Professional Documents

Culture Documents

Rule 18 19 Scope of Work

Rule 18 19 Scope of Work

Uploaded by

Krish0 ratings0% found this document useful (0 votes)

3 views1 pageThe document outlines the scope of work for testing and certification activities under Rules 18 and 19 of the SMPV rules.

Under Rule 18, the vendor is responsible for issuing certification for testing components and providing revised certificates if needed at no extra cost. ALL is responsible for testing components and providing results to the vendor.

Under Rule 19, the vendor's scope includes hydrotesting, inspecting, and certifying LPG bullets. The company is responsible for providing water, electricity, tankers if needed, replacement nuts and bolts if required, fabrication drawings and control certificate details. The work is estimated to take 4-5 days to complete.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the scope of work for testing and certification activities under Rules 18 and 19 of the SMPV rules.

Under Rule 18, the vendor is responsible for issuing certification for testing components and providing revised certificates if needed at no extra cost. ALL is responsible for testing components and providing results to the vendor.

Under Rule 19, the vendor's scope includes hydrotesting, inspecting, and certifying LPG bullets. The company is responsible for providing water, electricity, tankers if needed, replacement nuts and bolts if required, fabrication drawings and control certificate details. The work is estimated to take 4-5 days to complete.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

3 views1 pageRule 18 19 Scope of Work

Rule 18 19 Scope of Work

Uploaded by

KrishThe document outlines the scope of work for testing and certification activities under Rules 18 and 19 of the SMPV rules.

Under Rule 18, the vendor is responsible for issuing certification for testing components and providing revised certificates if needed at no extra cost. ALL is responsible for testing components and providing results to the vendor.

Under Rule 19, the vendor's scope includes hydrotesting, inspecting, and certifying LPG bullets. The company is responsible for providing water, electricity, tankers if needed, replacement nuts and bolts if required, fabrication drawings and control certificate details. The work is estimated to take 4-5 days to complete.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

Rule 18 Scope of work

Scope of Work:

1. In case of ALDS -

Scope of Work for Vendor:

- Issuance of Certification for testing of SRVs (02Nos), TRVs (06Nos), Unloading Hose

(02Nos) and dispensing hoses (04Nos.) under Rule 18 of SMPV rule.

- If any discrepancy comes, related to rule 18 certificate from PESO, Vendor will be

responsible to provide revised certificates with no extra cost .

- Responsible for providing soft copy as well as hard copy of all the certificates.

Scope of Work for ALL:

- Testing of SRVs, TRVs, Unloading Hoses and dispensing hoses

- To provide the testing readings/observations to vendor for certification.

Rule 19 Scope of work

A) JOB IN VENDOR SCOPE: - for all sites mentioned below

1. Hydro-Testing of LPG bullets: -

i) Duly de-pressurized by transferring complete Auto LPG from Under-ground Bullet

to the tanker if require.

ii) Isolating all Nozzles.

iii) Degassing by filling water and leaving it for 24 hours.

iv) Hydraulic/Pneumatic pressure testing as per SMPV rule whichever is applicable.

v) Depressurization.

vi) Manhole cover removal.

vii) Removing of complete water from inside the bullet & making it dry.

viii) Checking for gas free.

ix) Cleaning of bullet.

x) Carrying out 100% WET MAGNETIC PARTICAL TEST of all welds

xi) 25% ULTRASONIC FLAW DETECTION EXAMINATION including all T-Joints welds

xii) ULTRASONIC THICKNESS SURVEY of complete Bullet from inside.

xiii) Liquid Penetrant (DP) test

xiv) Re-connection of the nozzles and fittings.

xv) Manhole cover alignment and nut bolts to be fixed by torque wrench.

xvi) Purging with Nitrogen gas to remove complete air and carrying out leak check

with 14.0 Kg/Cm²g pressure with Nitrogen.

2. Disconnecting and/or re-connecting of all electrical and pneumatic connections

to the equipment, wherever required.

3. All type of Tools & consumables viz. –Grease, Oil, cotton waste, Gaskets (Spiral

wound metallic gaskets, Insulating Flanges Gasket Bolt Sleeve Sets), enough

Nitrogen gas in cylinders, PPE for labors/technician etc. are to be arranged.

4. Crane for uplifting & refitting of manhole covers OR any other heavy material

during tests.

