Professional Documents

Culture Documents

Marble Replacing Fine Aggregates

Marble Replacing Fine Aggregates

Uploaded by

digvijay singhOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marble Replacing Fine Aggregates

Marble Replacing Fine Aggregates

Uploaded by

digvijay singhCopyright:

Available Formats

Volume : 2 | Issue : 2 | Feb 2013 • ISSN No 2277 - 8160

Research Paper Engineering

Marble Waste: Opportunities For Development of Low

Cost Concrete

Student of final year M.E. in Construction Engineering & Manage-

Nutan Patel

ment, B.V.M. Engineering College, Vallabh Vidyanagar-Gujarat-India

Student of final year M.E. in Construction Engineering & Manage-

Amit Raval

ment, B.V.M. Engineering College, Vallabh Vidyanagar-Gujarat-India

Jayeshkumar Assistant Professor and Research Scholar, Civil Engineering Depart-

Pitroda ment, B.V.M. Engineering College, Vallabh Vidyanagar-Gujarat-India

Waste management is a fundamental component to any manufacturing or production enterprise. It is estimated

ABSTRACT that there are million tons of quarrying waste are produced in each year. Although a portion of this waste may be

utilized on-site such as for excavation pit refill. Waste generated at quarries and fabrication plants is quite similar.

Most commonly, scrap stone must be mitigated and managed, but attention must be paid to other types of wastes, as well. These include

marble sludge/slurry. Marble sawing powder wastes is widespread by-product of industrial process in India. Generally these wastes pollute

and damage the environment due to sawing and polishing processes. This waste is used for making a marble waste concrete. The main aim

of this waste management is to evaluate recovery and use marble waste in making a low cost concrete.

KEYWORDS: marble, marble waste, waste management, marble slurry, low cost concrete

INTRODUCTION

Marble waste use as a material is a very important environmental

management tool for achieving sustainable development. On the

other hand, recycling waste without properly based scientific research

and development can result in environmental problems greater than

the waste itself. Marble waste from quarry operations can be unsafe

and environmentally detrimental. Now-a-days the cost of material

is increasing so if we use the waste material in the production of the

concrete so we decrease the price. In India, million tons of wastes from

marble industries are being released from marble cutting, polishing,

processing and grinding. Exposing the waste material to the environ-

ment directly can cause environmental problems. Therefore, many

countries have still been working on how to re-use the waste materials. Fig 1:- Chemical analysis of marble slurry

PHYSICAL PROPERTIES OF MARBLE SLURRY MARBLE WASTE UTILIZATION

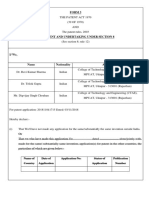

TABLE 1 TABLE 4

PHYSICAL PROPERTIES OF MARBLE SLURRY MARBLE WASTE UTILIZATION

Property Result Sr. No Utilization Area Utilization %

Bulk Density (gm/cc) 1.3-1.5 Structural fill ,Soil stabilization, and

Specific Gravity 2.83-2.87 1 road embankment work 10-15

2 Cement 10-12

TABLE 2

PARTICLE SIZE DISTRIBUTION OF MARBLE SLURRY 3 Aggregates 2-5

4 Bricks , Blocks, Tiles 11-13

Particle size (mm) % Finer by volume

5 Paint ,Binder ,Plaster 2-5

363.1 100

193.0-205.8 90 6 Concrete roofing sheets 5-10

7 Ceramic Products 10-12

Source: Research Paper on use of “Incorporation of Marble Sludge in Indus-

8 Particle Board, Panels 10-12

trial Building Eco-blocks or Cement Bricks Formulation” by Fakher J. Aukour

Source: Paper on “A Study of utilization aspect of stone

CHEMICAL ANALYSIS OF MARBLE SLURRY waste in Indian context” By Mamta B. Rajgor, Prof. Jayes-

hkumar Pitroda

TABLE 3

CHEMICAL ANALYSIS OF MARBLE SLURRY

Test carried out Test value %

Loss on ignition 43.46

Silica 1.69

Alumina 1.04

Iron Oxide 0.21

Lime 49.07

Magnesia 4.47

Source: Research Paper on use of “Incorporation of Marble Sludge in

Industrial Building Eco-blocks or Cement Bricks Formulation” by Fakher

J. Aukour. Fig 2:- Marble waste utilization

GRA - GLOBAL RESEARCH ANALYSIS X 94

Volume : 2 | Issue : 2 | Feb 2013 • ISSN No 2277 - 8160

(1) Structural fill, soil stabilization, and road embank- • Marble slurry or powder affect the soil fertility and reduce them.

