Professional Documents

Culture Documents

367 en Filter - 5

367 en Filter - 5

Uploaded by

mansoor.surahioCopyright:

Available Formats

You might also like

- Triumph Herald Owners Repair ManualDocument230 pagesTriumph Herald Owners Repair ManualArnoldo Martínez Baudrit100% (1)

- Manual de Partes Bobcat S-300 PDFDocument400 pagesManual de Partes Bobcat S-300 PDFRoberth Alexander Ríos Nieves100% (7)

- CLG418 Operation &maintainance ManualDocument66 pagesCLG418 Operation &maintainance ManualLYCANTROPOFAGO89% (9)

- 208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSDocument13 pages208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSPopa MihaiNo ratings yet

- Cyclone RX3 Owners ManualDocument79 pagesCyclone RX3 Owners ManualNorberto Correa100% (2)

- YamYFM80Moto4Man IndexedDocument179 pagesYamYFM80Moto4Man IndexedaschubartNo ratings yet

- Joy Twist AirDocument49 pagesJoy Twist AirChris SlyNo ratings yet

- Bomba de Gasolina Wp-30 ManualDocument20 pagesBomba de Gasolina Wp-30 ManualLluís FontNo ratings yet

- Zeks ZFC FiltersDocument4 pagesZeks ZFC FiltersHiram MenchacaNo ratings yet

- E7224 2 11 16 - ON Katalogversion PDFDocument4 pagesE7224 2 11 16 - ON Katalogversion PDFHANIF AKBARNo ratings yet

- Brochure Flanged Filter Oil-X enDocument2 pagesBrochure Flanged Filter Oil-X enademgsNo ratings yet

- Compressed Air FiltersDocument8 pagesCompressed Air FiltersJuan Carlos Vazquez RosasNo ratings yet

- EMW Filtertechnik - GT (GB)Document9 pagesEMW Filtertechnik - GT (GB)Nguyễn Kim HùngNo ratings yet

- E7210 2-11-16 BN4HC KatalogversionDocument4 pagesE7210 2-11-16 BN4HC KatalogversionsNo ratings yet

- E7215 2 11 16 - WHC KatalogversionDocument4 pagesE7215 2 11 16 - WHC KatalogversionQuy HoangNo ratings yet

- Ks FP M6-F9: Compact FiltersDocument1 pageKs FP M6-F9: Compact FiltersbkprodhNo ratings yet

- OilMistSmoke ODR2000Document2 pagesOilMistSmoke ODR2000Mandrak FantomNo ratings yet

- 27 6 14 16229 Compair Filters Brochure 02 Uk V2Document8 pages27 6 14 16229 Compair Filters Brochure 02 Uk V2Leonardo Tommy DacuNo ratings yet

- Brochure Compressed - Air-CF - N-Filter-11-05Document2 pagesBrochure Compressed - Air-CF - N-Filter-11-05abdur rohmanNo ratings yet

- BRO MobilePro ENDocument4 pagesBRO MobilePro ENkhoi nguyenvanNo ratings yet

- High Efficiency Compressed Air Filtration & Water SeparationDocument8 pagesHigh Efficiency Compressed Air Filtration & Water SeparationMelvic BinosNo ratings yet

- Unipore Air Gun: (Polypropylene Body Type)Document2 pagesUnipore Air Gun: (Polypropylene Body Type)bbNo ratings yet

- OIL XPlusHighPressureDocument2 pagesOIL XPlusHighPressureSuprimentos IndaloNo ratings yet

- DS ConcreteProduction WAMFLO 0415 ENG PDFDocument2 pagesDS ConcreteProduction WAMFLO 0415 ENG PDFmiguel gabilanNo ratings yet

- Product Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)Document4 pagesProduct Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)ademgsNo ratings yet

- Base Line Series: Piston Compressor RangeDocument2 pagesBase Line Series: Piston Compressor Rangemogwai71No ratings yet

- Filtri GP, HE, AC, DPDocument4 pagesFiltri GP, HE, AC, DPjuris.ligerisNo ratings yet

- 1cgde09jv 337626Document4 pages1cgde09jv 337626Fati ZoraNo ratings yet

- Ksi Pi Apf en 02 0421Document10 pagesKsi Pi Apf en 02 0421Mahmoud MagdyNo ratings yet

