Professional Documents

Culture Documents

Allergen Checklist

Allergen Checklist

Uploaded by

refineryCopyright:

Available Formats

You might also like

- Internal Audit Checklist 22716Document34 pagesInternal Audit Checklist 22716mrugeshj95% (20)

- Food Safety QuestionnaireDocument4 pagesFood Safety QuestionnaireSheredapple Orticio100% (2)

- Internal Audit Checklist PRODUCTIONDocument6 pagesInternal Audit Checklist PRODUCTIONRavi Baghel100% (3)

- NCM 102 - Module 1Document23 pagesNCM 102 - Module 1Cedrick Mesa Sali-ot100% (3)

- Lab 042Document12 pagesLab 042Néstor VargasNo ratings yet

- Untitledcarga ProDocument12 pagesUntitledcarga ProrenesaurioNo ratings yet

- PUR 06 Supplier Audit - Questionnaire 2Document9 pagesPUR 06 Supplier Audit - Questionnaire 2pakhidhokariyaNo ratings yet

- 35 Supplier Evaluation QuestionnaireDocument2 pages35 Supplier Evaluation QuestionnaireRizwan SiddiqiNo ratings yet

- GMP Food Manufacturing Audit Checklist - SafetyCultureDocument22 pagesGMP Food Manufacturing Audit Checklist - SafetyCultureNaeema100% (1)

- Supplier Self Audit FormDocument5 pagesSupplier Self Audit FormAllison Porter100% (2)

- Form FDA 2966 - Food GMP Inspection Report270348720211027Document4 pagesForm FDA 2966 - Food GMP Inspection Report270348720211027SPNo ratings yet

- OHS WorkplaceAssessment InspectionChecklistDocument9 pagesOHS WorkplaceAssessment InspectionChecklistAldrin ZlmdNo ratings yet

- ISO45001 Audit Checklist For Auditing The ETP of Large Dairy FarmDocument1 pageISO45001 Audit Checklist For Auditing The ETP of Large Dairy FarmVeeramuthu SundararajuNo ratings yet

- Questions and Answers On The Interpretation of ASEAN GMP Guideline For CosmeticDocument8 pagesQuestions and Answers On The Interpretation of ASEAN GMP Guideline For Cosmeticsmtamaskar2277No ratings yet

- Supplier Prequalification Form-NewDocument4 pagesSupplier Prequalification Form-Newdanu100% (1)

- 01 Manufacturer Checklist 101214Document13 pages01 Manufacturer Checklist 101214Maulana SyaifullahNo ratings yet

- ChecklistDocument9 pagesChecklistrenukaNo ratings yet

- FSR 109 - Farm Hygiene Audit Questionnaire - KIRIMIDocument4 pagesFSR 109 - Farm Hygiene Audit Questionnaire - KIRIMInderijohnsonNo ratings yet

- Instructions:: Task PerformanceDocument13 pagesInstructions:: Task PerformanceAubrey LandoyNo ratings yet

- Iodized Salt Sanitation SOPDocument16 pagesIodized Salt Sanitation SOPALIYNo ratings yet

- NAV 04 Calibration and Use of Measuring and Test EquipmentDocument5 pagesNAV 04 Calibration and Use of Measuring and Test Equipmentaaqipaper100% (1)

- SAMPLED-Example of Audit SheetDocument9 pagesSAMPLED-Example of Audit Sheetchristina sitorusNo ratings yet

- Allergen Control Checklist Manufacturer 0908Document4 pagesAllergen Control Checklist Manufacturer 0908shakeyken100% (1)

- Supplier Quality AuditDocument6 pagesSupplier Quality AuditRealsa OrganikNo ratings yet

- Ipc Obs Form EvsDocument15 pagesIpc Obs Form Evshailu.kingstonNo ratings yet

- FAB-QMF-60 (Outsources Process Audit Report)Document6 pagesFAB-QMF-60 (Outsources Process Audit Report)Ibrahim shaikNo ratings yet

