Professional Documents

Culture Documents

DH 1200TNS MO6VndC

DH 1200TNS MO6VndC

Uploaded by

GopiNath0 ratings0% found this document useful (0 votes)

11 views1 pageThe D&H 1200T (NS) electrode is a non-synthetic electrode that deposits a homogeneous nickel-chromium-iron alloy. It provides good resistance to abrasion, oxidation, and corrosion. The electrode is suitable for welding nickel-chromium-iron alloys and dissimilar metals like carbon steel, stainless steel, and nickel alloys. It can also be used for surfacing steel with the nickel-chromium-iron weld metal.

Original Description:

Original Title

DH_1200TNS_MO6VndC

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe D&H 1200T (NS) electrode is a non-synthetic electrode that deposits a homogeneous nickel-chromium-iron alloy. It provides good resistance to abrasion, oxidation, and corrosion. The electrode is suitable for welding nickel-chromium-iron alloys and dissimilar metals like carbon steel, stainless steel, and nickel alloys. It can also be used for surfacing steel with the nickel-chromium-iron weld metal.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

11 views1 pageDH 1200TNS MO6VndC

DH 1200TNS MO6VndC

Uploaded by

GopiNathThe D&H 1200T (NS) electrode is a non-synthetic electrode that deposits a homogeneous nickel-chromium-iron alloy. It provides good resistance to abrasion, oxidation, and corrosion. The electrode is suitable for welding nickel-chromium-iron alloys and dissimilar metals like carbon steel, stainless steel, and nickel alloys. It can also be used for surfacing steel with the nickel-chromium-iron weld metal.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

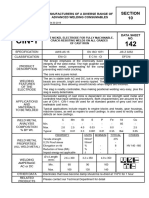

D&H 1200T (NS)

CODIFICATION: AWS : SFA 5.11 ENiCrFe-2

EN ISO : 14172 E Ni 6133

CHARACTERISTICS AND APPLICATIONS:

A non-synthetic electrode depositing homogeneous Ni-Cr-Fe alloy composition. It is

good resistance to abrasion, oxidation, and corrosion. It is suitable for welding

Ni-Cr-Fe alloys to themselves, dissimilar metals such as carbon steel, 9% nickel steel,

stainless steel, pure nickle to themselves or to each other, and for surfacing steel with

Ni-Cr-Fe weld metal. It is ideally suitable for welding Ni alloy UNS N06600. It is also

used for welding SS201LN type materials to get good toughness together with

strength.

TYPICAL CHEMICAL COMPOSITION OF ALL WELD METAL:

Element : C Mn Si Cr Ni Mo Nb+Ta Fe

Percent : 0.04 2.5 0.4 15.0 Bal. 1.5 1.5 7.0

TYPICAL MECHANICAL PROPERTIES OF ALL WELD METAL:

UTS Elongation CVN Impact Strength Lateral Expansion

(MPa) (L= 5d)% at minus 196 oC(J) at minus 196 oC (mm)

644 35.0 45 0.42

CURRENT AND PACKING DATA: DC (+)

Size (mm) : 5x350 4x350 3.15x350 2.5x350

Dia x Length

Current Range : 150-180 90-130 70-90 60-70

(Amps)

Weight/Carton : 2.5 2.5 2.5 2.5

(kgs)

APPROVALS: Adani Infra, CE, CIB-MP, L&T Power

PRECAUTIONS:

1. Use short arc and stringer beads.

2. Ensure the electrodes are dry. Re-dry the electrodes at 300-325°C for one hour.

3. Best results are obtained in flat position and wherever possible weld in flat

position only.

R1

info@dnhsecheron.net | www.dnhsecheron.com | +91 9833550505

You might also like

- DH 1232NSDocument1 pageDH 1232NSGopiNathNo ratings yet

- D - H - 1111CI Cast Iron Research PaperDocument1 pageD - H - 1111CI Cast Iron Research PapermriyazklNo ratings yet

- DH 1400modDocument1 pageDH 1400modGopiNathNo ratings yet

- 9Cr - 1mo Modified With V, NB, and N.: OdificationDocument1 page9Cr - 1mo Modified With V, NB, and N.: OdificationAshok RajNo ratings yet

- Secheron 316lDocument1 pageSecheron 316lAtmastco LimitedNo ratings yet

- D&H E7018Document1 pageD&H E7018jubieethegreatNo ratings yet

- D & H 11018ultratherme-M - P15yrcyDocument1 pageD & H 11018ultratherme-M - P15yrcyjubieethegreatNo ratings yet

- CR Om Ot He Rme-9 (M Od) Cromotherme-9 (SPL)Document1 pageCR Om Ot He Rme-9 (M Od) Cromotherme-9 (SPL)Parmasamy SubramaniNo ratings yet

- Norma VDocument1 pageNorma VjubieethegreatNo ratings yet

- Supratherm E7018Document1 pageSupratherm E7018yskushwah16No ratings yet

- SUPRATHERME M63jx6EDocument1 pageSUPRATHERME M63jx6EjubieethegreatNo ratings yet

