Professional Documents

Culture Documents

DGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)

DGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)

Uploaded by

সীমান্ত ছাড়িয়ে - Shemanto ChariyeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)

DGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)

Uploaded by

সীমান্ত ছাড়িয়ে - Shemanto ChariyeCopyright:

Available Formats

Dipon Gas Company Limited

Rangs FC Enclave Plot No. 6/A, Road No. 32, Gulshan Av. Dhaka01212

Composite Mechanical Work of Pipeline Laying and Terminal

Works (Part C) for (IBFPL) Project in Bangladesh

Page: 1 of 2

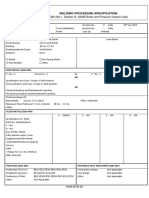

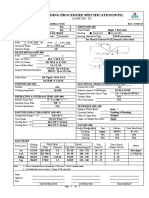

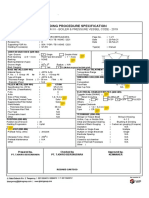

QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATION (WPS)

(See QW-200.1. SECTION IX ASME BOILER AND PRESURE VESSEL CODE, EDITION-1998)

Company Name Dipon Gas Company Limited By : QA/QC Department

Welding Procedure Spec. No. : DGCL/IBFPL/WPS-05 Date :

Rev. No. : 00

Supporting PQR No. (s) : to be taken Date :

Type(s) : Manual

Welding Process (es) : GTAW Piping Class: ASTM A 106 GR.B, API 5L GR.B PSL2, API 5L GR.X-52 PSL-

2, ASTM A 105, ASTM A 234 GR. WPB, MSS SP-75 GR. WPHY-52, ASTM

A 105, ASTM A 694 GR.F-52, GR.F-60

Joint Details: (QW-402)

✘ Metal Nonfusing Metal

Non Metalic Others

Base Material: (QW-403)

P-No. 1 Group No. 1 & 2 to P-No. 1 Group No. 1 & 2

Specfication & Type Grade:

ASTM A 106 GR.B, API 5L GR.B PSL2, API 5L GR.X-52 PSL-2, ASTM A 105, ASTM A 234

GR. WPB, MSS SP-75 GR. WPHY-52, ASTM A 105, ASTM A 694 GR.F-52, GR.F-60

Specfication & Type Grade:

ASTM A 106 GR.B, API 5L GR.B PSL2, API 5L GR.X-52 PSL-2, ASTM A 105, ASTM A 234

GR. WPB, MSS SP-75 GR. WPHY-52, ASTM A 105, ASTM A 694 GR.F-52, GR.F-60

Thickness Range & Groove: 3.91(T)mm through 5.54 (2T)mm Fillet: All Thickness

Pipe Dia Range: 2" and Below Fillet: All Thickness

Filler Materials: (QW-404) Root Pass (GTAW) Others Passes (GTAW)

Spec. No. (SFA) 5.18 5.18

AWS No. (Class) ER -70S2 ER -70S2

F No. 6 6

A. No. 1 1

Size of Filler Metals 1.2 to 2.4 1.2 to 2.4

Weld Metal

Trhickness Range 4mm for Root, 7mm for others

Groove All Thickness

Fillet All Thickness

Electrode-Flux (Class) N/A

Fluxtrade Name Lincolin, Kobelco

Consumable Insert N/A

Others N/A

Welding Position: (QW-405) Post Weld Heat Treatment: (QW-407) (NOTE-2)

Grove Position: : 6G (All Position) Method of Heating /Cooling : N/A

Weld Progression: : Uphill Rate of Heating : N/A

Position(s) of Fillet: : All Temp. Range : N/A

Preheat: (WQ-406) Holding Time : N/A

Preheat Temperature : Min 10°C to 60°C Rate of Cooling : N/A

Interpass Temperature : Min 79°C to 250°C Max. Method of Cooling : N/A

Preheat Mainteain : N/A Others : N/A

Document Responsibility: Quality Department Page 1 of 4

Dipon Gas Company Limited

Rangs FC Enclave Plot No. 6/A, Road No. 32, Gulshan Av. Dhaka01212

Composite Mechanical Work of Pipeline Laying and Terminal

Works (Part C) for (IBFPL) Project in Bangladesh

Page: 1 of 2

Post Heating : N/A

Document Responsibility: Quality Department Page 2 of 4

Dipon Gas Company Limited

Rangs FC Enclave Plot No. 6/A, Road No. 32, Gulshan Av. Dhaka01212

Composite Mechanical Work of Pipeline Laying and Terminal

Works (Part C) for (IBFPL) Project in Bangladesh

Page: 1 of 2

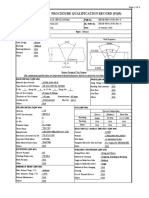

Gas: (QW-408) Percentage Composition Page: 2 of 2

GTAW Gas(es) Mixture Flow-rate GTAW Gas(es) Mixture Flow-rate

Purging N/A N/A N/A Trailing N/A N/A N/A

Sheilding Argon Nil 12-15 /Min Backing N/A N/A N/A

Electrical Characteristics: (WQ-409)