ments • The waste is dumped on land the dust is airborne by the wind and

As marble dust is an inert material it can be mixed with certain types of makes air pollution in environment.

soils for the preparation / raising of embankments etc. which will result • Marble slurry increases the accident of the slip.

in the saving of valuable soil. Unconfined Compressive Strength (UCS)

have been performed to determine the strength of the mixes with soils CASE STUDY

and it has been observed that, “Influence of Marble powder/granules in Concrete mix” by Baboo Rai,

Khan Naushad H, Abhishek Kr, Tabin Rushad S, Duggal S.K Motilal

• In silty soil, there is 12 percent increase in UCS with 10% marble Nehru National Institute of Technology, Allahabad

dust

• There is a 20% increase in UCS with 30% marble dust Marble as a building material especially in palaces and monuments has

• There is no improvement in clayey soil been in use for ages. However the use is limited as stone bricks in wall

or arches or as lining slabs in walls, roofs or floors, leaving its wastage

(2) Cement at quarry or at the sizing industry generally unattended for use in the

Limestone is the main raw material along with clay and other corrective building industry itself as filler or plasticizer in concrete. The result is that

materials for the manufacture of Portland cement. Analysis of marble the mass which is 40% of total marble quarried has reached as high as

waste shows that it satisfies the chemical composition requirements millions of tons. This huge unattended mass of marble waste consisting

of cement grade limestone to a great extent. As a part replacement of of very fine particles is today one of the environmental problems around

limestone, marble waste can be used. By utilization of the marble waste the world. One of the logical means for reduction of the waste marble

save the limestone. masses calls for utilizing them in building industry itself. Some attempts

have been made to find and assess the possibilities of using waste mar-

(3) Concrete ble powder in concretes and results about strength and workability were

In concrete mixes there is increase in compressive strength of the con- compared with control samples of conventional concrete. Compared to

crete and save the material like cement and sand which is replace by normal plain concrete of the same w/c ratio and the same cement, the

the marble waste. There is an improvement in the density of the con- concrete having high limestone filler content of suitable particle size dis-

crete as well. By using the marble waste in concrete save the material tribution generally improves the strength characteristics.

and make low cost concrete.

METHODOLOGY

(4) Bricks Based on the Indian Standard (IS: 10262-1982), design mix for M30

In brick manufacturing works lime as a bonding material. Marble slurry grade of concrete was prepared by partially replacing fine aggregate

is chemically dolomitic in nature and consists of very fine particles. with five different percentages by weight of marble powder (0%, 5%,

Considering the phusico-chemical properties, it may be used as a fine 10%, 15%, and 20%). The mix proportion for M30 Grades of concrete

aggregate in manufacturing bricks by replace the lime as a binder. with varying percentage of marble powder is presented in Table 5.

(5) Manufacture of Ceramic Tiles TABLE 5

A possibility of utilizing marble slurry as a raw material for production CONCRETE MIX PROPORTION

of Ceramic Wall tiles needs to be evaluated on a pilot plant level. A lead- Mix Material by Weight

ing ceramic producer in the country has undertaken laboratory scale

M% C(kg) S (kg) W. M.(kg) C. A. (kg)

studies on this matter, which were reported to be highly successful.

0 423 527.0 0.0 1272

(6) Manufacture of Thermoset Resin Composites 5 423 500.6 26.3 1272

The Macromolecular Research Centre at Jabalpur has conducted a short 10 423 474.3 52.7 1272

M30 15 423 447.9 79.0 1272

term programme with a view to explore the possibility of converting

marble slurry into Resin Composites. The preliminary results have dem- 20 423 421.6 105.4 1272

onstrated the technical feasibility of such an option. However, a pilot M= Marble , C=Cement, S=Sand, W.M.=Waste Marble, C.A.= Coarse Ag-

plant level study needs to be conducted. gregate

(7) Manufacture of lime Source: Baboo Rai, Khan Naushad H, Abhishek Kr, Tabin Rushad S, Dug-

