Professional Documents

Culture Documents

Torque de Brocas

Torque de Brocas

Uploaded by

kmf service0 ratings0% found this document useful (0 votes)

11 views2 pagesThis document provides recommendations for drill bit specifications including:

1) Minimum make-up torque values for various API connection sizes ranging from 2-3/8" to 8-5/8".

2) API tolerances for fixed cutter drill bit outer diameters between -0.015 to +0.00 inches for bits 6-3/4" and smaller up to -0.063 to +0.00 inches for bits 17-17/32" and larger.

3) A chart showing total flow area in square inches for drill bits ranging in size from 7" to 11" with up to 8 nozzles.

Original Description:

perforacion

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides recommendations for drill bit specifications including:

1) Minimum make-up torque values for various API connection sizes ranging from 2-3/8" to 8-5/8".

2) API tolerances for fixed cutter drill bit outer diameters between -0.015 to +0.00 inches for bits 6-3/4" and smaller up to -0.063 to +0.00 inches for bits 17-17/32" and larger.

3) A chart showing total flow area in square inches for drill bits ranging in size from 7" to 11" with up to 8 nozzles.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

11 views2 pagesTorque de Brocas

Torque de Brocas

Uploaded by

kmf serviceThis document provides recommendations for drill bit specifications including:

1) Minimum make-up torque values for various API connection sizes ranging from 2-3/8" to 8-5/8".

2) API tolerances for fixed cutter drill bit outer diameters between -0.015 to +0.00 inches for bits 6-3/4" and smaller up to -0.063 to +0.00 inches for bits 17-17/32" and larger.

3) A chart showing total flow area in square inches for drill bits ranging in size from 7" to 11" with up to 8 nozzles.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Drill Bits

Fixed Cutter

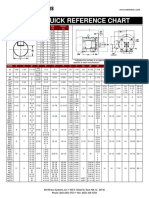

Recommended Make-Up Torque, API Tolerances, TFA Chart

Recommended Make-up Torque

Connection Maximum Pin ID Bit Sub OD Minimum Make-up Torque

in. in. in. FT-LBS (with or without Relief Groove)

2-3/8 API Regular 1 3 1,793 *

3-1/8 2,422 *

3-1/4 3,089 *

2-7/8 API Regular 1-1/4 3-1/2 3,071 *

3-3/4 4,620

3-7/8 4,662

3-1/2 API Regular 1-1/2 4-1/8 5,173 *

4-1/4 6,309 *

4-1/2 7,665

4-1/2 API Regular 2-1/4 5-1/2 12,461 *

5-3/4 16,488 *

6 17,560

6-1/4 17,766

4-1/2 API I.F. Box 2-1/4 6-1/2 23,743 *

7 30,941

8 32,169

6-5/8 API Regular 2-13/16 7-1/2 37,119 *

7-3/4 42,769

8 43,147

8-1/4 43,525

6-5/8 API Regular 3 7-1/2 37,119 *

7-3/4 40,753

8 41,114

8-1/4 41,474

7-5/8 API Regular 3-1/4 8-1/2 48,321 *

8-3/4 57,735 *

9 67,386

9-1/4 67,908

9-1/2 68,431

7-5/8 API Regular 3-1/2 8-1/2 48,321 *

8-3/4 57,735 *

9 63,824

9-1/4 64,318

9-1/2 64,813

8-5/8 API Regular 3-1/2 9-3/4 97,299

10 98,012

10-1/4 98,725

10-1/2 99,437

Note: Torque figures followed by an asterisk (*) indicate that the weaker member for the corresponding outside diameter (OD) and bore is the BOX. For all other torque values

the weaker member is the PIN. Basis of calculations for recommended make-up torque assumed the use of a thread compound containing 40 to 60 percent by weight of finely powdered metallic

zinc or 60 percent by weight of finely powdered metallic lead, with not more than 0.3 percent total active sulfur, applied thoroughly to all threads and shoulders (reference the CAUTION regarding

the use of hazardous materials in Appendix G of API Specification 7) and using the modified Screw Jack formula in A.8 and a unit stress of 50,000 psi in the box or pin, whichever is the weaker.

