Professional Documents

Culture Documents

M Isimark

M Isimark

Uploaded by

powerabsolut myanmarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M Isimark

M Isimark

Uploaded by

powerabsolut myanmarCopyright:

Available Formats

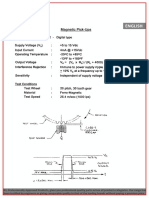

MONITOR - M - ISI MARKED

(CARBON STEEL, HOT DIP GALVANIZED) HD FIRE PROTECT

PVT. LTD.

TECHNICAL DATA

MODEL M

MAXIMUM RATED 12 BAR (175 PSI)

NOMINAL WATERWAY 65mm, 80mm & 100mm

SIZE

SPECIFICATION Reference : IS:8442 - 1977

FLOW AT 7 Kg. / 65 MM - 1750 LPM

Sq.Cm PRESSURE 80 MM - 2580 LPM

100 MM - 3500 LPM

FACTORY 25 Kg / Sq.Cm

HYDROSTATIC

TEST PRESSURE

NOZZLE THURST Flow in LPM X √ Pressure

REACTION IN Kg. in Kg./Sq.Cm. X 0.0228

The monitor has welded carbon steel water way.

INLET FLANGE SIZE 65 MM - 100 NB All steel parts are hot dip galvanized and painted

80 MM - 100 NB for excellent corrosion resistance. The vertical and

100 MM - 100 NB / 150 NB horizontal rotation is through corrosion resistant

Flange dimension as per bronze swiveling joint with double row of stainless steel

IS 6392-1971 Table 17 & 28 ball bearing. Both vertical and horizontal movements

NOZZLE Straight stream nozzle are controlled with handle with twist lock.

of Bronze or Aluminium The monitor has large flow capability and can be

material manually operated by a single fire fighter. The design

MONITOR ELEVATION 90 Deg. above horizontal ensures to prevent jet reaction forces from effecting

45 Deg. below horizontal the horizontal and vertical position of the monitor.

The monitor has the ability for 360 deg. continuous

ROTATION 360 Deg. continuous horizontal rotation and angle of elevation is adjustable

WEIGHT (Approx) 65MM - 33 Kg with fix stop from+90 deg. above horizontal to -45

80MM - 40 Kg deg. below horizontal.

100MM - 69 Kg The water vanes in discharge tube reduces the

FINISH Fire Red Shade 536 of turbulence and friction loss, thus increasing the

IS: 5-1961painted from nozzle performance to achieve greater range.

outside To ensure desired performance, the friction loss

ORDERING Specify Monitor Model, through monitor must be considered while selecting

INFORMATION Size and Inlet Flange Size the nozzle and flow through the monitor with reference

to available base pressure at inlet of the monitor. For

APPROVAL ISI marked flow and jet reach data refer table.

DESCRIPTION

The Monitor Model - M is durable manual controlled

monitor for fixed installation as well as for trailer

mounted unit. The monitor is generally used for

protection of flammable liquid storage tanks, loading

racks, dykes marine and many other industrial

applications.

The Monitor possess several design features that

provides ease of operation, minimum maintenance

and resistance to normally destructive environments.

The monitor is fitted with solid bore straight stream

nozzle.

SEPTEMBER, 2019 PAGE 1 OF 4 HD 133

HD FIRE PROTECT

PVT. LTD.

INSTALLATION, TESTING AND Application of water or foam on an electric appliance

can cause serious injury.

MAINTENANCE

The water supply to monitor must be

The monitor must be installed and operated carefully

increased / decreased gradually to prevent possible

by a trained person, having good knowledge of

water hammer occurrence.

equipment. Before assembly of the monitor to the

supply piping, thoroughly flush the piping with water Do not exceed the maximum pressure or flow rating

to avoid sand, residue, welding slag or other debris of the monitor. Exceeding the pressure or flow rating

hindering the proper functioning of the monitor. may cause injury or damage to the monitor.

After few initial successful tests, an authorized

person must be trained to perform the inspection and

testing of the monitor.