5. Tanker unloading, commissioning of ALDS and hand over to dealer.

6. Approximate period requirement for work done to be 4 to 5 days.

7. Issuance of Safety Certificate U/R 19 of The SMPV(U) Rules 2016.

B) JOB IN COMPANY SCOPE: -

1. Water (Approx. 21KL considering tank capacity = 20 KL) and electricity.

2. Empty/LPG tanker arrangement for LPG transfer if require.

3. Nuts & bolts if required to be replaced shall be provided if require.

4. Approved fabrication drawings and details of its approval reference by Chief

Controller of Explosives, Nagpur.

5. Copy of Control Certificate.

You might also like

- Method Statement For Underground Piping FCDocument17 pagesMethod Statement For Underground Piping FCmister pogi94% (17)

- Accord Boiler Safety Program Infopack PDFDocument10 pagesAccord Boiler Safety Program Infopack PDFTimeNo ratings yet

- Astm C24Document4 pagesAstm C24nee2790No ratings yet

- Manual of Modern Hydronics Section 1 4Document58 pagesManual of Modern Hydronics Section 1 4Tin Aung KyiNo ratings yet

- E.F. Area of Blank Xno. of Rowsx100 Pitch X Strip WidthDocument1 pageE.F. Area of Blank Xno. of Rowsx100 Pitch X Strip WidthAnkit BhadesiaNo ratings yet

- Method Statemant HydroDocument8 pagesMethod Statemant Hydrojay_rajeshirkeNo ratings yet

- Hot TappingDocument88 pagesHot TappingAlexis Pacheco100% (1)

- מפרט טכני 18334Document11 pagesמפרט טכני 18334Hassan GDOURANo ratings yet

- V-31P0-0001-A-0011 - 2 - 001 - Hydrostatic Test Procedure For Pipeline PDFDocument32 pagesV-31P0-0001-A-0011 - 2 - 001 - Hydrostatic Test Procedure For Pipeline PDFpertmaster100% (1)

- Peso Interview QuestiionsDocument3 pagesPeso Interview QuestiionsrajeshNo ratings yet

- Maintenance of Heat ExchangerDocument5 pagesMaintenance of Heat Exchangerdanish_1985100% (4)

- Method Statement Piping Works DABBIYADocument11 pagesMethod Statement Piping Works DABBIYAsivaparthiban100% (3)

- MRPL NHT Heater DecokingDocument7 pagesMRPL NHT Heater DecokingsmrndrdasNo ratings yet

- Gadkar Anwers PrabhatDocument191 pagesGadkar Anwers PrabhatRachit100% (1)

- Muhammad Aqib: Inspection TechnicianDocument4 pagesMuhammad Aqib: Inspection Technicianusama666No ratings yet

- TS - 11 KV Dead End ClampsDocument6 pagesTS - 11 KV Dead End ClampsAshim BhowmickNo ratings yet

- Sow TCP DST SWT 2023 - 2025 R0Document45 pagesSow TCP DST SWT 2023 - 2025 R0Marc LefrancqNo ratings yet

- Detailed Scope of WorkDocument5 pagesDetailed Scope of WorkBen AdaborNo ratings yet

- Class NK Technical Information TEC 0869Document9 pagesClass NK Technical Information TEC 0869consaldNo ratings yet

- Oil Tender Part 3Document40 pagesOil Tender Part 3Dhrubajyoti SonowalNo ratings yet

- Shuaiba RefineryDocument4 pagesShuaiba Refineryarun kumarNo ratings yet

- Gas Supplies To Industrial, Commercial Customers 03092020Document13 pagesGas Supplies To Industrial, Commercial Customers 03092020Ram ChaitanyaNo ratings yet

- Disposal Requirements Volume2Document8 pagesDisposal Requirements Volume2mcemceNo ratings yet

- Helicopter Refuelling System For H1103 CSBC LPD Project: Operating Manual & Commissioning ProcedureDocument17 pagesHelicopter Refuelling System For H1103 CSBC LPD Project: Operating Manual & Commissioning ProcedureMuhammad JabirNo ratings yet

- Aegis LPG TenderDocument147 pagesAegis LPG TenderKazeem100% (1)

- Auxiliary Boiler MSDocument10 pagesAuxiliary Boiler MSsharif339No ratings yet

- PR#12354332 - Decontamination Jobs - Sow 2016 OLE III TADocument11 pagesPR#12354332 - Decontamination Jobs - Sow 2016 OLE III TAGanga DaranNo ratings yet

