Professional Documents

Culture Documents

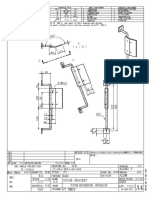

"Only Valid For Quotation": Component List Description #Material Hardness Heat Treatment Remarks

"Only Valid For Quotation": Component List Description #Material Hardness Heat Treatment Remarks

Uploaded by

Motiram SavargaveOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

"Only Valid For Quotation": Component List Description #Material Hardness Heat Treatment Remarks

"Only Valid For Quotation": Component List Description #Material Hardness Heat Treatment Remarks

Uploaded by

Motiram SavargaveCopyright:

Available Formats

Print-outs are not subject to the updating service

COMPONENT LIST

DESCRIPTION Nº MATERIAL HARDNESS HEAT TREATMENT REMARKS

1 Outer Ring 1 100Cr6 / SAE52100 / GCr15 59-63 HRc Through hardened

2 Inner Ring 1 100Cr6 / SAE52100 / GCr15 59-63 HRc Through hardened

3 Needles 37 100Cr6 / SAE52100 / GCr15 60-64 HRc Through hardened Ø 6,5 x 23 mm

4 Cage 1 PA 6.6. 25% G.F. -

TECHNICAL SPECIFICATIONS

INNER RING OUTER RING ROLLERS

Scale 1:3 Raceway Roughness < 0,15 µm < 0,15 µm < 0,16 µm

(CUT-OFF λc = 0,8)

Flange Roughness < 0,30 µm - -

(CUT-OFF λc = 0,08)

30,000

0,000 Roller Face Roughness

-0,200 - - < 0,30 µm

(CUT-OFF λc = 0,08)

+2,5

1,5 Bore/ OD surface Roughness

0,0

< 0,60 µm < 0,60 µm

1 (CUT-OFF λc = 0,8)

Face Roughness

+0,8

0,0

< 0,60 µm < 0,60 µm -

(CUT-OFF λc = 0,8)

1,5 Raceway Roundness ≤ 4 µm ≤ 5 µm ≤1 µm

3 (Gaussian filter: 1- 50)

Radial clearance (acc. ISO 5753): 0,050 - 0,085 mm

Tolerances PN Standard ISO 492 / DIN

R0,9 620-2

0

Oil Grease

Max. permissible speed (rpm):

4300 -

4

+0,8

0,0

LOAD CAPACITY acc. ISO 76, ISO 281

1,5

+2,5

1,5 0,0 Dynamic: 101,8 kN Static: 213,8 kN

2

116,50

0,000

130,000 -0,018

0,000

100,000 -0,020

119,500)

110,00)

Dm=

(

(

CAD DRAWING- Do not change manually

INITIAL F.R. N.S. 14/09/2023

INDEX MODIFICATION Nº MODIFICATION DRAWN APPROVED DATE

Tolerancing: The reproduction, distribution and utilization of this document as well as the communication of its

ISO 8015

contents to others without express authorization is prohibited. Offenders will be held liable for the

"ONLY VALID FOR QUOTATION"

payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

General tolerances: Weight:

DIN ISO 2768-fH 0,957 kg.

Sheet: Format: Scale: Complementary

1/1 A3 2:1 specifications:

Order drawing Cylindrical Roller Bearing Part number: Release

OD RFQ_37_23 23026281101000

You might also like

- Cost CVPDocument20 pagesCost CVPAllen Carl100% (1)

- Core Data Powder Core CatalogDocument36 pagesCore Data Powder Core CatalogjonatanrafaelNo ratings yet

- Bgy. BaliwagDocument1 pageBgy. BaliwagAilyn BelloNo ratings yet

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbNo ratings yet

- WCB 230.20.0414 Swing Circle Gear Roller and Ball Turntable Slewing Ring Bearing PDFDocument1 pageWCB 230.20.0414 Swing Circle Gear Roller and Ball Turntable Slewing Ring Bearing PDFWCB BEARINGNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- ATTAR AS3788 Assessment of Wall Thinning V1.02Document5 pagesATTAR AS3788 Assessment of Wall Thinning V1.02Ashraf BottaniNo ratings yet

