Professional Documents

Culture Documents

Qcpi 3

Qcpi 3

Uploaded by

Hausland Const. Corp.0 ratings0% found this document useful (0 votes)

2 views2 pagesThe document summarizes an inspection of welding activities for the upgrading of a wastewater treatment plant at Nestle Philippines' Cagayan de Oro factory. It lists items to be inspected, including welding procedures, consumables, and welders' qualifications. Acceptance requirements specify that welding must conform to ASME and other standards, use approved procedures and consumables, and have welders qualified by a recognized testing agency. The project inspection team is tasked with verifying all welding activities meet the acceptance requirements.

Original Description:

Original Title

QCPI_3

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes an inspection of welding activities for the upgrading of a wastewater treatment plant at Nestle Philippines' Cagayan de Oro factory. It lists items to be inspected, including welding procedures, consumables, and welders' qualifications. Acceptance requirements specify that welding must conform to ASME and other standards, use approved procedures and consumables, and have welders qualified by a recognized testing agency. The project inspection team is tasked with verifying all welding activities meet the acceptance requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

2 views2 pagesQcpi 3

Qcpi 3

Uploaded by

Hausland Const. Corp.The document summarizes an inspection of welding activities for the upgrading of a wastewater treatment plant at Nestle Philippines' Cagayan de Oro factory. It lists items to be inspected, including welding procedures, consumables, and welders' qualifications. Acceptance requirements specify that welding must conform to ASME and other standards, use approved procedures and consumables, and have welders qualified by a recognized testing agency. The project inspection team is tasked with verifying all welding activities meet the acceptance requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 2

Name of Project: NESTLE PHILIPPINES INC.

- CDO FACTORY

Nature of Project: UPGRADING OF WWTP MILK WASTE STREAM

ACTIVITY ITEMS/PARTS INSPECTED SPECIFIC CHECK AREA TEST/ EXTENT APPLICABLE

INSPECTION OF TEST/ INSPECTION DOCUMENTS

QC OP

5. SHOP WELDING WPS and PQR Essential and Non Verification 100% 100% WPS, PQR

Essential Variables Visual

Welding Type / Brand / Size Verification Random 100% Approved WPS

Consumables Condition

Welders and Qualification Verification 100% 100% ASME IX

Welding Operators Visual Approved WPS

Location: Brgy. Tablon, Cagayan de Oro City

Cover Period: September 2014 - February 2015

ACCEPTANCE REQUIREMENT PROJECT INSP. TEAM

BIPI - FMN BIPI QC NPI

detrimental to the weld or base metal. A minimum distance of 25 mm

from weld edge shall be clean.

4.5 Dimension tolerances for fabricated piping shall meet the C C W/R

requirements stated in the drawing.

5.1 Shall conform to ASME IX and ASME B 31.3 and shall be D/C H/R R/Ap

approved by party recognized by international testing agency.

5.2 Shall conform to approved welding procedures specifications and D/C C W

project specification.

5.3 Filler metals / electrodes with damaged coating, wetted or have D/C C W

been soaked in water shall not be used to avoid possible weld

defects.

5.4 Electrodes shall be stored in a dry environment, handled and D/C C W

conditioned in accordance with manufacturer's recommendations.

Electrodes shall only be redried twice befor being discarded.

5.5 Consumables which has no identification and approved mill D/C C W

certificate shall not be used.

5.6 Shall be qualified by an independent body recognized by D/C C W

international testing agency

5.7 Welder's and welding operator's repair rates shall not exceed 5% D/C H/R R

You might also like

- 91 Club HackDocument2 pages91 Club Hackbotplay301090% (30)

- Subsea Rigid Pipelines – Methods of InstallationFrom EverandSubsea Rigid Pipelines – Methods of InstallationRating: 5 out of 5 stars5/5 (1)

- CG4352 GM1927 03a Gas Mig Braze Weld Quality Verification ProcedureDocument10 pagesCG4352 GM1927 03a Gas Mig Braze Weld Quality Verification ProcedureBruna VitalNo ratings yet

- QAQC Procedure For FabricationDocument7 pagesQAQC Procedure For FabricationRajesh K Pillai100% (6)

