abdulhalimbinamrinNo ratings yet

- 16102023162524Document10 pages16102023162524abdulhalimbinamrinNo ratings yet

- 2023MT1384 - Test ReportDocument8 pages2023MT1384 - Test ReportabdulhalimbinamrinNo ratings yet

- Sapuraomv Upstream (Sarawak) Inc: Z0 07/11/22 Final MQR Mha MsaDocument3 pagesSapuraomv Upstream (Sarawak) Inc: Z0 07/11/22 Final MQR Mha MsaabdulhalimbinamrinNo ratings yet

- Copper-Beryllium Alloy Seamless Tube: Standard Specification ForDocument5 pagesCopper-Beryllium Alloy Seamless Tube: Standard Specification ForsamehNo ratings yet

- 20040930-What Is Process Capability - PpsDocument2 pages20040930-What Is Process Capability - PpsSanjay DhawasNo ratings yet

- Shaft Limit FitDocument3 pagesShaft Limit FitUmang DaveNo ratings yet

- ANSI B16.9 ElbowDocument3 pagesANSI B16.9 ElbowMahmoud Reda ElSherifNo ratings yet

- Chapter 5. Tolerable Foundation Deformation CriteriaDocument5 pagesChapter 5. Tolerable Foundation Deformation CriteriaAJR365No ratings yet

- Quality Control in The Fish IndustryDocument13 pagesQuality Control in The Fish IndustrysuritataNo ratings yet

- Is 4503 Specification For Shell and Tube Type Heat Exchangers PDFDocument69 pagesIs 4503 Specification For Shell and Tube Type Heat Exchangers PDFPiyush AgarwalNo ratings yet

- Is 2062Document14 pagesIs 2062Elumalai Srinivasan100% (1)

- Turcon Varilip PDR: Trelleborg Se Aling SolutionsDocument41 pagesTurcon Varilip PDR: Trelleborg Se Aling SolutionsaceinsteinNo ratings yet

- Model Answer Winter 2019Document9 pagesModel Answer Winter 2019Shubham NykNo ratings yet

- Catalogue BBSDocument28 pagesCatalogue BBSMohamed AlkharashyNo ratings yet

- Temperature Sensor For Fluids TSF: RE 95180/2021-06-30 Replaces: 2020-03-27Document12 pagesTemperature Sensor For Fluids TSF: RE 95180/2021-06-30 Replaces: 2020-03-27paolono maratonaNo ratings yet

- Zlib - Pub Statistical Quality Control MethodsDocument537 pagesZlib - Pub Statistical Quality Control MethodsyosNo ratings yet

- Bearing, Roller, Tapered, Single Row of Rollers (Metric Series)Document5 pagesBearing, Roller, Tapered, Single Row of Rollers (Metric Series)Darwin DarmawanNo ratings yet

- Quality: A. Quality: A Management PhilosophyDocument12 pagesQuality: A. Quality: A Management PhilosophyBehbehlynnNo ratings yet

- ESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockDocument57 pagesESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockRafael SchelbauerNo ratings yet

- GD&TDocument73 pagesGD&TschwerzerspanerNo ratings yet

- Iso 4759Document63 pagesIso 4759NatashaAggarwal50% (2)

- And Reverse: High Clutch ClutchDocument6 pagesAnd Reverse: High Clutch ClutchAnton FortovNo ratings yet

- 'Voebnfoubm 1sjodjqmft PG .Fdibojdbm &ohjoffsjoh: '-&/%&3 ESJWFTDocument150 pages'Voebnfoubm 1sjodjqmft PG .Fdibojdbm &ohjoffsjoh: '-&/%&3 ESJWFTraul carvajal rozasNo ratings yet

- Working With LiDAR in MicroStationDocument9 pagesWorking With LiDAR in MicroStationKélibiano FirasNo ratings yet