Polarity (SP/RP) : GTAW (Straight Polrity)

Current AC/DC : DC (Root & Hot Pass-DCEN, Other Passes-DCEN)

Amps (Range) : See Table

Volt (Range) : See Table

Tungsten Electrode Size & Type : 2mm Dia & 2.5% Ceriated (EW Ce-2) Pure Tungsten 2.5% Ceriated

Model of Metal Transfer for GMAW : N/A

Electrode Wire Feed Range : N/A

Technique: (WQ-410)

String or weave bead : String for Root and Weave for Other Passes

Orifice or Gas Cup Size: : 2.5 Times dia of Electrode

Initial and interpass cleaning : Wire Brushing, Chipping and Grinding

Method of back-gouging : N/A

Multiple to single pass (Per Side) : Multipule

Multiple or single electrode : Single

Travel speed (range) : See Table

Peening : N/A

Others : Weaving Shall not be Grater than 2.5 times of

the dia of Eectrode Used

Page: 2 of 2

Weld Pass Details Filler Metal Current

Volt Travel Speed

Weld Layer(s) Process Brand Name Class Dia (In mm) Polarity Amp. Range mm/min

Root Pass GTAW Lincolin ER70S-2 1.2 to 2.4 DECN 70-100 22-25 50 to 80

Kobelco

Hot pass GTAW Lincolin ER70S-2 1.2 to 2.4 DECN 100-110 20-25 60 to 90

Kobelco

Fill Pass GTAW Lincolin ER70S-2 1.2 to 2.4 DECN 110-120 20-26 50 to 100

Kobelco

Cap Pass GTAW Lincolin ER70S-2 1.2 to 2.4 DECN 110-120 20-26 70 to 110

Kobelco

Note:

a. For Piping Class 2" OD & Below shal be entirely welded by GTAW Process

b. PWHT shal be carried out for the wall thickness exceeding 20mm and Hardness shal be done & Post

Heat Treated hardnes of the weld shall not Exceed 200BHN

Rev Date Description Prepared By Checked By Reviewed By Approved By

Contractor Contractor EIL/NRL EIL/NRL

00 For Review and Ferdous Rahman Engr. Nasir Uddin

Approval Dipon Gas Co. Ltd. Dipon Gas Co. Ltd.

Document Responsibility: Quality Department Page 3 of 4

Dipon Gas Company Limited

Rangs FC Enclave Plot No. 6/A, Road No. 32, Gulshan Av. Dhaka01212

Composite Mechanical Work of Pipeline Laying and Terminal

Works (Part C) for (IBFPL) Project in Bangladesh

Page: 1 of 2

Document Responsibility: Quality Department Page 4 of 4

You might also like

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Pinakafinal BD Plan Floor PlanDocument3 pagesPinakafinal BD Plan Floor PlanJohn Carlo Telan Panganiban100% (1)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Megha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedDocument2 pagesMegha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedABINASH SINGHNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- WpsDocument2 pagesWpssamer8saifNo ratings yet

- Wps LCC Gt6 Cs GT 001Document3 pagesWps LCC Gt6 Cs GT 001AhedNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Wps LCC Gt6 Cs GTSM 002Document3 pagesWps LCC Gt6 Cs GTSM 002AhedNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Bdde PQR CS 001Document2 pagesBdde PQR CS 001mainur mechanical engineer0% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS-IOT-005 REV.0 Welding Procedure Specification (IOTPG) - For Proposed OnlyDocument10 pagesWPS-IOT-005 REV.0 Welding Procedure Specification (IOTPG) - For Proposed OnlyUripTobingNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- WQR V01 PLT 012-ComDocument3 pagesWQR V01 PLT 012-Comhaim timorNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 pagesMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozNo ratings yet

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- WPS & PQRDocument7 pagesWPS & PQRRanjan KumarNo ratings yet

- WPS Astm - A 53Document2 pagesWPS Astm - A 53S. K. M. ShujonNo ratings yet

- PQR (52a) ModelDocument1 pagePQR (52a) ModelSIDDHARTH BEHERAYNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- PQR FC-12-22Document2 pagesPQR FC-12-22cycsi02No ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- PQR 005-50-NLG PWHT (Icas)Document2 pagesPQR 005-50-NLG PWHT (Icas)Atilio BarriosNo ratings yet

- Rep PQR 02Document3 pagesRep PQR 02shaniraj BirajdarNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