The monitor should be ready for use. To achieve this

condition, scheduled inspection and maintenance

operation should be performed and it must be recorded

in the maintenance register book indicating the

requirement or recommendation. The recommended

maintenance, procedure must be followed as given in

the manual and also as per the local authority having

jurisdiction.

It is recommended to carry out weekly physical

inspection of the monitor. The inspection should verify

that no damage has taken place to any component and

the monitor is ready for use. Carry out functional test

every month for the flow, regular rotation in horizontal

and vertical plane for the entire operating range to

observe any leakage.

Periodic proper greasing through grease nipple

provided on bearing, worm wheel and worm shaft

must be ensured. Use water resistant low friction

synthetic grease. Lubrication is required for smooth

operation.

Each monitor must be operated with full flow in

accordance to the guidelines of the organisation

having local jurisdiction.

The owner is responsible for maintaining the equipment

in proper operating condition.

CAUTION

A trained personnel for fire fighting must use the

monitor. Appropriate guidance & training must be

given to reduce the risk or injury.

The nozzle must be fixed to the monitor carefully.

Do not over tighten the nozzle to the monitor.

The flange bolts must be tightened uniformly.

The piping must be able to withstand the horizontal

reaction force. Serious injury to personnel and

equipment can result from improper installation.

When installing monitor it is very essential that

flange bolts are tightened uniformly to prevent

cocking of the monitor relative to the flange or valve.

Before flowing water from monitor, check that

all personnel are out of stream path and the

stream direction will not cause avoidable property

damage.

SEPTEMBER, 2019 PAGE 2 OF 4 HD 133

HD FIRE PROTECT

PVT. LTD.

B D

C

9

8

30˚

7

A

4

6

2

3

1

ELEVATION SIDE VIEW

PART LIST

DIMENSION in millimeter (Approximate)

ITEM NO QTY. DESCRIPTION

SIZE A B C D 1 1 BASE FLANGE

65 NB 677 515 415 570 2 1 DRAIN VALVE

80 NB 720 560 470 620

3 1 REDUCER

100 NB 890 685 600 690

4 2 SWIVEL JOINT

5 4 GREASE NIPPLE

6 2 LOCK NUT

7 1 HANDLE

8 1 WATER BARREL

9 1 NOZZLE

1000

4500

LE

O ZZ HORIZONTAL STRAIGHT STREAM

4000 45N

/ NW

100

NB MONITOR NOZZLE FLOW IN WATER

FLOW IN LPM

3500 SIZE MODEL LPM JET IN

LE MTRS.

8N OZZ

3000 W3 65 NW 32 1750 53

B/ N

80N

2500 80 NW 38 2580 60

100 NW 45 3500 64

ZZLE

2000 NW 32 NO

6 5NB/

Note:

1500

Horizontal straight stream range is in still air

with nozzle elevation at 30° to inlet flange at 1 to

1000 1.5 meters above ground level and at 7 Kg./Sq.cm.

4 5 6 7 8 9 10 monitor inlet pressure.

PRESSURE (KG./SQ.CM.)

SEPTEMBER, 2019 PAGE 3 OF 4 HD 133

HD FIRE PROTECT

PVT. LTD.

LIMITED WARRANTY

HD FIRE PROTECT PVT. LTD. hereby referred to as HD FIRE warrants to the original purchaser of the fire protection products manufactured by HD FIRE and to any other person

to whom such equipment is transferred, that such products will be free from defect in material and workmanship under normal use and care, for two (2) years from the date of

shipment by HD FIRE. Products or Components supplied or used by HD FIRE, but manufactured by others, are warranted only to the extent of the manufacturer’s warranty.

No warranty is given for product or components which have been subject to misuse, improper installation, corrosion, unauthorized repair, alteration or un-maintained.

HD FIRE shall not be responsible for system design errors or improper installation or inaccurate or incomplete information supplied by buyer or buyer’s representatives.

