Professional Documents

Culture Documents

Design Report V2

Design Report V2

Uploaded by

Shantonu DeyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Report V2

Design Report V2

Uploaded by

Shantonu DeyCopyright:

Available Formats

Project Information

Project BRBCP

Job No

Company DCC

Designer Engr. Shantonu Dey

Remarks Pile capacity check

Software CSICOL (Version: 8.4 (Rev. 0))

File Name D:\BRBCP PILE \BRBCP PIL V2E

Working Units SI (mm, KN, KN-m, N/mm^2)

Design Code ACI-318-05

Column:Pile of Viaduct

Basic Design Parameters

Caption = Pile of

Viaduct

Default Concrete Strength, Fc = 30.0 N/mm^2

Default Concrete Modulus, Ec = 26000.0 N/mm^2

Maximum Concrete Strain = 0.003 in/in

Rebar Set = User

Default Rebar Yeild Strength, Fy = 400.0 N/mm^2

Default Rebar Modulus, Es = 200000.0 N/mm^2

Default Cover to Rebars = 91.0 mm

Maximum Steel Strain = Infinity

Transverse Rebar Type = Ties

Total Shapes in Section =1

Consider Slenderness = No

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 1

Section Diagram

Cross-section Shapes

Shape Width Height Conc Fc S/S Curve Rebars

mm mm N/mm^2

Circle 1500.0 1500.0 30.0 ACI-Whitney Rectangular 52-d 50

Rebar Properties

Sr.No Designation Area Cord-X Cord-Y Fy S/S Curve

mm^2 mm mm N/mm^2

1 d 50 1963 1384.0 750.0 400.0 Elasto-Plastic

2 d 50 1963 1368.1 891.1 400.0 Elasto-Plastic

3 d 50 1963 1321.2 1025.1 400.0 Elasto-Plastic

4 d 50 1963 1245.7 1145.3 400.0 Elasto-Plastic

5 d 50 1963 1145.3 1245.7 400.0 Elasto-Plastic

6 d 50 1963 1025.1 1321.2 400.0 Elasto-Plastic

7 d 50 1963 891.1 1368.1 400.0 Elasto-Plastic

8 d 50 1963 750.0 1384.0 400.0 Elasto-Plastic

9 d 50 1963 608.9 1368.1 400.0 Elasto-Plastic

10 d 50 1963 474.9 1321.2 400.0 Elasto-Plastic

11 d 50 1963 354.7 1245.7 400.0 Elasto-Plastic

12 d 50 1963 254.3 1145.3 400.0 Elasto-Plastic

13 d 50 1963 178.8 1025.1 400.0 Elasto-Plastic

14 d 50 1963 131.9 891.1 400.0 Elasto-Plastic

15 d 50 1963 116.0 750.0 400.0 Elasto-Plastic

16 d 50 1963 131.9 608.9 400.0 Elasto-Plastic

17 d 50 1963 178.8 474.9 400.0 Elasto-Plastic

18 d 50 1963 254.3 354.7 400.0 Elasto-Plastic

19 d 50 1963 354.7 254.3 400.0 Elasto-Plastic

20 d 50 1963 474.9 178.8 400.0 Elasto-Plastic

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 2

21 d 50 1963 608.9 131.9 400.0 Elasto-Plastic

22 d 50 1963 750.0 116.0 400.0 Elasto-Plastic

23 d 50 1963 891.1 131.9 400.0 Elasto-Plastic

24 d 50 1963 1025.1 178.8 400.0 Elasto-Plastic

25 d 50 1963 1145.3 254.3 400.0 Elasto-Plastic

26 d 50 1963 1245.7 354.7 400.0 Elasto-Plastic

27 d 50 1963 1321.2 474.9 400.0 Elasto-Plastic

28 d 50 1963 1368.1 608.9 400.0 Elasto-Plastic

29 d 50 1963 750.0 261.0 400.0 Elasto-Plastic