- Donaldson ultrafilter-DFTDocument4 pagesDonaldson ultrafilter-DFTsyrinxNo ratings yet

- Air Diffusers and Aerators: Aeration and Mixing SystemsDocument12 pagesAir Diffusers and Aerators: Aeration and Mixing SystemsMuhammadObaidullahNo ratings yet

- Type ZL: For High Dust Concentrations or As A Prefilter For Fine Dust FiltersDocument5 pagesType ZL: For High Dust Concentrations or As A Prefilter For Fine Dust Filtersaya maapNo ratings yet

- Scheuch Folder Ligno Impulsfilter E 20150522 02Document6 pagesScheuch Folder Ligno Impulsfilter E 20150522 02MagdalenaNo ratings yet

- Compatex TMPCDocument10 pagesCompatex TMPChussain mominNo ratings yet

- FH235-236 Lt36164-EngDocument2 pagesFH235-236 Lt36164-EngYudi setiawanNo ratings yet

- Fehlerfrei Mpj250 300-1Document4 pagesFehlerfrei Mpj250 300-1Sam BestNo ratings yet

- SO 61-2 W SO 126-2 W Oil-Free Compressors: A Clean Efficiency Boost: ToDocument2 pagesSO 61-2 W SO 126-2 W Oil-Free Compressors: A Clean Efficiency Boost: Tohendra matatiaNo ratings yet

- Donaldson LF Series PDFDocument8 pagesDonaldson LF Series PDFSebastian GanciNo ratings yet

- Fileslibreria de Descargas4459 Concentrador Millenium PDFDocument2 pagesFileslibreria de Descargas4459 Concentrador Millenium PDFJade MAres0% (1)

- DS PaintandVarnish HOPPERJET 0915 ENGDocument2 pagesDS PaintandVarnish HOPPERJET 0915 ENGLOPEZ LABRA CESAR ARTURO INGENIER�A EL�CTRICANo ratings yet

- Air Line Infrastructure (ALI) Catalogue 2023Document60 pagesAir Line Infrastructure (ALI) Catalogue 2023cyrano1091No ratings yet

- Jet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesDocument8 pagesJet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesErinc CelikNo ratings yet

- Scheuch Folder Ligno Entstauber E 120116 01Document8 pagesScheuch Folder Ligno Entstauber E 120116 01MagdalenaNo ratings yet

- Designed To Take The LeadDocument7 pagesDesigned To Take The Leadhendra matatiaNo ratings yet

- Product Documentation Dynavane PDFDocument1 pageProduct Documentation Dynavane PDFAnkit JainNo ratings yet

- MH Catalog Fuel Filters enDocument42 pagesMH Catalog Fuel Filters enerwerwerwerwewytiygNo ratings yet

- Fuel Filter: AKO COMDocument4 pagesFuel Filter: AKO COMAlexanderNo ratings yet

- Compressed Air Filtration: Oil and Particulate Air TreatmentDocument12 pagesCompressed Air Filtration: Oil and Particulate Air TreatmentALEJANDRONo ratings yet

- Sullair FiltersDocument12 pagesSullair FiltersNicolás TomelínNo ratings yet

- ALUP Linefilters ENG 6999640480Document7 pagesALUP Linefilters ENG 6999640480Eng.issam AlrshdanNo ratings yet

- Filter Mats AcelanDocument1 pageFilter Mats AcelanLGTNo ratings yet

- Filtros SCF SCHDocument10 pagesFiltros SCF SCHDiego TesinNo ratings yet

- HOPPERTOP Wam Inc 0912 EDITDocument4 pagesHOPPERTOP Wam Inc 0912 EDITPrzemek GóźdźNo ratings yet

- Cobetter BGPP160 FilterDocument1 pageCobetter BGPP160 FilterVictor LiangNo ratings yet

- P-726-ED-4-20 - 17-5602 FiltrosDocument20 pagesP-726-ED-4-20 - 17-5602 FiltrosSebastian Rodrigo OctavianoNo ratings yet

- Oil-X Evolution: Engineering SuccessDocument8 pagesOil-X Evolution: Engineering SuccesslwinooNo ratings yet

- Filters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersDocument2 pagesFilters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor Filtersnicholaus alfargoNo ratings yet

- Compressed Air Filter & Separator: Italian TechnologyDocument16 pagesCompressed Air Filter & Separator: Italian TechnologyRUN GONo ratings yet