- SOP-BPRL - Food DefenceDocument8 pagesSOP-BPRL - Food DefencesteevandNo ratings yet

- Food Defense Self-Assessment Checklist For Slaughter and Processing PlantsDocument8 pagesFood Defense Self-Assessment Checklist For Slaughter and Processing PlantsKhaoula KadiriNo ratings yet

- Food Safety Audit: Supplier Company: Audit Location: CountryDocument8 pagesFood Safety Audit: Supplier Company: Audit Location: CountryAsrel05No ratings yet

- General Controls: Instructions/Questions Note Any Exceptions and Comments in Notebook Yes/No/NADocument15 pagesGeneral Controls: Instructions/Questions Note Any Exceptions and Comments in Notebook Yes/No/NAMubarak PatelNo ratings yet

- In and OUTPATIENT Full Ward Audit Template May 2015Document27 pagesIn and OUTPATIENT Full Ward Audit Template May 2015ibrahim helwaNo ratings yet

- EGA SETP TT-CSM 13 Prequal Questionnaire v2.00Document6 pagesEGA SETP TT-CSM 13 Prequal Questionnaire v2.00shijadNo ratings yet

- Quality Management Systems Fundamentals Vocabulary AwarenessDocument6 pagesQuality Management Systems Fundamentals Vocabulary AwarenesssbtharanNo ratings yet

- ISO 22000 Audit Checklist - SafetyCultureDocument54 pagesISO 22000 Audit Checklist - SafetyCulturep kumarNo ratings yet

- ISO 22000 Audit ChecklistDocument54 pagesISO 22000 Audit ChecklistMuhammad ZafarNo ratings yet

- Food Defense Self-Assessment Checklist For Slaughter and Processing PlantsDocument16 pagesFood Defense Self-Assessment Checklist For Slaughter and Processing PlantsAgronomist ahmed hassanNo ratings yet

- TMC-IFMS-CL-05-FM-Food Service-Raw Food Preparation Area 07 Aug 2019Document3 pagesTMC-IFMS-CL-05-FM-Food Service-Raw Food Preparation Area 07 Aug 2019NiraNo ratings yet

- GMP Food Manufacturing Audit Checklist - SafetyCultureDocument21 pagesGMP Food Manufacturing Audit Checklist - SafetyCulturetitisari juwitaningtyasNo ratings yet

- Haccp Amp Ssop Manual PDFDocument41 pagesHaccp Amp Ssop Manual PDFTiara Shafa AyuNo ratings yet

- EHS Prequalification Questionnaire: Environmental Health and Safety (Ehs) StaffingDocument3 pagesEHS Prequalification Questionnaire: Environmental Health and Safety (Ehs) Staffingrahmankhan823No ratings yet

- Monthly Ispection CheklistDocument2 pagesMonthly Ispection CheklistYashpal Singh100% (1)

- Internal Audit Checklist HR - AdminDocument3 pagesInternal Audit Checklist HR - AdminRavi Baghel100% (1)

- Nama: Kadek Resa Sapina NIM: 1821172 Kelas: DIV MPH F / 5Document3 pagesNama: Kadek Resa Sapina NIM: 1821172 Kelas: DIV MPH F / 5AbdeNo ratings yet

- Checklist of Self Inspection (Quality Compliance) : Biotechnology Derived Product Facility (Unit-1)Document4 pagesChecklist of Self Inspection (Quality Compliance) : Biotechnology Derived Product Facility (Unit-1)DebasishNo ratings yet

- FD Self AssessmentDocument7 pagesFD Self Assessmentapi-277257927No ratings yet

- PRP03F09 - Supplier Self Audit Assessment For Supplier - Rev 0Document4 pagesPRP03F09 - Supplier Self Audit Assessment For Supplier - Rev 0Fatin NajehahNo ratings yet

- Food Defense Checklist - SafetyCultureDocument11 pagesFood Defense Checklist - SafetyCultureMagesha kumarNo ratings yet

