Professional Documents

Culture Documents

March-2020 CDR

March-2020 CDR

Uploaded by

Shivam SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

March-2020 CDR

March-2020 CDR

Uploaded by

Shivam SharmaCopyright:

Available Formats

Notification

Notification No. 34

Amendment No.9/IRC:112/December, 2019 (Effective from 1st March, 2020)

To

IRC:112-2011 “Code of Practice for Concrete Road Bridges”

S. No Clause No. For Read

Page No.

1. 12.4.1 (2) “In the absence……………......................

“In the absence of other criteria, the following deflection

(Page 131) .................……………………considered” limits for live load under frequent load combination may be

considered”

2. 13.4.1 Add subclause (4) (4) Special precautions are required in the case of joints

(Page 135 ) particularly in precast segmental construction. Leakages as well

as interconnections between ducts, should be avoided. Duct

spacing should be detailed in such a way that there is sufficient

concrete between parallel ducts to prevent interconnections

during grouting operations and to comply with relevant IRC

codes.

As a general rule, the joints of precast segmental construction

are treated with epoxy resin, if internal grouted tendons

are used. The epoxy resin seals the joint and prevents grout

leaking through and out of the segment joint. However there is

a possibility that epoxy may be squeezed into adjacent ducts,

when the segments are pressed together, causing blockages. To

prevent this, generally a compressible foam seal is provided in

the segment joint around the duct, and the excess is scraped out

with plastic or rubber scrapers before the epoxy sets. Also the

leak tightness of internal prestressing tendons can be improved

by the use of rubber rings around the ducts at the joints between

segments. Before casting of the segment, steel rings are placed

around the ducts, leaving an imprint of half the thickness of the

rubber rings. The rubber rings are placed in this recess, and are

compressed when the temporary prestressing is applied.

However, jointing with encapsulation is the preferable option and

system suppliers may be having their own method of doing so.

3. 13.4.2 (3) Add new sentence at the end For some types of M.S. sheathing ducts, refer Fig 13.1.

(Page 135)

4. 13.4.3 (3) Add new sentence at the end For some of the types of corrugated HDPE sheathing ducts,

(Page 135) refer Fig. 13.1.

5. 13.4.3 Add sub clause (4) (4) Minimum internal diameter of the HDPE duct shall not be

(new Sub less than 3 times the cross-sectional area of the tendon which

Clause) can be fitted in the anchorage system used. However, in case

(Page 135) of threading of tendons after concreting for spans larger than

30m, internal diameter of duct shall be 5mm larger than the

requirement stated above, in order to facilitate threading.

INDIAN HIGHWAYS MARCH 2020 47

Notification

S. No Clause No. For Read

Page No.

6. 13.4.2 Add Fig. 13.1 between the two clauses

&

13.4.3

(Page 135)

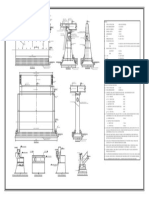

13.1 Typical Types of Sheathing Ducts

7. Fig. 13.1

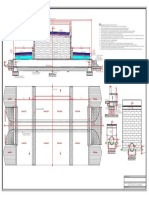

Fig. 13.1 Loaded Face of the End Block Fig. 13.2 Loaded Face of the End Block

(Page 137)

8. 13.5.1.1 (1) The bursting tensile force, Fbst existing in The bursting tensile force, Fbst existing in an individual square

Change in 2 an individual square end block loaded by a end block loaded by a symmetrically placed square anchorage

sentences, symmetrically placed square anchorage or or bearing plate, may be derived from Table 13.1 and Fig.

bearing plate, may be derived from Table 13.2

(Page 136)

13.1 and Fig. 13.1

This force, Fbst will be distributed in a region This force, Fbst will be distributed in a region extending from

extending from 0.2 Yo to 2 Yo from the 0.2 Yo to 2 Yo from the loaded face of the end block as shown

loaded face of the end block as shown in in Fig. 13.2

Fig. 13.1.

9. 15.3.1.1 (2) Add new sentence - In case of precast segmental construction, grouping of

cables is not permitted. The minimum clear distance

(Page 163 )

between the ducts shall be greater of 10 mm or the outer

diameter of the duct.

10. 18.8.2 Add new sub clause (5) Ready Mixed grout

(Page 215) Alternatively, the dry materials may be batched in a factory for

pre-mixed grout and mixed with the liquid materials on site as

per the instructions of the Manufacturers.

