Professional Documents

Culture Documents

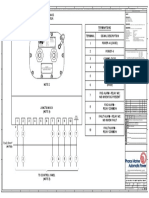

Insulgard (115VAC) in Enclosure With Terminal Strip

Insulgard (115VAC) in Enclosure With Terminal Strip

Uploaded by

Vivek SavaliyaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Insulgard (115VAC) in Enclosure With Terminal Strip

Insulgard (115VAC) in Enclosure With Terminal Strip

Uploaded by

Vivek SavaliyaCopyright:

Available Formats

Cables

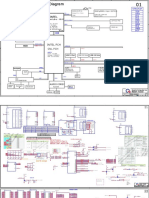

InsulGard Panel Wiring Diagram IG-115 from:

1 RTD-WHITE RTD

Temperature

2 RTD-BLACK Sensor

3 RTD-RED

CT-Load

4 LOAD-SIG-RED

sensor

5 LOAD-GND-BLACK

6 H%(GND)-WHITE

Humidity

7 H%(+5V)-RED sensor

8 H%(SIG)-BLACK

9 4-20mA- (+)

Signal

Ch1 10 4-20mA- (-)

DIN-Rail Terminal Strip

+

Connector to Sensor Interface

4-20

mA

Sensor Interface Board

T

Shield 11 RS485-A(+)

-

Connector to InsulGard

Ch2

12 RS485-B(-)

+5

Host

RS - 485

A

Ch3 13

B

Board 14 ALARM - NC

Coax cables from PD Sensors #1-15

G

Ch4

Device 15 ALARM - COM

Alarm 2

Alarm

Ch5

USB 16 ALARM - NO

Ch6

17 WARNING-NC

18 WARNING-COM

Ch7 Warning 19 WARNING-N0

Ethernet

Alarm 1

Ch8 20 STATUS-NC

21 STATUS-COM

Ch9

22 STATUS-NO

Ch10 23 NOT/USED

Status

1

Ch11

24 NOT/USED

2

RTD

3

4

Ch12 L

5 S

CT Ch13 InsulGard's GND

6

7 S1

Ch14

connectors N

GREEN

Power

8 S2 Ref

RED

WHITE

25

L

9 RED

Ch15

N

10 26

G

11 +5 H% Ch16 27 LINE

115 VAC

12 S (Noise) Ground Screw

H% Ref on back cover 28

WHITE 29 NEUTRAL

Sw 30

GREEN

GREEN 31 GROUND

GREEN

Connect Panel

DIN RAIL

to Local Ground

GROUND

FUSES:

Inside Insulgard for 115VAC application: Time-Lag 200mA, 250VAC, 5X20mm type 5ST by BEL Fuse Inc. , Catalog # 5ST 200.

On the panel: Fast Acting 3.0A, 250VAC, 5x20mm type 5MF by Bel Fuse Inc. Catalog # 5MF 3-R (or equivalent).

NOTES:

1) Relay "Status" changes its status when InsulGard has AC power and works properly. It returns in the status shown on the

label if InsulGard lost AC power or works not properly (has Error).

2) Relay "Alarm 1" is used for "Warning" and relay "Alarm 2" for "Alarm". They change their status if partial discharge level

exceeds predefined thresholds.

3) USB port "Device" is used for communication with PC. Port "Host" is not used now.

4) Switch "Sw" must be in position H% to monitor humidity.

5) Please pay special attention for PD sensor connection to Sensor Interface board. InsulGard comes preconfigured for

certain sequence of their connection to channels ##1-15. PD sensors must be connected accordingly. For motor/generator

connect coupling capacitors to the first PD channels in ABC order and then motor stator RTD sensors in incremental RTD

number order. For switchgear application this sequence is shown in the Questionnaire you provided to us. Also sensor

connection sequence can be verified in InsulGard software - "Unit Settings" - "Settings for Channel" section.