- Additional Parts - Entry Guide GlassDocument3 pagesAdditional Parts - Entry Guide GlassDanı PrasNo ratings yet

- Cummins Inc.: Unless Otherwise Specified The Information Within This Title Block Shall ApplyDocument1 pageCummins Inc.: Unless Otherwise Specified The Information Within This Title Block Shall ApplyGui SaidNo ratings yet

- Ncut Antiextrusion Ring For Metric Ing: MaterialDocument4 pagesNcut Antiextrusion Ring For Metric Ing: MaterialArun JaisonNo ratings yet

- AS3788 Appendix N - Assessment of Wall Thinning: Input Data CalculationsDocument5 pagesAS3788 Appendix N - Assessment of Wall Thinning: Input Data Calculationsأحمد حسنNo ratings yet

- 2811 Additional PartsDocument4 pages2811 Additional PartsDanı PrasNo ratings yet

- Sheet 16 U-820 Sulfur Recovery Unit: Technical ServicesDocument1 pageSheet 16 U-820 Sulfur Recovery Unit: Technical ServicesAsad PatelNo ratings yet

- AS3788 Appendix N - Assessment of Wall Thinning: Input Data CalculationsDocument5 pagesAS3788 Appendix N - Assessment of Wall Thinning: Input Data CalculationsGaneshNo ratings yet

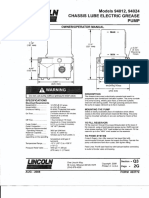

- Lincoln Lube Model 94012Document6 pagesLincoln Lube Model 94012luisNo ratings yet

- Inductive Sensor NCB10-30GM40-N0: DimensionsDocument3 pagesInductive Sensor NCB10-30GM40-N0: DimensionsplaninaNo ratings yet

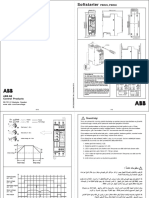

- Arrancador ABBDocument6 pagesArrancador ABBMax JavierNo ratings yet

- Allorde - E2Document1 pageAllorde - E2flor johnNo ratings yet

- KFD55HDocument1 pageKFD55Hpant.vk8514No ratings yet

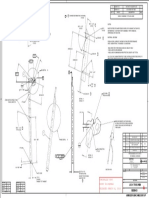

- 2811 Bracket LsDocument1 page2811 Bracket LsDanı PrasNo ratings yet

- Jig DW75 CNC2S 02Document1 pageJig DW75 CNC2S 02Luong LeNo ratings yet

- NG - CD - HD16 9 1939SX P080 - A - PDF - hd16 9 1939sx p080 - 605159Document2 pagesNG - CD - HD16 9 1939SX P080 - A - PDF - hd16 9 1939sx p080 - 605159O mecanicoNo ratings yet

- Inductive Sensor NCB10-30GM40-N0-V1: DimensionsDocument3 pagesInductive Sensor NCB10-30GM40-N0-V1: DimensionsARINo ratings yet

- Second Floor Girder Design: GRID 3 (BEAM 39-49) (Left Section)Document4 pagesSecond Floor Girder Design: GRID 3 (BEAM 39-49) (Left Section)CYNDRILLE JOHN BRAGATNo ratings yet

- Proximity SwitchDocument4 pagesProximity SwitchMohamed MekkyNo ratings yet

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- Abb Arrancador Compacto PSRDocument6 pagesAbb Arrancador Compacto PSRgvidela.grvNo ratings yet

- 1SFCPSR25, PSR30Document6 pages1SFCPSR25, PSR30Andre AndoNo ratings yet

- Abb PSR25Document6 pagesAbb PSR25Erdem UzunayNo ratings yet

- 1259AGDocument1 page1259AGnpdNo ratings yet

- 16py Q207 NMBDocument1 page16py Q207 NMBJulio Cezar Berte SilvaNo ratings yet

- Eta Engineering Private LimitedDocument2 pagesEta Engineering Private Limitedanon_501928972No ratings yet