- Sepralyte LG CoalescerDocument2 pagesSepralyte LG CoalescerAllen RichardNo ratings yet

- BOPP Sintered Wire Cloth PDFDocument12 pagesBOPP Sintered Wire Cloth PDFdiego100% (1)

- OilMistSmoke ODR9000Document2 pagesOilMistSmoke ODR9000Mandrak FantomNo ratings yet

- Silotop Zero en 0219 EditDocument4 pagesSilotop Zero en 0219 EditademgsNo ratings yet

- Gore Turbine Filters Brochure - 05-2010Document8 pagesGore Turbine Filters Brochure - 05-2010Mario MontessoriNo ratings yet

- Evo Filters 174004403 - ENDocument4 pagesEvo Filters 174004403 - ENandre_silva_camposNo ratings yet

- Side Channel BlowersDocument8 pagesSide Channel BlowersGraham BarrNo ratings yet

- Outstanding Performance in Extremely: Low Pressure and Low Pressure Ranges From 0.003 To 0.1 MpaDocument13 pagesOutstanding Performance in Extremely: Low Pressure and Low Pressure Ranges From 0.003 To 0.1 MpaAkmal ZuhriNo ratings yet

- P 726 ED tcm135 566229 PDFDocument11 pagesP 726 ED tcm135 566229 PDFВасилий ЗотовNo ratings yet

- Noise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionFrom EverandNoise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionNo ratings yet

- Electrical InnovationDocument2 pagesElectrical Innovationmansoor.surahioNo ratings yet

- CV Hafiz Umer 2018Document3 pagesCV Hafiz Umer 2018mansoor.surahioNo ratings yet

- CV M SalamDocument1 pageCV M Salammansoor.surahioNo ratings yet

- 1003BFFD98471EDDDocument2 pages1003BFFD98471EDDmansoor.surahioNo ratings yet

- ElectricianDocument3 pagesElectricianmansoor.surahioNo ratings yet

- 6-2-2022 Elect - 37546Document1 page6-2-2022 Elect - 37546mansoor.surahioNo ratings yet

- New Text DocumentDocument1 pageNew Text Documentmansoor.surahioNo ratings yet

- List Invetaris Aset BEH 2020-2021 (1) UPDATE 23032022Document87 pagesList Invetaris Aset BEH 2020-2021 (1) UPDATE 23032022Deny SaputraNo ratings yet

- PVC TUBE MSDS - (2019) - EngDocument25 pagesPVC TUBE MSDS - (2019) - EngEnzo AscañoNo ratings yet

- 414 Rs PartsDocument57 pages414 Rs PartsRicardo DavidNo ratings yet

- Bobcat Filter Reference Guide PDFDocument23 pagesBobcat Filter Reference Guide PDFweldsaidi100% (1)

- Commissioning Check List For HP Bypass SystemDocument8 pagesCommissioning Check List For HP Bypass SystemGansehNo ratings yet

- AP00.20 U 1208IB SERVICE SHEET For Mercedes Benz Maintenance System (USA) 8.11.04Document4 pagesAP00.20 U 1208IB SERVICE SHEET For Mercedes Benz Maintenance System (USA) 8.11.04Pedro ViegasNo ratings yet

- Engine Air Filtration (English)Document2 pagesEngine Air Filtration (English)Kaiser IqbalNo ratings yet

- DD310 26Document94 pagesDD310 26Raphael Ruiz RamosNo ratings yet

- Iso 1585 2020 en PDFDocument11 pagesIso 1585 2020 en PDFBraulio Gutierrez PimentaNo ratings yet

- American Woodworker 161Document76 pagesAmerican Woodworker 161Emilian Baluta100% (1)

- Welcome To Know Your Mahindra Tractor'Document198 pagesWelcome To Know Your Mahindra Tractor'Hanif UdinNo ratings yet

- Leminar Air FlowDocument17 pagesLeminar Air FlowTejas PatelNo ratings yet

- Hyundai LPG Forklift Trucks: - Applied Tier 4 EngineDocument12 pagesHyundai LPG Forklift Trucks: - Applied Tier 4 Engineedwinvartuan-1No ratings yet

- TM 9-1787B M1 Heavy Tractor Allis-Chalmers HD-10WDocument328 pagesTM 9-1787B M1 Heavy Tractor Allis-Chalmers HD-10WAdvocate100% (1)