Limestone is the main raw material for the production of Lime. Lime- gal S.K Motilal ,“Influence of Marble powder/granules in Concrete mix” ,

stone can be replaced by marble waste. Nehru National Institute of Technology, Allahabad

(8) Manufacture of Activated Calcium Carbonate TABLE 6

Limestone or combination of marble waste and marble dust (from slur- MATERIAL’S RATE PER KG

ry) can be used on the production of activated or precipitated calcium Material Rate per kg in rupees

carbonate. Cement 6.4

Sand 0.55

(9) Hollow Blocks and Wall Tiles

Coarse aggregate 0.60

Marble slurry waste and other clay products can be used in the pro-

Marble waste 0.20

duction of Hollow prefabricated blocks for buildings if used in the right

proportion. Source: Baboo Rai, Khan Naushad H, Abhishek Kr, Tabin Rushad S, Dug-

gal S.K Motilal ,“Influence of Marble powder/granules in Concrete mix” ,

ADVANTAGE OF MARBLE WASTE Nehru National Institute of Technology, Allahabad

• Marble slurry is used for replacement of other material and saves

the material. TABLE 7

• Marble slurry used in concrete so Increase the strength in concrete. DIFFERENT MIX PROPORTION PRICE

• Marble slurry we get in nominal or free of cost. Marble Coarse

• Marble scrape is used to make attractive flooring in minimum cost. Marble % Cement Sand waste aggregate Total rate

• Use of the marble waste decrease the cost of construction because 0 2707.2 289.85 0 763.2 3760.25

replace the material by marble waste.

• In Fly ash brick if lime is replace by marble waste so increase the 5 2707.2 275.33 5.27 763.2 3751

strength of brick. 10 2707.2 260.86 10.54 763.2 3741.8

• Binding property of marble slurry is very good. 15 2707.2 246.35 15.81 763.2 3732.56

20 2707.2 231.88 21.08 763.2 3723.36

DISADVANTAGE OF MARBLE WASTE

• Marble slurry increases the soil alkalinity. Source: Baboo Rai, Khan Naushad H, Abhishek Kr, Tabin Rushad S, Dug-

• Marble slurry affects the plants. gal S.K Motilal ,“Influence of Marble powder/granules in Concrete mix” ,

• Marble powder affects the human body. Nehru National Institute of Technology, Allahabad

GRA - GLOBAL RESEARCH ANALYSIS X 95

Volume : 2 | Issue : 2 | Feb 2013 • ISSN No 2277 - 8160

COMPRESSIVE STRENGTH CONCLUSION

By increasing the waste marble powder the compressive strength val- The mean strength of all concrete mixes with marble powder was

ues of concrete tends to increase at each curing age. This trend can be 5-10% higher than the references concrete conforming to IS: 456 2000.

attributed to the fact that marble powder possesses cementing prop- Compressive strength of the concrete has increased with increasing

erties. It is also as much effective in enhancing cohesiveness due to percentages of marble dust additions. The rate of the 0% marble waste

lower fineness modulus of the marble powder. Furthermore, the mean 28 days strength is 38 N/mm2 at this strength of concrete rate is Rs.

strength of concrete mixes with marble powder was 5-10% higher than 3760.25. After adding the marble dust increases the strength. The high-

the reference concretes. However, there is a slight decrease in compres- est compressive strength has been demonstrated by 15% marble dust

sive strength value concrete mix when 20% marble powder is used as is 40.5 N/mm2 at this strength of concrete rate is Rs. 3732.56. By us-

compared with that of 15% marble powder mix. ing the marble dust the rate of the concrete is decrease and strength

is increase.

TABLE 8

COMPRESSIVE STRENGTH OF CONCRETE WITH VARYING

PERCENTAGE OF MARBLE WASTE

Compressive strength

% Marble 7 day 14 day 28 day

0 31 33 38

5 31.5 34 39

10 33 34.5 40

15 33 35 40.5

20 33.5 35.5 39

REFERENCES [1] A K Mishra, Renu mathur, Y V Rao, A P Singh and Pankaj Goel, “A new technology of marble slurry waste utilization in roads”

Journal of science & industrial research, vol 69, (2010). | [2] Bahar Demirel “The effect of the using waste marble dust as fine sand on

the mechanical properties of the concrete” International Journal of the Physical Sciences Vol. 5(9), pp. 1372-1380, 18 August, (2010).