- Detail Plant OperationDocument5 pagesDetail Plant OperationMuhamad AsvarNo ratings yet

- Cleaning of Transformers Oil Catch Basins Oil Retention Pits at Various SecNational Grid SubstationsDocument2 pagesCleaning of Transformers Oil Catch Basins Oil Retention Pits at Various SecNational Grid SubstationsSyed Zuber AhmedNo ratings yet

- Elec BOQ As Per Price Schedule (138150) After TB 0 1 Rev.1Document627 pagesElec BOQ As Per Price Schedule (138150) After TB 0 1 Rev.1Farhan KhanNo ratings yet

- Reformer RepairDocument11 pagesReformer RepairNishant Kumar ThakurNo ratings yet

- Plumbing Test Umaish.Document5 pagesPlumbing Test Umaish.jana.alqimmaNo ratings yet

- Statutory Requirements On Pressure Vessels SystemsDocument42 pagesStatutory Requirements On Pressure Vessels Systemskashing_wongNo ratings yet

- Hydrotest Procedure For PipelineDocument12 pagesHydrotest Procedure For Pipelineaike_577% (13)

- Test CO2 SystemsDocument5 pagesTest CO2 SystemsAntonio FilipeNo ratings yet

- API 682 4th Edition Category 1 Configurations: 3CW-FBDocument19 pagesAPI 682 4th Edition Category 1 Configurations: 3CW-FBtuliofilipeNo ratings yet

- Hyd DamperDocument12 pagesHyd DampermailbkraoNo ratings yet

- RWPL TG LP Rotor Replacement Scope of JobDocument5 pagesRWPL TG LP Rotor Replacement Scope of JobSreekanthMylavarapuNo ratings yet

- Field Joint CoatingDocument7 pagesField Joint Coatingkrishna3794No ratings yet

- Scope of WorkDocument3 pagesScope of WorkSamuel HugosNo ratings yet

- Chapter 2 - ChillersDocument33 pagesChapter 2 - ChillersRajesh VenkiteswaranNo ratings yet

- Mohammed Zeeshan API InspectorDocument8 pagesMohammed Zeeshan API InspectorGulfam ShahzadNo ratings yet

- DEVIATIONS EXCLUSIONS 6522 Rev.01Document4 pagesDEVIATIONS EXCLUSIONS 6522 Rev.01Aftab Hussain ChaudhryNo ratings yet

- Replacement of Corroded Treated Waste For Water Piping From Neutralization Sump in Utility Area To Sea Water Outfall at Ruwais Refinery WestDocument8 pagesReplacement of Corroded Treated Waste For Water Piping From Neutralization Sump in Utility Area To Sea Water Outfall at Ruwais Refinery WestMirza AliNo ratings yet

- General Information Saudi Aramco Work Permit ReceiverDocument4 pagesGeneral Information Saudi Aramco Work Permit Receiverjohn samuelNo ratings yet

- 06 Scope of Work Site Inspn Services RasgasDocument17 pages06 Scope of Work Site Inspn Services RasgasGirijesh Verma100% (1)

- 2022Document17 pages2022mahdi_g100% (1)

- CORR-5057 TOR Pipeline PiggingDocument11 pagesCORR-5057 TOR Pipeline PiggingAbdelaaliNo ratings yet

- Scope Tnkge WKDocument7 pagesScope Tnkge WKPrabhu BalNo ratings yet

- LPG Filling Station COP Nov 2007 (11-2008) PDFDocument66 pagesLPG Filling Station COP Nov 2007 (11-2008) PDFBravii100% (2)

- MS For HDPE Pipes Laying ActivityDocument7 pagesMS For HDPE Pipes Laying ActivityJust Do LoveNo ratings yet

- 8 6 9Document4 pages8 6 9sonerNo ratings yet

- Scope of Work For NRV and MOVDocument2 pagesScope of Work For NRV and MOVSreekanthMylavarapuNo ratings yet

- Acid Rinsing FRP TankDocument2 pagesAcid Rinsing FRP Tankkasvikraj0% (1)

- SOW - WOR 23120 - Dismantle and Remove The Existing Pipeline in The RCR Loading System From Battery LimitDocument2 pagesSOW - WOR 23120 - Dismantle and Remove The Existing Pipeline in The RCR Loading System From Battery LimitmahmoudNo ratings yet