11. 18.8.4 sub (1) Water/Cement Ratio (1) Water/Cement Ratio

clause (1) Water/cement ratio should be as low as Water/cement ratio should be as low as possible, consistent

(Page 215) possible, consistent with workability. This with workability and should not exceed 0.40

ratio should not exceed 0.45

12. 18.8.4 sub (4) Compressive Strength (4) Compressive Strength

clause (4) The compressive strength of 100 mm cube The compressive strength of 100 mm cube of the grout shall

(Page 216) of the grout shall not be less than 17 MPa not be less than 27 MPa at 7 days or 30 MPa at 28 days. Cubes

at 7 days. Cubes shall be cured in a moist shall be cured in a moist atmosphere for the first 24 hours

atmosphere for the first 24 hours and and subsequently in water. These tests shall be conducted in

subsequently in water. These tests shall advance to ascertain the suitability of the grout mix. The 7 day

be conducted in advance to ascertain the strength is not mandatory if the 28 day strength requirement

suitability of the grout mix. is met.

48 INDIAN HIGHWAYS MARCH 2020

Notification

S. No Clause No. For Read

Page No.

13. 18.8.4 sub (7) Volume Change (7) Volume change

clause (7) The volume change of grout kept at rest for Volume change of the grout at rest for 24 h shall be within the

(Page 216) 24 hours and tested as per ASTM C1090 range of - 1 % and + 5 % of the original volume when tested

shall be within the range of 0.5 percent and as per EN 445. It should not be more than +0.2 percent at 28

5.0 percent of the original volume. It should days.

not be more than +0.2 percent at 28 days.

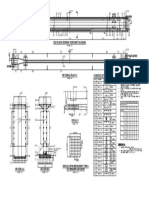

14. 18.8.4 sub (8) Fluidity (8) Fluidity

clause (8) Fluidity is tested as per ASTM C939 standard Fluidity is tested as per EN 445 by a) cone test and b) grout

spread test. The time for cone test (Fig 18.2a) shall be less

(Page 216) using standard flow cone.

than or equal to 25 seconds. The spread of the grout as per

grout spread test (Fig 18.2b) shall be greater than or equal to

140mm.

For retention of fluidity there shall not be more than 20%

reduction in fluidity at 30 minutes when tested as per EN 445.

Fig 18.2 (a) – Cone for fluidity test (as per EN 445)

1 - Cylinder (steel or plastic tube)

2 - Smooth plate

Fig 18.2 (b) – Grout spread test (as per EN 445)

INDIAN HIGHWAYS MARCH 2020 49

Notification

S. No Clause No. For Read

Page No.

15. 18.8.4 sub Add new sub clause (9) (9) Tests for Bleed and Volume Stability

clause (9) Wick Induced Bleed and volume change test shall be as per EN

(Page 216) 445. The details of the test are given in Figure 18.2 (c)

1. Seal 4. Grout ho - height at to

2. Air 5. Transparent tube ho - height at tn

3. Water 6. Strand, wires or bar

Fig 18.2 (c) – Wick induced test setup (as per EN 445)

Alternatively, the inclined tube bleed test can be done to

determine the bleed properties and volume stability of grout.

The details of the test are shown in figure 18.2(d).

1- Vent and stop valve 4- Transparent tube

2-Air 5-12 Strand

3-Water 6- Injection of grout

Fig 18.2 (d) – Inclined tube test set up (as per EN 445)

16. 18.8.5 Add New clause after 18.8.4 18.8.5 Grouting Procedure

The grouting procedure shall be as per EN 446. Guidelines for

(Page 216)

grouting are given below:

a) Ducts should be grouted at a continuous and steady

rate of 6 to12 m / minute for horizontal and 2 to 3 m

/ minute for vertical ducts. For parabolic ducts the

grouting rate should be 6 to 8m / minute.

b) Grouting pressure should not exceed 2 MPa.

c) Grouting should continue until the fluidity or density

of grout flowing from free ends and vent openings is

same as that of original grout.

After closing all the vents, retained pressure should be same

as adopted for grouting subject to a minimum of 0.5 MPa.