- Manual de Operacion - C186FD-C188FD-C192FDDocument29 pagesManual de Operacion - C186FD-C188FD-C192FDGeorgina ChNo ratings yet

- Lampiran Surat Perubahan Retail Price SGP Periode June 2019Document6 pagesLampiran Surat Perubahan Retail Price SGP Periode June 2019Istiqomah khaeriyyah100% (1)

- Delbag Filter System MultiAir Eco 2000-MWFDocument12 pagesDelbag Filter System MultiAir Eco 2000-MWFnileshNo ratings yet

- SD160DXDocument300 pagesSD160DXMohamed Ahmed Hassanin88% (16)

- CAT C9.3-C18 T4i Under 750hp L3 Rev06Document38 pagesCAT C9.3-C18 T4i Under 750hp L3 Rev06Ebied Yousif AlyNo ratings yet

- KTL Kamla Nagar Maruti Suzuki Workshop Session - 2019-2020Document13 pagesKTL Kamla Nagar Maruti Suzuki Workshop Session - 2019-2020Guru SatsangiNo ratings yet

- GTDocument228 pagesGTJustin NelsonNo ratings yet

- Operator's Manual: T-1080S Spectrum With Premium HMIDocument150 pagesOperator's Manual: T-1080S Spectrum With Premium HMIJean Carlos Lins100% (1)

367 en Filter - 5

367 en Filter - 5

Uploaded by

mansoor.surahioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

367 en Filter - 5

367 en Filter - 5

Uploaded by

mansoor.surahioCopyright:

Available Formats

HP compressed air filter

F 6 to F 5210

Flow capacity 0.60 – 520.8 m³/min, 21 – 18,392 cfm

Max. operating pressure: 16 bar, 235 psig

High performance filter elements:

The use of highly efficient element

membranes made of nano-fibres with

optimised exterior shell stand for

extreme filter efficiency. You can choose

between the coalescence fine element

P (1 μm) and the coalescence fine ele

ment M (0.01 μm) for droplet and aero

sol separation as well as the absorptive

element A for a highly efficient surface

binding of oil vapours and odours.

VALIDATED COMPRESSED AIR QUALITY HIGHLY EFFICIENT OPERATION

The new BOGE HP filters are designed to reliably The significantly lower pressure losses of this

separate solids, oil & water aerosols as well as filter series help to reduce your energy con-

oil vapours. To this purpose, the compressed air sumption and to improve the CO2 balance for

quality has been validated by independent experts your company. Never before has compressed air

and is confirmed to conform to ISO 12500 – filtering been so efficient! High-tech design:

1:2007 and ISO 8573 –1:2010 standards. The compressed air intake side is

clearly visible due to its rim at the filter

head – to ensure foolproof connection

LOW DIFFERENTIAL PRESSURES RELIABLE SYSTEM between the upper and lower filter

The optimised flow design and the use of HP Long term studies show that, if the specified housing sections during assembly. The

filter materials serve to keep the differential maintenance recommendations are adhered to, conical housing inlet provides a smooth

pressure at a constant low level during the entire the differential pressure of the filters can be kept and turbulence free airflow transition

service life of the element without compromising at a constant low level with consistently high when entering the filter element.

its dirt holding capacity. separation efficiency.

The new HP generation compressed air filters: With its flow optimised design BOGE Compressed Air Systems

and performance optimised filter materials the latest BOGE HP filter series are GmbH & Co. KG

P. O. Box 10 07 13 · 33507 Bielefeld

setting new standards. Compressed air purification at its best at the lowest Otto-Boge-Straße 1–7 · 33739 Bielefeld

possible differential pressures: the formula for success – guaranteed high phone +49 5206 601-0

quality compressed air at low operating costs is synonymous with user profit. fax +49 5206 601-200

info@boge.com · boge.com

Never before have compressed air filters been so efficient!

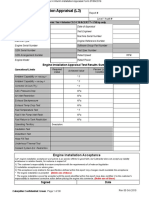

Filtration rate FP FM FA

Separation Aerosols (oil, water)) Aerosols (oil, water) Vapours

Suitability according to ISO 8573 –1:2010 [2:–:2] [1:–:1] [1:–:1]

Particle size ≥ 1 µm ≥ 0.01 µm n/a

Residual oil contents 0.6 mg/m³ 0.01 mg/m³ 0.003 mg/m³

Filter efficiency 99.925 % 99.9999 % n/a

Differential pressure, dry < 70 mbar < 140 mbar < 70 mbar

Differential pressure, wet < 140 mbar < 200 mbar not specified

BOGE Performance 2) Connec- Dimensions in mm Weight Max.

