Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

16 viewsWPS

WPS

Uploaded by

Bidang Dalkon QAQCCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 22420-00-M-86-CM-000 - P&id HSD Fuel SystemDocument1 page22420-00-M-86-CM-000 - P&id HSD Fuel SystemBidang Dalkon QAQCNo ratings yet

- 22420-00-M-118-CM-000 - Drawing - Air Pressure Tank - R2Document3 pages22420-00-M-118-CM-000 - Drawing - Air Pressure Tank - R2Bidang Dalkon QAQCNo ratings yet

- Perhitungan PengecatanDocument12 pagesPerhitungan PengecatanBidang Dalkon QAQCNo ratings yet

- Welding Procedure Document's PackageDocument22 pagesWelding Procedure Document's PackageBidang Dalkon QAQCNo ratings yet

- Summary Penetrant Test Daff TankDocument5 pagesSummary Penetrant Test Daff TankBidang Dalkon QAQCNo ratings yet

- Piping of Fire Pump System - Addendum-3Document1 pagePiping of Fire Pump System - Addendum-3Bidang Dalkon QAQCNo ratings yet

- Bab 4 SPV BoilerDocument73 pagesBab 4 SPV BoilerBidang Dalkon QAQCNo ratings yet

- Soak Testing ReportDocument3 pagesSoak Testing ReportBidang Dalkon QAQCNo ratings yet

- Welding ConsumableDocument7 pagesWelding ConsumableBidang Dalkon QAQCNo ratings yet

- Painting Procedure - ApprovedDocument8 pagesPainting Procedure - ApprovedBidang Dalkon QAQCNo ratings yet

- WPQTRDocument6 pagesWPQTRBidang Dalkon QAQCNo ratings yet

- Fabrication Procedure - ApprovedDocument12 pagesFabrication Procedure - ApprovedBidang Dalkon QAQCNo ratings yet

- Weld Repair ProcedureDocument13 pagesWeld Repair ProcedureBidang Dalkon QAQC100% (1)

- Weld Repair ProcedureDocument13 pagesWeld Repair ProcedureBidang Dalkon QAQCNo ratings yet

- 001 WPS Asme Gbi 2022Document22 pages001 WPS Asme Gbi 2022Bidang Dalkon QAQCNo ratings yet

- (For - Reference) - Specification & Outline Procedure For Blast Cleaning of Rotors and DiaphragmsDocument11 pages(For - Reference) - Specification & Outline Procedure For Blast Cleaning of Rotors and DiaphragmsBidang Dalkon QAQCNo ratings yet

- 1 Daily Report PaintingDocument16 pages1 Daily Report PaintingBidang Dalkon QAQCNo ratings yet

WPS

WPS

Uploaded by

Bidang Dalkon QAQC0 ratings0% found this document useful (0 votes)

16 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

16 views2 pagesWPS

WPS

Uploaded by

Bidang Dalkon QAQCCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

Indobara @ Bahana

generations @to come

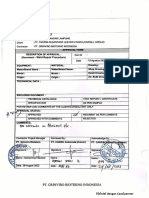

WELDING PROCEDURE SPECIFICATION (WPS)

(See QW-200.1, Section IX, ASME Boller and Pressue Vessel Code 2013 Edition)

Company Name

Welding Procedure Specification Ne ‘O01 WPSIASMENBI2015

Supporting POR No. (8) ‘001/PQR/ASMENB/2015

Revision No, 9

Welding Process(ee)

JOINT (QW-402)

‘aint Design SINGLE "V' GROOVE

Root Spacing: 20-35 mm

Backing Yes = No

Backing Maal ype) NA

FETT TT

1 wetat 1D Nontsing meta :

Ny

1 Nonmetst — (F} otter

‘Sketches, Producten Drawings, Well Symbols, or Writer Deserpen shoud how

‘he gonerl arrangement ote pars tobe weldes. Ware apical, te Gal of wed =H

FN 20+19 0m

goove may be specie

[atthe ceten ofthe manutacurers, setehes may be atached ott ink dba,

‘wot afore, and bead eoqunee (eg, for noch iaughness precedes, fo multiple process

rooeaures ot

“BASE METALS (QW-403)

Po, 4 ‘Group No 1 Pio, 1 Group No, 4

oR

+ Spectcation and typelgrade or UNS Number AISA 53 Gr. B or Equivalent

to specification and typefgrade or UNS Number ‘AISA 53 Gr. B or Equivalent

‘OR

(Chem, Anaiyeis and Mech. Prop. NIA,

to-Chem. Analysis and Mech. Prop NA.

‘Thickness Range

Base Metal Groove : 15.