HD FIRE will repair or replace defective material free of charge, which is returned to our factory, transportation charge prepaid, provided after our inspection the material is

found to have been defective at the time of initial shipment from our works. HD FIRE shall not be liable for any incidental or consequential loss, damage or expense arising directly

or indirectly from the use of the product including damages for injury to person, damages to property and penalties resulting from any products and components manufactured

by HD FIRE. HD FIRE shall not be liable for any damages or labour charges or expense in making repair or adjustment to the product. HD FIRE shall not be liable for any

damages or charges sustained in the adaptation or use of its engineering data & services. In no event shall HD Fire’s product liability exceed an amount equal to the sale price.

The foregoing warranty is exclusive and in lieu of all other warranties and representation whether expressed, implied, oral or written, including but not limited

to, any implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations are hereby cancelled.

NOTICE :

The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also with the

provision of government codes or ordinances wherever applicable.

The information provided by us is to the best of our knowledge and belief, and consist of general guidelines only. Site handling and installation control is not in our scope.

Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever, resulting from our suggestion, information, recommendation or

damages due to our product.

Product development is a continuous programme of HD FIRE PROTECT PVT. LTD. and hence the right to modify any specification without prior notice is reserved with

the company.

D-6/2, ROAD NO. 34, WAGLE INDUSTRIAL ESTATE, THANE 400 604, INDIA.

HD FIRE PROTECT PVT. LTD. • TEL: + (91) 22 2158 2600 • FAX: +(91) 22 2158 2602

Protecting What Matters Most to You • EMAIL: info@hdfire.com • WEB: www.hdfire.com

SEPTEMBER, 2019 PAGE 4 OF 4 HD 133

You might also like

- Monitor - M 211: (Carbon Steel, Hot Dip Galvanized) Technical DataDocument4 pagesMonitor - M 211: (Carbon Steel, Hot Dip Galvanized) Technical DataDHAVAL PANCHALNo ratings yet

- VAJRA 536: Electric DC Remote Controlled MonitorDocument4 pagesVAJRA 536: Electric DC Remote Controlled MonitorKumararaja KonikkiNo ratings yet

- Data Sheet of Fire Water Monitor PDFDocument5 pagesData Sheet of Fire Water Monitor PDFAlvin Smith100% (1)

- Vajra 322P: Technical DataDocument4 pagesVajra 322P: Technical DataKumararaja KonikkiNo ratings yet

- Rei Vol IiDocument142 pagesRei Vol IiDineshNo ratings yet

- NewAge Fixed Flow MonitorDocument2 pagesNewAge Fixed Flow MonitoradityaridzkyNo ratings yet

- Mfm220 - 2" FP Manifold Flowmeter: This Is A Self-Calibrating FlowmeterDocument9 pagesMfm220 - 2" FP Manifold Flowmeter: This Is A Self-Calibrating FlowmeterMarcelo GonçalvesNo ratings yet

- SP Series Magnetostrictive Probe 2016 V2.0Document16 pagesSP Series Magnetostrictive Probe 2016 V2.0Mantenimiento MineriaNo ratings yet

- Moog ServoValves G761 761series Catalog enDocument20 pagesMoog ServoValves G761 761series Catalog enDhiraj ShrivastavNo ratings yet

- 3-6 Quad BopDocument29 pages3-6 Quad Bopsambhaji100% (1)

- LG Home TheaterDocument121 pagesLG Home TheaterhermieNo ratings yet

- HB806TM PDFDocument121 pagesHB806TM PDFhermie100% (1)

- Bayard Monostab PRVDocument2 pagesBayard Monostab PRVAnuj RaizadaNo ratings yet

- Water Flow Switch: Model: SD-WFD SeriesDocument3 pagesWater Flow Switch: Model: SD-WFD SeriesAbdul RahmanNo ratings yet

- Installation and Operation Manual: Fire Hose Rack CabinetDocument15 pagesInstallation and Operation Manual: Fire Hose Rack CabinetirshadNo ratings yet

- sl2023 743Document32 pagessl2023 743iodinecoil02No ratings yet

- Daewoo Sa100 Dsa-9310e Receiver SMDocument46 pagesDaewoo Sa100 Dsa-9310e Receiver SMRoman MakarNo ratings yet

