Professional Documents

Culture Documents

Vibrox TDS en

Vibrox TDS en

Uploaded by

ankarthik11Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vibrox TDS en

Vibrox TDS en

Uploaded by

ankarthik11Copyright:

Available Formats

TDS VIBROX

Epoxy casting mortar 4 to 40mm

USAGE PROCESSING

VIBROX is a fluid mortar for constructively • Preparing the application surface

filling under machine bases, rails and other

items requiring casting where a fast high Make sure the surface is clean. The recommended processing temperature for the surface, the

compressive strength is required. surroundings and the material is 15 to 25°C. Do not use below 10°C.

VIBROX is ideally suited for the casting of

high-tech machines that have to operate • Casting formwork

vibration-free.

The minimum pouring height is 4mm, for larger flow distances 1cm.

The formwork should be sturdy and well balanced. The pouring opening must be at least 5cm

Can be poured in a layer thickness of 4 to

wide. Make sure there is a vent hole of 1cm on the opposite side. For a non-flat surface, pour

40mm in one step.

from the largest layer thickness to the smallest.

The formwork must be 5cm higher than the pouring height.

CHEMICAL RESISTANCE

• Mixing

VIBROX has an excellent chemical resistance

to alkalis, petroleum derivatives, acid,

Stir the base (component A) evenly before use. Add the full amount of hardener (component B)

diluted organic acids, salts and solutions.

and mix mechanically (300 rev/min) until both components are homogeneous.

For more information please contact

RESIPLAST NV. • Application

Pour the mortar through the pouring opening in one go without stopping. Make sure that the

PROPERTIES vent hole is open. Stop filling when the mortar is 1cm from the top level.

Check the level after 15 minutes. Add more if necessary.

• Very high spread size

• Low reaction temperature Use mixed mortar as quickly as possible.

• Non-shrinking

• High pressure resistance

• Finishing

• High impact resistance

• Moisture-insensitive hardening VIBROX can be painted. The cured mortar must be sanded to the filler before you apply paint or

• Impermeable a coating.

• High chemical resistance

• Use

Mechanical resistance after 48 hours for a layer thickness of 10mm.

Complete chemical resistance after 7 days at 20°C.

RESIPLAST® - A brand of KORAMIC Construction Chemicals.

Gulkenrodestraat 3 - B-2160 Wommelgem - België

info@resiplast.be

EUCOCHEM bv | -Esperantolaan

www.resiplast.be

13/7 | -3300

Tel.+32 3 320

Tienen 02 11| -office@eucochem.com

| België Fax.+32 3 322 63 80| www.eucochem.com | Tel.+32 16 81 11 52

EUCOCHEM BV - OFFICIAL RESIPLAST DEALER

PACKAGING USAGE

VIBROX Comp A Comp B 1.4kg VIBROX per litre of mortar.

Set 5kg 3.75kg 1.25kg

Set 30kg 22.50kg 7.50kg APPEARANCE

A-component Modified epoxy resin with filler and additives.

TECHNICAL SPECIFICATIONS B-component Polyamine hardener

Colour Green, grey-green

Specific mass 1.4kg/dm³

Colour Grey-green

Surface Smooth YOU WILL NEED TO SUPPLY

Pressure resistance >100N/mm²

Flexural strength >25N/mm² • Cleaning solvent for tools: MEK SOLVENT

E-modulus 3 kN/mm²

Tensile strength >25N/mm²

STORAGE

Adhesion to concrete 5N/mm²

Adhesion to metal 1.5 to 8N/mm²

Store VIBROX in a dry, well ventilated storage area between 5 and 35°C. 24

dependent on the pre-treatment

months shelf life.

Heat resistance 60°C continuous

Layer thickness 4mm to 40mm If in doubt, contact RESIPLAST NV and provide the batch number on the

Application temperature +15°C to+25°C package. Do not let the product get in contact with ground water, surface

Minimum curing temperature +10°C water or sewage systems. Dispose of contaminated packaging and remnants

Processing time 30 minutes at 20°C according to legal regulations.