- Heat Transfer SolutionsDocument783 pagesHeat Transfer SolutionsArianna CarleyNo ratings yet

- Quality Assurance For MS PipeDocument54 pagesQuality Assurance For MS PipeRam Narendra Nath100% (2)

- Quick Guide To Welding Procedure Qualification (WPS & PQR)Document5 pagesQuick Guide To Welding Procedure Qualification (WPS & PQR)Annamalai Ram JGCNo ratings yet

- File1 20090929 173721Document20 pagesFile1 20090929 173721rabindra pratamaNo ratings yet

- Shovels BucyrusDocument8 pagesShovels BucyrusAlexisPereiraVásquezNo ratings yet

- Qcpi 4Document2 pagesQcpi 4Hausland Const. Corp.No ratings yet

- Qcpi 1Document2 pagesQcpi 1Hausland Const. Corp.No ratings yet

- ITP Piping Nitrogen SystemDocument48 pagesITP Piping Nitrogen Systemmohd as shahiddin jafriNo ratings yet

- Welder and Wps Qualification Control ProcedureDocument24 pagesWelder and Wps Qualification Control ProcedurejhuliocessarsNo ratings yet

- Itp For Fabn. & Erection of Structural WorksDocument4 pagesItp For Fabn. & Erection of Structural Workscrm 2No ratings yet

- Oil Pantriting ProcedureDocument5 pagesOil Pantriting ProcedureSERT-QA/QC- BUZNo ratings yet

- API 510 Pressure Vessel Inspector Certification Preparation CourseDocument4 pagesAPI 510 Pressure Vessel Inspector Certification Preparation CoursejbsantoNo ratings yet

- Charlie Chong CV-2022 OctoberDocument40 pagesCharlie Chong CV-2022 OctobercharliechongNo ratings yet

- ITP Piping-PMLSB Fire WaterDocument22 pagesITP Piping-PMLSB Fire Watermohd as shahiddin jafriNo ratings yet

- PP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0Document14 pagesPP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0ibrahimNo ratings yet

- Qcpi 5Document2 pagesQcpi 5Hausland Const. Corp.No ratings yet

- Inspection and Testing For Under Ground Piping WorksDocument9 pagesInspection and Testing For Under Ground Piping WorksJOHNKNo ratings yet

- Project Name Project No.: OOOO: General Cable Pulling WorksDocument8 pagesProject Name Project No.: OOOO: General Cable Pulling WorksReynante AlimNo ratings yet

- Inspection Engineer - Senior Welding - Arunkumar Andavar - CVDocument7 pagesInspection Engineer - Senior Welding - Arunkumar Andavar - CVArun KumarNo ratings yet

- Jsa Installation of Supports and Cable Racks1Document16 pagesJsa Installation of Supports and Cable Racks1loveson709100% (3)

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- 2 API 570 Info PDFDocument4 pages2 API 570 Info PDFاحمد حسنNo ratings yet

- 2.13 QK-CL-09-00001-Site Readiness Check List For Vitrified Clay Pipes InstallationDocument1 page2.13 QK-CL-09-00001-Site Readiness Check List For Vitrified Clay Pipes InstallationMoh'd SameerNo ratings yet

- Fe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Document10 pagesFe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Parag WadekarNo ratings yet

- I Can Do That WPS'S, PQR's and WQ'sDocument93 pagesI Can Do That WPS'S, PQR's and WQ'sKo NSNo ratings yet

- uPVC Pipes & Fittings PDFDocument20 pagesuPVC Pipes & Fittings PDFjanith100% (1)

- Qcpi 7Document2 pagesQcpi 7Hausland Const. Corp.No ratings yet

- Ub Engineering LimitedDocument1 pageUb Engineering LimitedproxywarNo ratings yet

- BNDP3 in CSCEC P3C EL XX MS CI 00004 Method Statement For Waterproofing For SubstationsDocument175 pagesBNDP3 in CSCEC P3C EL XX MS CI 00004 Method Statement For Waterproofing For Substationssivalakshan96No ratings yet

- Charlie Chong CV-2018 March Rev04Document24 pagesCharlie Chong CV-2018 March Rev04charliechongNo ratings yet