- FSMA - GMP ChecklistDocument10 pagesFSMA - GMP Checklistaji sulaimanNo ratings yet

- Supplier Qualification Form C-67194Document11 pagesSupplier Qualification Form C-67194MinJeong Cuteemo Kim0% (1)

- Checklist WHO GMPDocument20 pagesChecklist WHO GMPbach2007No ratings yet

- GMP Audit Check List-Sanitation & HygieneDocument1 pageGMP Audit Check List-Sanitation & HygieneDharmesh Patel100% (1)

- SKII Factory Inspection ReportDocument6 pagesSKII Factory Inspection Reportrgrao85No ratings yet

- SKII Factory Inspection Report 4Document6 pagesSKII Factory Inspection Report 4george_hemNo ratings yet

- Housekeeping ChecklistDocument3 pagesHousekeeping ChecklistDewan Md Maniruzzaman HR GeneralistNo ratings yet

- 4th Module 1Document18 pages4th Module 1Mha RizNo ratings yet

- Supplier Questionnare - Section E Quality Q. - ModifiedDocument20 pagesSupplier Questionnare - Section E Quality Q. - ModifiedKushal WadheraNo ratings yet

- Basic GMP ChecklistDocument12 pagesBasic GMP Checklistsubirme50% (2)

- Form-Vendor Survey Form - ENGDocument2 pagesForm-Vendor Survey Form - ENGAndrei IЗNo ratings yet

- HACCP and SSOP BasicsDocument35 pagesHACCP and SSOP Basicsfitria lindasariNo ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- Community Assessment On Antibiotic Medication Compliance in Barangay GuizoDocument67 pagesCommunity Assessment On Antibiotic Medication Compliance in Barangay GuizoJeanny Mae NgujoNo ratings yet

- Prioritizing Learning GEEAP Report Final 01 24 2022Document21 pagesPrioritizing Learning GEEAP Report Final 01 24 2022Cindy MangayaNo ratings yet

- AB PSYCH Chapter 2Document33 pagesAB PSYCH Chapter 2ALEXANDRA SAN PEDRONo ratings yet

- She PlusDocument2 pagesShe PlusHarjinder SinghNo ratings yet

- Chess and NutritionDocument6 pagesChess and NutritionAnonymous pTZCrF7No ratings yet

- Review: Macrophage Activation Syndrome in Adults: Recent Advances in Pathophysiology, Diagnosis and TreatmentDocument13 pagesReview: Macrophage Activation Syndrome in Adults: Recent Advances in Pathophysiology, Diagnosis and TreatmentSilvia Leticia BrunoNo ratings yet

- Why Do Some Women Still Prefer Traditional Birth Attendants and Home Delivery?: A Qualitative Study On Delivery Care Services in West Java Province, IndonesiaDocument14 pagesWhy Do Some Women Still Prefer Traditional Birth Attendants and Home Delivery?: A Qualitative Study On Delivery Care Services in West Java Province, IndonesiaKarlinaNo ratings yet

- Practice Summary Paper IntroDocument3 pagesPractice Summary Paper Introapi-630699625No ratings yet

- Moller Linda Crandall Clifford C JR Moving Beyond DisabilitiDocument127 pagesMoller Linda Crandall Clifford C JR Moving Beyond Disabilitisrbjkd100% (2)

- Part 2. Causes of DiseasesDocument12 pagesPart 2. Causes of DiseasesKakuru Joseph mNo ratings yet

- Gujarat Neet Sebc Merit ListDocument187 pagesGujarat Neet Sebc Merit ListDharmendra PalNo ratings yet

- Npdmdu PFT Clearance Form 2023Document1 pageNpdmdu PFT Clearance Form 2023Substationsix MalaboncpsNo ratings yet

- Research - Assessment 2Document14 pagesResearch - Assessment 2api-374359307No ratings yet

- MT - TOPIC 01 - Roles of A Safety OfficerDocument33 pagesMT - TOPIC 01 - Roles of A Safety OfficerGreen ArcNo ratings yet