- K3VDocument15 pagesK3VJacques Van Niekerk100% (14)

- Sidewall Horizontal Extended Coverage - 15mm GW-DD F2 WWHEC QR (SH035 1001 F)Document4 pagesSidewall Horizontal Extended Coverage - 15mm GW-DD F2 WWHEC QR (SH035 1001 F)DatNo ratings yet

- Two Three Way Ball ValvesDocument6 pagesTwo Three Way Ball ValvesUzair AnsariNo ratings yet

- Trainee Name: Trainee Engineer Mechanical Maintenance DeptDocument50 pagesTrainee Name: Trainee Engineer Mechanical Maintenance DeptAdnan119No ratings yet

- 741-742-743-743ds 6566109 SM 4-88 PDFDocument6 pages741-742-743-743ds 6566109 SM 4-88 PDFJavier AnezNo ratings yet

- 3-2540.090 Rev 10 English ManualDocument12 pages3-2540.090 Rev 10 English ManualAgung PrasetyoNo ratings yet

- ISIC Heavy Duty Pneumatic ActuatorDocument14 pagesISIC Heavy Duty Pneumatic Actuatoraizat91.acisNo ratings yet

- Rotary Flow Meter - Instruction Manual - MNV10151-1907Document18 pagesRotary Flow Meter - Instruction Manual - MNV10151-1907dharanNo ratings yet

- Model FC PDFDocument22 pagesModel FC PDFAbde Esselam100% (2)

- MNV20052 1210 (SS)Document16 pagesMNV20052 1210 (SS)wikijeg975No ratings yet

- 1200 SeriesDocument4 pages1200 SerieschrisocamNo ratings yet

- Network Blu-Ray Disc / DVD Home Theater System: Service ManualDocument151 pagesNetwork Blu-Ray Disc / DVD Home Theater System: Service ManualAlexNo ratings yet

- Schwing TSR 30.14 Mark II May 2022Document11 pagesSchwing TSR 30.14 Mark II May 2022NITHISH KUMAR S SECNo ratings yet

- 7 Fms 2Document2 pages7 Fms 2kuldeepNo ratings yet

- Submersible Sewage Ejector Pump: Safety InformationDocument8 pagesSubmersible Sewage Ejector Pump: Safety Informationallen_worstNo ratings yet

- Canadian - Solar Datasheet KuMax - CS3U P - High Efficiency - EN 2Document2 pagesCanadian - Solar Datasheet KuMax - CS3U P - High Efficiency - EN 2Alak RenukuntlaNo ratings yet

- Commercial Multiport Valves: Owners ManualDocument16 pagesCommercial Multiport Valves: Owners ManualEmanuel MurilloNo ratings yet

- 1268Document20 pages1268ChiragNo ratings yet

- Features: 96330I Internal Safety Shutoff & Operating Valve W/ Integral Position IndicatorDocument6 pagesFeatures: 96330I Internal Safety Shutoff & Operating Valve W/ Integral Position Indicatordiego leonel noguez vacaNo ratings yet

- LG bh7220bwDocument137 pagesLG bh7220bwCristiano BragaNo ratings yet

- Sukrut: Oil Level IndicatorDocument2 pagesSukrut: Oil Level IndicatorvipulpanchotiyaNo ratings yet

- Ise-Magtech: LG Series Liquid Level Gages Instruction ManualDocument12 pagesIse-Magtech: LG Series Liquid Level Gages Instruction ManualghantasingNo ratings yet

- Water-Powered Oscillating Unit and Oscillating Monitor AssembliesDocument4 pagesWater-Powered Oscillating Unit and Oscillating Monitor AssembliessridharanNo ratings yet

- Swivel Joints - Operating & MaintenanceDocument4 pagesSwivel Joints - Operating & MaintenanceGenard Sabenacio GarciaNo ratings yet

- Operation Manual: BPFV Series Pneumatic Flow Control ValveDocument8 pagesOperation Manual: BPFV Series Pneumatic Flow Control ValveFerryNo ratings yet