30 d 50 1963 877.0 278.0 400.0 Elasto-Plastic

31 d 50 1963 995.0 327.0 400.0 Elasto-Plastic

32 d 50 1963 1096.0 404.0 400.0 Elasto-Plastic

33 d 50 1963 1173.0 506.0 400.0 Elasto-Plastic

34 d 50 1963 1222.0 623.0 400.0 Elasto-Plastic

35 d 50 1963 1239.0 750.0 400.0 Elasto-Plastic

36 d 50 1963 1222.0 877.0 400.0 Elasto-Plastic

37 d 50 1963 1173.0 995.0 400.0 Elasto-Plastic

38 d 50 1963 1096.0 1096.0 400.0 Elasto-Plastic

39 d 50 1963 995.0 1173.0 400.0 Elasto-Plastic

40 d 50 1963 877.0 1222.0 400.0 Elasto-Plastic

41 d 50 1963 750.0 1239.0 400.0 Elasto-Plastic

42 d 50 1963 623.0 1222.0 400.0 Elasto-Plastic

43 d 50 1963 506.0 1173.0 400.0 Elasto-Plastic

44 d 50 1963 404.0 1096.0 400.0 Elasto-Plastic

45 d 50 1963 327.0 995.0 400.0 Elasto-Plastic

46 d 50 1963 278.0 877.0 400.0 Elasto-Plastic

47 d 50 1963 261.0 750.0 400.0 Elasto-Plastic

48 d 50 1963 278.0 623.0 400.0 Elasto-Plastic

49 d 50 1963 327.0 506.0 400.0 Elasto-Plastic

50 d 50 1963 404.0 404.0 400.0 Elasto-Plastic

51 d 50 1963 506.0 327.0 400.0 Elasto-Plastic

52 d 50 1963 623.0 278.0 400.0 Elasto-Plastic

52-d 50

Total Area = 102076 mm^2

Steel Ratio = 5.78 %

Basic Section Properties:

Total Width = 1,500.0 mm

Total Height = 1,500.0 mm

Center, Xo = 0.0 mm

Center, Yo = 0.0 mm

X-bar (Right) = 750.0 mm

X-bar (Left) = 750.0 mm

Y-bar (Top) = 750.0 mm

Y-bar (Bot) = 750.0 mm

Transformed Properties:

Base Material = fc' = 30

N/mm^2

Area, A = 1.77E+06 mm^2

Inertia, I33 = 2.49E+11 mm^4

Inertia, I22 = 2.49E+11 mm^4

Inertia, I32 = 0.00E+00 mm^4

Radius, r3 = 375.00 mm

Radius, r2 = 375.00 mm

Additional Section Properties:

Transformed Properties:

Base Material = fc' = 30

N/mm^2

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 3

Modulus, S3(Top) = 3.31E+08 mm^3

Modulus, S3(Bot) = 3.31E+08 mm^3

Modulus, S2(Left) = 3.31E+08 mm^3

Modulus, S2(Right) = 3.31E+08 mm^3

Plastic Modulus, Z3 = 8.13E+08 mm^3

Plastic Modulus, Z2 = 8.13E+08 mm^3

Torsional, J = 4.97E+11 mm^4

Shear Area, A3 = 1.71E+06 mm^2

Shear Area, A2 = 1.71E+06 mm^2

Principal Angle = 0.00E+00 Deg

Inertia, I33' = 2.49E+11 mm^4

Inertia, I22' = 2.49E+11 mm^4

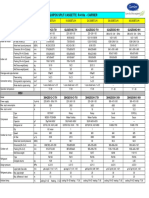

Final Design Loads

Sr.No Combination Load Pu Mux-Bot Muy-Bot Mux-Top Muy-Top

kN kN-m kN-m kN-m kN-m

1 Combination1 5,327.0 6,917.0 0.0 0.0 0.0

2 Combination2 1,180.0 6,917.0 0.0 0.0 0.0

Result Summary

Sr.No Combination Pu (kN) Cap. Ratio-Bot Cap. Ratio- Remarks

Top

1 Combination1 5,327.0 0.53 0.124 Capacity OK

2 Combination2 1,180.0 0.493 0.027 Capacity OK

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 4

Load-Moment Interaction

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 5

Moment-Moment Interaction

Moment-Curvature Curve (Angle = 0)