- Personal DataDocument5 pagesPersonal Datamaria teresa casiliNo ratings yet

- What Happens If We Release The Sperm DailyDocument5 pagesWhat Happens If We Release The Sperm DailyJiesaNo ratings yet

- Drug StudyDocument2 pagesDrug Studycrianne_1180% (5)

- SFH - Report KartikDocument16 pagesSFH - Report KartikMadhuNo ratings yet

- Management of Sinusitis in Family PracticeDocument17 pagesManagement of Sinusitis in Family PracticebloopermaniaNo ratings yet

- What Is Advantage of Following Principles of Training When Implementing A Training Regime Compared To Randomly Doing Exercises?Document2 pagesWhat Is Advantage of Following Principles of Training When Implementing A Training Regime Compared To Randomly Doing Exercises?Heinix FrØxt WalfletNo ratings yet

- 1.) Generic Name: Gabapentin Brand Name Classification Dosage Route and Frequency Mechanism of ActionDocument15 pages1.) Generic Name: Gabapentin Brand Name Classification Dosage Route and Frequency Mechanism of ActionTyron ChuaNo ratings yet

- Nursing Care PlanDocument4 pagesNursing Care PlanCharlene Grace ReginoNo ratings yet

- Medical TechnologyDocument9 pagesMedical TechnologyAly Bint Smbs0% (1)

- CHSSDocument8 pagesCHSSsariyu143No ratings yet

- PvPI EditedDocument29 pagesPvPI Editedneeraj devarintiNo ratings yet

- 2020 DPRI Updated As of 03 05Document46 pages2020 DPRI Updated As of 03 05JorymagatNo ratings yet

- Cannabis Effects On Driving SkillsDocument15 pagesCannabis Effects On Driving SkillsCharles PetersNo ratings yet

- Purdy Andrew Curriculum VitaeDocument8 pagesPurdy Andrew Curriculum Vitaeapi-614156568No ratings yet

- Antimicrobial Susceptibility Testing PDFDocument19 pagesAntimicrobial Susceptibility Testing PDFdatitoxNo ratings yet

Allergen Checklist

Allergen Checklist

Uploaded by

refineryOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Allergen Checklist

Allergen Checklist

Uploaded by

refineryCopyright:

Available Formats

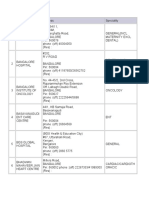

MUKWANO INDUSTRIES UGANDA LIMITED

Allergen Control Checklist

Use this allergen checklist to assess areas of food production procedures. Ensure that allergen control measures are implemented

and executed properly. This checklist was converted using Safety Culture and covers a review on raw materials, production,

premises, equipment and cleaning.

Conducted on:

Date:

Conducted by:

General Points

1. Are HACCP programs in place covering allergen risks in the total production chain – from

receiving and storage of raw materials to finished product?

Yes No

2. Do those working with food production receive regular allergen training?

Yes No

3. Are there procedures in place on how recipe changes are to be handled in production

including information to production staff?

Yes No

4. Are there procedures in place to ensure that prior approval by the responsible persons within

the company is needed before changes are made to suppliers of raw materials, processing

aids, etc?

Yes No

5. Are employees encouraged to immediately report suspected contamination, incorrect labeling,

etc., and are there procedures in place?

Yes No

6. Are regular internal audits conducted to ensure compliance with the general requirements for

control of allergens?

Yes No

Raw materials: Receiving, storage, weighing

7. Is the risk for allergen contamination considered prior to purchasing and receiving new raw

materials?

Yes No

8. Are there procedures in place at reception of raw materials, ingredients and intermediate

goods to verify that the correct material has been delivered?

Yes No

9. Are raw materials, ingredients and intermediate goods kept separate from each other and

from other foods so the risk of contamination is minimized?

Revision Date: 14/01/2023 Rev.No:00 Doc. No: MUUFS-12

Approved by: FSTL Issue Date: 15/01/2023

MUKWANO INDUSTRIES UGANDA LIMITED

Yes No

Production, premises and equipment

10. Are instructions on how to prevent contamination clearly presented or readily available in the

production area?