| [3] Fakher J. Aukour “Incorporation of Marble Sludge in Industrial Building Eco-blocks or Cement Bricks Formulation” Jordan Journal of Civil Engineering, Volume

3, No. 1, (2009) | [4] Hanifi Binici, Hasan Kaplan and Salih Yilmaz, “Influence of marble and limestone dusts as additives on some mechanical properties of concrete”

Scientific Research and Essay Vol. 2 (9), pp. 372-379, (2007). | [5] H. Βinici, H kaplan. And S. Yilmaz ‘Influence of marble and limestone dusts as additives on some

mechanical properties of concrete’, Scientific Research and Essay, Vol.2 (9), 372-379, Full Length Research Paper (2007). | [6] Helena lima, “Application of marble

quarry waste in pavement layers” ICOR-Road construction institute, Portugal. | [7] Karasahin, M. and S. Terzi, “Evaluation of marble waste dust Mixture of asphaltic

concrete”. Construct. Build. Mater., 21: 616-620. (2007) | [8] Mamta B. Rajgor , Prof. Jayeshkumar Pitroda “A study of utilization aspect of stone waste in indian context.”

Global Research Analysis (2013) | [9] Mathur R, Misra A K & Goel P, “Marble slurry dust and wholastonite – nert mineral admixture for cement concrete”Indian highway

(2007) | [10] M. Belachia and H. Hebhoub, “Use of the Marble wastes in the Hydraulic Concrete” 6th International Advanced Technologies Symposium (IATS’11),

(2011). | [11] M. E. TAWFIK, S. B. ESKANDER, “Polymer Concrete from Marble Wastes and Recycled Poly(ethylene terephthalate)” Journal of Elastomers and Plastics

(2005). | [12] MSME-Development institute, “Status report on commercial utilization of marble slurry in Rajasthan.” | [13] Municipality of Hebron, “Marble and stone

waste management” Guidance document for collecting, disposing and reusing solid and liquid residuals from marble and stone extraction and cutting. (2007). | [14]

Rania Hamza, Salah El-Haggar, Safwan Khedr, “Utilization of Marble and Granite Waste in Concrete Bricks” International Conference on Environment and BioScience

IPCBEE vol.21 (2011). | [15] The University of Tennesse Center for Clean Products, “Solid waste management at the quarry and Fabrication facility” (2009). | [16]

Valeria Corinaldesi, Giacomo Moriconi, and Tarun R. Naik, “Characterization of marble powder for its use in mortar and concrete” For Presentation and Publication

at the CANMET/ACI Three-Day International Symposium on Sustainable Development of Cement and Concrete, October 5-7, (2005). | [17] Vijayalakshmi, V., Singh,

S., &Bhatnagar, D. “Developmental Efforts in R & D for Gainful Utilization of Marble Slurry in India”. Centre for Development of Stones. Retrieved January 3, (2010)

GRA - GLOBAL RESEARCH ANALYSIS X 96

You might also like

- BC-10 CatalogDocument2 pagesBC-10 CatalogDairo CarrilloNo ratings yet

- Construction and Building Materials: Valeria Corinaldesi, Giacomo Moriconi, Tarun R. NaikDocument5 pagesConstruction and Building Materials: Valeria Corinaldesi, Giacomo Moriconi, Tarun R. NaikShekharNo ratings yet

- Cement MortarDocument4 pagesCement MortarJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- ProjectDocument33 pagesProjectSuresh BabuNo ratings yet

- Eco Friendly ReportDocument21 pagesEco Friendly ReportSaranyaleoNo ratings yet

- Properties - of - Green - Concrete - Containing - Quarry - Roc (1) REFDocument8 pagesProperties - of - Green - Concrete - Containing - Quarry - Roc (1) REFPriyamvada BijuNo ratings yet

- Study On Fatigue and Rutting Response of FlexibleDocument5 pagesStudy On Fatigue and Rutting Response of FlexibleDeputy controller of examinationNo ratings yet

- Research Paper and ReportsDocument77 pagesResearch Paper and ReportsSHUBHAM NANCHENo ratings yet

- Marble Powder For Normal Concrete M20 PDFDocument12 pagesMarble Powder For Normal Concrete M20 PDFgururajNo ratings yet

- 13 Concrete Paving Block Using Marble Stone Industry WasteDocument7 pages13 Concrete Paving Block Using Marble Stone Industry WasteAravind kumarNo ratings yet