You might also like

- ELARA Wiring DiagramDocument6 pagesELARA Wiring DiagramSuubi brianNo ratings yet

- EPON/GPON ONU User's ManualDocument2 pagesEPON/GPON ONU User's ManualNayeemNo ratings yet

- 751001D4D2C4D81A6F1Document1 page751001D4D2C4D81A6F1jppreciadomNo ratings yet

- In Out SEL 787Document1 pageIn Out SEL 787Tosikur RahmanNo ratings yet

- DS7240V2 Control PanelDocument6 pagesDS7240V2 Control PanelForward MyanmarNo ratings yet

- HP 15 - Ab225ur DAX12AMB6D0 Quanta X12 6L R1aDocument40 pagesHP 15 - Ab225ur DAX12AMB6D0 Quanta X12 6L R1asaffunnutretro-9095No ratings yet

- Panasonic TH-42PX80U Chassis GPH11DU-94987Document74 pagesPanasonic TH-42PX80U Chassis GPH11DU-94987sebastian sanchez gomezNo ratings yet

- Insulgard (115 VAC) in EnclosureDocument2 pagesInsulgard (115 VAC) in EnclosureVivek SavaliyaNo ratings yet

- Quanta Daz8vrmb8e0 R1aDocument44 pagesQuanta Daz8vrmb8e0 R1aduc leNo ratings yet

- Insulgard (230 VAC) in EnclosureDocument2 pagesInsulgard (230 VAC) in EnclosureVivek SavaliyaNo ratings yet

- Uenr5472uenr5472 Sis PDFDocument4 pagesUenr5472uenr5472 Sis PDFfranz montezaNo ratings yet

- SCX-6345N XET SM EN 20070130090204078 08-Blockdiagram PDFDocument3 pagesSCX-6345N XET SM EN 20070130090204078 08-Blockdiagram PDFSoraphong NaknoppakoonNo ratings yet

- B737NG - 49 00 A3 02 PDFDocument1 pageB737NG - 49 00 A3 02 PDFMuhammed MudassirNo ratings yet

- Dop 103WQ 107WV 110WS - Q - TC SC en Tur - 20171003Document8 pagesDop 103WQ 107WV 110WS - Q - TC SC en Tur - 20171003Eduardo GonzalezNo ratings yet

- Blue 2Document1 pageBlue 2Civil Engineering DreamNo ratings yet

- Ngoc Long Marine: Everest 3 01Document4 pagesNgoc Long Marine: Everest 3 01Tran GlNo ratings yet

- Lock Close Lock: Feeder Protection RelayDocument1 pageLock Close Lock: Feeder Protection RelayJulianNo ratings yet

- Схема подключения к контроллеру BR4Document1 pageСхема подключения к контроллеру BR4jetwash.uaNo ratings yet

- DOP 110WS - CleanedDocument2 pagesDOP 110WS - Cleanedcorporacionraffo.mNo ratings yet

- Wiring Diagram: Attention !!!Document1 pageWiring Diagram: Attention !!!one2883 pratamaNo ratings yet

- Brochure Alarm Prestige APS787Z - QSDocument2 pagesBrochure Alarm Prestige APS787Z - QSRogerNo ratings yet

- Rayan CarteDocument12 pagesRayan CarteRadhika RanaNo ratings yet

- Quanta BKXB - SCHDocument60 pagesQuanta BKXB - SCHTech CentralNo ratings yet

- Hisense MTK8223L Circuit Diagram PDFDocument7 pagesHisense MTK8223L Circuit Diagram PDFManuel GarciaNo ratings yet

- Diagram Ddec Ii R115-4521 B 1: General NotesDocument2 pagesDiagram Ddec Ii R115-4521 B 1: General NotesAlfredo Chavez100% (2)

- STAG-TAP-03 - 2 - Wiring Diagram - (2021.01.12) - ENGDocument2 pagesSTAG-TAP-03 - 2 - Wiring Diagram - (2021.01.12) - ENGPiterKK KosewskiNo ratings yet