Yes No

11. Are premises, equipment, and work tools designed so that they are easy to clean and that

contamination between products and production lines is minimized?

Yes No

12. Do maintenance personnel have knowledge about hygiene design to minimize the risk of

contamination, e.g., through proper design of piping, elbows and bends, pumps, etc.?

Yes No

13. Are schedules for maintenance of the premises and equipment in place?

Yes No

14. Are there hygiene rules for all personnel, covering, e.g., clothing, hand-washing and hand

contact with foods?

Yes No

15. Are there procedures in place to ensure that the correct raw materials are always used?

Yes No

16. Are there procedures in place to ensure that the correct recipe is always used?

Yes No

17. Are there clear procedures in place for production sequencing and how this is determined?

Yes No

18. Are there procedures in place to ensure that the packaging material used is correct for the

product?

Yes No

19. Does production staff carry out a continuous review of possible situations for cross-

contamination between products or production lines?

Yes No

20. Are there procedures in place for the use of rework (internally recycled product)?

Yes No

21. Is there a procedure in place for traceability of rework used in the finished product?

Yes No

22. Are there procedures in place for handling products that do not fulfill specifications?

Revision Date: 14/01/2023 Rev.No:00 Doc. No: MUUFS-12

Approved by: FSTL Issue Date: 15/01/2023

MUKWANO INDUSTRIES UGANDA LIMITED

Yes No

Cleaning and controls

23. Are there clear instructions in place for the cleaning of premises, equipment and work tools?

Yes No

24. Are there clear instructions for the cleaning required between productions of different

products on the same production line?

Yes No

25. Are there procedures for, when relevant, testing a food after manufacturing, in order to

confirm that no unintentional exposure to allergen has occurred?

Yes No

Name & Signature of Assigned Personnel Sign

Revision Date: 14/01/2023 Rev.No:00 Doc. No: MUUFS-12

Approved by: FSTL Issue Date: 15/01/2023

You might also like

- Internal Audit Checklist 22716Document34 pagesInternal Audit Checklist 22716mrugeshj95% (20)

- Food Safety QuestionnaireDocument4 pagesFood Safety QuestionnaireSheredapple Orticio100% (2)

- Internal Audit Checklist PRODUCTIONDocument6 pagesInternal Audit Checklist PRODUCTIONRavi Baghel100% (3)

- NCM 102 - Module 1Document23 pagesNCM 102 - Module 1Cedrick Mesa Sali-ot100% (3)

- Lab 042Document12 pagesLab 042Néstor VargasNo ratings yet

- Untitledcarga ProDocument12 pagesUntitledcarga ProrenesaurioNo ratings yet

- PUR 06 Supplier Audit - Questionnaire 2Document9 pagesPUR 06 Supplier Audit - Questionnaire 2pakhidhokariyaNo ratings yet

- 35 Supplier Evaluation QuestionnaireDocument2 pages35 Supplier Evaluation QuestionnaireRizwan SiddiqiNo ratings yet

- GMP Food Manufacturing Audit Checklist - SafetyCultureDocument22 pagesGMP Food Manufacturing Audit Checklist - SafetyCultureNaeema100% (1)

- Supplier Self Audit FormDocument5 pagesSupplier Self Audit FormAllison Porter100% (2)

- Form FDA 2966 - Food GMP Inspection Report270348720211027Document4 pagesForm FDA 2966 - Food GMP Inspection Report270348720211027SPNo ratings yet

- OHS WorkplaceAssessment InspectionChecklistDocument9 pagesOHS WorkplaceAssessment InspectionChecklistAldrin ZlmdNo ratings yet

- ISO45001 Audit Checklist For Auditing The ETP of Large Dairy FarmDocument1 pageISO45001 Audit Checklist For Auditing The ETP of Large Dairy FarmVeeramuthu SundararajuNo ratings yet