- Feasibility and Need of Use of Waste Marble Powder in Concrete ProductionDocument4 pagesFeasibility and Need of Use of Waste Marble Powder in Concrete ProductionAjithNo ratings yet

- A Review On Lime Stone & Fly Ash Based With M-25 Grade ConcreteDocument4 pagesA Review On Lime Stone & Fly Ash Based With M-25 Grade Concreteiaset123No ratings yet

- Utilization of Marble and Granite Wastes in Brick Products 145 150Document6 pagesUtilization of Marble and Granite Wastes in Brick Products 145 150Soundhar RajanNo ratings yet

- An Experimental Study On Strength Characteristics of Concrete With The Partial Replacement of Cement by Marble Dust and Sand by Stone DustDocument22 pagesAn Experimental Study On Strength Characteristics of Concrete With The Partial Replacement of Cement by Marble Dust and Sand by Stone DustTeslim SulaimanNo ratings yet

- Marble Waste Use in Concrete 111Document20 pagesMarble Waste Use in Concrete 111mohd waseemNo ratings yet

- With ReadingsDocument44 pagesWith ReadingsGaurav JethleNo ratings yet

- Stone Waste in India For Concrete With Value Creation OpportunitiesDocument8 pagesStone Waste in India For Concrete With Value Creation OpportunitieskalamjNo ratings yet

- Experimental Study of Partial Replacement of Cement in Concrete With Marble Dust and Recron Fibre As AdmixtureDocument9 pagesExperimental Study of Partial Replacement of Cement in Concrete With Marble Dust and Recron Fibre As AdmixtureEditor IJTSRDNo ratings yet

- Experimental Investigation On Utilization of Ceramic Tile Waste As A Partial Replacement of Fine Aggregate in Cement MortarDocument6 pagesExperimental Investigation On Utilization of Ceramic Tile Waste As A Partial Replacement of Fine Aggregate in Cement MortarInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Concrete Paving Block Using Marble Stone Industry Waste: January 2015Document7 pagesConcrete Paving Block Using Marble Stone Industry Waste: January 2015Awash BanjadeNo ratings yet

- Sustainable Design of Concrete Using IndDocument6 pagesSustainable Design of Concrete Using IndMILON KUMAR HORENo ratings yet

- Partial Replacement of Fine Aggregate With Marble Waste Powder in Cement Concrete.Document36 pagesPartial Replacement of Fine Aggregate With Marble Waste Powder in Cement Concrete.Harihara Priyadharshan100% (2)

- Seminor Edited 1Document22 pagesSeminor Edited 1Bharath BabuNo ratings yet

- Estimating The Strength of Concrete Cube Using Copper Slag in The Replacement of Fine AggregateDocument5 pagesEstimating The Strength of Concrete Cube Using Copper Slag in The Replacement of Fine Aggregateshivanand hippargaNo ratings yet

- Experimental Studies On M40 Grade Concrete Utilizing Red Mud As A Partial Replacement of CementDocument6 pagesExperimental Studies On M40 Grade Concrete Utilizing Red Mud As A Partial Replacement of Cementshivanand hippargaNo ratings yet

- 1 Iccsme-15th June-Nag-Ird14 - 035Document4 pages1 Iccsme-15th June-Nag-Ird14 - 035Pamela Joanne Falo AndradeNo ratings yet

- 2023 V14i260Document11 pages2023 V14i260D. AnweshNo ratings yet

- Case Studies in Construction Materials: Sudarshan D. Kore, A.K. VyasDocument8 pagesCase Studies in Construction Materials: Sudarshan D. Kore, A.K. VyasJoanne VillaNo ratings yet

- Irjet A Study On Compressive Strength ofDocument4 pagesIrjet A Study On Compressive Strength ofshivanand hippargaNo ratings yet

- Utilization of Sawdust in Concrete Masonry Blocks: A ReviewDocument8 pagesUtilization of Sawdust in Concrete Masonry Blocks: A ReviewHussain MarzooqNo ratings yet

- Sustainable Stone Masonary BlocksDocument6 pagesSustainable Stone Masonary BlocksGirish PushparajNo ratings yet

- Comparative Analysis of River SandDocument5 pagesComparative Analysis of River SandMatt T100% (1)