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 6

Neutral Axis Location: Loading-1 (Bot)

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 7

Elastic Stresses: Loading-1 (Bot)

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 8

Cracked Stresses: Loading-1 (Bot)

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 9

Rebar Stresses: Loading-1 (Bot)

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 10

Neutral Axis Location: Loading-2 (Bot)

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 11

Elastic Stresses: Loading-2 (Bot)

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 12

Cracked Stresses: Loading-2 (Bot)

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 13

Cracked Stresses: Loading-2 (Bot)

D:\BRBCP PILE\BRBCP PIL V2E.CDB Page 14

You might also like

- ASTM C478-15 ManholesDocument9 pagesASTM C478-15 Manholessethhoffman85100% (1)

- Method Statement For Casting of Segment: Name of The Project: Construction of Four Lane Fly OverDocument8 pagesMethod Statement For Casting of Segment: Name of The Project: Construction of Four Lane Fly Overvenkateswara rao Pothina100% (2)

- Column:PILOTE-ESTRIBO-2: Basic Design ParametersDocument4 pagesColumn:PILOTE-ESTRIBO-2: Basic Design ParametersIvar David Gallardo ArispeNo ratings yet

- Project Information: Basic Design ParametersDocument16 pagesProject Information: Basic Design Parameterscsa csaNo ratings yet

- Project Information: Basic Design ParametersDocument6 pagesProject Information: Basic Design ParametersLuis C. A. A.No ratings yet

- Reporte Columna CircularDocument6 pagesReporte Columna Circularjose reyesNo ratings yet

- Podium and BasementsDocument706 pagesPodium and Basementsphuckha2012No ratings yet

- Diepa B50 - High Performance Rotation Resistant Steel Wire RopeDocument1 pageDiepa B50 - High Performance Rotation Resistant Steel Wire RopeKonstantinos SynodinosNo ratings yet

- Project Information: Basic Design ParametersDocument4 pagesProject Information: Basic Design Parametersrocio isabel navarro carihuasairoNo ratings yet

- MS-Copper Lugs and Ferrules PDFDocument8 pagesMS-Copper Lugs and Ferrules PDFMacSparesNo ratings yet

- Steel Column FOR SCRIBDDocument8 pagesSteel Column FOR SCRIBDdarshika.jaganiNo ratings yet

- Diepa Χ43Document2 pagesDiepa Χ43Konstantinos SynodinosNo ratings yet

- ELECTRICAL WORK - Copy-1Document11 pagesELECTRICAL WORK - Copy-1Myo Sandar MinNo ratings yet

- B 50 (D 1315 Z) B 53 (D 1315 ZP) B 55 (D 1315 CZ) B 58 (D 1315 CZP)Document4 pagesB 50 (D 1315 Z) B 53 (D 1315 ZP) B 55 (D 1315 CZ) B 58 (D 1315 CZP)Fernando LaraNo ratings yet

- Gording ConnectionDocument9 pagesGording ConnectionRicho MSNo ratings yet

- GeotextleDocument2 pagesGeotextleShashwati DobaiNo ratings yet

- Yokohama Fabric Splice ManualDocument28 pagesYokohama Fabric Splice ManualnicolasNo ratings yet

- ESP Calculation (External Static Pressure Calculation)Document54 pagesESP Calculation (External Static Pressure Calculation)Ajeet KumarNo ratings yet

- Techson Brochure SEP NEWDocument15 pagesTechson Brochure SEP NEWKamal SharmaNo ratings yet

- Frame Kaki KakiDocument21 pagesFrame Kaki KakiMuhammad NaufalNo ratings yet

- Solution Manual For Materials For Civil and Construction Engineers 3rd Edition by MamloukDocument13 pagesSolution Manual For Materials For Civil and Construction Engineers 3rd Edition by Mamloukdawkexhume0ixeh6100% (30)

- Static Geometry Plan:: ) Fork Rectangular Bar (Aisc 360-10)Document2 pagesStatic Geometry Plan:: ) Fork Rectangular Bar (Aisc 360-10)Anonymous dSFbLxc9No ratings yet