- 10 Structure, Function and Maintenance Standard 2 ParteDocument102 pages10 Structure, Function and Maintenance Standard 2 ParteAugusto OliveiraNo ratings yet

- Mineral Fiber Blanket Insulation and Blanket-Type Pipe Insulation (Metal-Mesh Covered) (Industrial Type)Document9 pagesMineral Fiber Blanket Insulation and Blanket-Type Pipe Insulation (Metal-Mesh Covered) (Industrial Type)Syed Shoaib RazaNo ratings yet

- Aitchison2017 PDFDocument13 pagesAitchison2017 PDFPepo Girones MasanetNo ratings yet

- Sensor Geophones BR 091509Document8 pagesSensor Geophones BR 091509Andy KurniyantoNo ratings yet

02 - Ro PTS

02 - Ro PTS

Uploaded by

abdulhalimbinamrinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 - Ro PTS

02 - Ro PTS

Uploaded by

abdulhalimbinamrinCopyright:

Available Formats

2 3 4

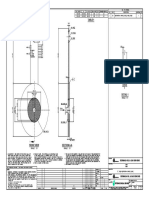

NOTES: co

0

0

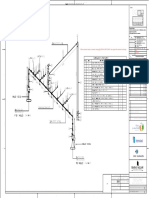

Unless otherwise specified in the requisition, the following applies: N

CTl

1. Dimensions Expressed in millimetres unless otherwise indicated. 'CJ-

p Stated tolerances shall be strictly adhered to. 0

R=3

2. Material As per requisition.

3. Plate thickness The difference between any two measurements of plate thickness, for annular

port d-D0, shall not differ by more than 0.001 DN in mm.

A The plate shall not deport from flatness along any diameter by more than 0.01 DO

U)

--+-----+--~ n Tolerance for N shall be:

Hole (2 mm dia.) N ~ 6 mm-- +0.1 /-0.25 mm and

marks the relative position 100 N > 6 mrn-e-- +/-1 5 mm

of the vent/drain hole RO Thickness for annular port D0-0, may be slightly less, max 0.05 mm, due to

if present (see note 7) 004 surface finishing difference between d-D0 and D0 -0.

ANS 600 RF-+---------+- (See note 6).

Typical example of marking DN 250

See note 9 d=60.4 4. Concentricity The centre of the orifice shall not differ from the centre of the plate by more

Mot. 316 than 0.1 mm for DN .::; 200 mm and 0.2 mm for DN > 200 mm.

RESTRICTIO '------+--------"-____J_

5. Finish of throat The throat and outlet cone shall hove a surface roughness Ro ::;; 0.4 µ m

According to ANSI 846.1.

All edges shall be sharp and free from burrs, so that when viewed with the

naked eye no light is reflected by the corners.

6. Finish of plate The upstream and downstream faces of the orifice plate to a diameter equal to DO

See note 8 shall hove a surface roughness Ro .::; 0.8 µm according to ANSI 846.1.

The remaining annular port (between O and D0 ) of upstream and downstream faces

shall hove a surface roughness Ro between 3.2 and 3.6 µ m according to ANSI 846.1.

See note 7 See note 7

This finish shall be obtained by machining with a round nosed cutting tool having a

(vent hole) 0.8 mm radius at a feed rote between 0.35 and 0.45 mm per revolution.

B See detail A Facing roughness may be checked by visual or tactile comparison with roughness

specimen: "rubert 319" or "flexitollic 319".

7. Bleed/Vent hole If so specified on the requisition, either a vent hole (for liquids) or a drain hole

x

N (for gases/steam) shall be provided.

-+- ---- - D FLOW~ 1

8. Welding of tab Tab may be integral

In other coses full

with orifice

penetration

plate

joint

up to and

to be applied.

including 7 mm plate thickness.

x

See notes 4 and 5 9. Marking The upstream side of the orifice tab shall be stomped at the indicated locations with:

- the word UPSTREAM

- the Tog Number (in three lines)

- the ANS flange class, followed by RF

- the nominal line size DN (in mm)

- the measured orifice diameter d (in mm)

See note 6

t FLOW ~ 0

- the material of the orifice plate

31L

u the word RESTRICTION

c

See

(drain

note

hole)

7

A~

I

See nole JL u

11 10.