- Partial Replacement of River Sand With Quarry Rock DustDocument8 pagesPartial Replacement of River Sand With Quarry Rock DustDharma banothuNo ratings yet

- Marble Slurry UtilisationDocument5 pagesMarble Slurry UtilisationRamesh BabuNo ratings yet

- Sand Replaced by Stone Dust in ConcreteDocument9 pagesSand Replaced by Stone Dust in Concreteabhishek KumarNo ratings yet

- Experimental Investigation of Crumb Rubber Concrete Confined by FRP SheetsDocument5 pagesExperimental Investigation of Crumb Rubber Concrete Confined by FRP SheetsnancusharmaNo ratings yet

- With ReadingsDocument50 pagesWith ReadingsGaurav JethleNo ratings yet

- Assessing The Mechanical and Durability Performance of Concrete Made Using Recycled AggregateDocument7 pagesAssessing The Mechanical and Durability Performance of Concrete Made Using Recycled Aggregatenksbon028No ratings yet

- Study of Partial Replacement of Fine Aggregate by Using Quarry DustDocument8 pagesStudy of Partial Replacement of Fine Aggregate by Using Quarry DustramakrishnaNo ratings yet

- Durabilidade Do Concreto Feito Com Granito e Mármore Como Agregados de ReciclagemDocument10 pagesDurabilidade Do Concreto Feito Com Granito e Mármore Como Agregados de ReciclagemWendel MeloNo ratings yet

- Construction and Building Materials: Turhan Bilir, Osman Gencel, Ilker Bekir TopcuDocument8 pagesConstruction and Building Materials: Turhan Bilir, Osman Gencel, Ilker Bekir TopcukanomasiNo ratings yet

- 11845-Article Text-21011-1-10-20211229Document6 pages11845-Article Text-21011-1-10-20211229shailenderkarreNo ratings yet

- Experimental Study On Strength of Concrete by Partial Replacement of Fine Aggregate With Sawdust and Robo SandDocument6 pagesExperimental Study On Strength of Concrete by Partial Replacement of Fine Aggregate With Sawdust and Robo SandSabapathy Venkat KrishnanNo ratings yet

- Filler Replacement in Flexible PavementDocument4 pagesFiller Replacement in Flexible PavementDipendra AwasthiNo ratings yet

- IJETR032903Document4 pagesIJETR032903erpublicationNo ratings yet

- Use of M Sand As A Replacement ofDocument7 pagesUse of M Sand As A Replacement ofbasanth babuNo ratings yet

- Vardhan 2015Document7 pagesVardhan 2015axel sosa aguilarNo ratings yet

- I-Sand: Replacement of Natural SandDocument9 pagesI-Sand: Replacement of Natural SandVinay Kumar H SNo ratings yet

- Application of Waste Foundry Sand For Evolution of Low-Cost ConcreteDocument6 pagesApplication of Waste Foundry Sand For Evolution of Low-Cost ConcreteseventhsensegroupNo ratings yet

- Importance and Significance of The StudyDocument3 pagesImportance and Significance of The StudyCris OrtoneroNo ratings yet

- 543 373 1 PBDocument12 pages543 373 1 PBsuba vNo ratings yet

- Review On Use of Waste Marble Powder As Partial Replacement in Concrete MixDocument4 pagesReview On Use of Waste Marble Powder As Partial Replacement in Concrete MixYu Paing HanNo ratings yet

- Effect of Quarry Dust On High Performance ConcreteDocument5 pagesEffect of Quarry Dust On High Performance ConcreteMark EliasNo ratings yet

- Experimental Study On Concrete by Replacement of Fine Aggregate With Copper Slag, GGBS and M - SandDocument4 pagesExperimental Study On Concrete by Replacement of Fine Aggregate With Copper Slag, GGBS and M - SandInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Use of Gold Mill Tailings in Making Bricks: A Feasibility StudyDocument8 pagesUse of Gold Mill Tailings in Making Bricks: A Feasibility StudyArdian Kris BramantyoNo ratings yet

- An Experimental Investigation On Stabilized Mud MortarDocument9 pagesAn Experimental Investigation On Stabilized Mud MortarasyreenhaikalNo ratings yet

- 1 s2.0 S0950061813008453 MainDocument14 pages1 s2.0 S0950061813008453 MainAjithNo ratings yet