Maximum Pass Thickness «sin. (13 mi)

SMA

75.10,

E7018

4

1

Size of Filler Metals 32-40 mm

Filler Metals Product Form ESAB or Equivalent

Supplemental Filer Mota

Weld Wetat

Thickeness Range

‘Groove

Fitet

Electrode Flux (Class)

Foc Type

Flux Trade Name

Consumable Inset

Nendo Ste tee Wotan anh esrb

Scoomsinne — KGrwrgieteg ‘Rimactoetes Etmuangroess Saar

hori eorese weorese Teasewqactzstinconee Sabon fabortinie

ipsse.200m%8 —uprsee apse02 apna 27007 ‘pcos

Fi ifoudseaucad Ema hltinobancokt Ema odsenban.aid Cru fayendobarcalt mal atop

www.indobara.co.id

Indobara (@ Bahana © 2) =

WELDING PROCEDURE SPECIFICATION (wPs)

(See QW-200.1, Section Ix, ASME Boller and Pressue Vessel Code 2013 Edition)

WPS No._: OO‘ WPSIASMENB/2015 Rev: 0

POSTWELD HEAT TREATMENT (QW-407)

POSITION (aW-405)

Postion (s)of Groove All Position Temperature Range NIA

Welding Progression: Up __¥_Down Time Range NA,

Poston (s)of Filet. All other

Other :

PREHEAT (GW-406)

reheat Temperature, Minimum

{nterpass Temperature, Maximum

‘GAS (QW-408)

recent Composition

Gasfes) (Mature) Flow Rate

Preheat Maintenance ‘Shistcing : :

other ‘rating enn era

(Contras or sped ating, wher apa, sou be eco) Backing

Other

ApS endosperm ge a BOTS RE wD tate Se, PA TI WI

using Current Heat input (max)

Tungsten Electrode Size and Type

Mode of Metal Transfer for GMAW (FCAW)

4.87 Kiln

or Weave,

Orifice, Nozze, or Gas Cup Size NA.

Initial and iterpass Clearing (Brushing, Grinding, ete.) Brushing and Grinding

‘Methods of Back Gouging NA

seiaton NA.

‘Contact Tube to Work Distance NA.

‘Multiple or Single Pass (Per Side) Multiple and Single Pass

Mutiple or Single Electrode ‘Single

NA

Head fen Sates ethan eanchofiSacteys rane aoe

NGremtanye —-Rerurgiewaing tebtetangs — Eecpectik_knaem buen eentotorn

Erab'ehotaktiencon! Eewilihietancosl Ena nawnendebacd Casi ineabaindcmral Eralhopsiaacsd

www.indobara.co.ld

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 22420-00-M-86-CM-000 - P&id HSD Fuel SystemDocument1 page22420-00-M-86-CM-000 - P&id HSD Fuel SystemBidang Dalkon QAQCNo ratings yet

- 22420-00-M-118-CM-000 - Drawing - Air Pressure Tank - R2Document3 pages22420-00-M-118-CM-000 - Drawing - Air Pressure Tank - R2Bidang Dalkon QAQCNo ratings yet

- Perhitungan PengecatanDocument12 pagesPerhitungan PengecatanBidang Dalkon QAQCNo ratings yet

- Welding Procedure Document's PackageDocument22 pagesWelding Procedure Document's PackageBidang Dalkon QAQCNo ratings yet

- Summary Penetrant Test Daff TankDocument5 pagesSummary Penetrant Test Daff TankBidang Dalkon QAQCNo ratings yet

- Piping of Fire Pump System - Addendum-3Document1 pagePiping of Fire Pump System - Addendum-3Bidang Dalkon QAQCNo ratings yet

- Bab 4 SPV BoilerDocument73 pagesBab 4 SPV BoilerBidang Dalkon QAQCNo ratings yet

- Soak Testing ReportDocument3 pagesSoak Testing ReportBidang Dalkon QAQCNo ratings yet

- Welding ConsumableDocument7 pagesWelding ConsumableBidang Dalkon QAQCNo ratings yet

- Painting Procedure - ApprovedDocument8 pagesPainting Procedure - ApprovedBidang Dalkon QAQCNo ratings yet

- WPQTRDocument6 pagesWPQTRBidang Dalkon QAQCNo ratings yet

- Fabrication Procedure - ApprovedDocument12 pagesFabrication Procedure - ApprovedBidang Dalkon QAQCNo ratings yet

- Weld Repair ProcedureDocument13 pagesWeld Repair ProcedureBidang Dalkon QAQC100% (1)

- Weld Repair ProcedureDocument13 pagesWeld Repair ProcedureBidang Dalkon QAQCNo ratings yet

- 001 WPS Asme Gbi 2022Document22 pages001 WPS Asme Gbi 2022Bidang Dalkon QAQCNo ratings yet

- (For - Reference) - Specification & Outline Procedure For Blast Cleaning of Rotors and DiaphragmsDocument11 pages(For - Reference) - Specification & Outline Procedure For Blast Cleaning of Rotors and DiaphragmsBidang Dalkon QAQCNo ratings yet

- 1 Daily Report PaintingDocument16 pages1 Daily Report PaintingBidang Dalkon QAQCNo ratings yet