- Graco Fire Ball 300Document20 pagesGraco Fire Ball 300Rudi Abu ZahraNo ratings yet

- Stereo CD Cassette Deck Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Document78 pagesStereo CD Cassette Deck Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Claudelino ToffolettiNo ratings yet

- Piezometer Casagrande TipDocument9 pagesPiezometer Casagrande TipAdhitya Gilang IrawantoNo ratings yet

- Econominder Remote Reset Meters: 2750RM, 2850RM, 3100RM & 3900RMDocument32 pagesEconominder Remote Reset Meters: 2750RM, 2850RM, 3100RM & 3900RMGreg ReynekeNo ratings yet

- Tech Manual: Tech-5.12 10K Eh Dual Combi InvDocument22 pagesTech Manual: Tech-5.12 10K Eh Dual Combi InvRiski KurniawanNo ratings yet

- LG Arx8000 sr85ts-f Afn33798513 Av ReceiverDocument53 pagesLG Arx8000 sr85ts-f Afn33798513 Av ReceiverSilomo-saka Mamba0% (1)

- Leak Standard LS-20B-instruction-manualDocument20 pagesLeak Standard LS-20B-instruction-manualVadim RiabovNo ratings yet

- Sure-Stop PVC Waterstop BrochureDocument4 pagesSure-Stop PVC Waterstop Brochuremyke_0101No ratings yet

- HD114 Jumbo Water Curtain NozzleDocument2 pagesHD114 Jumbo Water Curtain NozzlemeetusalesNo ratings yet

- Lenntech: Engineering Drawing PacketDocument7 pagesLenntech: Engineering Drawing PacketjazaibNo ratings yet

- Canadian Solar CS3K 325MS 325 WDocument2 pagesCanadian Solar CS3K 325MS 325 WFane BabanulNo ratings yet

- 2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4Document4 pages2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4Mohamed HamedNo ratings yet

- Transparent Level GaugesDocument4 pagesTransparent Level GaugesAlfonso BlancoNo ratings yet

- Acid Washing of ANCDocument7 pagesAcid Washing of ANCUzair AshrafNo ratings yet

- Subsea Actuation: Valves and ActuatorsDocument20 pagesSubsea Actuation: Valves and ActuatorsSeymur AkbarovNo ratings yet

- Master Stream Nozzle For Monitor: Model - Varsha - 40Document2 pagesMaster Stream Nozzle For Monitor: Model - Varsha - 40Kumararaja KonikkiNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ukca Doc 4910290514 UkDocument1 pageUkca Doc 4910290514 Ukpowerabsolut myanmarNo ratings yet

- Sim Q - Adl - Aal Green Passport 4123000004a Mepc 197 62Document1 pageSim Q - Adl - Aal Green Passport 4123000004a Mepc 197 62powerabsolut myanmarNo ratings yet

- DNV GL Tae000045v UkDocument3 pagesDNV GL Tae000045v Ukpowerabsolut myanmarNo ratings yet

- Illuminated Indicators Can Specification 4189350023 UkDocument16 pagesIlluminated Indicators Can Specification 4189350023 Ukpowerabsolut myanmarNo ratings yet

- Illuminated Indicators Data Sheet 4921250057 UkDocument19 pagesIlluminated Indicators Data Sheet 4921250057 Ukpowerabsolut myanmarNo ratings yet

- Illuminated Indicators Standard Scale Designs 4921290030 UkDocument9 pagesIlluminated Indicators Standard Scale Designs 4921290030 Ukpowerabsolut myanmarNo ratings yet

- BR20170505 Conext CL 60 String Inverter 1Document4 pagesBR20170505 Conext CL 60 String Inverter 1powerabsolut myanmarNo ratings yet

- Fuji MCDocument1 pageFuji MCpowerabsolut myanmarNo ratings yet

- Agc 150 and Asc 150 Installation Instructions 4189341185 UkDocument36 pagesAgc 150 and Asc 150 Installation Instructions 4189341185 Ukpowerabsolut myanmarNo ratings yet