Hardening time at 20°C Can be mechanically loaded 48 days

Can be chemically loaded 7 days

Curing Non-shrinking SAFETY

Shelf life 24 months

Carefully read the safety instructions before using VIBROX. Products

have a characteristic odour when being applied. Ensure there is sufficient

ventilation, stay away from ignition sources and do not smoke. Avoid contact

CE CERTIFICATE with skin. Eye irritation and/or sensitivity may occur during heavy vapour

concentrations, inhalation and/or skin contact. Do not keep food products

(food, beverages) in the same workspace. Always wear personal protective

equipment according to local guidelines and regulations. Gloves and safety

goggles are mandatory.

0749-CPD

Resiplast NV, Gulkenrodestraat 3, B-2160 Wommelgem

13

BC2-563-4714-0002-001

EN 1504-3

Concrete repair product for structural repairs based on polymers.

Compressive strength class R4 (>105Mpa)

Chloride ion content <0.05%

Adhesion strength ≥2Mpa (>4Mpa)

Carbonation resistance satisfactory

E-modulus >2900N/mm²

Thermal compatibility part I Class R4

Capillary absorption <0.5kg.m-2.h-0.5

Fire resistance NPD

Dangerous substances Complies with 5.4

The above information is provided in good faith, but without any guarantees. The application, use and

processing of the products are beyond our control and are, as such, the sole responsibility of the user/

processor. In the event that Resiplast N.V. is still held liable for damages, then the claim will still be

limited to the value of the goods delivered. We always aim to deliver consistently high quality goods.

This version replaces all previous versions. Version 1.3 Date: 5 November 2020 4:04 pm

RESIPLAST® - A brand of KORAMIC Construction Chemicals.

Gulkenrodestraat 3 - B-2160 Wommelgem - België

EUCOCHEM BV - OFFICIAL RESIPLAST DEALER EUCOCHEM bv | -Esperantolaan

info@resiplast.be 13/7 | -3300

www.resiplast.be Tienen

Tel.+32 | België

3 320 02 11| office@eucochem.com | www.eucochem.com | Tel.+32 16 81 11 52

- Fax.+32 3 322 63 80

You might also like

- Mercedes Tourismo Euro 6 Manual PDFDocument519 pagesMercedes Tourismo Euro 6 Manual PDFAshley Cardwell50% (2)

- BOYSEN® Elasti-Kote™: Description Technical DataDocument2 pagesBOYSEN® Elasti-Kote™: Description Technical DataRam Marc OnaNo ratings yet

- Bostik Powermix Tds Rev1 PDFDocument2 pagesBostik Powermix Tds Rev1 PDFRafael Obusan IINo ratings yet

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- Masterflow 400: High Strength, Free Flowing Epoxy GroutDocument2 pagesMasterflow 400: High Strength, Free Flowing Epoxy GroutFrancois-No ratings yet

- Pressure Vessel 1Document66 pagesPressure Vessel 1gst ajahNo ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- Monneli Betocem HCS_DOC_TECHNICAL_MAP_en_1213Document3 pagesMonneli Betocem HCS_DOC_TECHNICAL_MAP_en_1213Malak HindiNo ratings yet

- 15 - TDS - Concresive ERLDocument3 pages15 - TDS - Concresive ERLAlexi ALfred H. TagoNo ratings yet

- ChemFlex (2019 - 06 - 16 07 - 33 - 19 UTC)Document2 pagesChemFlex (2019 - 06 - 16 07 - 33 - 19 UTC)smart construction solution solutionNo ratings yet

- 04 - TDS - Concresive 2200Document3 pages04 - TDS - Concresive 2200aahtagoNo ratings yet

- CHRYSO Beton Cire Finishing - DsDocument4 pagesCHRYSO Beton Cire Finishing - Dsjeffkarthick1No ratings yet

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- Duraflex DSDocument2 pagesDuraflex DSFeyiNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- Tekafiks Multi Use Super enDocument2 pagesTekafiks Multi Use Super enEzeval GráficaNo ratings yet