Type 1) tion pressure

m3/h cfm A B C D kg bar

F6P/F6M/F6A 36 21 G 1⁄4 67 208 23 40 0.55 16.00

F9P/F9M/F9A 55 32 G 3⁄8 89 270 38 50 1.30 16.00

F 12 P / F 12 M / F 12 A 72 42 G 1⁄2 89 270 38 50 1.30 16.00

F 18 P / F 18 M / F 18 A 108 64 G 3⁄4 89 270 38 50 1.30 16.00

F 36 P / F 36 M / F 36 A 216 127 G1 130 309 46 70 3.00 16.00

F 65 P / F 65 M / F 65 A 396 233 G 11⁄2 130 399 46 70 3.20 16.00

F 95 P / F 95 M / F 95 A 576 339 G 11⁄2 164 471 57 100 6.90 16.00

F 130 P / F 130 M / F 130 A 792 466 G2 164 563 57 100 7.30 16.00

F 190 P / F 190 M / F 190 A 1188 699 G 21⁄2 164 563 57 100 7.10 16.00

F 260 P / F 260 M / F 260 A 1548 911 G 21⁄2 192 685 72 120 10.30 16.00

F 380 P / F 380 M / F 380 A 2232 1314 G3 192 875 72 120 15.30 16.00

Steel casing with flange connection according to EN 1092-1

BOGE Performance ²) Connection Dimensions in mm Weight Filter element

Type ¹)

m³/h cfm A B C D kg Quantity

F 375 FP / F 375 FM / F 375 FA 2232 1313 DN 80 440 1222 221 523 72 1

367-EN-BI-1-01.2018/d · Technical changes and errors reserved.

F 745 FP / F 745 FM / F 745 FA 4464 2627 DN 100 500 1235 258 523 99 2

F 1115 FP / F 1115 FM / F 1115 FA 6696 3941 DN 150 600 1429 308 523 150 3

F 1490 FP / F 1490 FM / F 1490 FA 8928 5255 DN 150 650 1505 346 523 189 4

F 2230 FP / F 2230 FM / F 2230 FA 13392 7882 DN 200 750 1572 386 523 242 6

F 3720 FP / F 3720 FM / F 3720 FA 22320 13137 DN 250 1000 1733 482 523 472 10

F 5210 FP / F 5210 FM / F 5210 FA 31248 18392 DN 300 1050 1836 513 523 583 14

Max. operating pressure 16 bar, 1) including automatic condensate drain, differential pressure gauge as of F 9, 2) based on +20 °C and 1 bar absolute at 7 bar overpressure.

Conversion factor f for other operating pressures

bar overpressure 1 2 3 4 5 6 7 8 9 10 11 12 13

f= 0.25 0.38 0.50 0.65 0.78 0.88 1.00 1.13 1.25 1.38 1.50 1.63 1.75

You might also like

- Triumph Herald Owners Repair ManualDocument230 pagesTriumph Herald Owners Repair ManualArnoldo Martínez Baudrit100% (1)

- Manual de Partes Bobcat S-300 PDFDocument400 pagesManual de Partes Bobcat S-300 PDFRoberth Alexander Ríos Nieves100% (7)

- CLG418 Operation &maintainance ManualDocument66 pagesCLG418 Operation &maintainance ManualLYCANTROPOFAGO89% (9)

- 208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSDocument13 pages208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSPopa MihaiNo ratings yet

- Cyclone RX3 Owners ManualDocument79 pagesCyclone RX3 Owners ManualNorberto Correa100% (2)

- YamYFM80Moto4Man IndexedDocument179 pagesYamYFM80Moto4Man IndexedaschubartNo ratings yet

- Joy Twist AirDocument49 pagesJoy Twist AirChris SlyNo ratings yet

- Bomba de Gasolina Wp-30 ManualDocument20 pagesBomba de Gasolina Wp-30 ManualLluís FontNo ratings yet