- DT-1.4462 WP 380: Stainless Steel Subarc Wire Fused Welding FluxDocument1 pageDT-1.4462 WP 380: Stainless Steel Subarc Wire Fused Welding Fluxmarketing.automatizatNo ratings yet

- Welding Electrodes PDFDocument1 pageWelding Electrodes PDFSai PoojaNo ratings yet

- Wire M10SDocument1 pageWire M10SCristian BoselliNo ratings yet

- SS 316 (0.5 FN) : Stainless Steel ElectrodeDocument1 pageSS 316 (0.5 FN) : Stainless Steel Electrodeflasher_for_nokiaNo ratings yet

- GMM Mag.Document1 pageGMM Mag.Ehsan KhanNo ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- 1 - UTP 614 KBDocument1 page1 - UTP 614 KBKrishna VachaNo ratings yet

- Shanghai Zhiyou Marine & Offshore Equipment Co., LTDDocument2 pagesShanghai Zhiyou Marine & Offshore Equipment Co., LTDSuperSingleNo ratings yet

- UTP A 6222 MoDocument1 pageUTP A 6222 MoKara WhiteNo ratings yet

- OK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWDocument1 pageOK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWGokul RajanNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- 02112015000000B - Boehler FOX EASN 25 M - CeDocument1 page02112015000000B - Boehler FOX EASN 25 M - CeABNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- 02.CARBO - RC 3 Blau eDocument1 page02.CARBO - RC 3 Blau eMario CastilloNo ratings yet

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNo ratings yet

- Fluxofil M42: Cored Wires High-Strength SteelsDocument1 pageFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNo ratings yet

- Inweld Nickel A (ENiCrFe-2)Document1 pageInweld Nickel A (ENiCrFe-2)brunizzaNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- Bohler Ti 52Document1 pageBohler Ti 52Anonymous nKOyHbNo ratings yet

- 1127-1 AWS ASME A 5.11 E NiCu-7Document3 pages1127-1 AWS ASME A 5.11 E NiCu-7Julio VargasNo ratings yet

- L1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Document2 pagesL1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Απόστολος ΣτεργιάδηςNo ratings yet

- Maxflux SAF-8 (LS) : Agglomerated Basic Flux For Submerged Arc WeldingDocument1 pageMaxflux SAF-8 (LS) : Agglomerated Basic Flux For Submerged Arc WeldingPrashant KumarNo ratings yet

- ER316L Ss en 1Document1 pageER316L Ss en 1brayanNo ratings yet

- 3dprint AM 625: Material TypeDocument1 page3dprint AM 625: Material TypeKara WhiteNo ratings yet

- XuperFab E2209-17Document1 pageXuperFab E2209-17Napoleon DasNo ratings yet

- L1 8581 en Diamondspark 44 BC CU03100F 3379759 ENDocument1 pageL1 8581 en Diamondspark 44 BC CU03100F 3379759 ENRaviTeja BhamidiNo ratings yet

- 347MVNb BasicDocument1 page347MVNb BasicKevin WilliamsNo ratings yet

- Technical Sheet Cusn12: The Above Data Are Subject To Change Without Notice by StellaDocument1 pageTechnical Sheet Cusn12: The Above Data Are Subject To Change Without Notice by StellaVarma DantuluriNo ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- Wb2000e E6013Document1 pageWb2000e E6013cwiksjNo ratings yet

- 05042016000000A - Avesta 904L - CeDocument1 page05042016000000A - Avesta 904L - CeJorge Uribe RochaNo ratings yet

- Cin 1 Post File 2019 12 17 100704Document1 pageCin 1 Post File 2019 12 17 100704Adrian SetyadharmaNo ratings yet

- Selectrode: High Deposition 316L Stainless Steel International ClassificationsDocument2 pagesSelectrode: High Deposition 316L Stainless Steel International ClassificationsMohamed AdelNo ratings yet

- L1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENDocument1 pageL1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENbrayanNo ratings yet

- Boehler FOX CN 25 9 CuT - CeDocument1 pageBoehler FOX CN 25 9 CuT - CeNiranjan Fakirchand YadavNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- مكونات نقط اللحام شامل بنط اللحامDocument2 pagesمكونات نقط اللحام شامل بنط اللحامdaha333No ratings yet

- Barrettetig Catalogo Oerlikon 35035Document44 pagesBarrettetig Catalogo Oerlikon 35035mp303No ratings yet

- OK 67.60 Esab 309LcDocument1 pageOK 67.60 Esab 309LcSadashiva sahooNo ratings yet

- Technical Specification For 18 (30) KV Cold-Shrinkable Cable AccessoriesDocument9 pagesTechnical Specification For 18 (30) KV Cold-Shrinkable Cable AccessoriesDkalestNo ratings yet

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- DS482Document3 pagesDS482mariomatoNo ratings yet

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Document1 pageNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelNo ratings yet