- DIY Hydroproof DSDocument2 pagesDIY Hydroproof DSJohn MasangoNo ratings yet

- DR Fixit Pidipoxy MI EP Jan 2020Document3 pagesDR Fixit Pidipoxy MI EP Jan 2020rakeshNo ratings yet

- Floor - 80 - Primer MsdsDocument4 pagesFloor - 80 - Primer MsdsRasiq AbideenNo ratings yet

- Datasheet Epidermix 344Document2 pagesDatasheet Epidermix 344Vicky MunienNo ratings yet

- PDS - Moisture SealDocument2 pagesPDS - Moisture Sealjasondouglas1810workNo ratings yet

- Weber Euroflor DesignDocument3 pagesWeber Euroflor DesignMaya Trad wehbeNo ratings yet

- Solvent-Free, Low Viscosity Epoxy ResinDocument2 pagesSolvent-Free, Low Viscosity Epoxy ResinYASHICA VAITTIANATHANNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- 14 - TDS - Concresive 2020Document2 pages14 - TDS - Concresive 2020aahtagoNo ratings yet

- Consol Grout 600 MF PDFDocument2 pagesConsol Grout 600 MF PDFKhaerul SidikNo ratings yet

- Iec 62219Document3 pagesIec 62219Insaf MohamedNo ratings yet

- Bond Aid 100 - TDSDocument2 pagesBond Aid 100 - TDSAnoop ShankarNo ratings yet

- TDS Brushbond IndiaDocument2 pagesTDS Brushbond IndiahemantrulzNo ratings yet

- Brushbond: Uses PropertiesDocument2 pagesBrushbond: Uses PropertiesNagabhushanamNo ratings yet

- Boscoflex: Flexible Cementitious Waterprofing MembraneDocument2 pagesBoscoflex: Flexible Cementitious Waterprofing MembraneCLENTH FLORentinoNo ratings yet

- Probuild PB200Document2 pagesProbuild PB200osama mohNo ratings yet

- Polyhard: Mineral Based Dry Shake Floor HardenerDocument2 pagesPolyhard: Mineral Based Dry Shake Floor HardenerAlexi ALfred H. TagoNo ratings yet

- EnamopxyDocument5 pagesEnamopxyTawfiq ZidanNo ratings yet

- PDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKDocument2 pagesPDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKRoemaric AguasNo ratings yet

- Lightweight Aggregates - How Do You Make The Right Decision - NPCADocument2 pagesLightweight Aggregates - How Do You Make The Right Decision - NPCARafael Obusan IINo ratings yet

- Epoxy Floor Coating: Description FeaturesDocument2 pagesEpoxy Floor Coating: Description FeaturesRayon 9No ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Davco TTB ECO Brochure 1Document2 pagesDavco TTB ECO Brochure 1hinal pNo ratings yet

- Polypoxy SL 20: Epoxy Resin Based Self Levelling Floor ToppingDocument2 pagesPolypoxy SL 20: Epoxy Resin Based Self Levelling Floor ToppingAlexi ALfred H. TagoNo ratings yet

- Weberfloor Rapid TDSDocument3 pagesWeberfloor Rapid TDSIbrahim EzzatNo ratings yet

- JTCC - Neopox LiningDocument3 pagesJTCC - Neopox LiningAdhigana QSNo ratings yet

- Consol Cosmetic: Polymer Modified Portland Cement CoatingDocument2 pagesConsol Cosmetic: Polymer Modified Portland Cement CoatingCiput MardiantoNo ratings yet

- Konsol PDFDocument2 pagesKonsol PDFCiput MardiantoNo ratings yet

- Smartcare Bituprotek Emulsion Rbe 5Document2 pagesSmartcare Bituprotek Emulsion Rbe 5Rubul AliNo ratings yet

- Fosroc Nitomortar EL-HB TDSDocument2 pagesFosroc Nitomortar EL-HB TDSabdelsalamassarNo ratings yet