- Zeks ZFC FiltersDocument4 pagesZeks ZFC FiltersHiram MenchacaNo ratings yet

- E7224 2 11 16 - ON Katalogversion PDFDocument4 pagesE7224 2 11 16 - ON Katalogversion PDFHANIF AKBARNo ratings yet

- Brochure Flanged Filter Oil-X enDocument2 pagesBrochure Flanged Filter Oil-X enademgsNo ratings yet

- Compressed Air FiltersDocument8 pagesCompressed Air FiltersJuan Carlos Vazquez RosasNo ratings yet

- EMW Filtertechnik - GT (GB)Document9 pagesEMW Filtertechnik - GT (GB)Nguyễn Kim HùngNo ratings yet

- E7210 2-11-16 BN4HC KatalogversionDocument4 pagesE7210 2-11-16 BN4HC KatalogversionsNo ratings yet

- E7215 2 11 16 - WHC KatalogversionDocument4 pagesE7215 2 11 16 - WHC KatalogversionQuy HoangNo ratings yet

- Ks FP M6-F9: Compact FiltersDocument1 pageKs FP M6-F9: Compact FiltersbkprodhNo ratings yet

- OilMistSmoke ODR2000Document2 pagesOilMistSmoke ODR2000Mandrak FantomNo ratings yet

- 27 6 14 16229 Compair Filters Brochure 02 Uk V2Document8 pages27 6 14 16229 Compair Filters Brochure 02 Uk V2Leonardo Tommy DacuNo ratings yet

- Brochure Compressed - Air-CF - N-Filter-11-05Document2 pagesBrochure Compressed - Air-CF - N-Filter-11-05abdur rohmanNo ratings yet

- BRO MobilePro ENDocument4 pagesBRO MobilePro ENkhoi nguyenvanNo ratings yet

- High Efficiency Compressed Air Filtration & Water SeparationDocument8 pagesHigh Efficiency Compressed Air Filtration & Water SeparationMelvic BinosNo ratings yet

- Unipore Air Gun: (Polypropylene Body Type)Document2 pagesUnipore Air Gun: (Polypropylene Body Type)bbNo ratings yet

- OIL XPlusHighPressureDocument2 pagesOIL XPlusHighPressureSuprimentos IndaloNo ratings yet

- DS ConcreteProduction WAMFLO 0415 ENG PDFDocument2 pagesDS ConcreteProduction WAMFLO 0415 ENG PDFmiguel gabilanNo ratings yet

- Product Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)Document4 pagesProduct Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)ademgsNo ratings yet

- Base Line Series: Piston Compressor RangeDocument2 pagesBase Line Series: Piston Compressor Rangemogwai71No ratings yet

- Filtri GP, HE, AC, DPDocument4 pagesFiltri GP, HE, AC, DPjuris.ligerisNo ratings yet

- 1cgde09jv 337626Document4 pages1cgde09jv 337626Fati ZoraNo ratings yet

- Ksi Pi Apf en 02 0421Document10 pagesKsi Pi Apf en 02 0421Mahmoud MagdyNo ratings yet

- Donaldson ultrafilter-DFTDocument4 pagesDonaldson ultrafilter-DFTsyrinxNo ratings yet

- Air Diffusers and Aerators: Aeration and Mixing SystemsDocument12 pagesAir Diffusers and Aerators: Aeration and Mixing SystemsMuhammadObaidullahNo ratings yet

- Type ZL: For High Dust Concentrations or As A Prefilter For Fine Dust FiltersDocument5 pagesType ZL: For High Dust Concentrations or As A Prefilter For Fine Dust Filtersaya maapNo ratings yet

- Scheuch Folder Ligno Impulsfilter E 20150522 02Document6 pagesScheuch Folder Ligno Impulsfilter E 20150522 02MagdalenaNo ratings yet

- Compatex TMPCDocument10 pagesCompatex TMPChussain mominNo ratings yet

- FH235-236 Lt36164-EngDocument2 pagesFH235-236 Lt36164-EngYudi setiawanNo ratings yet

- Fehlerfrei Mpj250 300-1Document4 pagesFehlerfrei Mpj250 300-1Sam BestNo ratings yet

- SO 61-2 W SO 126-2 W Oil-Free Compressors: A Clean Efficiency Boost: ToDocument2 pagesSO 61-2 W SO 126-2 W Oil-Free Compressors: A Clean Efficiency Boost: Tohendra matatiaNo ratings yet