- R307. Environmental Quality, Air Quality. R307-327. Ozone Nonattainment and Maintenance Areas: Petroleum Liquid Storage. R307-327-1. PurposeDocument5 pagesR307. Environmental Quality, Air Quality. R307-327. Ozone Nonattainment and Maintenance Areas: Petroleum Liquid Storage. R307-327-1. PurposeMatthew BallardNo ratings yet

- SpecificationDocument26 pagesSpecificationdanhielitNo ratings yet

- Scope of Work For High Pressure Rotomol Cleaning of Underground Cooling Water PipelinesDocument4 pagesScope of Work For High Pressure Rotomol Cleaning of Underground Cooling Water PipelinesSumeet PanwarNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- CU-01 Cable SizingDocument1 pageCU-01 Cable SizingKrishNo ratings yet

- CTP-02 Cable SizingDocument1 pageCTP-02 Cable SizingKrishNo ratings yet

- Omntec Protocol String ManualDocument1 pageOmntec Protocol String ManualKrishNo ratings yet

- CTFM-01 Cable SizingDocument1 pageCTFM-01 Cable SizingKrishNo ratings yet

- CWP-01 Cable SizingDocument1 pageCWP-01 Cable SizingKrishNo ratings yet

- PCP - 01 With DOL Cable SizingDocument1 pagePCP - 01 With DOL Cable SizingKrishNo ratings yet

- 40 Fabulous BooksDocument3 pages40 Fabulous BooksKrishNo ratings yet

- Heat Treatment For Heart AttackDocument1 pageHeat Treatment For Heart AttackKrishNo ratings yet

- GeM Bidding 4644198Document6 pagesGeM Bidding 4644198KrishNo ratings yet

- Kamals InstinctDocument1 pageKamals InstinctKrishNo ratings yet

- Trees For TreeDocument1 pageTrees For TreeKrishNo ratings yet

- Proposed QAPDocument5 pagesProposed QAPKrishNo ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- Drugs and EffectsDocument2 pagesDrugs and EffectsKrishNo ratings yet

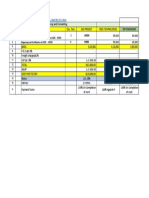

- Degasification CostingDocument1 pageDegasification CostingKrishNo ratings yet

- To All The Guys Who Read ThisDocument9 pagesTo All The Guys Who Read ThisKrishNo ratings yet

- Q. What Is The Q. Doctor: App Ka Aur Aapki Biwi KaDocument1 pageQ. What Is The Q. Doctor: App Ka Aur Aapki Biwi KaKrishNo ratings yet

- Naqsh Automation - VFDDocument1 pageNaqsh Automation - VFDKrishNo ratings yet

- TLS-450+ UlDocument4 pagesTLS-450+ UlKrishNo ratings yet

- She Makes Babies From Clay!: HI TO ALL...........................Document7 pagesShe Makes Babies From Clay!: HI TO ALL...........................KrishNo ratings yet

- PNGRB Technical Standards 2018 Schedule 2Document34 pagesPNGRB Technical Standards 2018 Schedule 2KrishNo ratings yet

- An American Decided To Write A Book About Famous Churches Around The WorldDocument3 pagesAn American Decided To Write A Book About Famous Churches Around The WorldKrishNo ratings yet

- Draft Cover Letter For Renewal KolhapurDocument2 pagesDraft Cover Letter For Renewal KolhapurKrishNo ratings yet

- Compare Different Fuels (19052016)Document2 pagesCompare Different Fuels (19052016)KrishNo ratings yet

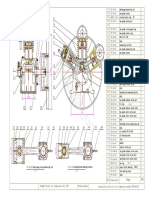

- 10 KL LPG Underground Storage TankDocument2 pages10 KL LPG Underground Storage TankKrishNo ratings yet

- Electrical Boq For Sulphuric Handling at Enclosure-1Document2 pagesElectrical Boq For Sulphuric Handling at Enclosure-1KrishNo ratings yet

- CSS Data Sheet-500KVADocument7 pagesCSS Data Sheet-500KVAKrishNo ratings yet

- Tamil Nadu Transmission Corporation Limited: Specification NoDocument7 pagesTamil Nadu Transmission Corporation Limited: Specification NoKrishNo ratings yet

- Weekly Housekeeping ReportDocument6 pagesWeekly Housekeeping ReportKrishNo ratings yet