Normal torque range is tabulated value plus 10 percent. Higher torque values may be used under extreme conditions.

Drill Bits

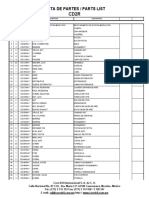

Fixed Cutter Bits - API Tolerances

Fixed Cutter Bit

Bit Size OD Tolerance

In. In.

6-3/4 and Smaller -0.015 to +0.00

6-25/32 to 9 -0.020 to +0.00

9-1/32 to 13-3/4 -0.030 to +0.00

13-25/32 to 17-1/2 -0.045 to +0.00

17-17/32 and Larger -0.063 to +0.00

(TFA) Total Flow Area Chart (Square Inches)

Nozzle 1 2 3 4 5 6 7 8

SIZE Nozzle nozzles nozzles nozzles nozzles nozzles nozzles nozzles

7 0.0376 0.0752 0.1128 0.1504 0.1880 0.2256 0.2632 0.3007

8 0.0491 0.0982 0.1473 0.1964 0.2455 0.2946 0.3437 0.3927

9 0.0621 0.1242 0.1863 0.2484 0.3105 0.3728 0.4349 0.4970

10 0.0767 0.1534 0.2301 0.3068 0.3835 0.4602 0.5369 0.6136

11 0.0928 0.1856 0.2784 0.3712 0.4640 0.5568 0.6496 0.7424

12 0.1104 0.2208 0.3312 0.4418 0.5522 0.6627 0.7731 0.8836

13 0.1296 0.2592 0.3888 0.5184 0.6480 0.7776 0.9072 1.0370

14 0.1503 0.3006 0.4509 0.6012 0.7515 0.9020 1.0523 1.2026

15 0.1726 0.3452 0.5178 0.6904 0.8630 1.0354 1.2080 1.3806

16 0.1963 0.3926 0.5889 0.7854 0.9817 1.1781 1.3744 1.5708

17 0.2217 0.4433 0.6650 0.8866 1.1083 1.3300 1.5516 1.7733

18 0.2485 0.4970 0.7455 0.9940 1.2425 1.4910 1.7395 1.9880

19 0.2769 0.5538 0.8307 1.1076 1.3845 1.6614 1.9382 2.2151

20 0.3068 0.6136 0.9204 1.2272 1.5340 1.8408 2.1476 2.4544

21 0.3382 0.6764 1.10146 1.3530 1.6912 2.0295 2.3677 2.7059

22 0.3712 0.7424 1.1136 1.4848 1.8560 2.2272 2.5986 2.9698

24 0.4418 0.8836 1.3254 1.7671 2.2089 2.6507 3.0925 3.5343

26 0.5185 1.0370 1.5555 2.0739 2.5924 3.1109 3.294 4.1479

28 0.6013 1.2026 1.8040 2.4053 3.0066 3.6079 4.2092 4.8105

© 2009 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the contract

between Halliburton and the customer that is applicable to the sale. H03041 9/09

www.halliburton.com

You might also like

- API Reg - Thread FormsDocument1 pageAPI Reg - Thread FormsPetrotrim Services100% (2)

- National Pipe Thread Chart PDFDocument1 pageNational Pipe Thread Chart PDFLiu YangtzeNo ratings yet

- Well Head Schematic LVT 2Document1 pageWell Head Schematic LVT 2luico37100% (2)

- 70 070 Autocreaser 50 Service ManualDocument31 pages70 070 Autocreaser 50 Service ManualPeter Galuszka0% (1)

- Providing Gage Solutions Since 1912Document154 pagesProviding Gage Solutions Since 1912qcomoNo ratings yet

- MAX-Brush ToolDocument2 pagesMAX-Brush ToolErnest AmadiNo ratings yet

- Drill Bit and Casing CombinationsDocument1 pageDrill Bit and Casing CombinationsJose CervantesNo ratings yet