- Design of CHQRD PlateDocument20 pagesDesign of CHQRD PlateRagavanNo ratings yet

- REPORT Ibis Style Hotel Bogor RayaDocument333 pagesREPORT Ibis Style Hotel Bogor RayakillerjackassNo ratings yet

- MAIN BEAM 1200 X 600: Double WebDocument2 pagesMAIN BEAM 1200 X 600: Double WebsalmanNo ratings yet

- RCC Design Based in Indian CodesDocument43 pagesRCC Design Based in Indian Codeschaos_atulNo ratings yet

- Breitkeilriemen - Flankenoffen, Formgezahnt: Moulded Cogged, Raw Edge Variable Speed BeltsDocument7 pagesBreitkeilriemen - Flankenoffen, Formgezahnt: Moulded Cogged, Raw Edge Variable Speed BeltsXamir Suarez AlejandroNo ratings yet

- OUTPUTDocument436 pagesOUTPUTDaron DaronoNo ratings yet

- SteelDesignSeries SDS3Document9 pagesSteelDesignSeries SDS3dongheep811No ratings yet

- Fans FlexibleDucting DuctsDocument5 pagesFans FlexibleDucting DuctsdieseljccNo ratings yet

- Design of Columns For MeDocument9 pagesDesign of Columns For MeAli SabriNo ratings yet

- RCC Design Programmed by OthersDocument43 pagesRCC Design Programmed by OthersJessie Radaza TutorNo ratings yet

- Tech Info Young ModulusDocument3 pagesTech Info Young ModulusAkin ErsozNo ratings yet

- DI Pipes PU Coating - BOQ BalnkDocument4 pagesDI Pipes PU Coating - BOQ Balnkahmed HOSNYNo ratings yet

- Sheltor CostDocument1 pageSheltor CostBalajiYachawadNo ratings yet

- S1239 Epoxy Primer: DescriptionDocument2 pagesS1239 Epoxy Primer: DescriptionELEJONDO Pablo - VCNo ratings yet

- Split Cassette Carrier R410a Ficha TecnicaDocument1 pageSplit Cassette Carrier R410a Ficha TecnicaCarlos ManriquezNo ratings yet

- Project Information: Basic Design ParametersDocument5 pagesProject Information: Basic Design Parameterseduper3No ratings yet

- Project Information: Basic Design ParametersDocument6 pagesProject Information: Basic Design Parameterseduper3No ratings yet

- Pyuntaza Station - Ele - Material+ServiceDocument6 pagesPyuntaza Station - Ele - Material+Servicekhinzawkhinzaw031No ratings yet

- Abs PVC PipeDocument44 pagesAbs PVC PipeAdanaNo ratings yet

- RCC11 Element DesignDocument6 pagesRCC11 Element DesignCioabla BogdanNo ratings yet

- RCD Composite ColumnsDocument8 pagesRCD Composite ColumnsGlaysa AsiloNo ratings yet

- Beam CalculationDocument93 pagesBeam CalculationFairus FizzNo ratings yet

- PSC I Girder Design by IRC Code (Old)Document109 pagesPSC I Girder Design by IRC Code (Old)Structural SpreadsheetsNo ratings yet

- Frame Analysis Penampang AtasDocument21 pagesFrame Analysis Penampang AtasMuhammad NaufalNo ratings yet

- PVC-DWV and ABS-DWV Pipe and Fittings: Dimensional CatalogDocument44 pagesPVC-DWV and ABS-DWV Pipe and Fittings: Dimensional CatalogMohamed AtefNo ratings yet

- Prysmian EU 11kV 1core ArmourDocument5 pagesPrysmian EU 11kV 1core ArmourBhagoo HatheyNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Load-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresFrom EverandLoad-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Smart Textiles: Wearable NanotechnologyFrom EverandSmart Textiles: Wearable NanotechnologyNazire D. YilmazNo ratings yet