- Donaldson LF Series PDFDocument8 pagesDonaldson LF Series PDFSebastian GanciNo ratings yet

- Fileslibreria de Descargas4459 Concentrador Millenium PDFDocument2 pagesFileslibreria de Descargas4459 Concentrador Millenium PDFJade MAres0% (1)

- DS PaintandVarnish HOPPERJET 0915 ENGDocument2 pagesDS PaintandVarnish HOPPERJET 0915 ENGLOPEZ LABRA CESAR ARTURO INGENIER�A EL�CTRICANo ratings yet

- Air Line Infrastructure (ALI) Catalogue 2023Document60 pagesAir Line Infrastructure (ALI) Catalogue 2023cyrano1091No ratings yet

- Jet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesDocument8 pagesJet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesErinc CelikNo ratings yet

- Scheuch Folder Ligno Entstauber E 120116 01Document8 pagesScheuch Folder Ligno Entstauber E 120116 01MagdalenaNo ratings yet

- Designed To Take The LeadDocument7 pagesDesigned To Take The Leadhendra matatiaNo ratings yet

- Product Documentation Dynavane PDFDocument1 pageProduct Documentation Dynavane PDFAnkit JainNo ratings yet

- MH Catalog Fuel Filters enDocument42 pagesMH Catalog Fuel Filters enerwerwerwerwewytiygNo ratings yet

- Fuel Filter: AKO COMDocument4 pagesFuel Filter: AKO COMAlexanderNo ratings yet

- Compressed Air Filtration: Oil and Particulate Air TreatmentDocument12 pagesCompressed Air Filtration: Oil and Particulate Air TreatmentALEJANDRONo ratings yet

- Sullair FiltersDocument12 pagesSullair FiltersNicolás TomelínNo ratings yet

- ALUP Linefilters ENG 6999640480Document7 pagesALUP Linefilters ENG 6999640480Eng.issam AlrshdanNo ratings yet

- Filter Mats AcelanDocument1 pageFilter Mats AcelanLGTNo ratings yet

- Filtros SCF SCHDocument10 pagesFiltros SCF SCHDiego TesinNo ratings yet

- HOPPERTOP Wam Inc 0912 EDITDocument4 pagesHOPPERTOP Wam Inc 0912 EDITPrzemek GóźdźNo ratings yet

- Cobetter BGPP160 FilterDocument1 pageCobetter BGPP160 FilterVictor LiangNo ratings yet

- P-726-ED-4-20 - 17-5602 FiltrosDocument20 pagesP-726-ED-4-20 - 17-5602 FiltrosSebastian Rodrigo OctavianoNo ratings yet

- Oil-X Evolution: Engineering SuccessDocument8 pagesOil-X Evolution: Engineering SuccesslwinooNo ratings yet

- Filters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersDocument2 pagesFilters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor Filtersnicholaus alfargoNo ratings yet

- Compressed Air Filter & Separator: Italian TechnologyDocument16 pagesCompressed Air Filter & Separator: Italian TechnologyRUN GONo ratings yet

- Sepralyte LG CoalescerDocument2 pagesSepralyte LG CoalescerAllen RichardNo ratings yet

- BOPP Sintered Wire Cloth PDFDocument12 pagesBOPP Sintered Wire Cloth PDFdiego100% (1)

- OilMistSmoke ODR9000Document2 pagesOilMistSmoke ODR9000Mandrak FantomNo ratings yet

- Silotop Zero en 0219 EditDocument4 pagesSilotop Zero en 0219 EditademgsNo ratings yet

- Gore Turbine Filters Brochure - 05-2010Document8 pagesGore Turbine Filters Brochure - 05-2010Mario MontessoriNo ratings yet

- Evo Filters 174004403 - ENDocument4 pagesEvo Filters 174004403 - ENandre_silva_camposNo ratings yet

- Side Channel BlowersDocument8 pagesSide Channel BlowersGraham BarrNo ratings yet

- Outstanding Performance in Extremely: Low Pressure and Low Pressure Ranges From 0.003 To 0.1 MpaDocument13 pagesOutstanding Performance in Extremely: Low Pressure and Low Pressure Ranges From 0.003 To 0.1 MpaAkmal ZuhriNo ratings yet

- P 726 ED tcm135 566229 PDFDocument11 pagesP 726 ED tcm135 566229 PDFВасилий ЗотовNo ratings yet