50 INDIAN HIGHWAYS MARCH 2020

You might also like

- Capital Investment Analysis For Engineering and ManagementDocument316 pagesCapital Investment Analysis For Engineering and ManagementCFA100% (2)

- TMS 402 - Chapter 6 PDFDocument22 pagesTMS 402 - Chapter 6 PDFAlina Shrestha100% (1)

- How To Calculate Anchorage and Lap Lengths To Eurocode 2Document9 pagesHow To Calculate Anchorage and Lap Lengths To Eurocode 2selinaNo ratings yet

- Concrete Design Guide No5 - How To Calculate Anchorage and Lap Lengths To Eurocode 2Document8 pagesConcrete Design Guide No5 - How To Calculate Anchorage and Lap Lengths To Eurocode 2Gurvir BahraNo ratings yet

- Post-Tensioned Slab On GroundDocument3 pagesPost-Tensioned Slab On GroundstkhedakarNo ratings yet

- Anchoring Into Housekeeping Pads: ConcreteDocument2 pagesAnchoring Into Housekeeping Pads: ConcreteFredie UnabiaNo ratings yet

- Addendum IRC 112Document8 pagesAddendum IRC 112suphal.ghoshNo ratings yet

- 123 - Concrete CoverDocument2 pages123 - Concrete CoverrealchicNo ratings yet

- Effect of Self Compacting Concrete and Aggregate Size On Anchorage Performance at Highly Congested Reinforcement RegionsDocument9 pagesEffect of Self Compacting Concrete and Aggregate Size On Anchorage Performance at Highly Congested Reinforcement Regionsumair baigNo ratings yet

- Serviceability Limit StateDocument12 pagesServiceability Limit StateMohamad Salleh YassinNo ratings yet

- Eb9 PDFDocument7 pagesEb9 PDFAndyPalmerNo ratings yet

- 2006 Beam Column Joint ICJDocument9 pages2006 Beam Column Joint ICJvishalgoreNo ratings yet

- 2006 Beam Column Joint ICJ PDFDocument9 pages2006 Beam Column Joint ICJ PDFSanjeev MishraNo ratings yet

- Eurocode: 1.0 Column DesignDocument5 pagesEurocode: 1.0 Column DesignsopnanairNo ratings yet

- AnchorsDocument8 pagesAnchors2Suraj2100% (2)

- Latest Amendments in IRC Codes 2Document24 pagesLatest Amendments in IRC Codes 2Pravin GundeliNo ratings yet

- Strengthening Powerpoint PDFDocument109 pagesStrengthening Powerpoint PDFAndrew PetryszakNo ratings yet

- Heating Pipes in Composite Floors - Effects On Slab Beam DesignDocument2 pagesHeating Pipes in Composite Floors - Effects On Slab Beam DesignJianhua WuNo ratings yet

- BehaviorofGroutedAnchors NSandCook Apr2004 PDFDocument9 pagesBehaviorofGroutedAnchors NSandCook Apr2004 PDFAmol GoleNo ratings yet

- TS-Gabion and Geotextile 24082011-R1Document10 pagesTS-Gabion and Geotextile 24082011-R1gopal10120No ratings yet

- CoP SUC2013e (Concrete) 7.2Document1 pageCoP SUC2013e (Concrete) 7.2P CNo ratings yet

- Modelling of The Mechanical Interaction Between Anchored Wire Meshes and Granular SoilsDocument17 pagesModelling of The Mechanical Interaction Between Anchored Wire Meshes and Granular SoilsRodrigo MorgadoNo ratings yet

- Flexural Behaviour of RC Beams in Fibre Reinforced ConcreteDocument8 pagesFlexural Behaviour of RC Beams in Fibre Reinforced ConcretejayanthNo ratings yet

- Plate Girder Behaviour and Design I: ObjectiveDocument48 pagesPlate Girder Behaviour and Design I: ObjectiveSachin MNo ratings yet

- Pages From Knapton, John - Single Pour Industrial Floor Slabs - Specification, Design, Construction and Behaviour-Thomas Telford Publishing (1999)Document7 pagesPages From Knapton, John - Single Pour Industrial Floor Slabs - Specification, Design, Construction and Behaviour-Thomas Telford Publishing (1999)Bunkun15No ratings yet

- The Practice of Warping Double TeesDocument17 pagesThe Practice of Warping Double Teesunix0123No ratings yet

- Plate Girder Behaviour and DesignDocument48 pagesPlate Girder Behaviour and DesignayingbaNo ratings yet