- 0369.schneider Electric Quotation For Power AbsoluteDocument1 page0369.schneider Electric Quotation For Power Absolutepowerabsolut myanmarNo ratings yet

- LEO GROUP PUMP Myanmar Authorised Agent HEIN LWIN EnterpriseDocument1 pageLEO GROUP PUMP Myanmar Authorised Agent HEIN LWIN Enterprisepowerabsolut myanmarNo ratings yet

- Agc 150 Operators Manual 4189341186 UkDocument38 pagesAgc 150 Operators Manual 4189341186 Ukpowerabsolut myanmarNo ratings yet

- Wiring DiagramsDocument8 pagesWiring Diagramspowerabsolut myanmarNo ratings yet

- LEO Hunan - Industrial Pump Product List (By HEIN LWIN Enterprise)Document58 pagesLEO Hunan - Industrial Pump Product List (By HEIN LWIN Enterprise)powerabsolut myanmarNo ratings yet

- Datasheet SHP100 150 20 ENDocument2 pagesDatasheet SHP100 150 20 ENpowerabsolut myanmarNo ratings yet

- POLYVINYL ALCOHOL From SINOPEC (PVA (By HEIN LWIN Enterprise & SEMPIRE) )Document6 pagesPOLYVINYL ALCOHOL From SINOPEC (PVA (By HEIN LWIN Enterprise & SEMPIRE) )powerabsolut myanmarNo ratings yet

- Spec 23.02.2608.212.53.364.21-22.1590Document1 pageSpec 23.02.2608.212.53.364.21-22.1590powerabsolut myanmarNo ratings yet

- Electrical Tri Nobal 0121-RV0Document4 pagesElectrical Tri Nobal 0121-RV0powerabsolut myanmarNo ratings yet

- Tech Spec STD Winches THR 7Document2 pagesTech Spec STD Winches THR 7powerabsolut myanmarNo ratings yet

- DCU 410E DatasheetDocument3 pagesDCU 410E Datasheetpowerabsolut myanmarNo ratings yet

- Aplicacoes Jaquet - TurbochargersDocument12 pagesAplicacoes Jaquet - Turbochargerspowerabsolut myanmarNo ratings yet

- B 815827 CBDocument6 pagesB 815827 CBpowerabsolut myanmarNo ratings yet

- Datasheet: EnglishDocument2 pagesDatasheet: Englishpowerabsolut myanmarNo ratings yet

- Chromium Hmi Device User S Manual 4189341234 UkDocument18 pagesChromium Hmi Device User S Manual 4189341234 Ukpowerabsolut myanmarNo ratings yet

- LC1DGK11M7,16.7kVar ContactorDocument2 pagesLC1DGK11M7,16.7kVar Contactorpowerabsolut myanmarNo ratings yet

- RT6, 6steps ControllerDocument2 pagesRT6, 6steps Controllerpowerabsolut myanmarNo ratings yet

- PM1130H Dual Source MeterDocument4 pagesPM1130H Dual Source Meterpowerabsolut myanmarNo ratings yet

- SGC 410 Product Sheet 4189341242 UkDocument2 pagesSGC 410 Product Sheet 4189341242 Ukpowerabsolut myanmarNo ratings yet

- Tri 2 Data Sheet 4921250066 UkDocument9 pagesTri 2 Data Sheet 4921250066 Ukpowerabsolut myanmarNo ratings yet

- DSE2510 DSE2520 Data SheetDocument2 pagesDSE2510 DSE2520 Data Sheetpowerabsolut myanmarNo ratings yet

- Crack Resistant Hardfacing AlloysDocument42 pagesCrack Resistant Hardfacing AlloysVedaant ShahNo ratings yet

- About The Company: Central America Nickel (CAN) Is A Montreal-Based Company That HasDocument4 pagesAbout The Company: Central America Nickel (CAN) Is A Montreal-Based Company That HasFerdiansyah FerdiansyahNo ratings yet