- Questions and Answers On The Interpretation of ASEAN GMP Guideline For CosmeticDocument8 pagesQuestions and Answers On The Interpretation of ASEAN GMP Guideline For Cosmeticsmtamaskar2277No ratings yet

- Supplier Prequalification Form-NewDocument4 pagesSupplier Prequalification Form-Newdanu100% (1)

- 01 Manufacturer Checklist 101214Document13 pages01 Manufacturer Checklist 101214Maulana SyaifullahNo ratings yet

- ChecklistDocument9 pagesChecklistrenukaNo ratings yet

- FSR 109 - Farm Hygiene Audit Questionnaire - KIRIMIDocument4 pagesFSR 109 - Farm Hygiene Audit Questionnaire - KIRIMInderijohnsonNo ratings yet

- Instructions:: Task PerformanceDocument13 pagesInstructions:: Task PerformanceAubrey LandoyNo ratings yet

- Iodized Salt Sanitation SOPDocument16 pagesIodized Salt Sanitation SOPALIYNo ratings yet

- NAV 04 Calibration and Use of Measuring and Test EquipmentDocument5 pagesNAV 04 Calibration and Use of Measuring and Test Equipmentaaqipaper100% (1)

- SAMPLED-Example of Audit SheetDocument9 pagesSAMPLED-Example of Audit Sheetchristina sitorusNo ratings yet

- Allergen Control Checklist Manufacturer 0908Document4 pagesAllergen Control Checklist Manufacturer 0908shakeyken100% (1)

- Supplier Quality AuditDocument6 pagesSupplier Quality AuditRealsa OrganikNo ratings yet

- Ipc Obs Form EvsDocument15 pagesIpc Obs Form Evshailu.kingstonNo ratings yet

- FAB-QMF-60 (Outsources Process Audit Report)Document6 pagesFAB-QMF-60 (Outsources Process Audit Report)Ibrahim shaikNo ratings yet

- SOP-BPRL - Food DefenceDocument8 pagesSOP-BPRL - Food DefencesteevandNo ratings yet

- Food Defense Self-Assessment Checklist For Slaughter and Processing PlantsDocument8 pagesFood Defense Self-Assessment Checklist For Slaughter and Processing PlantsKhaoula KadiriNo ratings yet

- Food Safety Audit: Supplier Company: Audit Location: CountryDocument8 pagesFood Safety Audit: Supplier Company: Audit Location: CountryAsrel05No ratings yet

- General Controls: Instructions/Questions Note Any Exceptions and Comments in Notebook Yes/No/NADocument15 pagesGeneral Controls: Instructions/Questions Note Any Exceptions and Comments in Notebook Yes/No/NAMubarak PatelNo ratings yet

- In and OUTPATIENT Full Ward Audit Template May 2015Document27 pagesIn and OUTPATIENT Full Ward Audit Template May 2015ibrahim helwaNo ratings yet

- EGA SETP TT-CSM 13 Prequal Questionnaire v2.00Document6 pagesEGA SETP TT-CSM 13 Prequal Questionnaire v2.00shijadNo ratings yet

- Quality Management Systems Fundamentals Vocabulary AwarenessDocument6 pagesQuality Management Systems Fundamentals Vocabulary AwarenesssbtharanNo ratings yet

- ISO 22000 Audit Checklist - SafetyCultureDocument54 pagesISO 22000 Audit Checklist - SafetyCulturep kumarNo ratings yet

- ISO 22000 Audit ChecklistDocument54 pagesISO 22000 Audit ChecklistMuhammad ZafarNo ratings yet

- Food Defense Self-Assessment Checklist For Slaughter and Processing PlantsDocument16 pagesFood Defense Self-Assessment Checklist For Slaughter and Processing PlantsAgronomist ahmed hassanNo ratings yet

- TMC-IFMS-CL-05-FM-Food Service-Raw Food Preparation Area 07 Aug 2019Document3 pagesTMC-IFMS-CL-05-FM-Food Service-Raw Food Preparation Area 07 Aug 2019NiraNo ratings yet