- Guia RápidoDocument2 pagesGuia RápidoWandesson DuarteNo ratings yet

- WMRT Schaltbild R1.00Document1 pageWMRT Schaltbild R1.00ropiNo ratings yet

- Korg X50 Service ManualDocument16 pagesKorg X50 Service ManualPatricio SandovalNo ratings yet

- Antenna Terminal Control Unit: 1 2 3 Can H GND +15V SHLD 1 2 3 SHLD 15V+ GND Can H Can LDocument1 pageAntenna Terminal Control Unit: 1 2 3 Can H GND +15V SHLD 1 2 3 SHLD 15V+ GND Can H Can LlyonanimeNo ratings yet

- Acer Aspire E5-476 Series - Quanta Z8VR - DA0Z8VMB8E0 - Rev-1A - KabylakeDocument44 pagesAcer Aspire E5-476 Series - Quanta Z8VR - DA0Z8VMB8E0 - Rev-1A - KabylakeAryanNo ratings yet

- Aspire E5-522 - ZRZL - ZRZDocument40 pagesAspire E5-522 - ZRZL - ZRZAdmin 010% (1)

- Acer Aspire E5-575 735T DAZAAMB16E0 Quanta ZAA-x16 - Ironman - SK (ZAA) & Captain - SK (ZAAA) - 2016-0203-C-GerberDocument48 pagesAcer Aspire E5-575 735T DAZAAMB16E0 Quanta ZAA-x16 - Ironman - SK (ZAA) & Captain - SK (ZAAA) - 2016-0203-C-GerberThaigo Santos Vs Rosilânia100% (1)

- Korg X50 - Manual de Servicio PDFDocument16 pagesKorg X50 - Manual de Servicio PDFSilvestre OxellNo ratings yet

- LED Digital Timers: RT-13/14 SeriesDocument1 pageLED Digital Timers: RT-13/14 SeriesWSR indiaNo ratings yet

- OS ABB Comem BR EN 16-05-2018Document12 pagesOS ABB Comem BR EN 16-05-2018RosaFNo ratings yet

- Overlay Karate ComentadoDocument2 pagesOverlay Karate ComentadoElizeu SmartcellNo ratings yet

- PB1 PB2: Programmable Automation ControllerDocument1 pagePB1 PB2: Programmable Automation Controllerjorge_moralesmNo ratings yet

- Hmi Dop B07e415Document2 pagesHmi Dop B07e415Canek UnoNo ratings yet

- Acer P3 Daee3mb1ae0Document32 pagesAcer P3 Daee3mb1ae0Fixpro Laptop ServiceNo ratings yet

- Sample Floor PlanDocument2 pagesSample Floor PlanDonald Billy C. Abugan IINo ratings yet

- 137-Safety Jewellery BoxDocument1 page137-Safety Jewellery BoxzulNo ratings yet

- FD 410ex Mk2 SCH 01 - r3 FD 410ex Mini Oc Fog Detector SCHDocument1 pageFD 410ex Mk2 SCH 01 - r3 FD 410ex Mini Oc Fog Detector SCHOmkumar KSNo ratings yet

- Haswell ULT 15W: Vram Ddr3L-Sodimm ChaDocument45 pagesHaswell ULT 15W: Vram Ddr3L-Sodimm ChaRobertas VNo ratings yet

- Blue 1Document1 pageBlue 1Civil Engineering DreamNo ratings yet

- QM3G-FH All-in-One User ManualtyDocument2 pagesQM3G-FH All-in-One User Manualtyzaki abbasNo ratings yet

- DA0Z8CMB8D0 REV D Schematic Diagram 2Document48 pagesDA0Z8CMB8D0 REV D Schematic Diagram 2Tim SamaelNo ratings yet

- Zoro (BA50) - SL (ZRW ZRWA) SKL - C TEST 0720Document48 pagesZoro (BA50) - SL (ZRW ZRWA) SKL - C TEST 0720Roberto MouraNo ratings yet