Letter

Allowable

height

pressure

The thickness

approx.

difference

of the plate

4mm.

20 bar for temperatures

needs to be verified

up to 400 'C and d/Do:::O:

for strength in case the pressure

0.1.

difference is higher than 20 bar and/ or the temperature is beyond 400 'C.

SECTION A-A DETAIL-A Based on the outcome of the calculation the thickness of the plate needs to be

adjusted.

Norn. line d Do L N 0 p s±1mm T x y

o-0.4mm

size ±0.1% ±1mm ±0.1mm see ±1mm (see ±1mm

ON note 3 note 8)

ANS flange class ANS flange class

mm in. dia dia 150 300 600 900 1500 2500 150 300 600 900 1500 2500 (See note 7)

*) *)

x

15 1/2 13 0.24 48 54 54 64 64 70 28

1.5 110 110 115 115 120 1.5

*) 20 3/4 19 0.34 57 67 67 70 70 77

*) 25 1 25 0.42 2.0 67 73 73 80 80 86 30 110 115 115 120 120 125 2.0

*) 40 11/2 40 0.64 3.0 86 96 96 99 99 118 120 120

125 130

c

50 2 0 51 1 .0 6.0 105 111 111 143 143 146 115 115 125 3.0 21.0 1.0

+--'

80 3 en 76 8.0 137 149 149 168 175 197 120 120 135 140 33.0 1.5

100 4 ::J

o 102 1 .5 10.0 175 181 194 206 209 235 115 125 125 130 140 150 45.5 2.0

40 5.0 Ref.Ind. Sign/init. Ref.Ind. Sign/init.

150 6 2:'. 152 15.0 222 250 266 289 282 317 120 130 135 145 70.5 2.5 Designer Custodian

170

200 8 L

202 15.0 279 307 320 358 352 387 125 135 155 95.0 3.5 ISSUE DATE DESCRIPTION

(])

120 7.0 APPROVED. BY

Q_

250 10 253 3.5 19.0 339 361 399 434 434 475 130 145 190 120.0 4.5 This document is confidential. Neither the whole nor ony port of this document may be disclosed to any third

en 145 165

D 300 12 <( 302 20.0 409 422 456 497 520 549 45 125 135 140 195 144.0 5.5 party without the prior written consent of PETRONAS. The copyright of this document is vested in this company.

10.0 All rights reserved. Neither the whole nor any port of this document may be reproduced, stored in any retrieval

577 175

x x

350 14 341 20.0 450 485 491 519 140 145 150 163.5 6.0

6.0 system or transmitted in any form or by any means (electronic, mechanical, reprographic, recording or otherwise)

400 16 392 21.0 513 539 564 573 640 130 150 155 180 11.0 188.5 7.0 without the prior written consent of the copyright owner.

145

450 18 443 23.0 548 596 611 637 703 50 160 195 13.0 213.5 8.0

8.0 155

500 20 494 25.0 605 653 681 697 754 150 165 205 16.0 238.0 9.0 RES TR I CT ION OR I FI C E PLATES

135

600 24 595 10.0 29.0 716 773 789 836 899 60 160 165 190 225 18.0 288.0 10.0 FOR ANSI/ ASM E B 16.5 RAISED FACE FLANGE

*) p 28 for DN 15 - class 150 only.