- LRL20201218Document22 pagesLRL20201218Y̵̡̯͊ͅö̴̢̞̰̖̤̫̬̫̫̠́̆̍͒̒̿̀̕n̸̢̧̧̡̪̱̱̪͙̈́̒̌̋̕͠͠ą̴͙͙̬̲̻̯̺̍̌͐̍̔̌̌̚̚ţ̵̙͙̜̮̠͐̏̀h̴̛̹̬̲̻͉̆̑͊ȁ̴͚̝̻͌͘n̷̛̟̪̑̈́͑́͗̌͋́͘͜ Briceño TorresNo ratings yet

- Conversion Tables, Inches - MM - Nordic Fastening Group ABDocument1 pageConversion Tables, Inches - MM - Nordic Fastening Group ABSudhakar KrishnamurthyNo ratings yet

- C3121810 Dra STDocument1 pageC3121810 Dra STMax JunghannsNo ratings yet

- Spesifikasi Alat BlueprintDocument18 pagesSpesifikasi Alat BlueprintTopaz AdityaNo ratings yet

- AN565 REV. 7 - Part2Document1 pageAN565 REV. 7 - Part2David WongNo ratings yet

- INCH TO MM BOLT CONVERSION TABLEDocument1 pageINCH TO MM BOLT CONVERSION TABLECESARCARDONo ratings yet

- MAX-Blade ToolDocument2 pagesMAX-Blade ToolErnest AmadiNo ratings yet

- Common Sucker Rod SpecificationsDocument1 pageCommon Sucker Rod SpecificationsMichelangeloTiberiiNo ratings yet

- Drill Collar Sizes PDFDocument1 pageDrill Collar Sizes PDFRahul BattaarNo ratings yet

- Drill Collar Sizes and Weights: Drill Collars OD (In) ID (In) Weight (LB/FT)Document1 pageDrill Collar Sizes and Weights: Drill Collars OD (In) ID (In) Weight (LB/FT)Rahul BattaarNo ratings yet

- Drill Collar Sizes PDFDocument1 pageDrill Collar Sizes PDFCristopherSacaNo ratings yet

- Carbon Steel Flange Nut & Bolt Set Astm A307 Grade A / Sae J995 Grade 2Document1 pageCarbon Steel Flange Nut & Bolt Set Astm A307 Grade A / Sae J995 Grade 2Gerardo JM PalaciosNo ratings yet

- LEESON Frame SizesDocument3 pagesLEESON Frame SizesAnuragNo ratings yet

- 5 3/4 Bolt Dia: E-4BF-TRB-85MMDocument1 page5 3/4 Bolt Dia: E-4BF-TRB-85MMashey7777No ratings yet

- Stair CheckDocument1 pageStair Checkdnl_vicarsNo ratings yet

- Lokasi PartDocument4 pagesLokasi PartrioNo ratings yet

- National Pipe Thread Chart PDFDocument1 pageNational Pipe Thread Chart PDFafiqaziz86No ratings yet

- National Pipe Thread Chart OPT P PDFDocument1 pageNational Pipe Thread Chart OPT P PDFRoselio MayoNo ratings yet

- NPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Document1 pageNPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Carlos Andrés Mancera TrejosNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PVasantha KumarNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PAbhi PrajapatiNo ratings yet

- NPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Document1 pageNPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Deden SobirinNo ratings yet

- National Pipe Thread ChartDocument1 pageNational Pipe Thread Chartafiqaziz86No ratings yet

- NPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460Document1 pageNPT-National Pipe Thread Chart: Connect With Us On: 855.728.5460RicNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PAbhi PrajapatiNo ratings yet

- Nema - Quick Reference Chart: ESR Motor SystemsDocument2 pagesNema - Quick Reference Chart: ESR Motor SystemsadolfNo ratings yet

- Rj45 Pushpull Connector Installation Guide Part. No. 39680Document1 pageRj45 Pushpull Connector Installation Guide Part. No. 39680jhon bayonaNo ratings yet

- Asme b16.5 Class 150 Flanges Bolting Pattern and Dimensions Chart Northwest FastenerDocument1 pageAsme b16.5 Class 150 Flanges Bolting Pattern and Dimensions Chart Northwest Fastenerbappysarker9654No ratings yet

- Asme b16.5 Class 150 Flanges Bolting Pattern and Dimensions Chart Northwest FastenerDocument1 pageAsme b16.5 Class 150 Flanges Bolting Pattern and Dimensions Chart Northwest FastenerRyan SolomonNo ratings yet