- Coupler Solenoid Wire Color Key Rear Coupler Front Coupler Main Wire Color TAN Blue Direction Strip Color Left RED Right Black UP Green Down YellowDocument5 pagesCoupler Solenoid Wire Color Key Rear Coupler Front Coupler Main Wire Color TAN Blue Direction Strip Color Left RED Right Black UP Green Down Yellowksdow87No ratings yet

- Te4 - R1a 1112 Uma Toshiba L700Document37 pagesTe4 - R1a 1112 Uma Toshiba L700Mohamad YahyaNo ratings yet

- 19d46 Quanta TE4 (DAOTE4MB6D0) - Satellite L700-L740 PDFDocument37 pages19d46 Quanta TE4 (DAOTE4MB6D0) - Satellite L700-L740 PDFBee WokoNo ratings yet

- RGBW/RGB/CCT/Dimming 4 Channel LED RF Controller: Model No.: C4 (150-500ma) / C4 (350-1200ma)Document2 pagesRGBW/RGB/CCT/Dimming 4 Channel LED RF Controller: Model No.: C4 (150-500ma) / C4 (350-1200ma)justfanloveNo ratings yet

- Diagrama 6Document1 pageDiagrama 6Joaquin FernandezNo ratings yet

- Diagrama 6 ACCELERATOR PEDAL ..Document1 pageDiagrama 6 ACCELERATOR PEDAL ..Joaquin FernandezNo ratings yet

- FX504GM 1.0 FX80GM SchematicDocument60 pagesFX504GM 1.0 FX80GM SchematicSDFVBNNo ratings yet

- Quanta Da0z8vmb8e0 R1aDocument44 pagesQuanta Da0z8vmb8e0 R1aRene Ruiz100% (1)

- Service: Samsung FacsimileDocument23 pagesService: Samsung Facsimileapi-3702225No ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- InsulGard Sensors ManualDocument25 pagesInsulGard Sensors ManualVivek SavaliyaNo ratings yet

- InsulGard Software Manual V5Document41 pagesInsulGard Software Manual V5Vivek SavaliyaNo ratings yet

- Installation and StartUp InsulGard SystemDocument35 pagesInstallation and StartUp InsulGard SystemVivek SavaliyaNo ratings yet

- Q6f559Brev1 DRGDocument1 pageQ6f559Brev1 DRGVivek SavaliyaNo ratings yet

- Door Mount Insulgard With Internal Temperature and Humidity SensorsDocument2 pagesDoor Mount Insulgard With Internal Temperature and Humidity SensorsVivek SavaliyaNo ratings yet

- 8.annexure 2 Design Philosophy For Electrical FacilitiesDocument24 pages8.annexure 2 Design Philosophy For Electrical FacilitiesVivek SavaliyaNo ratings yet

- Technical Appraisal of An Industrial ProjectDocument8 pagesTechnical Appraisal of An Industrial ProjectVivek SavaliyaNo ratings yet

- Ceragon IP10 Product DescriptionDocument40 pagesCeragon IP10 Product DescriptionAlberto PerezNo ratings yet

- Intro To IT by Peter Norton, MacGraw Hills Chap 07BDocument16 pagesIntro To IT by Peter Norton, MacGraw Hills Chap 07BMurtaza MoizNo ratings yet

- 1.1 Recognize The Following Logical or Physical Network Topologies Given A Schematic Diagram or DescriptionDocument6 pages1.1 Recognize The Following Logical or Physical Network Topologies Given A Schematic Diagram or DescriptionChe MashepaNo ratings yet

- Wireless and CELLULAR COMMUNICATION (18EC81) Module-5Document52 pagesWireless and CELLULAR COMMUNICATION (18EC81) Module-51DT18EC106 Y SAI MEGHANANo ratings yet

- WCDMA RNO Special Guide Inter-RAT Roaming and Handover-20050316-A-1.0Document69 pagesWCDMA RNO Special Guide Inter-RAT Roaming and Handover-20050316-A-1.0LOCK VALUE3No ratings yet