1-----S_T

A_N_D_A_R_D

_D_R_A_W_I

N_G_ _______, SCALE Sheet No. of

0 2 3 4 5 6 7 8 9 10 PETRONAS DRG No. 014.92.006-E

You might also like

- Orange Crush 20l Guitar Amp SchematicDocument1 pageOrange Crush 20l Guitar Amp SchematicThiago Darós Fernandes80% (5)

- 11Document74 pages11Carolina Duque0% (1)

- Orange Crush 20l Guitar Amp SCH PDFDocument1 pageOrange Crush 20l Guitar Amp SCH PDFToto WaltherNo ratings yet

- Spec - Ohe - Cat (Cu MG) 0120 (11 - 12Document21 pagesSpec - Ohe - Cat (Cu MG) 0120 (11 - 12hardeep08No ratings yet

- ANSI H35-2 - ERRATA Pages - Dec 19 2017 - 0 PDFDocument3 pagesANSI H35-2 - ERRATA Pages - Dec 19 2017 - 0 PDFAhmad SyafiqNo ratings yet

- FS PLM 111 0008Document14 pagesFS PLM 111 0008Jako MishyNo ratings yet

- 6-2 Plan Situatie VLAICU BERD-43 PDFDocument1 page6-2 Plan Situatie VLAICU BERD-43 PDFwww.criticarad.roNo ratings yet

- DW044 P03 PRB SL 1059Document1 pageDW044 P03 PRB SL 1059mohammad shabazNo ratings yet

- Gon SNR B12Document1 pageGon SNR B12BNG GondomarNo ratings yet

- Aicc CNCH 3 PK000 FFP DRW 01 00103 - 00aDocument1 pageAicc CNCH 3 PK000 FFP DRW 01 00103 - 00aFrancisco QuiñonezNo ratings yet

- Planimetria General - Okok-Tramo 01 y 02 OkDocument1 pagePlanimetria General - Okok-Tramo 01 y 02 OkJHOAN APOLINARIONo ratings yet

- SHD Cscec 18 F01 ST SC 01 Ex 05 0007 0000 01 PDFDocument1 pageSHD Cscec 18 F01 ST SC 01 Ex 05 0007 0000 01 PDFMohamed SherifNo ratings yet

- Houston Bikeway NetworkDocument2 pagesHouston Bikeway NetworkCarl JonardNo ratings yet

- Guitar Collection: E B G D A EDocument3 pagesGuitar Collection: E B G D A EОлександр РешетухаNo ratings yet

- Shilparamam Hyderabad Revised1 Model 1 PDFDocument1 pageShilparamam Hyderabad Revised1 Model 1 PDFPratima MaheshNo ratings yet

- 1473a-Ir-A0-0003 - Site Dev - Dripper Irrigation LayoutDocument1 page1473a-Ir-A0-0003 - Site Dev - Dripper Irrigation LayoutMohsin ShaikhNo ratings yet

- 1473a-Ir-A0-0005 - Site Dev - Popup Irrigation LayoutDocument1 page1473a-Ir-A0-0005 - Site Dev - Popup Irrigation LayoutMohsin ShaikhNo ratings yet

- Plano Belen 1 PDFDocument1 pagePlano Belen 1 PDFJunior BarbozaNo ratings yet

- Uno Emn Mil QuinientosDocument1 pageUno Emn Mil QuinientosPercy HNNo ratings yet

- Isométrico - Sprinklers Legenda: Detalhe Do Dreno Do SPKDocument1 pageIsométrico - Sprinklers Legenda: Detalhe Do Dreno Do SPKSamuel BatistaNo ratings yet

- Fadil 2013 Fix-A3 (Plot)Document1 pageFadil 2013 Fix-A3 (Plot)Dimas WiryaNo ratings yet

- Sector Huancapata 03Document1 pageSector Huancapata 03Carlos BustamanteNo ratings yet

- Plano en Planta: UbicaciónDocument1 pagePlano en Planta: UbicaciónCARLOS ALBERTONo ratings yet

- KEC RWSS GAN KHA SLU GA 014 Layout1Document1 pageKEC RWSS GAN KHA SLU GA 014 Layout1IkramNo ratings yet