- Federal Highway Administration Post-Tensioning Tendon Installation and Grouting ManualDocument95 pagesFederal Highway Administration Post-Tensioning Tendon Installation and Grouting ManualThập NguyễnNo ratings yet

- Figure 10-10 Pipe Cast in ConcreteDocument1 pageFigure 10-10 Pipe Cast in Concretenorman moralesNo ratings yet

- Design of An Industrial Shed Using Prestressed ConcreteDocument8 pagesDesign of An Industrial Shed Using Prestressed ConcreteSasi HoneyNo ratings yet

- GN-Guideline-98 - Wall Bracing Tie-DownDocument1 pageGN-Guideline-98 - Wall Bracing Tie-Downsparta_avatarNo ratings yet

- Guidance Note Shear Connectors No. 2.11: ScopeDocument4 pagesGuidance Note Shear Connectors No. 2.11: ScopeDesigns3 ShreeprefabNo ratings yet

- 4 Lecture 4 - Durability 2020 PDFDocument18 pages4 Lecture 4 - Durability 2020 PDFMohamad Salleh YassinNo ratings yet

- Prestressed Concrete Design Prestressed Concrete Design: CBDG Design Guide CBDG Design GuideDocument6 pagesPrestressed Concrete Design Prestressed Concrete Design: CBDG Design Guide CBDG Design GuideKeith GarridoNo ratings yet

- Railway Bridge Design Assessment - Design of Plate Girders-1Document79 pagesRailway Bridge Design Assessment - Design of Plate Girders-1Mohamed ShabibNo ratings yet

- EM 1110-2-2002 ch6Document23 pagesEM 1110-2-2002 ch6shaik saifulla lNo ratings yet

- Repair of Joint SpallingDocument2 pagesRepair of Joint SpallingHuaman Chavez Jesus AngelNo ratings yet

- Attachment of Brick Veneer in High-Wind Regions: Purpose: Key IssuesDocument3 pagesAttachment of Brick Veneer in High-Wind Regions: Purpose: Key IssuesSugarPOP666100% (1)

- Shear Check As Per CodesDocument10 pagesShear Check As Per Codesabdul samadNo ratings yet

- Area of Reinforcement For Slabs & FootingDocument1 pageArea of Reinforcement For Slabs & Footingloft diamondNo ratings yet

- Finite Element Modelling of Composite Castellated Beam: Richard FransDocument9 pagesFinite Element Modelling of Composite Castellated Beam: Richard FransAdnan NajemNo ratings yet

- 3Document6 pages3k2org.seoNo ratings yet

- Plate GirderDocument74 pagesPlate Girderarif_rubin100% (1)

- How To Calculate Anchorage and Lap Lengths To Eurocode 2Document8 pagesHow To Calculate Anchorage and Lap Lengths To Eurocode 2DavidNo ratings yet

- Bridge Plating PDFDocument4 pagesBridge Plating PDFKae 王珊婷 Wang100% (1)

- Grouting ManualDocument36 pagesGrouting ManualJorgeaul100% (1)

- Za Sans 10021 2012Document109 pagesZa Sans 10021 2012Forbes KambaNo ratings yet

- 800-4 ExtractDocument17 pages800-4 Extractsai vivekNo ratings yet

- Removable Temporary Ground Anchor BookletDocument12 pagesRemovable Temporary Ground Anchor BookletRajesh KyasanipalleyNo ratings yet

- Specifications PDFDocument30 pagesSpecifications PDFRivaiNo ratings yet

- Serviceability of Beams and One Way SlabsDocument20 pagesServiceability of Beams and One Way Slabsjust meNo ratings yet

- ASTM D4071-84 Reapproved 2016Document3 pagesASTM D4071-84 Reapproved 2016anant11235No ratings yet

- 1 s2.0 S1359835X20304747 MainDocument16 pages1 s2.0 S1359835X20304747 Maindjarir yahiaouiNo ratings yet

- Two Stage Method ConcreteDocument5 pagesTwo Stage Method ConcreteReynhard WijayaNo ratings yet

- Drop-Off Laminate CalculationDocument12 pagesDrop-Off Laminate CalculationalfborbrNo ratings yet

- Important Questions PDFDocument20 pagesImportant Questions PDFresha bhatiaNo ratings yet

- CE2404 QB PDFDocument20 pagesCE2404 QB PDFresha bhatiaNo ratings yet

- Section 2. Metallic Sandwich Secondary Structure RepairsDocument5 pagesSection 2. Metallic Sandwich Secondary Structure RepairsrobinyNo ratings yet