- Noise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionFrom EverandNoise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionNo ratings yet

- Electrical InnovationDocument2 pagesElectrical Innovationmansoor.surahioNo ratings yet

- CV Hafiz Umer 2018Document3 pagesCV Hafiz Umer 2018mansoor.surahioNo ratings yet

- CV M SalamDocument1 pageCV M Salammansoor.surahioNo ratings yet

- 1003BFFD98471EDDDocument2 pages1003BFFD98471EDDmansoor.surahioNo ratings yet

- ElectricianDocument3 pagesElectricianmansoor.surahioNo ratings yet

- 6-2-2022 Elect - 37546Document1 page6-2-2022 Elect - 37546mansoor.surahioNo ratings yet

- New Text DocumentDocument1 pageNew Text Documentmansoor.surahioNo ratings yet

- List Invetaris Aset BEH 2020-2021 (1) UPDATE 23032022Document87 pagesList Invetaris Aset BEH 2020-2021 (1) UPDATE 23032022Deny SaputraNo ratings yet

- PVC TUBE MSDS - (2019) - EngDocument25 pagesPVC TUBE MSDS - (2019) - EngEnzo AscañoNo ratings yet

- 414 Rs PartsDocument57 pages414 Rs PartsRicardo DavidNo ratings yet

- Bobcat Filter Reference Guide PDFDocument23 pagesBobcat Filter Reference Guide PDFweldsaidi100% (1)

- Commissioning Check List For HP Bypass SystemDocument8 pagesCommissioning Check List For HP Bypass SystemGansehNo ratings yet

- AP00.20 U 1208IB SERVICE SHEET For Mercedes Benz Maintenance System (USA) 8.11.04Document4 pagesAP00.20 U 1208IB SERVICE SHEET For Mercedes Benz Maintenance System (USA) 8.11.04Pedro ViegasNo ratings yet

- Engine Air Filtration (English)Document2 pagesEngine Air Filtration (English)Kaiser IqbalNo ratings yet

- DD310 26Document94 pagesDD310 26Raphael Ruiz RamosNo ratings yet

- Iso 1585 2020 en PDFDocument11 pagesIso 1585 2020 en PDFBraulio Gutierrez PimentaNo ratings yet

- American Woodworker 161Document76 pagesAmerican Woodworker 161Emilian Baluta100% (1)

- Welcome To Know Your Mahindra Tractor'Document198 pagesWelcome To Know Your Mahindra Tractor'Hanif UdinNo ratings yet

- Leminar Air FlowDocument17 pagesLeminar Air FlowTejas PatelNo ratings yet

- Hyundai LPG Forklift Trucks: - Applied Tier 4 EngineDocument12 pagesHyundai LPG Forklift Trucks: - Applied Tier 4 Engineedwinvartuan-1No ratings yet

- TM 9-1787B M1 Heavy Tractor Allis-Chalmers HD-10WDocument328 pagesTM 9-1787B M1 Heavy Tractor Allis-Chalmers HD-10WAdvocate100% (1)

- Manual de Operacion - C186FD-C188FD-C192FDDocument29 pagesManual de Operacion - C186FD-C188FD-C192FDGeorgina ChNo ratings yet

- Lampiran Surat Perubahan Retail Price SGP Periode June 2019Document6 pagesLampiran Surat Perubahan Retail Price SGP Periode June 2019Istiqomah khaeriyyah100% (1)

- Delbag Filter System MultiAir Eco 2000-MWFDocument12 pagesDelbag Filter System MultiAir Eco 2000-MWFnileshNo ratings yet

- SD160DXDocument300 pagesSD160DXMohamed Ahmed Hassanin88% (16)

- CAT C9.3-C18 T4i Under 750hp L3 Rev06Document38 pagesCAT C9.3-C18 T4i Under 750hp L3 Rev06Ebied Yousif AlyNo ratings yet

- KTL Kamla Nagar Maruti Suzuki Workshop Session - 2019-2020Document13 pagesKTL Kamla Nagar Maruti Suzuki Workshop Session - 2019-2020Guru SatsangiNo ratings yet

- GTDocument228 pagesGTJustin NelsonNo ratings yet

- Operator's Manual: T-1080S Spectrum With Premium HMIDocument150 pagesOperator's Manual: T-1080S Spectrum With Premium HMIJean Carlos Lins100% (1)