- 191 Pampero J.morelDocument4 pages191 Pampero J.morelgiiuseppe.11No ratings yet

- Cobotta eDocument6 pagesCobotta eThắng HoàngNo ratings yet

- SANTA - PARCELLARY PLAN REVISED 6.0 Sheet 5Document1 pageSANTA - PARCELLARY PLAN REVISED 6.0 Sheet 5Gwapo AkoNo ratings yet

- Multi Purpose Hall GF LayoutDocument1 pageMulti Purpose Hall GF LayoutShivraj KmNo ratings yet

- Plano de Planimetria: Compañia Minera AntapaccayDocument1 pagePlano de Planimetria: Compañia Minera AntapaccayJoshep jimenez pereyraNo ratings yet

- X0231 PDW Eut DG 20007 AaDocument1 pageX0231 PDW Eut DG 20007 AajianranrenNo ratings yet

- Andante: "Broken Strings" Old Russian Waltz Music By: P.Gapon Arr. For Guitar O.KrohaDocument3 pagesAndante: "Broken Strings" Old Russian Waltz Music By: P.Gapon Arr. For Guitar O.Krohahuong trinhNo ratings yet

- Hotel SDP For DrawingDocument1 pageHotel SDP For DrawingJohn Zedrick MacaisaNo ratings yet

- FL3B-474-P-2635 As BuiltDocument1 pageFL3B-474-P-2635 As BuiltAlbet MulyonoNo ratings yet

- Hassan Allam: Refer Comments Made On Isometric Drawing at 693186-V-5001-0345-01 and Update This Isometric AccordinglyDocument1 pageHassan Allam: Refer Comments Made On Isometric Drawing at 693186-V-5001-0345-01 and Update This Isometric AccordinglymohsinqcqaNo ratings yet

- 191 Pampero J.MorelDocument4 pages191 Pampero J.Morelhuong trinhNo ratings yet

- Ubicacion Sr. Roger CumapaDocument1 pageUbicacion Sr. Roger CumapaAnghy VicenteNo ratings yet

- Mudarra Alonso Fantasia N 10Document2 pagesMudarra Alonso Fantasia N 10saornil100% (1)

- Pyramids Sections-Sec A-ADocument1 pagePyramids Sections-Sec A-AMAHMOUD HISHAMNo ratings yet

- BP805 BP805 BP806 BP806: Bav70 (Sot-23) Bav70 (Sot-23)Document3 pagesBP805 BP805 BP806 BP806: Bav70 (Sot-23) Bav70 (Sot-23)Adilson ManoelNo ratings yet

- Ku Plumbing Progress Set-6162023Document19 pagesKu Plumbing Progress Set-6162023Chainlink EngineeringNo ratings yet

- Remi K30 ProDocument14 pagesRemi K30 ProMohamed RafiudeenNo ratings yet

- Colour Tv Schematic Diagram: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Document1 pageColour Tv Schematic Diagram: Pdf 文件使用 "Pdffactory Pro" 试用版本创建gansolNo ratings yet

- PDF Pembahasan Osk Fisika 2023Document5 pagesPDF Pembahasan Osk Fisika 2023syakurahyNo ratings yet

- Project Oxygas (15687558)Document2 pagesProject Oxygas (15687558)Mario Alberto Pineda CastilloNo ratings yet

- El CálizDocument1 pageEl CálizscribdcristinaNo ratings yet

- Catalog of Book Publish in Burma 1877-1882Document26 pagesCatalog of Book Publish in Burma 1877-1882kerrypwlNo ratings yet

- Sewer Pipe Installation PDFDocument1 pageSewer Pipe Installation PDFnavisNo ratings yet

- Clearing and Grubbing 052622Document1 pageClearing and Grubbing 052622CCDC PTP MabalacatNo ratings yet