- Fundamentals of PrestressingDocument7 pagesFundamentals of Prestressingsankar_rao333No ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Amendments 2017 (IRC-6, 22,83 'Spherical and Cylindrical Bearing' &112)Document24 pagesAmendments 2017 (IRC-6, 22,83 'Spherical and Cylindrical Bearing' &112)Shivam SharmaNo ratings yet

- July-2020 CDRDocument3 pagesJuly-2020 CDRShivam SharmaNo ratings yet

- Gad (PCC Sub Structure) 3X10.0Document1 pageGad (PCC Sub Structure) 3X10.0Shivam SharmaNo ratings yet

- May - 2021.cdrDocument24 pagesMay - 2021.cdrShivam SharmaNo ratings yet

- UntitledDocument1 pageUntitledShivam SharmaNo ratings yet

- Toilet Plan MorthDocument1 pageToilet Plan MorthShivam SharmaNo ratings yet

- Pedestrain Guard RailDocument1 pagePedestrain Guard RailShivam SharmaNo ratings yet

- No. G47A2: Scale 1:50,000Document1 pageNo. G47A2: Scale 1:50,000Shivam SharmaNo ratings yet

- No. G47A1: Scale 1:50,000Document1 pageNo. G47A1: Scale 1:50,000Shivam SharmaNo ratings yet

- No. G47A5: Scale 1:50,000Document1 pageNo. G47A5: Scale 1:50,000Shivam SharmaNo ratings yet

- Detail of RCC SlabDocument1 pageDetail of RCC SlabShivam SharmaNo ratings yet

- Reinforcement Detail of SlabDocument1 pageReinforcement Detail of SlabShivam SharmaNo ratings yet

- Detail of Abutment and PierDocument1 pageDetail of Abutment and PierShivam SharmaNo ratings yet

- HPC VupDocument1 pageHPC VupShivam SharmaNo ratings yet

- HPC at VUP TransitionDocument1 pageHPC at VUP TransitionShivam SharmaNo ratings yet

- Deletion of Provision For IMS - DT 27-01-22Document2 pagesDeletion of Provision For IMS - DT 27-01-22Shivam SharmaNo ratings yet

- 2 Row HPC For BC SoilDocument1 page2 Row HPC For BC SoilShivam SharmaNo ratings yet

- 1X12X5.5 Vup PDFDocument55 pages1X12X5.5 Vup PDFShivam SharmaNo ratings yet

- Lower GodavariDocument10 pagesLower GodavariShivam SharmaNo ratings yet

- Schedule of Reinforcent: Section C-C Section D-DDocument1 pageSchedule of Reinforcent: Section C-C Section D-DShivam SharmaNo ratings yet

- Introduction To Mellin Transforms Part - 01Document5 pagesIntroduction To Mellin Transforms Part - 01Shivam SharmaNo ratings yet

- Compendium On National Highway, CRF EtcDocument427 pagesCompendium On National Highway, CRF EtcShivam SharmaNo ratings yet

- Design of Straight Retaining Wall For Height 5.5m FROM G.L & NBC 100 KN/SQMDocument24 pagesDesign of Straight Retaining Wall For Height 5.5m FROM G.L & NBC 100 KN/SQMShivam SharmaNo ratings yet

- Reinforcement Details of End DiaphragmDocument1 pageReinforcement Details of End DiaphragmShivam SharmaNo ratings yet

- Elevation Showing Side Reinf. in Girder: NotesDocument1 pageElevation Showing Side Reinf. in Girder: NotesShivam SharmaNo ratings yet

- (Near Mid Span) (Near Support) X-Section of Precast RCC Girder Detail-1Document1 page(Near Mid Span) (Near Support) X-Section of Precast RCC Girder Detail-1Shivam SharmaNo ratings yet

- Plan (Showing RCC Pedestal and Elastomeric BearingDocument1 pagePlan (Showing RCC Pedestal and Elastomeric BearingShivam SharmaNo ratings yet

- Effect of Earthquake in BuildingDocument20 pagesEffect of Earthquake in BuildingShivam SharmaNo ratings yet

- Introduction To Hankel Transforms Part 1Document6 pagesIntroduction To Hankel Transforms Part 1Shivam SharmaNo ratings yet