- Polypoxy SL 40: Epoxy Resin Based Self Levelling Floor ToppingDocument2 pagesPolypoxy SL 40: Epoxy Resin Based Self Levelling Floor ToppingAlexi ALfred H. TagoNo ratings yet

- 2020 06 03 Foreva Resin Epx TFC1000 en V2Document2 pages2020 06 03 Foreva Resin Epx TFC1000 en V2pabloNo ratings yet

- Premix Skim Coat: High Quality Cementitious RenderingDocument2 pagesPremix Skim Coat: High Quality Cementitious RenderingHaytham KhairyNo ratings yet

- Nitomortar ELDocument4 pagesNitomortar ELMansoor AliNo ratings yet

- TDS Weberfloor 620 PMB PlusDocument3 pagesTDS Weberfloor 620 PMB PlusBurak AkyazıNo ratings yet

- BoscoflexDocument2 pagesBoscoflexGeloNo ratings yet

- Sikafloor 24NPurcem IDDocument4 pagesSikafloor 24NPurcem IDRobin PrayogoNo ratings yet

- Concresive Fluido: Two-Pack Solvent-Free Fluid Epoxy Adhesive For Fixings, Construction Joints and AnchoragesDocument3 pagesConcresive Fluido: Two-Pack Solvent-Free Fluid Epoxy Adhesive For Fixings, Construction Joints and AnchoragesKarl FarrugiaNo ratings yet

- Rheomix 131: Page 1 of 2Document2 pagesRheomix 131: Page 1 of 2Ankita Baban Gavade100% (1)

- Ds Medapoxy PrimerDocument2 pagesDs Medapoxy PrimerfaridNo ratings yet

- Tehnički List - KIMITECH EP INDocument5 pagesTehnički List - KIMITECH EP INMARKO MATUHANo ratings yet

- iKOTE CM 40X (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Mastertop 1705 TdsDocument3 pagesMastertop 1705 TdsrenandiaNo ratings yet

- Palmn ENDocument2 pagesPalmn ENIbrahim GharibNo ratings yet

- Pareto+Chart ActivityDocument2 pagesPareto+Chart Activityankarthik11No ratings yet

- Box+Plot ActivityDocument3 pagesBox+Plot Activityankarthik11No ratings yet

- சதவீதம் 1st chapterDocument14 pagesசதவீதம் 1st chapterankarthik11No ratings yet

- 6 Sigma Green Belt Introduction EnglishDocument21 pages6 Sigma Green Belt Introduction Englishankarthik11No ratings yet

- 148Document8 pages148ankarthik11No ratings yet

- L6 GOMS 86 27042015 CompressedDocument2 pagesL6 GOMS 86 27042015 Compressedankarthik11No ratings yet

- 358Document4 pages358ankarthik11No ratings yet

- CleanstarDocument18 pagesCleanstarankarthik11No ratings yet

- Review On Wear Behavior of Nickel-Silicon Carbide Electrodeposition CoatingDocument7 pagesReview On Wear Behavior of Nickel-Silicon Carbide Electrodeposition Coatingankarthik11No ratings yet

- PADT OptDocument48 pagesPADT Optankarthik11No ratings yet

- Silo - Tips - Equipamentos de Limpeza e DesengorduramentoDocument12 pagesSilo - Tips - Equipamentos de Limpeza e Desengorduramentoankarthik11No ratings yet

- CL MerritDocument16 pagesCL Merritankarthik11No ratings yet

- Gift Boxes - 014335Document2 pagesGift Boxes - 014335ankarthik11No ratings yet

- Vijayawada Vizag Nellore Guntur Kakinada Plots Lands FlatsDocument10 pagesVijayawada Vizag Nellore Guntur Kakinada Plots Lands FlatsrowsolutionsNo ratings yet

- Cellulose Acetate Butyrate Molding and Extrusion Compounds: Standard Specification ForDocument5 pagesCellulose Acetate Butyrate Molding and Extrusion Compounds: Standard Specification Formukhkhalid6288No ratings yet