- Conwell EveryManHisOwnUniversityDocument80 pagesConwell EveryManHisOwnUniversityJoseph AdikwuNo ratings yet

- ONA-800 Remote Control Getting Started GuideDocument52 pagesONA-800 Remote Control Getting Started GuideOrlando MedinaNo ratings yet

- Evaluation of Timing Characteristics of A Prototype System Based On PROFINET IO RT Class 3Document8 pagesEvaluation of Timing Characteristics of A Prototype System Based On PROFINET IO RT Class 3Gene LiNo ratings yet

- Quanta Op6, Op7 Ra SchematicsDocument38 pagesQuanta Op6, Op7 Ra Schematicsjoe wiillsonNo ratings yet

- Daftar Harga Material KomputerDocument12 pagesDaftar Harga Material KomputerariefNo ratings yet

- Switch Brocade 1020 Specsheet PDFDocument2 pagesSwitch Brocade 1020 Specsheet PDFIonescu AdrianNo ratings yet

- DEM-311GT Datasheet 01 (HQ)Document3 pagesDEM-311GT Datasheet 01 (HQ)ionelescugigelescu1No ratings yet

- Ieee 1394 (Aka Firewire & Ilink ) : Electus Distribution Reference Data Sheet: Firewire PDFDocument3 pagesIeee 1394 (Aka Firewire & Ilink ) : Electus Distribution Reference Data Sheet: Firewire PDFLakshmi KanthNo ratings yet

- M814 12 4-2W4WEM A4 E ScreenDocument26 pagesM814 12 4-2W4WEM A4 E ScreenRikyNo ratings yet

- GSM Network and Services: Channel Coding - From Source Data To Radio BurstsDocument21 pagesGSM Network and Services: Channel Coding - From Source Data To Radio BurstsTrevorPNo ratings yet

- 04 HSPA ProtocolsDocument19 pages04 HSPA ProtocolsUsman WaseemNo ratings yet

- FRICTION (Types)Document1 pageFRICTION (Types)Anurag MalikNo ratings yet

- WPL 29 Aprilie 2017 - 29 Iulie 2017 - ParteneriDocument531 pagesWPL 29 Aprilie 2017 - 29 Iulie 2017 - ParteneriAlexandru LucaNo ratings yet

- Enhanced VPC Design n5kDocument12 pagesEnhanced VPC Design n5ktopdavisNo ratings yet

- RS485 Modbus Adapter For RVT Controller: User GuideDocument10 pagesRS485 Modbus Adapter For RVT Controller: User GuideMartinCastilloSancheNo ratings yet

- FiberLinX OverviewDocument61 pagesFiberLinX OverviewConstantin TucaNo ratings yet

- Debug 1214Document16 pagesDebug 1214PeachBlossomNo ratings yet

- WLan ArchitectureDocument4 pagesWLan ArchitectureseventhsensegroupNo ratings yet

- ePMP1000 - 4f3698 - Subscriber ModuleDocument3 pagesePMP1000 - 4f3698 - Subscriber ModuleSanagesi KomaNo ratings yet

- Ethernet Cable: Color-Code StandardsDocument3 pagesEthernet Cable: Color-Code StandardsCristian ParaschivNo ratings yet

- Wistron Sjv50 TRDocument59 pagesWistron Sjv50 TRvimaro24No ratings yet

- Momo LteDocument3 pagesMomo Lteسام النعمانNo ratings yet

- Esquema Schematic Dell - Inspiron 15 DAAM9AMB8D0 Quanta AM9ADocument57 pagesEsquema Schematic Dell - Inspiron 15 DAAM9AMB8D0 Quanta AM9ADayamLauthOliveiraNo ratings yet

- Ca 1 Automation Controller Installation Guide Rev A - 7c72cDocument2 pagesCa 1 Automation Controller Installation Guide Rev A - 7c72cEdie HunterNo ratings yet