- Tendernotice 1 PDFDocument11 pagesTendernotice 1 PDFKrishNo ratings yet

- Lzizj: Comprehensive Manuals of Surgical SpecialtiesDocument288 pagesLzizj: Comprehensive Manuals of Surgical SpecialtiesBeatriz BelottiNo ratings yet

- Cambridge International AS & A Level Information Technology: Topic Support GuideDocument9 pagesCambridge International AS & A Level Information Technology: Topic Support GuideMohammad Ihab MehyarNo ratings yet

- Siva VaidhyanathanDocument1 pageSiva VaidhyanathantreborschNo ratings yet

- Ufc 3 301 01 2013Document168 pagesUfc 3 301 01 2013praveen0907No ratings yet

- User Manual: Promia 50 Application - Material HandlingDocument110 pagesUser Manual: Promia 50 Application - Material Handlingred_shobo_85100% (2)

- Inspyrus - White PaperDocument8 pagesInspyrus - White PaperBayCreativeNo ratings yet

- Indian Institute of Insurance Surveyors and Loss Assessors: (Promoted by IRDA, Govt. of India)Document2 pagesIndian Institute of Insurance Surveyors and Loss Assessors: (Promoted by IRDA, Govt. of India)Sachin PrajapatiNo ratings yet

- E 20240407 Charge Calc MethodsDocument3 pagesE 20240407 Charge Calc Methodsamarsoni03697No ratings yet

- 5.recognizing A Firm's Intellectual AssetsDocument32 pages5.recognizing A Firm's Intellectual Assetswildan hakimNo ratings yet

- Technical Presentation From LJUNGSTROM On Advance Heat Recovery in Rotary Air Preheaters-WBPDCL PDFDocument2 pagesTechnical Presentation From LJUNGSTROM On Advance Heat Recovery in Rotary Air Preheaters-WBPDCL PDFLipika Ghosh BiswasNo ratings yet

- Varsha PitrodaDocument1 pageVarsha Pitrodaarun sivaNo ratings yet

- Wget - Curl Large File From Google Drive - Stack OverflowDocument29 pagesWget - Curl Large File From Google Drive - Stack OverflowManoj KamisettiNo ratings yet

- Song Review Ysabelle CuevasDocument4 pagesSong Review Ysabelle Cuevasnurul amaliaNo ratings yet

- Cwf-60-30air CompressorDocument2 pagesCwf-60-30air CompressorHuy Lễ NguyễnNo ratings yet

- Ch. 9 - Basic Router TroubleshootingDocument15 pagesCh. 9 - Basic Router TroubleshootingArad RezaNo ratings yet

- 8101-01-07 Constructions - Student Guide Part 2Document4 pages8101-01-07 Constructions - Student Guide Part 2Jonathan AllmanNo ratings yet

- Itc 6700 IP PA SystemDocument56 pagesItc 6700 IP PA Systemjudy kimNo ratings yet

- Scheme of Marking For 014 UPSR 2016 FormatDocument3 pagesScheme of Marking For 014 UPSR 2016 Formatawesome_teacher88% (8)

- BL M22 1011 PDFDocument46 pagesBL M22 1011 PDFDmitryNo ratings yet

- GST RegistrationDocument3 pagesGST RegistrationJabagodu SP & CoNo ratings yet

- Data Stock Nutrimart 05-04-2023Document8 pagesData Stock Nutrimart 05-04-2023aqmalwiragunaNo ratings yet

- Consolidated Terminals Inc. v. Artex - G.R. No. L-25748Document1 pageConsolidated Terminals Inc. v. Artex - G.R. No. L-25748eiram23No ratings yet

- DP2 IaDocument13 pagesDP2 IaZ AlbertNo ratings yet

- .. Thesis Title .Document31 pages.. Thesis Title .Tanut VongsoontornNo ratings yet

- Protocol Germ CellDocument82 pagesProtocol Germ CellTanh NguyenNo ratings yet

- PDF DPWH Cost Estimation Manual For Low Rise Buildings DLDocument260 pagesPDF DPWH Cost Estimation Manual For Low Rise Buildings DLMichael Angelo Ballon100% (1)

- Confidence Siswa Sma Dalam Materi Peluang: Analisis Kemampuan Kemampuan Penalaran Dan SelfDocument8 pagesConfidence Siswa Sma Dalam Materi Peluang: Analisis Kemampuan Kemampuan Penalaran Dan SelfAfifah R. AminiNo ratings yet