- Technical Data Sheet Bolt Diameter Tolerances For Crosby® S/G-2130/2140 ShacklesDocument1 pageTechnical Data Sheet Bolt Diameter Tolerances For Crosby® S/G-2130/2140 ShacklesozkanhasanNo ratings yet

- Asme b16.5 Class 300 Flanges Bolting Pattern and Dimensions Chart Northwest FastenerDocument1 pageAsme b16.5 Class 300 Flanges Bolting Pattern and Dimensions Chart Northwest FastenerRyan SolomonNo ratings yet

- NEMA FrameDocument1 pageNEMA Frameriff100% (9)

- Ig Rj45 Push-Pull Connector 39680 en 1512Document1 pageIg Rj45 Push-Pull Connector 39680 en 1512Henry WoartNo ratings yet

- Bolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronDocument1 pageBolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronGiorgi KOGOSHVILINo ratings yet

- Studbolt Size ChartDocument3 pagesStudbolt Size ChartRenalyn TorioNo ratings yet

- NEMA Motor Dimensions - Reference ChartDocument2 pagesNEMA Motor Dimensions - Reference ChartMOTORES, MOTORREDUCTORES Y COMPONENTES GUADALAJARA100% (1)

- Flange Dimensions 250# & 300#Document1 pageFlange Dimensions 250# & 300#NathanNo ratings yet

- Imperial Drill Pipe Thread DataDocument3 pagesImperial Drill Pipe Thread DataDon BraithwaiteNo ratings yet

- Taperlock BushesDocument3 pagesTaperlock BushessatishNo ratings yet

- Cover of Manhole According To Land Trabspport AuthDocument10 pagesCover of Manhole According To Land Trabspport AuthKiren RajNo ratings yet

- Bolting Chart For Industrial FlangesDocument6 pagesBolting Chart For Industrial FlangesPritam JadhavNo ratings yet

- Flanges and Bolt Dimensions ASME - ANSI B16Document3 pagesFlanges and Bolt Dimensions ASME - ANSI B16A.YOGAGURUNo ratings yet

- Pocket Bolt Reference Chart: Sealing Global - Servicing LocalDocument2 pagesPocket Bolt Reference Chart: Sealing Global - Servicing LocalMazhar MahadzirNo ratings yet

- Electrical Motors - Frame Sizes PDFDocument5 pagesElectrical Motors - Frame Sizes PDFGustavo CuatzoNo ratings yet

- Ss Stub TypesDocument1 pageSs Stub Typeslambu_ladNo ratings yet

- LB&A CatalogueDocument127 pagesLB&A CataloguekingdbmNo ratings yet

- 600 Flange Bolt Chart 1 PDFDocument1 page600 Flange Bolt Chart 1 PDFRizalzi BachtiarNo ratings yet

- Item Current Part Description Replaced Qty Notes Kits/Assys Where UsedDocument1 pageItem Current Part Description Replaced Qty Notes Kits/Assys Where UsedAlex Renne ChambiNo ratings yet

- NEMA Motor Dim ChartDocument2 pagesNEMA Motor Dim Chartmilind1983100% (2)

- Tadano GR 1200XLDocument16 pagesTadano GR 1200XLAsad Mohammad RafiqueNo ratings yet

- General Schematic - CR30-XDocument9 pagesGeneral Schematic - CR30-XPatou PatriceNo ratings yet

- Average Nails Per PoundDocument1 pageAverage Nails Per PoundRenzel EstebanNo ratings yet

- Mechanical Solar Tracker - BOMDocument7 pagesMechanical Solar Tracker - BOMDeepak MisraNo ratings yet

- Npk03-Cp-Pi-G001.03-Piping and Instrumentation Diagrams - Simbology I GeneralDocument1 pageNpk03-Cp-Pi-G001.03-Piping and Instrumentation Diagrams - Simbology I GeneralhuyNo ratings yet

- Chapter 9Document22 pagesChapter 9m90abdelwahabNo ratings yet

- QAHD Office Building 30 M Structural Plans-S102.0Document1 pageQAHD Office Building 30 M Structural Plans-S102.0Adrian PachecoNo ratings yet