- Pot Bearing - Guided Bearing DesignDocument2 pagesPot Bearing - Guided Bearing Designtrichandra maharjanNo ratings yet

- PART 8 SealtechDocument42 pagesPART 8 SealtechjorgebarrocasNo ratings yet

- Engine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitDocument86 pagesEngine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitWSMengine WSMengine100% (1)

- Tig Er308lDocument1 pageTig Er308lShailesh DeshmukhNo ratings yet

- Ncut Antiextrusion Ring For Standard Ing: MaterialDocument6 pagesNcut Antiextrusion Ring For Standard Ing: MaterialArun JaisonNo ratings yet

- Chimnny Sheet 2-3Document1 pageChimnny Sheet 2-3jayant raikopandNo ratings yet

- 90399-01 - Lock PostDocument1 page90399-01 - Lock PostJuan Posada GNo ratings yet

- End Mill Cutter: DRG Ref - No:-New DRG No: - Abm/Rkt/Ab627Document1 pageEnd Mill Cutter: DRG Ref - No:-New DRG No: - Abm/Rkt/Ab627Uandt Tractor EarthmoversNo ratings yet

- AB627Document1 pageAB627Uandt Tractor EarthmoversNo ratings yet

- Mechanical Test Properties (Minimum) : RemarksDocument6 pagesMechanical Test Properties (Minimum) : RemarksSandeepNo ratings yet

- Ave Verpic GasolineDocument2 pagesAve Verpic GasolinefredhNo ratings yet

- Rydon Industries PVT LTD: Details of Inspection Description SpecificationDocument1 pageRydon Industries PVT LTD: Details of Inspection Description SpecificationmuthuselvanNo ratings yet

- RJ45 Down Without LEDDocument1 pageRJ45 Down Without LEDreza_azadNo ratings yet

- End Mill Cutter: DRG Ref - No:-New DRG No: - Abm/Rkt/Ab627Document1 pageEnd Mill Cutter: DRG Ref - No:-New DRG No: - Abm/Rkt/Ab627Uandt Tractor EarthmoversNo ratings yet

- AB627Document1 pageAB627Uandt Tractor EarthmoversNo ratings yet

- 3011 Additional Parts 3Document4 pages3011 Additional Parts 3Danı PrasNo ratings yet

- CCF 000163Document1 pageCCF 000163Erik Jhonattan Jara YpanaqueNo ratings yet

- Ncut Antiextrusion Ring For Standard Ing: MaterialDocument6 pagesNcut Antiextrusion Ring For Standard Ing: MaterialRPINILLA (EICO S.A.)No ratings yet

- Technical Sheets GPX PumpDocument6 pagesTechnical Sheets GPX PumpazkNo ratings yet

- Mill T CDocument3 pagesMill T CSM AreaNo ratings yet

- Dilao, Rojim A.: Esamelco 60AT 15 AT 15 ATDocument1 pageDilao, Rojim A.: Esamelco 60AT 15 AT 15 ATRojim Asio DilaoNo ratings yet

- 9 - PneumaticsDocument44 pages9 - PneumaticsJOHNNo ratings yet

- Inductive Sensor NBB15-30GM50-E2-M-Y246536: DimensionsDocument3 pagesInductive Sensor NBB15-30GM50-E2-M-Y246536: Dimensionscold storageNo ratings yet

- Versamatic MetalicaDocument12 pagesVersamatic MetalicaJahaziel VegaNo ratings yet

- Ring PM-6436 For Casting - RedactedDocument2 pagesRing PM-6436 For Casting - RedactedFranco Damián Vilca DíazNo ratings yet

- 42CrMo4QT-Pulley Shaft MaterialDocument1 page42CrMo4QT-Pulley Shaft MaterialanishgirmeNo ratings yet

- 150w Core ZW42712TCDocument1 page150w Core ZW42712TCErkanNo ratings yet

- Ind Nifty RealtyDocument2 pagesInd Nifty RealtyParth AsnaniNo ratings yet

- Determination of Income and Employment - 2Document1 pageDetermination of Income and Employment - 2shalomsamuel008No ratings yet