- Plasma Etching Processes for Interconnect Realization in VLSIFrom EverandPlasma Etching Processes for Interconnect Realization in VLSINicolas PossemeNo ratings yet

- A Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsFrom EverandA Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsRating: 3 out of 5 stars3/5 (1)

- Floor PlansDocument2 pagesFloor PlansShantonu DeyNo ratings yet

- DR - Sumi STR FinalDocument13 pagesDR - Sumi STR FinalShantonu DeyNo ratings yet

- Boundary Wall Details of Pile PartDocument9 pagesBoundary Wall Details of Pile PartShantonu DeyNo ratings yet

- Concrete Column Design Based On ACI 318-08: Input Data & Design SummaryDocument3 pagesConcrete Column Design Based On ACI 318-08: Input Data & Design SummaryShantonu DeyNo ratings yet

- Structuiral Drawings of Revised PlanDocument28 pagesStructuiral Drawings of Revised PlanShantonu DeyNo ratings yet

- Class 01 (Ntroduction and Overview of BNBC 2020)Document23 pagesClass 01 (Ntroduction and Overview of BNBC 2020)Shantonu DeyNo ratings yet

- 18.seismic Design 2Document99 pages18.seismic Design 2Shantonu Dey100% (1)

- 4 Storied Building (Bachelor Dormitory)Document6 pages4 Storied Building (Bachelor Dormitory)Shantonu DeyNo ratings yet

- 1.introduction and Overview of BNBCDocument47 pages1.introduction and Overview of BNBCShantonu DeyNo ratings yet

- Class 01 (ntroduction-and-overview-of-BNBC 2020)Document23 pagesClass 01 (ntroduction-and-overview-of-BNBC 2020)Shantonu DeyNo ratings yet

- 16.seismic Design 1Document73 pages16.seismic Design 1Shantonu DeyNo ratings yet

- S2 - Introduction To ECPSDocument52 pagesS2 - Introduction To ECPSShantonu DeyNo ratings yet

- AISC Seismic Design-Module5-Buckling Restrained Braced Frames-V2Document62 pagesAISC Seismic Design-Module5-Buckling Restrained Braced Frames-V2Shantonu DeyNo ratings yet

- Earthquake BNBC 2020Document48 pagesEarthquake BNBC 2020Shantonu Dey100% (1)

- AISC Seismic Design-Module4-Eccentrically Braced Frames-V2Document139 pagesAISC Seismic Design-Module4-Eccentrically Braced Frames-V2Shantonu DeyNo ratings yet

- Wind Load Calculation As Per BNBC and Asce: Shafiqur Rahman Shafi 1Document56 pagesWind Load Calculation As Per BNBC and Asce: Shafiqur Rahman Shafi 1Shantonu Dey100% (2)

- AISC Seismic Design-Module6-Special Plate Shear Walls-V2Document103 pagesAISC Seismic Design-Module6-Special Plate Shear Walls-V2Shantonu DeyNo ratings yet

- S - 1 - Introduction To Building Codes and Overview of BNBCDocument95 pagesS - 1 - Introduction To Building Codes and Overview of BNBCShantonu DeyNo ratings yet

- Design of Seismic-Resistant Steel Building Structures: 3. Concentrically Braced FramesDocument123 pagesDesign of Seismic-Resistant Steel Building Structures: 3. Concentrically Braced FramesMarvin MessiNo ratings yet

- S6 - Concrete 01 Material Aspects Strength Design - WBDocument164 pagesS6 - Concrete 01 Material Aspects Strength Design - WBShantonu DeyNo ratings yet

- AISC Seismic Design Module1 Introduction V2Document103 pagesAISC Seismic Design Module1 Introduction V2Shantonu DeyNo ratings yet

- AISC Seismic Design Module0 Brief Overview V2Document86 pagesAISC Seismic Design Module0 Brief Overview V2Shantonu DeyNo ratings yet

- AISC Seismic Design-Module2-Moment Resistant Frames-V2Document233 pagesAISC Seismic Design-Module2-Moment Resistant Frames-V2Shantonu DeyNo ratings yet

- 1.analysis of Existing StructuresDocument24 pages1.analysis of Existing StructuresGilmer Challco MamaniNo ratings yet