- Calculus of VariationDocument21 pagesCalculus of VariationShivam SharmaNo ratings yet

- Effect of Public ExpenditureDocument5 pagesEffect of Public ExpenditureSantosh ChhetriNo ratings yet

- Patterns of Mobility Among Ancient Near Eastern CraftsmenDocument20 pagesPatterns of Mobility Among Ancient Near Eastern CraftsmenBelial Von HohenheimNo ratings yet

- HWAC2 - Final PeriodDocument5 pagesHWAC2 - Final PeriodhussainNo ratings yet

- Perjanjian Kontrak Kerja FreelineDocument1 pagePerjanjian Kontrak Kerja Freelineaji sadewaNo ratings yet

- Pallet RacksDocument16 pagesPallet RacksJagadeesan ManogaranNo ratings yet

- AR Customer Ledger: Mukhtar A Sheikh HospitalDocument2 pagesAR Customer Ledger: Mukhtar A Sheikh HospitalMuhammad AyubNo ratings yet

- International Political Economy (Ipe)Document52 pagesInternational Political Economy (Ipe)Fiseha GetachewNo ratings yet

- Activity Based CostingDocument4 pagesActivity Based CostingMaria Via Cristian MauricioNo ratings yet

- 2021-09-10040912pm2021-Bethanie Clinic Stormwater Drain - Glencore - Tender Boq Section 1Document4 pages2021-09-10040912pm2021-Bethanie Clinic Stormwater Drain - Glencore - Tender Boq Section 1ALLANNo ratings yet

- Trade Creation and Trade Diversion - Economics OnlineDocument5 pagesTrade Creation and Trade Diversion - Economics OnlineNguyễn Huyền TrangNo ratings yet

- Morocco Economic MonitorDocument44 pagesMorocco Economic MonitorReddahi BrahimNo ratings yet

- Fogg AnalysisDocument2 pagesFogg AnalysisShoutik Chakrabarti100% (1)

- Presentation 270823Document26 pagesPresentation 270823samarth080569No ratings yet

- Grp-3 Case Study 5 Ghan and CIVDocument4 pagesGrp-3 Case Study 5 Ghan and CIVRoisu De KuriNo ratings yet

- GEC 8 The Contemporary WorldDocument68 pagesGEC 8 The Contemporary WorldMay MedranoNo ratings yet

- Class 11 Economics Sample Paper With Solutions Set 1 2020 2021Document19 pagesClass 11 Economics Sample Paper With Solutions Set 1 2020 2021Zeeshan AkhtarNo ratings yet

- UMA Synthetic Token Builder FAQDocument4 pagesUMA Synthetic Token Builder FAQNibir PalNo ratings yet

- Tech TipsDocument5 pagesTech TipsAngel CastNo ratings yet

- Mac Q4Document5 pagesMac Q4Sameer AgrawalNo ratings yet

- Chapter 2 ValuationDocument4 pagesChapter 2 ValuationArielle CabritoNo ratings yet

- The Critique of Traditional Free Trade Theory in The Context of Developing Country ExperienceDocument5 pagesThe Critique of Traditional Free Trade Theory in The Context of Developing Country ExperienceNay Win Aung100% (1)

- MMW ReviewerDocument38 pagesMMW ReviewerMichyll KyutNo ratings yet

- Special Power of Attorney Citi Fire NewDocument2 pagesSpecial Power of Attorney Citi Fire NewRobert marollanoNo ratings yet

- Practice Set 5 With Answers 2022Document5 pagesPractice Set 5 With Answers 2022Romit BanerjeeNo ratings yet

- Vicinity Vacation RentalsDocument4 pagesVicinity Vacation RentalsHendry teikNo ratings yet

- Jawaban Inter 1 Modul 9Document4 pagesJawaban Inter 1 Modul 9Sebastian T.MNo ratings yet

- Please Fill in The Yellow Cells Based On Your Analysis: InstructionsDocument4 pagesPlease Fill in The Yellow Cells Based On Your Analysis: InstructionskhaledNo ratings yet

- Bài kiểm tra tự luận Lợi nhuận mỗi cổ phiếu - Xem lại bài làmDocument8 pagesBài kiểm tra tự luận Lợi nhuận mỗi cổ phiếu - Xem lại bài làmAh TuanNo ratings yet

- International Accounting: A User PerspectiveDocument38 pagesInternational Accounting: A User PerspectiveMarietzaNo ratings yet