- CV PidDocument6 pagesCV PidSibin DevasiaNo ratings yet

- A-Qac-Pro-730-38928 Rev ADocument10 pagesA-Qac-Pro-730-38928 Rev ARamzi ZoghlamiNo ratings yet

- C-6.2 Inspection of Materials and Equipment: DemoDocument1 pageC-6.2 Inspection of Materials and Equipment: DemoZega ChrisNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Pag 3 420Mwcfpp: Cable Splicing Works (Fiber Optic)Document20 pagesPag 3 420Mwcfpp: Cable Splicing Works (Fiber Optic)Reynante AlimNo ratings yet

- Pile Welding Quality Control Plan: SpecificationsDocument8 pagesPile Welding Quality Control Plan: Specificationsvelmurug_balaNo ratings yet

- Updated WMS - Welding of Duplex Stainless SteelDocument5 pagesUpdated WMS - Welding of Duplex Stainless Steelcameron toolseeNo ratings yet

- Resume of Mohd Illias Uddin (SR Welding-Mech QC)Document7 pagesResume of Mohd Illias Uddin (SR Welding-Mech QC)Mohammed IlliasuddinNo ratings yet

- 2.19 QK-CL-10-00001-Preinstallation (Material) I Pre Leak Testing For HVACs Duct & Duct AccessoriesDocument1 page2.19 QK-CL-10-00001-Preinstallation (Material) I Pre Leak Testing For HVACs Duct & Duct AccessoriesMoh'd SameerNo ratings yet

- Ayub Ali Mohammed CVDocument12 pagesAyub Ali Mohammed CVMatías AlonsoNo ratings yet

- Alm-Ims-Prc-Si-012 Piping Site Fabrication & Installation Inspection FDocument12 pagesAlm-Ims-Prc-Si-012 Piping Site Fabrication & Installation Inspection F123netflix542No ratings yet

- Inspection and Test Plan For Shell and Tube Heat Exchanger - Sample01Document3 pagesInspection and Test Plan For Shell and Tube Heat Exchanger - Sample01Mohamed AtefNo ratings yet

- Daily - Exam - 5A - Closed and AnswerDocument6 pagesDaily - Exam - 5A - Closed and AnswerGeorge KudiaborNo ratings yet

- Underck Insulation MSTDocument8 pagesUnderck Insulation MSTmahesh naikNo ratings yet

- Method Statement For Gravel Surfacing Around New Lift Station IW-10ADocument6 pagesMethod Statement For Gravel Surfacing Around New Lift Station IW-10ANazirNo ratings yet

- Qap - Sail-WbDocument2 pagesQap - Sail-WbRiyu RathodNo ratings yet

- RA 9262 - Law Against Violence Against Women and Their ChildrenDocument2 pagesRA 9262 - Law Against Violence Against Women and Their ChildrenKeneth Samson Del CarmenNo ratings yet

- SOP For ReactorDocument4 pagesSOP For ReactorqualityNo ratings yet

- Alaa Kamel Abd El-Hakm Kamel Abo Zeina: 4, El-Gameia ST, El-Mansoria, Embaba, Giza, EgyptDocument17 pagesAlaa Kamel Abd El-Hakm Kamel Abo Zeina: 4, El-Gameia ST, El-Mansoria, Embaba, Giza, EgyptAshraf SalamaNo ratings yet

- Weld Repair - PR - 0XXDocument10 pagesWeld Repair - PR - 0XXRAMAKRISHNANo ratings yet

- Op 08 Qualification of Welding ProceduresDocument3 pagesOp 08 Qualification of Welding ProceduresSalmanEjazNo ratings yet

- Inspection Plan For Pipe LineDocument4 pagesInspection Plan For Pipe LineArfanAliNo ratings yet

- 2.22 QK-CL-10-00002-Installation of Aboveground HVACs Chilled Water! Hot WaterDocument1 page2.22 QK-CL-10-00002-Installation of Aboveground HVACs Chilled Water! Hot WaterMoh'd SameerNo ratings yet

- Method Statement For Fabrication and Erection of Demineralized Water TankDocument12 pagesMethod Statement For Fabrication and Erection of Demineralized Water TanksomiqatarNo ratings yet