- Project Subject Date: Material Labor I. General Requirements Total Amount Item Description Unit QTY Unit CostDocument16 pagesProject Subject Date: Material Labor I. General Requirements Total Amount Item Description Unit QTY Unit Costbilog13100% (1)

- From Footing & 5th Floor Finishing Budget For YONA 230609 154459Document36 pagesFrom Footing & 5th Floor Finishing Budget For YONA 230609 154459fisehaNo ratings yet

- Model DBRDocument77 pagesModel DBRArnab SurNo ratings yet

- Aci 307Document14 pagesAci 307Hemanth RaoNo ratings yet

- Elementary Design of Structures 2015Document23 pagesElementary Design of Structures 2015Brian Masogoyi NNo ratings yet

- Chapter 5 - Components PropertiesDocument47 pagesChapter 5 - Components PropertiesHamza CheemaNo ratings yet

- Design and Construction of Swimming Pools Ib P Bc2014 014Document11 pagesDesign and Construction of Swimming Pools Ib P Bc2014 014shams-87No ratings yet

- 2.5 Material Submittal For Protection BoardDocument82 pages2.5 Material Submittal For Protection BoardMariam MousaNo ratings yet

- Lap Splices and DowelsDocument4 pagesLap Splices and DowelsJaewoo ParkNo ratings yet

- Monthy Construction ActivityDocument8 pagesMonthy Construction ActivityRi SovannaphumiNo ratings yet

- Section 03210 Epoxy Coated Concrete ReinforcementDocument7 pagesSection 03210 Epoxy Coated Concrete ReinforcementgulzamanNo ratings yet

- Reinforced Cement ConcreteDocument81 pagesReinforced Cement Concretepandya aksharNo ratings yet

- PEP-SP-SAL-CV-CAL-202 Calculation For Bund Wall - Rev0Document43 pagesPEP-SP-SAL-CV-CAL-202 Calculation For Bund Wall - Rev0Didi Hadi RiantoNo ratings yet

- BS 4483Document15 pagesBS 4483parin gosar67% (3)

- A Critical Analysis of The Donghai Bridge, ShanghaiDocument10 pagesA Critical Analysis of The Donghai Bridge, ShanghaiPunithan PunithanNo ratings yet

- EC2 - General Rules PDFDocument141 pagesEC2 - General Rules PDFglmuralidharNo ratings yet

- Reinforcement of Timber Beams: Steffen FrankeDocument21 pagesReinforcement of Timber Beams: Steffen FrankeANDRES FELIPE GRAJALES ACEVEDONo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFDrainage Division CHIRALA0% (2)

- Petra PDFDocument32 pagesPetra PDFtopnoch5454No ratings yet

- SP-1284 2017Document102 pagesSP-1284 2017Abu MajdNo ratings yet

- CE 415 2 Analysis and Design of Rectangular Beams For FlexureDocument103 pagesCE 415 2 Analysis and Design of Rectangular Beams For FlexureLhee Ann GarboNo ratings yet

- Reinforced Masonry DesignDocument4 pagesReinforced Masonry DesignAhad Aziz100% (1)

- Austroads - Guide To Bridge Technology Part 2 - MaterialsDocument144 pagesAustroads - Guide To Bridge Technology Part 2 - MaterialstoddlbyrnesNo ratings yet

- Interim Guidelines On Use of Fibre-ReinforcedDocument38 pagesInterim Guidelines On Use of Fibre-ReinforcedDevesh Kumar PandeyNo ratings yet

- Design of Pedestal Mkd. On Grid A (Braced Bay)Document10 pagesDesign of Pedestal Mkd. On Grid A (Braced Bay)Kaustubh JadhavNo ratings yet

- Structure - IV CE 3251Document63 pagesStructure - IV CE 3251Abbdullah RayhanNo ratings yet

- FiReP Rebar Green ColFiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar greenDocument16 pagesFiReP Rebar Green ColFiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar green color KT Ver2FiReP rebar greenAnonymous hIzhxjNo ratings yet