- Cooli Additive Maintenance GuideDocument8 pagesCooli Additive Maintenance GuideJavi AmadoNo ratings yet

- Toothed GearingDocument33 pagesToothed GearingpvkkrNo ratings yet

- Brammer Standard Catalog Cast IronDocument40 pagesBrammer Standard Catalog Cast IronFabFabFabFabNo ratings yet

- The Bubbler SystemDocument2 pagesThe Bubbler Systemmikelb5No ratings yet

- 1 s2.0 S0950061820335297 MainDocument10 pages1 s2.0 S0950061820335297 MainZaid Al SaffarNo ratings yet

- 8 Vacuum LeakDocument42 pages8 Vacuum Leakapi-3856548100% (4)

- EN - Datasheet Copperhead MonitorDocument3 pagesEN - Datasheet Copperhead MonitorRomina CZNo ratings yet

- Jadual Penilai Kedua PSM Sem 1 Sesi 20112012 Updates211211-Utk PrintDocument9 pagesJadual Penilai Kedua PSM Sem 1 Sesi 20112012 Updates211211-Utk PrintutemianNo ratings yet

- Tamprint 60: Tablet Linear Printing MachineDocument2 pagesTamprint 60: Tablet Linear Printing MachineSandeep PurohitNo ratings yet

- Smartruss - English VersionDocument2 pagesSmartruss - English Versiontrung1983No ratings yet

- Resilient Seated Wedge Gate Valve Data SheetDocument2 pagesResilient Seated Wedge Gate Valve Data Sheetkbc404100% (1)

- Radio News 1924 10 RDocument196 pagesRadio News 1924 10 REnache Daniel100% (1)

- FMHM - EEE - Final Exam Important QuestionsDocument5 pagesFMHM - EEE - Final Exam Important QuestionsBhavani Chandra Unique100% (1)

- KVX Product CatalogueDocument88 pagesKVX Product CatalogueMARCO CHELINo ratings yet

- FSY FSM Electronic Speed Controller DatasheetDocument6 pagesFSY FSM Electronic Speed Controller DatasheetAndre VargasNo ratings yet

- Wide-Lite Effex Series Area Light Brochure 1996Document16 pagesWide-Lite Effex Series Area Light Brochure 1996Alan Masters100% (1)

- SEF201 Mod3Document79 pagesSEF201 Mod3Arka MitraNo ratings yet

- High Temperature Epoxy Tooling Board: Trelleborg Applied TechnologiesDocument3 pagesHigh Temperature Epoxy Tooling Board: Trelleborg Applied TechnologiesMert KıraçNo ratings yet

- Synthetic Fibres and Plastics - Class 8 - Notes - PANTOMATHDocument7 pagesSynthetic Fibres and Plastics - Class 8 - Notes - PANTOMATHsourav9823No ratings yet

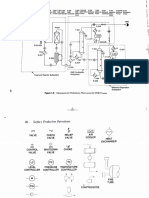

- PFD ISA Standard PDFDocument4 pagesPFD ISA Standard PDFRodolfo Solano SilvaNo ratings yet

- Advanced Mechanics of Solids by L S Srinath 140715044642 Phpapp01 PDFDocument521 pagesAdvanced Mechanics of Solids by L S Srinath 140715044642 Phpapp01 PDFMohammed Asif N100% (2)

- Building Tech 1 (Div 02 Sitework) ReviewerDocument5 pagesBuilding Tech 1 (Div 02 Sitework) ReviewerKristin Josette RempilloNo ratings yet

- Resutile Topcoat SD System Guide SWDocument4 pagesResutile Topcoat SD System Guide SWServandoNo ratings yet

- Introduction To Fracture MechanicsDocument22 pagesIntroduction To Fracture Mechanicsrpadhra8803No ratings yet

- 9....... Waste Water TreatmentDocument19 pages9....... Waste Water TreatmentLeo ThomasNo ratings yet

- PVC Ror Og FittingsDocument20 pagesPVC Ror Og FittingsOsama sayedNo ratings yet