- SACIC-Q-1026 Rev.01 Precast Concrete Compressive Strenght Insp.Document2 pagesSACIC-Q-1026 Rev.01 Precast Concrete Compressive Strenght Insp.Muhammad AbrarNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- 102-V-5 QipDocument8 pages102-V-5 QipSaleemSahabNo ratings yet

- 4 API 653 AST Inspector CourseDocument4 pages4 API 653 AST Inspector CourseshaajiNo ratings yet

- Method of Statements (Rolling Rolling Procedure)Document12 pagesMethod of Statements (Rolling Rolling Procedure)Ravi TyagiNo ratings yet

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- Pamana Expenses NewDocument48 pagesPamana Expenses NewHausland Const. Corp.No ratings yet

- The Diverse WorkforceDocument22 pagesThe Diverse WorkforceHausland Const. Corp.No ratings yet

- TFOE Membership Application Form - FINAL2024Document3 pagesTFOE Membership Application Form - FINAL2024Hausland Const. Corp.No ratings yet

- Complete Colution CalcualtionDocument80 pagesComplete Colution CalcualtionHausland Const. Corp.No ratings yet

- Group 3 (MMPA) Chapter 8 CommunicationDocument66 pagesGroup 3 (MMPA) Chapter 8 CommunicationHausland Const. Corp.No ratings yet

- CH10 Foundations of Control (Group4 14-MMPA)Document16 pagesCH10 Foundations of Control (Group4 14-MMPA)Hausland Const. Corp.No ratings yet

- Le Ja COMPLTE ANALYSISDocument630 pagesLe Ja COMPLTE ANALYSISHausland Const. Corp.No ratings yet

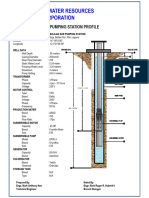

- Water Resources Inc - Pumping Station Profile - Well DesignDocument2 pagesWater Resources Inc - Pumping Station Profile - Well DesignHausland Const. Corp.No ratings yet

- 02.01.16 Process Flow DiagramDocument1 page02.01.16 Process Flow DiagramHausland Const. Corp.No ratings yet

- Report RCC DesignDocument21 pagesReport RCC DesignHausland Const. Corp.No ratings yet

- 1.28.16 Coca Cola Femsa Commercial ProposalDocument4 pages1.28.16 Coca Cola Femsa Commercial ProposalHausland Const. Corp.No ratings yet

- Canva 5 Design Milestone BadgeDocument3 pagesCanva 5 Design Milestone BadgeHausland Const. Corp.No ratings yet

- 01.25.16 BOQ2 Civil EstimateDocument25 pages01.25.16 BOQ2 Civil EstimateHausland Const. Corp.No ratings yet

- Kpi OpsDocument2 pagesKpi OpsHausland Const. Corp.No ratings yet

- 11.90 Design ReprotDocument10 pages11.90 Design ReprotHausland Const. Corp.No ratings yet

- BF Productivity RateDocument80 pagesBF Productivity RateHausland Const. Corp.No ratings yet

- For BILLING For Next BillingDocument28 pagesFor BILLING For Next BillingHausland Const. Corp.No ratings yet

- MP OrgDocument2 pagesMP OrgHausland Const. Corp.No ratings yet

- Layout & StakingDocument5 pagesLayout & StakingHausland Const. Corp.No ratings yet

- Le JaDocument198 pagesLe JaHausland Const. Corp.No ratings yet

- Engaging Theme - ReportDocument2 pagesEngaging Theme - ReportHausland Const. Corp.No ratings yet

- 8.75 DesignDocument26 pages8.75 DesignHausland Const. Corp.No ratings yet

- ExcavationDocument5 pagesExcavationHausland Const. Corp.No ratings yet

- Org Chart 1Document2 pagesOrg Chart 1Hausland Const. Corp.No ratings yet

- Executive SummaryDocument3 pagesExecutive SummaryHausland Const. Corp.No ratings yet

- Refined Process Flow-Concrete ProductsDocument2 pagesRefined Process Flow-Concrete ProductsHausland Const. Corp.No ratings yet

- Project Schedule HCDocument8 pagesProject Schedule HCHausland Const. Corp.No ratings yet