- Pump Control Valve (Implement, Steering) - Test and Adjust: 16M Series 3, 16, 18M Series 3 and 18 Motor GraderDocument18 pagesPump Control Valve (Implement, Steering) - Test and Adjust: 16M Series 3, 16, 18M Series 3 and 18 Motor GraderNasrul arulNo ratings yet

- Puposal For Consolidation Grouting in TunnelDocument22 pagesPuposal For Consolidation Grouting in TunneljunaidNo ratings yet

- Is 5519 - 12Document1 pageIs 5519 - 12Svapnesh ParikhNo ratings yet

- Automatic Motorized Bench-ViceDocument24 pagesAutomatic Motorized Bench-Vicekaran pitrodaNo ratings yet

- Partes Motor CD2RDocument3 pagesPartes Motor CD2Rdany riversNo ratings yet

- 59237-Vk-Komatsu PC20-7 Alter With Sprocket ChangeDocument3 pages59237-Vk-Komatsu PC20-7 Alter With Sprocket ChangeAnonymous srN69mFENo ratings yet

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument48 pagesDesign and Drawing of RC Structures: Dr. G.S.SureshDouglas Au Yeung0% (1)

- Danfoss MBC 5000 5100 Pressure ControlDocument4 pagesDanfoss MBC 5000 5100 Pressure ControlAnom HarimurtiNo ratings yet

- CP100 STD Pump Build & Service Manual Revision 2 01-Sep-09Document11 pagesCP100 STD Pump Build & Service Manual Revision 2 01-Sep-09ISRAEL GONZALESNo ratings yet

- Table T-233.1 For RTDocument1 pageTable T-233.1 For RTLipika GayenNo ratings yet

- RW SFB 22 - 2Document1 pageRW SFB 22 - 2Yong TonghannNo ratings yet

- Electromechanics & AUTOMATION (1) (1) FiniDocument12 pagesElectromechanics & AUTOMATION (1) (1) FiniSalah ElbakriNo ratings yet

- Card #1: A Puppy Weighs 0.8 Pounds at Birth and Gains An Average of 0.1 Pounds Per DayDocument10 pagesCard #1: A Puppy Weighs 0.8 Pounds at Birth and Gains An Average of 0.1 Pounds Per DayLogan DeWildNo ratings yet

- New Holland 100hp - 115hp - 135hp - 160hp Power Take-OffDocument15 pagesNew Holland 100hp - 115hp - 135hp - 160hp Power Take-OffDrag TrakNo ratings yet

- Introduction To Pneumatic SlideDocument23 pagesIntroduction To Pneumatic SlideMuhammad Danish HakimNo ratings yet

- Colunn & Beam DesignsDocument22 pagesColunn & Beam Designsmadhu sudhanNo ratings yet

- Screw Jack Selection: Product CodesDocument16 pagesScrew Jack Selection: Product CodesTrived DoijodNo ratings yet

- Crosby-Pentair Omni 800, 900 DatasheetDocument24 pagesCrosby-Pentair Omni 800, 900 DatasheetMijin28No ratings yet

- Act. 2 - Belts & Pulleys PDFDocument18 pagesAct. 2 - Belts & Pulleys PDFDAGANATO, APPLE GRACE S.No ratings yet

- Basic Machine Design Situational Problem by Alcorcon 1Document170 pagesBasic Machine Design Situational Problem by Alcorcon 1Richard YapNo ratings yet

- PLANE STRESS (Part 1) : Tr2005 - Mechanics of Deformable SolidsDocument53 pagesPLANE STRESS (Part 1) : Tr2005 - Mechanics of Deformable SolidshuynhnhuNo ratings yet

- BTS 84 Technical - GBDocument4 pagesBTS 84 Technical - GBPham LamNo ratings yet

- Anti-Lock Brake System / Accelera-Tion GeneralDocument165 pagesAnti-Lock Brake System / Accelera-Tion GeneralLe ThanhNo ratings yet

- MAIN Air Compressor - Instruction Manual HV2-200Document32 pagesMAIN Air Compressor - Instruction Manual HV2-200Black ScorpionNo ratings yet