- SHD Cscec 18 F01 ST SC 01 Ex 05 0009 0000 00Document1 pageSHD Cscec 18 F01 ST SC 01 Ex 05 0009 0000 00Mohamed SherifNo ratings yet

- Choque PlanoDocument1 pageChoque Planojosue elias colqueNo ratings yet

- RMC Plant LayoutDocument1 pageRMC Plant LayoutSinamm Engineering LimitedNo ratings yet

- Baritone Sax JF - Baritone Sax Days of Whine and RoseDocument3 pagesBaritone Sax JF - Baritone Sax Days of Whine and RoseTadeo RodriguezNo ratings yet

- Ci PW 01 06 004Document1 pageCi PW 01 06 004harihfclNo ratings yet

- Project 257 DBPDocument10 pagesProject 257 DBPĐỨC LÊ QUANGNo ratings yet

- TOPOGRAFICODocument1 pageTOPOGRAFICOpaulorenita1997No ratings yet

- Redmi Note 8 (LLDM516) Schematic DiagramDocument29 pagesRedmi Note 8 (LLDM516) Schematic Diagramakash0% (1)

- Oslo M Schematics KB 180929 1438Document2 pagesOslo M Schematics KB 180929 1438Federico Héctor UsseglioNo ratings yet

- Road Crossing DuctsDocument1 pageRoad Crossing Ductsmohan890No ratings yet

- Orange Crush 20l Guitar Amp SCHDocument1 pageOrange Crush 20l Guitar Amp SCHHelson Jader RochaNo ratings yet

- Birsa Munda To Fauzi Chouk-0-230Document1 pageBirsa Munda To Fauzi Chouk-0-230shivshankar kushwahaNo ratings yet

- 3.0 LPG 2010 Schematic Rev C 2010-11-26Document1 page3.0 LPG 2010 Schematic Rev C 2010-11-26David CraigNo ratings yet

- 2.1 - Manual Ball ValveDocument4 pages2.1 - Manual Ball ValveabdulhalimbinamrinNo ratings yet

- Noreply@fiorentini Com - 20150306 - 102137 (LATEST!!!)Document13 pagesNoreply@fiorentini Com - 20150306 - 102137 (LATEST!!!)abdulhalimbinamrinNo ratings yet

- ContentsDocument8 pagesContentsabdulhalimbinamrinNo ratings yet

- Iso 5168 - 1998Document75 pagesIso 5168 - 1998abdulhalimbinamrinNo ratings yet

- Visio-PLAN LAYOUT SJL TIOMAN 2020 Rev.1 UpgradingDocument1 pageVisio-PLAN LAYOUT SJL TIOMAN 2020 Rev.1 UpgradingabdulhalimbinamrinNo ratings yet

- 11kV Primary SG DWG (Tioman) - Tender AttachmentDocument48 pages11kV Primary SG DWG (Tioman) - Tender AttachmentabdulhalimbinamrinNo ratings yet

- PR FormDocument2 pagesPR FormabdulhalimbinamrinNo ratings yet

- Manufacturing-Equipment Calibration CertificateDocument14 pagesManufacturing-Equipment Calibration CertificateabdulhalimbinamrinNo ratings yet

- Pet Ro 26Document1 pagePet Ro 26abdulhalimbinamrinNo ratings yet

- 16102023162524Document10 pages16102023162524abdulhalimbinamrinNo ratings yet

- 2023MT1384 - Test ReportDocument8 pages2023MT1384 - Test ReportabdulhalimbinamrinNo ratings yet

- Sapuraomv Upstream (Sarawak) Inc: Z0 07/11/22 Final MQR Mha MsaDocument3 pagesSapuraomv Upstream (Sarawak) Inc: Z0 07/11/22 Final MQR Mha MsaabdulhalimbinamrinNo ratings yet

- Copper-Beryllium Alloy Seamless Tube: Standard Specification ForDocument5 pagesCopper-Beryllium Alloy Seamless Tube: Standard Specification ForsamehNo ratings yet