- Comparative Study On Fly Ash Bricks andDocument5 pagesComparative Study On Fly Ash Bricks andElleNo ratings yet

- Behavior of Concrete With Quarry Dust As Partial Replacement of Fine AggregateDocument8 pagesBehavior of Concrete With Quarry Dust As Partial Replacement of Fine AggregateSuman VarmaNo ratings yet

- Ijsrdv3i110384 PDFDocument5 pagesIjsrdv3i110384 PDFtonydisojaNo ratings yet

- Advance Package Estimate 19042024 Digvijay SinghDocument2 pagesAdvance Package Estimate 19042024 Digvijay Singhdigvijay singhNo ratings yet

- CHINIDocument3 pagesCHINIdigvijay singhNo ratings yet

- Uppsc 2023 - Paper 5 Model AnswersDocument27 pagesUppsc 2023 - Paper 5 Model Answersdigvijay singhNo ratings yet

- RA - Gabion BoxesDocument1 pageRA - Gabion Boxesdigvijay singhNo ratings yet

- Pankaj Petrol Pump EstimateDocument6 pagesPankaj Petrol Pump Estimatedigvijay singhNo ratings yet

- TS-Gabion - 10x12 - Galmac+PolimacDocument8 pagesTS-Gabion - 10x12 - Galmac+Polimacdigvijay singhNo ratings yet

- UPPCS 2024 Prelims PlanDocument7 pagesUPPCS 2024 Prelims Plandigvijay singhNo ratings yet

- Uppsc Pre Last 5 Year CutoffDocument1 pageUppsc Pre Last 5 Year Cutoffdigvijay singhNo ratings yet

- TAPERED OPTION - SALUMBER GATE - r1Document1 pageTAPERED OPTION - SALUMBER GATE - r1digvijay singhNo ratings yet

- Result - Mark Sheet For ExaminationDocument3 pagesResult - Mark Sheet For Examinationdigvijay singhNo ratings yet

- DRGDocument1 pageDRGdigvijay singhNo ratings yet

- Openwell Staircase 1 2 RotatedDocument6 pagesOpenwell Staircase 1 2 Rotateddigvijay singhNo ratings yet

- Economic Important Key TermsDocument4 pagesEconomic Important Key Termsdigvijay singhNo ratings yet

- Vas 227Document6 pagesVas 227digvijay singhNo ratings yet

- Fto Trasction DTLDocument215 pagesFto Trasction DTLdigvijay singhNo ratings yet

- Literature Review SummaryDocument3 pagesLiterature Review Summarydigvijay singhNo ratings yet

- She 126Document6 pagesShe 126digvijay singhNo ratings yet

- Form 3Document2 pagesForm 3digvijay singhNo ratings yet

- Nitttr 2017Document6 pagesNitttr 2017digvijay singhNo ratings yet

- 1412070509411stvarvind DevanganDocument6 pages1412070509411stvarvind Devangandigvijay singhNo ratings yet

- Development of High Strength High Performance Concrete Using Indian MetakaolinDocument10 pagesDevelopment of High Strength High Performance Concrete Using Indian Metakaolindigvijay singhNo ratings yet

- Cement IntrooductionDocument4 pagesCement Introoductiondigvijay singhNo ratings yet

- San 190Document6 pagesSan 190digvijay singhNo ratings yet

- Har 999Document6 pagesHar 999digvijay singhNo ratings yet

- PKG 888Document12 pagesPKG 888digvijay singhNo ratings yet

- 2015 - Experimental Study of ConcreteDocument4 pages2015 - Experimental Study of Concretedigvijay singhNo ratings yet

- VKS 148Document6 pagesVKS 148digvijay singhNo ratings yet

- 2011 - Recycled Aggregate Concrete Produced With Red Granite Dust As A Partial Cement ReplacementDocument7 pages2011 - Recycled Aggregate Concrete Produced With Red Granite Dust As A Partial Cement Replacementdigvijay singhNo ratings yet

- Vin 400Document6 pagesVin 400digvijay singhNo ratings yet

- Das 111Document8 pagesDas 111digvijay singhNo ratings yet

- Manual Blender 2.78 (1683 Páginas)Document2 pagesManual Blender 2.78 (1683 Páginas)Jose F CDNo ratings yet

- Managing Projects and Program BUS 5611 Written Assignment - 7Document6 pagesManaging Projects and Program BUS 5611 Written Assignment - 7Fahruddin ArrazyNo ratings yet