- Assignment TableDocument3 pagesAssignment TableHausland Const. Corp.No ratings yet

- 081223-Alfonso-Franco Boq - Client - OpDocument4 pages081223-Alfonso-Franco Boq - Client - OpHausland Const. Corp.No ratings yet

- Alfonso Project Sched For ExecomDocument1 pageAlfonso Project Sched For ExecomHausland Const. Corp.No ratings yet

- NSK - Drawn Cup Needle Roller ClutchesDocument11 pagesNSK - Drawn Cup Needle Roller ClutchesWillian MoreiraNo ratings yet

- Tga CatalogueDocument172 pagesTga Cataloguea_salehiNo ratings yet

- X MPL PhyDocument111 pagesX MPL PhysugothaaaNo ratings yet

- Detail Biofile 1Document1 pageDetail Biofile 1Rully SaputraNo ratings yet

- Trelleborg 170 Pre-Lube Manhole SealDocument2 pagesTrelleborg 170 Pre-Lube Manhole Sealluis garciaNo ratings yet

- Datsun Crank To Kent Crossflow 1600Document7 pagesDatsun Crank To Kent Crossflow 1600FstaRockr BurnsNo ratings yet

- 6gr Smaw WQTR - F. Edilo (Sn-189)Document1 page6gr Smaw WQTR - F. Edilo (Sn-189)hanz bermejoNo ratings yet

- H2 Tutorial Solutions - KinematicsDocument11 pagesH2 Tutorial Solutions - KinematicsWee Chee LimNo ratings yet

- BS AU 050-1.4.6-1996 (ISO 7867-2-1996) Scan PDFDocument15 pagesBS AU 050-1.4.6-1996 (ISO 7867-2-1996) Scan PDFamerNo ratings yet

- Katalog Hydraulic Jack Merek SunrunDocument4 pagesKatalog Hydraulic Jack Merek SunrunFebri SartikaNo ratings yet

- Tarea 8 Bombas Damian A61610 Minor B06661Document7 pagesTarea 8 Bombas Damian A61610 Minor B06661Orlando Porras MoraNo ratings yet

- Bronze Relief Valve DN10 DN15 DN20Document2 pagesBronze Relief Valve DN10 DN15 DN20billNo ratings yet

- Shipboard Oil Pollution Emergency Plan (SOPEP)Document2 pagesShipboard Oil Pollution Emergency Plan (SOPEP)ibnuharyNo ratings yet

- P and ID SYMBOLS P and ID SYMBOLS ISA Sy PDFDocument21 pagesP and ID SYMBOLS P and ID SYMBOLS ISA Sy PDFAniruthan Ranganathan Singaraju100% (1)

- P P B B A: Design of Machinery Robert L. NortonDocument1 pageP P B B A: Design of Machinery Robert L. NortonCARLOS FABIAN MELGAREJO AGUDELONo ratings yet

- Thesesaastu 2019 264Document132 pagesThesesaastu 2019 264alex cordova cruzNo ratings yet

- Drager Paslite Ba SetDocument4 pagesDrager Paslite Ba SetSUNIL MISHRANo ratings yet

- Construction Specification 402. Steel Pipe Conduits 1. ScopeDocument5 pagesConstruction Specification 402. Steel Pipe Conduits 1. ScopeHendrys AguileraNo ratings yet

- 05 GsaNotes FootfallDocument6 pages05 GsaNotes FootfallAJA14No ratings yet

- PreviewDocument2,231 pagesPreviewMukhitur Rusda100% (3)

- SN007 - TorsionDocument11 pagesSN007 - TorsionflorinNo ratings yet

- Change: SCR App Lies AllDocument4 pagesChange: SCR App Lies AllAditi DasNo ratings yet

- Manual Transaxle: SectionDocument34 pagesManual Transaxle: SectionRifki AwaludinNo ratings yet

- VW Golf HandbookDocument98 pagesVW Golf HandbookΖαχος ΤσελιοςNo ratings yet

- MosDocument3 pagesMosapi-296698256100% (1)

- Chapter 2. Deriving The Vlasov Equation From The Klimontovich EquationDocument6 pagesChapter 2. Deriving The Vlasov Equation From The Klimontovich EquationMerlin MendozaNo ratings yet