- Swarovski Components Collection 2023 LowResDocument450 pagesSwarovski Components Collection 2023 LowResjuliabalbi01No ratings yet

- Redisgn by Srwa Hidayat PDFDocument149 pagesRedisgn by Srwa Hidayat PDFmahnazNo ratings yet

- Trading The Ichimoku WayDocument4 pagesTrading The Ichimoku Waysaa6383No ratings yet

- As Distributor Locator Asia Pacific v7Document5 pagesAs Distributor Locator Asia Pacific v7michel trevezNo ratings yet

- Eco 301 Topic 1 Consumer Theory Lecture Notes 2023Document60 pagesEco 301 Topic 1 Consumer Theory Lecture Notes 2023lubisithembinkosi4No ratings yet

- Backed Cloths StructuresDocument12 pagesBacked Cloths StructuresMina Samy abd el zaherNo ratings yet

- Receipt - SEZJUF PDFDocument1 pageReceipt - SEZJUF PDFNurhadriyanty HamidNo ratings yet

- Promise To PayDocument3 pagesPromise To PayDaraire OlowokereNo ratings yet

- Hortatory TextDocument2 pagesHortatory TextDaffa MuhammadNo ratings yet

- Tutorial Week 8 Preparation RequirementsDocument14 pagesTutorial Week 8 Preparation RequirementsBáchHợpNo ratings yet

- Universal Business SolutionsDocument6 pagesUniversal Business SolutionsAbraham AchuNo ratings yet

- ACO RainDrain DatasheetDocument2 pagesACO RainDrain Datasheetpeter3972No ratings yet

- Abdc Journal Quality List 2019 Web Version 130919aDocument267 pagesAbdc Journal Quality List 2019 Web Version 130919aJacob ericNo ratings yet

- By-Basharat Hossain Assistant Professor of Economics International Islamic University ChittagongDocument4 pagesBy-Basharat Hossain Assistant Professor of Economics International Islamic University ChittagongAmartuya DorjpalamNo ratings yet

- 1 Formulation - AssignmentDocument4 pages1 Formulation - AssignmentNamanNo ratings yet

- PPT09 - Simple Linear Regression and CorrelationDocument53 pagesPPT09 - Simple Linear Regression and CorrelationaekimNo ratings yet

- TOEFL Additional Score Report Request FormDocument2 pagesTOEFL Additional Score Report Request Formvishwa tejaNo ratings yet

- Entry BBMA - SNR Advance - Ms.enDocument17 pagesEntry BBMA - SNR Advance - Ms.ennimeshdinuka46No ratings yet

- Transaction KeysDocument8 pagesTransaction KeysKamleshSarojNo ratings yet

- Banking's Delusions of Digital TransformationDocument11 pagesBanking's Delusions of Digital Transformationraja farhanNo ratings yet

- CAPACITY PLANNING ReadingsDocument4 pagesCAPACITY PLANNING Readingsasmelash gideyNo ratings yet

- Cattleya Tent Events: Event Planning BusinessDocument8 pagesCattleya Tent Events: Event Planning BusinessRobert StefanNo ratings yet

- Dhiraj Internship Report - DP WORLD With Cover PageDocument88 pagesDhiraj Internship Report - DP WORLD With Cover PageMehul Vadnere100% (1)

- HDFC Balanced Advantage Fund - IDCW Illustration March 2022Document2 pagesHDFC Balanced Advantage Fund - IDCW Illustration March 2022Shravan RatheeshNo ratings yet

- Reference No: 863191: American International University - BangladeshDocument1 pageReference No: 863191: American International University - BangladeshTanvir PrantoNo ratings yet

- 46SV2N075T, 200gpm@120ftDocument4 pages46SV2N075T, 200gpm@120ftSajidNo ratings yet

- Studi Hubungan Ruralisasi Dengan Penduduk Lokal: Pola Kerukunan Hidup Umat Beragama Di Daerah Pinggiran JakartaDocument16 pagesStudi Hubungan Ruralisasi Dengan Penduduk Lokal: Pola Kerukunan Hidup Umat Beragama Di Daerah Pinggiran Jakartapaklek joNo ratings yet