- GMP Food Manufacturing Audit Checklist - SafetyCultureDocument21 pagesGMP Food Manufacturing Audit Checklist - SafetyCulturetitisari juwitaningtyasNo ratings yet

- Haccp Amp Ssop Manual PDFDocument41 pagesHaccp Amp Ssop Manual PDFTiara Shafa AyuNo ratings yet

- EHS Prequalification Questionnaire: Environmental Health and Safety (Ehs) StaffingDocument3 pagesEHS Prequalification Questionnaire: Environmental Health and Safety (Ehs) Staffingrahmankhan823No ratings yet

- Monthly Ispection CheklistDocument2 pagesMonthly Ispection CheklistYashpal Singh100% (1)

- Internal Audit Checklist HR - AdminDocument3 pagesInternal Audit Checklist HR - AdminRavi Baghel100% (1)

- Nama: Kadek Resa Sapina NIM: 1821172 Kelas: DIV MPH F / 5Document3 pagesNama: Kadek Resa Sapina NIM: 1821172 Kelas: DIV MPH F / 5AbdeNo ratings yet

- Checklist of Self Inspection (Quality Compliance) : Biotechnology Derived Product Facility (Unit-1)Document4 pagesChecklist of Self Inspection (Quality Compliance) : Biotechnology Derived Product Facility (Unit-1)DebasishNo ratings yet

- FD Self AssessmentDocument7 pagesFD Self Assessmentapi-277257927No ratings yet

- PRP03F09 - Supplier Self Audit Assessment For Supplier - Rev 0Document4 pagesPRP03F09 - Supplier Self Audit Assessment For Supplier - Rev 0Fatin NajehahNo ratings yet

- Food Defense Checklist - SafetyCultureDocument11 pagesFood Defense Checklist - SafetyCultureMagesha kumarNo ratings yet

- FSMA - GMP ChecklistDocument10 pagesFSMA - GMP Checklistaji sulaimanNo ratings yet

- Supplier Qualification Form C-67194Document11 pagesSupplier Qualification Form C-67194MinJeong Cuteemo Kim0% (1)

- Checklist WHO GMPDocument20 pagesChecklist WHO GMPbach2007No ratings yet

- GMP Audit Check List-Sanitation & HygieneDocument1 pageGMP Audit Check List-Sanitation & HygieneDharmesh Patel100% (1)

- SKII Factory Inspection ReportDocument6 pagesSKII Factory Inspection Reportrgrao85No ratings yet

- SKII Factory Inspection Report 4Document6 pagesSKII Factory Inspection Report 4george_hemNo ratings yet

- Housekeeping ChecklistDocument3 pagesHousekeeping ChecklistDewan Md Maniruzzaman HR GeneralistNo ratings yet

- 4th Module 1Document18 pages4th Module 1Mha RizNo ratings yet

- Supplier Questionnare - Section E Quality Q. - ModifiedDocument20 pagesSupplier Questionnare - Section E Quality Q. - ModifiedKushal WadheraNo ratings yet

- Basic GMP ChecklistDocument12 pagesBasic GMP Checklistsubirme50% (2)

- Form-Vendor Survey Form - ENGDocument2 pagesForm-Vendor Survey Form - ENGAndrei IЗNo ratings yet

- HACCP and SSOP BasicsDocument35 pagesHACCP and SSOP Basicsfitria lindasariNo ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- Community Assessment On Antibiotic Medication Compliance in Barangay GuizoDocument67 pagesCommunity Assessment On Antibiotic Medication Compliance in Barangay GuizoJeanny Mae NgujoNo ratings yet

- Prioritizing Learning GEEAP Report Final 01 24 2022Document21 pagesPrioritizing Learning GEEAP Report Final 01 24 2022Cindy MangayaNo ratings yet

- AB PSYCH Chapter 2Document33 pagesAB PSYCH Chapter 2ALEXANDRA SAN PEDRONo ratings yet