- Hinged 45 MMDocument134 pagesHinged 45 MMMuraleedharanNo ratings yet

- Astm A482.a482mDocument3 pagesAstm A482.a482mOS LaboratoryNo ratings yet

- Glass As Food Packaging MaterialDocument47 pagesGlass As Food Packaging Materialdeepshikha vermaNo ratings yet

- MacrosDocument26 pagesMacrosAbhishek ChavanNo ratings yet

- Weight Oiml R 111 - 1 VS Astm E617 PDFDocument28 pagesWeight Oiml R 111 - 1 VS Astm E617 PDFAlief SetiawanNo ratings yet

- Sfu RatingsDocument6 pagesSfu RatingsShrikant KajaleNo ratings yet

- Production of Tin Powder Using Gas Atomization ProcessDocument6 pagesProduction of Tin Powder Using Gas Atomization ProcessdaffaNo ratings yet

- Jigs and Tools Specification: Model of Special Production ToolsDocument7 pagesJigs and Tools Specification: Model of Special Production ToolsRafaelNo ratings yet

- Delegate List - 10th IMRC With Contact Details - RemovedDocument334 pagesDelegate List - 10th IMRC With Contact Details - RemovedSharon SusmithaNo ratings yet

- List of PMKKs Established 25 Oct 2017Document45 pagesList of PMKKs Established 25 Oct 2017Avik K DuttaNo ratings yet

- Owner'S Manual GH-1340W/1440W Lathes: Jet Equipment & Tools, IncDocument24 pagesOwner'S Manual GH-1340W/1440W Lathes: Jet Equipment & Tools, IncNoé MuñozNo ratings yet

- Company Profile-Falcon CompDocument9 pagesCompany Profile-Falcon Compamit.mandalNo ratings yet

- Common Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsDocument8 pagesCommon Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsJerry BeanNo ratings yet

- 5 Expensive But Worth Every Penny Woodworking ToolsDocument7 pages5 Expensive But Worth Every Penny Woodworking ToolsGerardo BarbaNo ratings yet

- Listagem ASTM Volume 01 02 Ferrous Castings FerroalloysDocument6 pagesListagem ASTM Volume 01 02 Ferrous Castings FerroalloysCamilla BragançaNo ratings yet

- EXEOR MIG Torches: Gas-Cooled Torch With Unique PerformanceDocument3 pagesEXEOR MIG Torches: Gas-Cooled Torch With Unique Performancekismikloshun55No ratings yet

- HANCOCK - Needle Valve 2500 PDFDocument4 pagesHANCOCK - Needle Valve 2500 PDFThomasFrenchNo ratings yet

- A Guide To Aluminum Welding - Lincoln ElectricDocument2 pagesA Guide To Aluminum Welding - Lincoln ElectriccvjdjmNo ratings yet

- NC-SMQ81: Solder PasteDocument2 pagesNC-SMQ81: Solder Pastealireza221369No ratings yet

- Dovetail Clamp AP Instructions: What You'll Need: Included in PackageDocument2 pagesDovetail Clamp AP Instructions: What You'll Need: Included in PackageJaime MontielNo ratings yet

- UTP Tooling EN 2019 GL 086Document28 pagesUTP Tooling EN 2019 GL 086Florea AdrianNo ratings yet

- Tensioning StripsDocument11 pagesTensioning StripssuksesNo ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- Polishing Compound Chart: Phase OneDocument1 pagePolishing Compound Chart: Phase Onemihai moldovanNo ratings yet

- An Innovative Tin Plating Process: High Performance and Significant SavingsDocument14 pagesAn Innovative Tin Plating Process: High Performance and Significant SavingsNgô TrungNo ratings yet

- Aisi A2 Data SheetDocument1 pageAisi A2 Data SheetShivuNo ratings yet

- A351A351M 2003 Specification For Castings, Austenitic, Austenitic-Ferritic (Duplex), For Presure-Containing PartsDocument5 pagesA351A351M 2003 Specification For Castings, Austenitic, Austenitic-Ferritic (Duplex), For Presure-Containing PartsPhong ThanhNo ratings yet

- En 12245 (2022) (E)Document9 pagesEn 12245 (2022) (E)David Chirinos100% (1)