- Swire Helifuel Tanks US Spec SheetDocument2 pagesSwire Helifuel Tanks US Spec SheetBruno Moreira SilvaNo ratings yet

- Trimod Besta - Complete Catalogue (LTKEN1610)Document46 pagesTrimod Besta - Complete Catalogue (LTKEN1610)gustavoaponteunoNo ratings yet

- Osmobsc Vty ReferenceDocument272 pagesOsmobsc Vty Referencelong leeNo ratings yet

- 9 - CFG SimplificationDocument7 pages9 - CFG Simplificationعلي عبد الحمزه100% (1)

- Features Include: High Pressure Gear Pump (HGP)Document2 pagesFeatures Include: High Pressure Gear Pump (HGP)Nitin ShenoyNo ratings yet

- 41 Comp Lab LPoly J47Document23 pages41 Comp Lab LPoly J47Amel ElfirjaniNo ratings yet

- Effect of Water Injection On Reservoir Performance ofDocument18 pagesEffect of Water Injection On Reservoir Performance ofKacha SmitNo ratings yet

- Faculty of Management and Tecnology Harishchandra Post Graduate CollegeDocument16 pagesFaculty of Management and Tecnology Harishchandra Post Graduate Collegeaniket chauhanNo ratings yet

- Xiaomi MiA2 Jasmine Sprout 2021-03-27 23-28-07Document9 pagesXiaomi MiA2 Jasmine Sprout 2021-03-27 23-28-07Muhammad Arief RobiNo ratings yet

- Boiler Chimny Assesment ReportDocument4 pagesBoiler Chimny Assesment ReportArshad SadatNo ratings yet

- Final Date Sheet For Internal Class Test May 2023Document13 pagesFinal Date Sheet For Internal Class Test May 2023Manvi AroraNo ratings yet

- Interlock ChecklistDocument11 pagesInterlock ChecklistArmando Carranza LeónNo ratings yet

- Spreadsheet Modeling and Decision Analysis A Practical Introduction To Business Analytics 7th Edition Cliff Ragsdale Test Bank Full DownloadDocument41 pagesSpreadsheet Modeling and Decision Analysis A Practical Introduction To Business Analytics 7th Edition Cliff Ragsdale Test Bank Full Downloadmichaeljonesjecimdobxs100% (26)

- BESCOM - Part-VI - 33 KV MaterialDocument6 pagesBESCOM - Part-VI - 33 KV MaterialAbdul QayumNo ratings yet

- Tutorial 1: A Review of AC Circuit Analysis and Frequency Response AnalysisDocument5 pagesTutorial 1: A Review of AC Circuit Analysis and Frequency Response AnalysisSahil WalkeNo ratings yet

- Balmerol MP Grease No.3 BLGXDocument2 pagesBalmerol MP Grease No.3 BLGXamit1003_kumarNo ratings yet

- KV DH1L 5 - DatasheetDocument1 pageKV DH1L 5 - DatasheetWSR indiaNo ratings yet

- Malaysia Marine and Heavy EngineeringDocument10 pagesMalaysia Marine and Heavy EngineeringAzwaniAnuarNo ratings yet

- Tps 54312Document27 pagesTps 54312Dino NecciNo ratings yet

- App Form BayswaterDocument1 pageApp Form BayswaterPaulo LuizNo ratings yet

- Module Research PRELIMDocument38 pagesModule Research PRELIMjhon rey corderoNo ratings yet

- Manual de Partes QAS 200VdDocument118 pagesManual de Partes QAS 200VdLeandro ToledoNo ratings yet

- Power ToolsDocument5 pagesPower ToolsAhmed MoniemNo ratings yet

- Du 00216Document12 pagesDu 00216Hari Hara SuthanNo ratings yet

- DD - PlatformEPA10ddc SVC Man 0131Document236 pagesDD - PlatformEPA10ddc SVC Man 0131Cesar Bayes RamosNo ratings yet

- 15advanced JAVA For Beginners JSP, JSTL, JSON and SERVLET TUTORIALS... Etc (Learn With Examples)Document303 pages15advanced JAVA For Beginners JSP, JSTL, JSON and SERVLET TUTORIALS... Etc (Learn With Examples)ArunKumar AlagarsamyNo ratings yet