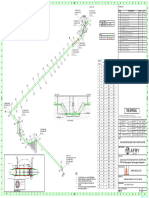

- DGCL-RBLPL-ISO-001-RD - Isometric DrawingDocument5 pagesDGCL-RBLPL-ISO-001-RD - Isometric Drawingসীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- Correction WPS For Construction of 24 Inch Dia.X1000 PSIG Gas Transmission Pipeline. (RELIANDocument6 pagesCorrection WPS For Construction of 24 Inch Dia.X1000 PSIG Gas Transmission Pipeline. (RELIANসীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- Reliance 0001Document13 pagesReliance 0001সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- TECHNICALPart 5Document1,521 pagesTECHNICALPart 5সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- NRL MapDocument44 pagesNRL Mapসীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- TECHNICALPart 6Document1,280 pagesTECHNICALPart 6সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- TECHNICALPart 4Document320 pagesTECHNICALPart 4সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- Schedule of Charges and Procedure PDFDocument58 pagesSchedule of Charges and Procedure PDFabhi...No ratings yet

- Data Sheet ZenerDocument2 pagesData Sheet ZenerMeitaNo ratings yet

- International JournalDocument4 pagesInternational JournalBrahma Hakim Yuanda HutabaratNo ratings yet

- Fill in The Blanks (Dynamo)Document2 pagesFill in The Blanks (Dynamo)Mac Raphael VillanuevaNo ratings yet

- L 7-8 Periodic Variations in Atomic PropertiesDocument15 pagesL 7-8 Periodic Variations in Atomic PropertiesアゼロスレイゼルNo ratings yet

- Practical ResearchDocument22 pagesPractical ResearchKyle Bravo0% (1)

- Process System Engineers (India) Pvt. LTD.: Marketing, Distribution & System Building ByDocument13 pagesProcess System Engineers (India) Pvt. LTD.: Marketing, Distribution & System Building ByvuongNo ratings yet

- SUBTOPIC 1 - Electrical Design and Standard For Commercial EstablishmentDocument30 pagesSUBTOPIC 1 - Electrical Design and Standard For Commercial EstablishmentJasperNo ratings yet

- Electric EquipmentDocument221 pagesElectric EquipmentCarlos Andrés Sánchez Vargas100% (1)

- Light Is Technology PDFDocument84 pagesLight Is Technology PDFJoao SilvaNo ratings yet

- FrassDocument152 pagesFrassManikanta SwamyNo ratings yet

- Eart162: Planetary Interiors: Francis NimmoDocument29 pagesEart162: Planetary Interiors: Francis NimmoasmitaNo ratings yet

- Ee 2202: Introduction To Electronic Engineering: Laboratory 01Document18 pagesEe 2202: Introduction To Electronic Engineering: Laboratory 01daytodayfeelings123No ratings yet

- Final Paper Gas Hydrates Around Makassar StraitsDocument6 pagesFinal Paper Gas Hydrates Around Makassar StraitsriowicaksonoNo ratings yet

- Three Phase Synchronous GeneratorDocument29 pagesThree Phase Synchronous GeneratorYazan YousefNo ratings yet

- MWT - Product Intro - Artsen Plus - ENDocument13 pagesMWT - Product Intro - Artsen Plus - ENBhumikaNo ratings yet

- HVAC Brochure Rev No 12Document66 pagesHVAC Brochure Rev No 12steve@air-innovations.co.zaNo ratings yet

- Gas Dynamics Volume Multi Dimensional Flow 0471018066 PDFDocument4 pagesGas Dynamics Volume Multi Dimensional Flow 0471018066 PDFpuryNo ratings yet

- Illustration 29 07 2017Document1 pageIllustration 29 07 2017Glenn D. KleinNo ratings yet

- Breathable Waterproof ClothingDocument14 pagesBreathable Waterproof ClothingYashica GuptaNo ratings yet

- To Investigate Relationship Between Specific Energy and Depth of FlowDocument8 pagesTo Investigate Relationship Between Specific Energy and Depth of FlowEngr Muhammad TariqNo ratings yet

- Setting Instructions For Movement Caliber 0855: (Click On A Topic)Document12 pagesSetting Instructions For Movement Caliber 0855: (Click On A Topic)Enrike Krema UNo ratings yet

- AA Metatron The Story of The Fall of AtlantisDocument54 pagesAA Metatron The Story of The Fall of AtlantisMeaghan Mathews100% (1)

- Presentation From Sem Sepulveda, Forum On Residential Recycling, 10/7/19Document33 pagesPresentation From Sem Sepulveda, Forum On Residential Recycling, 10/7/19State Senator Liz KruegerNo ratings yet

- Formal Interpretations 2012Document5 pagesFormal Interpretations 2012sgttomasNo ratings yet

- Presentation Case A 4 Shell Greenpeace and Brent SparDocument24 pagesPresentation Case A 4 Shell Greenpeace and Brent SparBhaiNo ratings yet

- Brosur ToyotaDocument8 pagesBrosur Toyotayuliani fitriaNo ratings yet

- A 5HP Electrical Generator Fully Powered With The BingoFuel Reactor by JL NaudinDocument5 pagesA 5HP Electrical Generator Fully Powered With The BingoFuel Reactor by JL Naudinsuherlan endanNo ratings yet