- She PlusDocument2 pagesShe PlusHarjinder SinghNo ratings yet

- Chess and NutritionDocument6 pagesChess and NutritionAnonymous pTZCrF7No ratings yet

- Review: Macrophage Activation Syndrome in Adults: Recent Advances in Pathophysiology, Diagnosis and TreatmentDocument13 pagesReview: Macrophage Activation Syndrome in Adults: Recent Advances in Pathophysiology, Diagnosis and TreatmentSilvia Leticia BrunoNo ratings yet

- Why Do Some Women Still Prefer Traditional Birth Attendants and Home Delivery?: A Qualitative Study On Delivery Care Services in West Java Province, IndonesiaDocument14 pagesWhy Do Some Women Still Prefer Traditional Birth Attendants and Home Delivery?: A Qualitative Study On Delivery Care Services in West Java Province, IndonesiaKarlinaNo ratings yet

- Practice Summary Paper IntroDocument3 pagesPractice Summary Paper Introapi-630699625No ratings yet

- Moller Linda Crandall Clifford C JR Moving Beyond DisabilitiDocument127 pagesMoller Linda Crandall Clifford C JR Moving Beyond Disabilitisrbjkd100% (2)

- Part 2. Causes of DiseasesDocument12 pagesPart 2. Causes of DiseasesKakuru Joseph mNo ratings yet

- Gujarat Neet Sebc Merit ListDocument187 pagesGujarat Neet Sebc Merit ListDharmendra PalNo ratings yet

- Npdmdu PFT Clearance Form 2023Document1 pageNpdmdu PFT Clearance Form 2023Substationsix MalaboncpsNo ratings yet

- Research - Assessment 2Document14 pagesResearch - Assessment 2api-374359307No ratings yet

- MT - TOPIC 01 - Roles of A Safety OfficerDocument33 pagesMT - TOPIC 01 - Roles of A Safety OfficerGreen ArcNo ratings yet

- Personal DataDocument5 pagesPersonal Datamaria teresa casiliNo ratings yet

- What Happens If We Release The Sperm DailyDocument5 pagesWhat Happens If We Release The Sperm DailyJiesaNo ratings yet

- Drug StudyDocument2 pagesDrug Studycrianne_1180% (5)

- SFH - Report KartikDocument16 pagesSFH - Report KartikMadhuNo ratings yet

- Management of Sinusitis in Family PracticeDocument17 pagesManagement of Sinusitis in Family PracticebloopermaniaNo ratings yet

- What Is Advantage of Following Principles of Training When Implementing A Training Regime Compared To Randomly Doing Exercises?Document2 pagesWhat Is Advantage of Following Principles of Training When Implementing A Training Regime Compared To Randomly Doing Exercises?Heinix FrØxt WalfletNo ratings yet

- 1.) Generic Name: Gabapentin Brand Name Classification Dosage Route and Frequency Mechanism of ActionDocument15 pages1.) Generic Name: Gabapentin Brand Name Classification Dosage Route and Frequency Mechanism of ActionTyron ChuaNo ratings yet

- Nursing Care PlanDocument4 pagesNursing Care PlanCharlene Grace ReginoNo ratings yet

- Medical TechnologyDocument9 pagesMedical TechnologyAly Bint Smbs0% (1)

- CHSSDocument8 pagesCHSSsariyu143No ratings yet

- PvPI EditedDocument29 pagesPvPI Editedneeraj devarintiNo ratings yet

- 2020 DPRI Updated As of 03 05Document46 pages2020 DPRI Updated As of 03 05JorymagatNo ratings yet

- Cannabis Effects On Driving SkillsDocument15 pagesCannabis Effects On Driving SkillsCharles PetersNo ratings yet

- Purdy Andrew Curriculum VitaeDocument8 pagesPurdy Andrew Curriculum Vitaeapi-614156568No ratings yet

- Antimicrobial Susceptibility Testing PDFDocument19 pagesAntimicrobial Susceptibility Testing PDFdatitoxNo ratings yet