- 20040930-What Is Process Capability - PpsDocument2 pages20040930-What Is Process Capability - PpsSanjay DhawasNo ratings yet

- Shaft Limit FitDocument3 pagesShaft Limit FitUmang DaveNo ratings yet

- ANSI B16.9 ElbowDocument3 pagesANSI B16.9 ElbowMahmoud Reda ElSherifNo ratings yet

- Chapter 5. Tolerable Foundation Deformation CriteriaDocument5 pagesChapter 5. Tolerable Foundation Deformation CriteriaAJR365No ratings yet

- Quality Control in The Fish IndustryDocument13 pagesQuality Control in The Fish IndustrysuritataNo ratings yet

- Is 4503 Specification For Shell and Tube Type Heat Exchangers PDFDocument69 pagesIs 4503 Specification For Shell and Tube Type Heat Exchangers PDFPiyush AgarwalNo ratings yet

- Is 2062Document14 pagesIs 2062Elumalai Srinivasan100% (1)

- Turcon Varilip PDR: Trelleborg Se Aling SolutionsDocument41 pagesTurcon Varilip PDR: Trelleborg Se Aling SolutionsaceinsteinNo ratings yet

- Model Answer Winter 2019Document9 pagesModel Answer Winter 2019Shubham NykNo ratings yet

- Catalogue BBSDocument28 pagesCatalogue BBSMohamed AlkharashyNo ratings yet

- Temperature Sensor For Fluids TSF: RE 95180/2021-06-30 Replaces: 2020-03-27Document12 pagesTemperature Sensor For Fluids TSF: RE 95180/2021-06-30 Replaces: 2020-03-27paolono maratonaNo ratings yet

- Zlib - Pub Statistical Quality Control MethodsDocument537 pagesZlib - Pub Statistical Quality Control MethodsyosNo ratings yet

- Bearing, Roller, Tapered, Single Row of Rollers (Metric Series)Document5 pagesBearing, Roller, Tapered, Single Row of Rollers (Metric Series)Darwin DarmawanNo ratings yet

- Quality: A. Quality: A Management PhilosophyDocument12 pagesQuality: A. Quality: A Management PhilosophyBehbehlynnNo ratings yet

- ESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockDocument57 pagesESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockRafael SchelbauerNo ratings yet

- GD&TDocument73 pagesGD&TschwerzerspanerNo ratings yet

- Iso 4759Document63 pagesIso 4759NatashaAggarwal50% (2)

- And Reverse: High Clutch ClutchDocument6 pagesAnd Reverse: High Clutch ClutchAnton FortovNo ratings yet

- 'Voebnfoubm 1sjodjqmft PG .Fdibojdbm &ohjoffsjoh: '-&/%&3 ESJWFTDocument150 pages'Voebnfoubm 1sjodjqmft PG .Fdibojdbm &ohjoffsjoh: '-&/%&3 ESJWFTraul carvajal rozasNo ratings yet

- Working With LiDAR in MicroStationDocument9 pagesWorking With LiDAR in MicroStationKélibiano FirasNo ratings yet

- 10 Structure, Function and Maintenance Standard 2 ParteDocument102 pages10 Structure, Function and Maintenance Standard 2 ParteAugusto OliveiraNo ratings yet

- Mineral Fiber Blanket Insulation and Blanket-Type Pipe Insulation (Metal-Mesh Covered) (Industrial Type)Document9 pagesMineral Fiber Blanket Insulation and Blanket-Type Pipe Insulation (Metal-Mesh Covered) (Industrial Type)Syed Shoaib RazaNo ratings yet

- Aitchison2017 PDFDocument13 pagesAitchison2017 PDFPepo Girones MasanetNo ratings yet

- Sensor Geophones BR 091509Document8 pagesSensor Geophones BR 091509Andy KurniyantoNo ratings yet